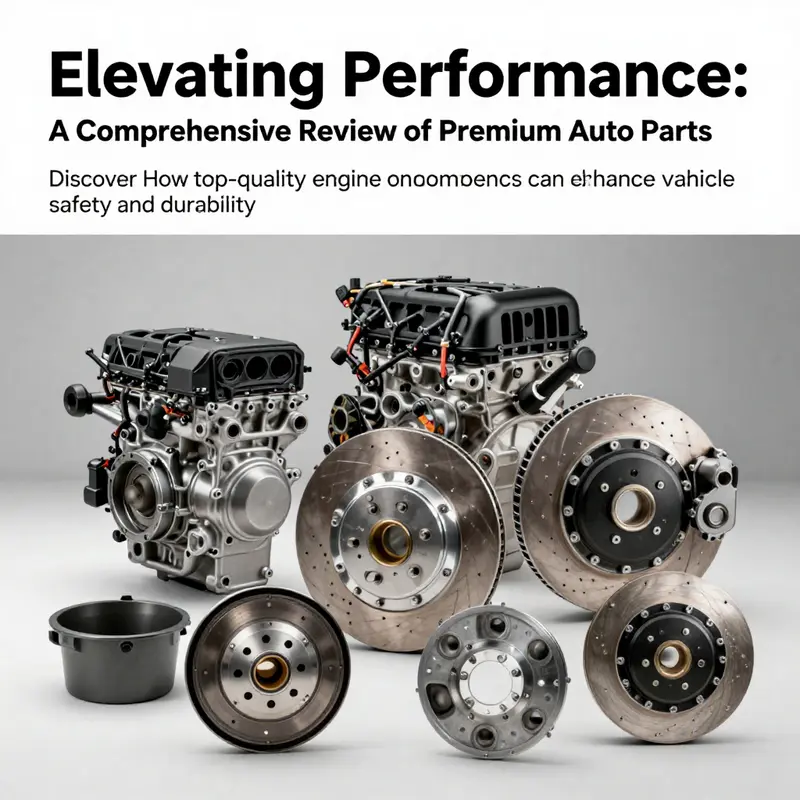

In today’s competitive automotive landscape, business owners must prioritize the quality of premium auto parts to ensure customer satisfaction and vehicle longevity. The right components directly influence a vehicle’s performance, safety, and overall efficiency. This review delves into key categories of premium auto parts, including high-performance engine components, superior brake system parts, and strategies for building longevity. As we navigate the landscape of reliable suppliers for these premium offerings, each chapter aims to equip business owners with crucial insights that reinforce the importance of quality in their automotive endeavors.

null

null

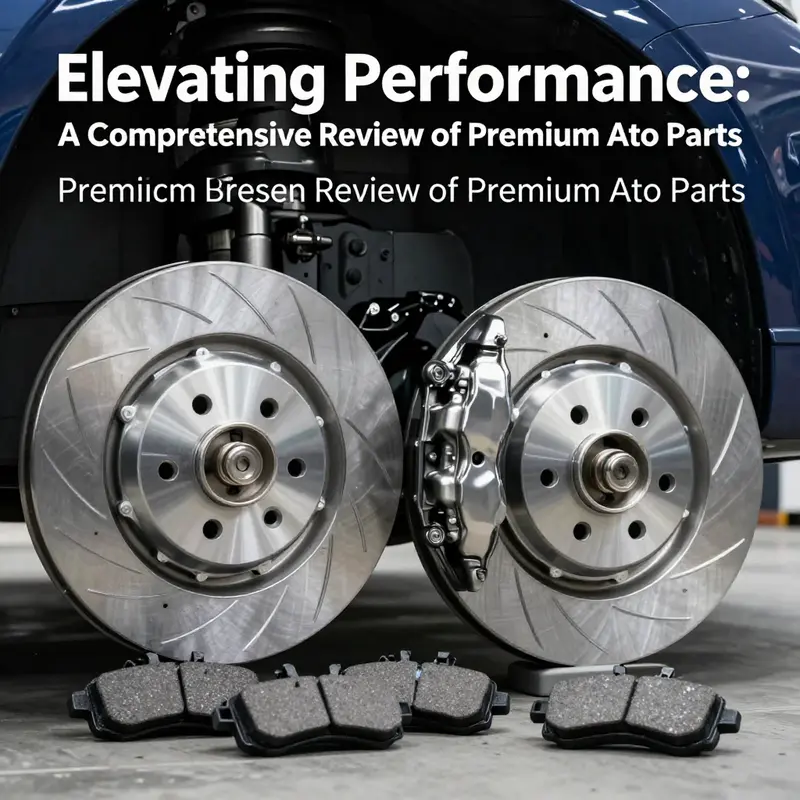

Refined Stopping Power: Evaluating Premium Brake System Components in Auto Parts Reviews

Braking sits at the intersection of safety, performance, and daily practicality. In a premium auto parts review, the brake system is more than a single component; it is a carefully engineered ecosystem where pads, shoes, rotors, calipers, and the related hardware must work in concert to deliver consistent feedback, predictable response, and enduring reliability. The promise of premium brake parts rests on three pillars: quality, performance, and longevity. Quality translates to material selection, manufacturing precision, and adherence to stringent standards that often mirror original equipment specifications. Performance is the measurable output delivered under real-world conditions—how quickly a pedal translates into wheel bite, how a rotor sheds heat during repeated stops, and how the system resists fade when the road pitches uphill or the air becomes heavy with humidity. Longevity, perhaps the most pragmatic of the three, is about the total cost of ownership. Higher upfront investment in quality brake parts can reduce downtime, limit wear on rotors and calipers, and preserve the overall integrity of the braking system through countless miles.

The value proposition of premium brake components becomes most evident when you move from generalities to the specifics of what defines a superior setup. Premium brake pads and shoes are designed not just for strong initial bite but for sustained performance across thermal cycles. Ceramic formulations, for instance, are celebrated for low dust output and steady friction across a broad temperature range, while advanced semi-metallic blends emphasize heat tolerance and fade resistance in demanding duty cycles. In tandem, rotors with optimized venting and heat dissipation help maintain consistent friction characteristics, preventing hot spots that distort pedal feel. Calipers, pistons, and hardware crafted from corrosion-resistant alloys round out the package, contributing to reliable piston retraction, smooth actuation, and long service intervals. In practice, these characteristics translate into a braking experience that feels gradual and controlled in normal driving yet remains robust when an emergency requires rapid deceleration. This aligns with the core idea driving premium parts selection: the system should enhance safety without requiring constant adjustment or frequent maintenance.

To illustrate how these principles translate into real-world offerings, consider the role of a leading brake components supplier that operates at the OEM and aftermarket interface. This company emphasizes a comprehensive approach to brake design, producing a range of premium pads and shoes engineered for durability, consistent performance, and dependable wear characteristics. While the exact formula is guarded as proprietary, the emphasis is on materials engineered to maintain friction stability across temperatures and humid conditions, on reliable bedding-in behavior that reduces rotor wear, and on coatings and backing plates that minimize noise and vibration. The product lineup commonly features options tailored to fleet operations—vehicles that log substantial mileage in city traffic, on undulating terrain, or in climates where humidity and elevation stress braking systems. In fleet contexts, where the cost of downtime and the consequences of unpredictable braking are magnified, the value of a brake part that can deliver reliable performance for tens of thousands of kilometers becomes a decisive factor.

Among these premium components, a prominent brake pad model is often highlighted for its balance of performance and warranty coverage. The model carries a long warranty period and an accompanying manufacturer guarantee that signals confidence in long-term reliability. In practice, a warranty horizon of fifty thousand kilometers paired with a one-year manufacturer guarantee provides a practical assurance for operators managing varied driving routines—from daily urban errands to longer highway runs and seasonal adverse conditions. The stated applications typically point to safety-centered fleets operating under humid or mountainous conditions, where the combination of frequent braking and fluctuating ambient temperatures tests material resilience and heat management. Such context is instructive for discerning drivers and operators: it is not merely the peak bite that matters, but how consistently that bite is maintained as the brakes heat up, cool down, and are subjected to moisture and debris over time. This emphasis on consistent performance helps explain why premium components often command a premium price: the extra cost reflects a design that prioritizes reliability, repeatability, and predictable behavior in the harshest conditions a driver may encounter.

Beyond the tangible parts themselves, the broader narrative of premium braking rests on the quality of information available to the buyer. An industry review that dissects brake components—covering material composition, mechanical properties, and practical applications—provides a critical counterpoint to marketing claims. Such analyses typically highlight how friction materials are engineered for stability across temperature swings, how bedding-in procedures influence wear and rotor life, and how noise, vibration, and harshness are mitigated through careful backing plate design and pad shims. For mechanics and fleet managers, these insights demystify the decision-making process. They illuminate how a seemingly small difference in pad formulation or rotor geometry can yield meaningful improvements in pedal feel, fade resistance, and rotor longevity. In the end, the goal is to equip practitioners with the knowledge needed to align component choices with vehicle use, driver expectations, and maintenance capabilities.

Quality brake parts do more than preserve safety; they support the sustained performance of the entire vehicle. A well-chosen premium brake system minimizes wear on other elements, such as wheel bearings and suspension components, by delivering predictable deceleration forces and reducing vibrations that can cascade into broader mechanical issues. When a braking system delivers consistent friction and heat management, brake fluid stability is also better preserved, reducing the risk of moisture-related degradation and corrosion inside the caliper assemblies. This holistic view reinforces a central tenet of premium parts evaluation: value is not merely the lowest upfront price but the sum of performance, reliability, and long-term maintenance costs. For the discerning consumer or fleet operator, that broader frame of reference matters as much as any single component credential.

The path to identifying high-quality braking components is anchored in sourcing decisions. Trusted suppliers with rigorous testing protocols, transparent material disclosures, and clear compatibility information play a crucial role. While consumer reviews and user testimonials add practical context, the technical documentation—friction coefficients, wear rates, and heat dissipation data—provides the substantive basis for comparison. Certifications, genuineness checks, and after-sales support also help safeguard against counterfeit or substandard parts compromising safety or reliability. In this sense, the purchase of premium brake components resembles a careful calibration process: the buyer balances upfront expenditure with long-term value, factoring in vehicle type, typical driving conditions, and maintenance capabilities. This approach aligns with the broader philosophy of premium auto parts reviews, which favor components that deliver consistent performance over the long haul rather than momentary gains in stopping power.

As markets evolve, the braking landscape continues to adapt to new vehicle architectures and driving patterns. Electrified powertrains, regenerative braking systems, and increasingly sophisticated stability control algorithms place greater importance on brake system integrity. Premium brake parts, in this sense, are not static; they are part of an evolving ecosystem that must respond to higher operating temperatures, more frequent thermal cycling, and tighter tolerances in braking surfaces. The result is a more nuanced decision-making framework for buyers: select parts that demonstrate thermal stability, low noise, and predictable wear behavior while also offering compatibility with current and anticipated vehicle technologies. This forward-looking view does not diminish the value of proven materials and tested designs. It simply broadens the criteria by which we assess quality, ensuring that premium components remain reliable as the driving experience and the governing technologies change.

Integrating these insights into a practical assessment means looking beyond brochures to the actual performance stories that come from real-world use. Fleet operators, transport fleets, and individual enthusiasts alike benefit when the brake components they choose consistently meet or exceed OEM specifications—while delivering the durability needed for heavy use. The best premium components deliver a seamless relationship: strong, controllable initial bite; stable friction across heat cycles; reduced rotor wear; and reliable caliper operation under a wide range of weather conditions. In the context of a premium auto parts review, the emphasis on tested performance, durable construction, and thoughtful design translates into a clear standard by which every candidate brake part can be weighed. The goal is not to chase a single best metric but to identify a balanced composition that maintains stopping power, reliability, and quiet operation under the everyday stress of city traffic and the occasional demanding drive.

Ultimately, the choice of premium brake components should reflect a broader understanding of vehicle health and driving expectations. It is about choosing parts that help the vehicle maintain its braking discipline across miles, seasons, and road conditions. It is about recognizing that safety, efficiency, and comfort emerge from the fine details—the materials chosen for the friction system, the geometry of the pad-back plate, the design of the rotor ventilation, and the reliability of the caliper mechanism. When these details are aligned with accurate information, verified performance data, and clear warranty promises, buyers can approach maintenance and upgrades with confidence rather than hesitation. The result is a driving experience that feels refined, predictable, and secure, where brake performance reinforces the whole vehicle narrative rather than complicating it.

External resource for further reading: https://www.rcfb-brake.com/

How Premium Parts Extend Vehicle Life: Quality, Fit, and Sourcing Strategies

Building longevity for a vehicle begins with a clear decision: invest in components that are engineered to last. Quality parts reduce wear across systems. They resist heat, tolerate stress, and maintain precise tolerances. When replacing or upgrading a component, choosing premium materials and manufacturing standards means the new part will harmonize with existing assemblies. That harmony limits vibration, prevents misalignment, and reduces the chance of cascading failures. Over time, those small advantages add up. Fewer roadside breakdowns, fewer surprise repairs, and steadier performance all compound to extend a vehicle’s usable life.

Premium components are produced with an eye for the long run. Forged metals, high-tolerance machined surfaces, advanced composites, and robust coatings withstand fatigue far longer than cheap alternatives. This matters most in systems subject to repeated stress, like the engine and transmission. For example, pistons and crankshafts manufactured to tighter tolerances deliver smoother power transfer. Precision timing components maintain valve timing under pressure. Those gains protect the engine’s internals and maintain fuel efficiency as mileage accrues. Similarly, brake parts designed for high thermal capacity and gradual wear reduce rotor scoring and pad glazing. That means consistent stopping power and less frequent replacements.

Longevity is not just about raw materials. Part compatibility plays an equally vital role. A premium component that does not match the vehicle’s original specifications can create new failure modes. Poor fitment causes bearing preloads to shift, seals to leak, or suspension points to bind. Rarely does an ill-fitting premium part last as long as a correctly fitted, slightly lower-grade OEM equivalent. That is why attention to model, trim, VIN, and production year matters. Proper fit prevents undue mechanical stress and preserves alignment both structurally and functionally. For restoration projects or performance upgrades, this attention prevents costly trial-and-error, wasted labor, and premature wear.

In the realm of bodywork and structural panels, material choice affects longevity and vehicle integrity. Modern composites and high-impact plastics can be lighter than steel while resisting corrosion. They also maintain aerodynamic shapes longer, reducing drag and stabilizing fuel consumption. In performance or restoration work, carbon fiber and reinforced composites offer significant weight savings and stiffness. These materials transmit loads differently than metal. When installed with correct mounting hardware and alignment, they protect internal components while enhancing handling. A well-installed composite bonnet or fender reduces stress concentrations around attachment points. That reduces fatigue where body meets frame, extending service life for both parts and chassis.

Sourcing plays a central role in the lifecycle equation. Suppliers that embed R&D into production tend to produce parts that last longer. They test materials, iterate designs, and refine manufacturing controls. Suppliers with traceable quality systems and consistent batch testing reduce variability between parts. That consistency matters most for multi-part systems where one weak link can undermine the rest. Cheap alternatives sometimes omit critical testing steps or use substandard alloys and adhesives. The consequence is early failure, sometimes in ways that damage neighboring systems. A data-driven supplier selection strategy reduces that risk. Look for suppliers that publish test data, tolerance specifications, and compatibility matrices. Those details let technicians and owners make decisions based on measurable performance rather than marketing claims.

Fleet operators and high-mileage drivers benefit most from a total-cost-of-ownership perspective. Premium parts typically cost more upfront but lower downtime and extend service intervals. For a fleet, that translates into fewer vehicle-days lost and lower labor costs per mile. Preventive replacement with durable parts also avoids the secondary damage that occurs when a cheap part fails late in its short life. A failed mounting bracket, for instance, might damage wiring harnesses, sensors, or structural mounts. Replacing only the broken piece leaves latent damage untreated. Replacing with a premium assembly often eliminates those risks. Over thousands of miles, the initial premium becomes an investment in operational continuity.

Specialized applications magnify the value of premium components. High-performance builds, towing setups, and off-road conversions expose vehicles to stresses beyond stock design. In those applications, components rated for higher loads and temperatures are essential. Suspension systems with adjustable damping and stronger mounting points reduce stress transfer to the chassis. Upgraded engine mounts tuned for higher torque protect the drivetrain and prevent harmonic vibration. Braking systems built for greater thermal capacity prevent fade under repeated heavy use. In short, selecting components that match the application prevents overloading parts and reduces cascading failures.

Maintenance practices amplify the lifespan benefits of premium parts. Even the best components require correct installation, proper lubrication, and periodic inspection. Torque specifications must be observed to avoid overloading threads. Sealant and gasket choices influence fluid containment and corrosion resistance. Filters and fluids must be chosen to match the improved tolerances of premium parts. For example, tighter tolerances in an upgraded engine may necessitate higher-spec lubricants to ensure proper film strength. Scheduled inspections catch early signs of wear. When technicians document torque readings, clearances, and visual inspection notes, they build a maintenance record. That record helps predict end-of-life and plan replacements before failures occur.

When customizing or restoring a vehicle, balancing originality and improvement is essential. Enthusiasts often face a choice: preserve period-correct parts or upgrade to modern materials. Each choice impacts longevity differently. Restoring with high-quality reproduction parts preserves historical integrity while improving service life. Conversely, sympathetic upgrades—like modern braking or reinforced suspension—improve safety and extend usable life without drastically altering driving character. The judgment is subjective, but the principle is universal: choose parts that harmonize with the vehicle’s intended use. That ensures a coherent systems approach where each component supports the others.

Installation quality often determines whether a premium part realizes its lifespan potential. Proper jigs, alignment fixtures, and calibrated tools reduce human error. For body parts and panels, precise alignment avoids stress points that accelerate fatigue. For drivetrain components, balanced assembly prevents vibration and uneven loading. Certified technicians, or thorough DIYers following factory service manuals, reduce the chance of installation-induced failures. Even seemingly minor choices, such as threadlocker grade or gasket orientation, influence long-term durability. When shops and owners adopt consistent installation protocols, they protect their parts investments.

A holistic approach to longevity treats parts selection, sourcing, installation, and maintenance as integrated steps. Start with clear priorities for use-case and mileage expectations. Verify compatibility using VIN or model-year lookup. Favor suppliers who disclose testing and manufacturing controls. Ensure installation follows specification and document the work. Track wear items and schedule replacements before catastrophic failure. This cycle reduces surprises and extends vehicle life through predictable, planned interventions.

For those who value both performance and life expectancy, premium parts make sense. They provide better materials, tighter tolerances, and clearer engineering margins. When matched carefully to application and installed correctly, they reduce wear across the vehicle. That translates into consistent performance, lower long-term cost, and fewer emergency repairs. In many cases, the decision to invest in quality replaces repeated short-term fixes with a single durable solution.

As a practical illustration, consider upgrading a hood or bonnet to a lighter composite for a restoration or performance project. When the replacement fits precisely and uses proper mounting hardware, it reduces hood flutter and mounting stress. It also localizes weight reduction without altering balance dramatically. To see a specific example of how composite panels are packaged and sold for a classic sports model, review this offering for a 1994–1999 carbon fiber hood that demonstrates aftermarket approaches to fitment and finish: 1994–1999 Mitsubishi 3000GT pit fighter carbon fiber hood.

A final practical tip: maintain records of part origins, batch numbers, and installation dates. That history helps warranty claims and guides future choices. When a component eventually needs replacement, the record informs whether the previous choice met expectations. Over years, this evidence-driven approach refines procurement and maintenance decisions. It shifts the focus from reacting to part failure to managing component life proactively. The result is a vehicle that serves reliably, performs well, and remains economical to own.

For additional reading on how choosing premium parts saves time and reduces hassle, consult the supplier guide linked below. It offers real-world examples showing the cost effectiveness of investing in quality components for long-term vehicle care.

https://www.autoonekarratha.com.au/why-investing-in-premium-auto-parts-saves-you-time-and-hassle/

Gatekeepers of Quality: Navigating Reliable Suppliers in a Premium Auto Parts Review

Every premium driving experience hinges on the unseen infrastructure behind the parts you replace or upgrade. A premium auto parts review must look beyond the glossy finish or the latest performance figure and ask where the component came from, how it was made, and how reliably it will perform across years of road use. In practice, the most telling stories about quality come from the suppliers themselves—how they manage materials, how they train their workforce, and how they synchronize manufacturing with global demand. The reliability of a part is rarely a solo achievement; it is the result of a continuous collaboration between manufacturers, quality assurance teams, and logistics partners who understand that precision, traceability, and consistency are nonnegotiable. The reader who wants to invest in longevity and safety will quickly learn that premium parts are best judged by the strength of the supply network behind them as much as by the performance numbers the parts deliver on a dyno or on the road. This perspective reframes the evaluation from a single part’s capability to the entire ecosystem that guarantees that capability over time. In this sense, the chapter is less about a single catalog entry and more about the relationships that turn a good component into a dependable one, season after season, model after model, year after year. It is the network—the factories, the standards, and the logistical rails—that determines whether premium performance remains consistent under heavy use, extreme temperatures, and the wear and tear of daily driving. The best suppliers function like careful custodians of quality. They insist on stable processes, rigorous testing, and clear documentation so that every batch can be traced back to its origin. They see compliance not as a nuisance but as a foundation for trust. When a driver invests in premium auto parts, they are often buying into a system that promises reduced wear on critical systems, lower risk of unexpected failures, and the quiet assurance that a part will behave as intended when it matters most. That assurance is seldom accidental; it is built through standards, location-specific advantages, and long-term partnerships that reward consistency as much as innovation. A key part of communicating this reliability is understanding the standards that govern production. The most reputable suppliers align their processes with international quality systems such as ISO 9001 and IATF 16949. These standards establish a framework for process control, supplier management, and continual improvement that transcends geography. They are more than a certification; they are a practical map of how a supplier reduces variability, improves defect prevention, and strengthens traceability. In the context of premium parts, that traceability becomes a practical asset for repair shops and end users alike. When a shop orders a high-performance component, it is not just buying a component but gaining access to a documented lineage that can be audited if questions arise about material composition, heat treatment, or dimensional tolerances. The result is a predictable supply chain that supports consistent fit and function across multiple vehicle configurations and model years. Geography matters in meaningful ways. Regions with mature industrial clusters can deliver advantages that translate into real value for buyers who demand timely delivery, stable pricing, and the ability to scale orders—from small-batch customization to mass production. The chapter’s focal points point to three hubs where premium parts ecosystems have become especially robust. In the southern coastal corridor of Guangdong Province, the density of verified suppliers has created a highly responsive network that can handle sophisticated, OEM-like production runs. Proximity to major ports such as Nansha and Shekou translates into shorter lead times and more reliable scheduling, benefits that compound as orders grow. In Zhejiang Province, Ningbo has forged a reputation for precision engineering and CNC machining. The ability to hold tight tolerances, particularly for high-precision mechanical components, is a defining trait of this region. And in Jiangsu Province, Changzhou offers a robust metal fabrication capacity that underpins structural and chassis-level parts. These regional ecosystems do more than reduce costs through economies of scale; they foster agile prototyping and robust communication channels—capabilities that are essential for B2B buyers who must manage intricate supply chains across continents. The value of these hubs extends beyond the shop floor. They support a kind of resilience that matters when a model line shifts gears, or a tuning spec demands a rapid swap of a nonstandard part. The ability to source from suppliers with established OEM-compliant production experience means manufacturers can respond to bespoke requests without sacrificing consistency. For luxury brands seeking premium performance components, this alignment of technical capability and logistics is a fundamental reason to rely on specific regional clusters rather than chasing marginal price advantages from distant suppliers. It is also worth noting how the broader market context supports this supplier reliability. The presence of bonded warehousing and tax incentives in select hubs can translate into cost efficiency and faster time-to-market for certain markets. Buyers planning to serve Eastern Europe or other demanding regions may benefit from these arrangements, where the combination of storage, compliance, and favorable logistics reduces the friction often seen in cross-border procurement. It is not only about the parts themselves but about the environment that enables timely, predictable delivery of those parts. Within this landscape, the procurement equation becomes more strategic. It invites buyers to look for suppliers that couple technical expertise with rigorous quality assurance systems and strong logistical infrastructure. The strongest partnerships are those in which the supplier can demonstrate that each stage of production—material selection, heat treatment, machining, finishing, and final inspection—has a documented control point. This ensures not only that the parts meet the intended specifications but also that any deviation is quickly detected and corrected. The difference is palpable in the buyer’s confidence—when a part is installed, there is a sense of uniformity across fleets, workshops, and service centers. A consumer-facing perspective on reliability can be reinforced by platforms that curate premium auto parts with experienced technical support and compatibility checks. Trusted suppliers who provide detailed product information and compatibility guidance save precious time for technicians and enthusiasts who demand precise fits. A prominent consumer platform in this space emphasizes not only product performance but also the procedural rigor behind it. It demonstrates how premium parts are verified before they reach the shelf, how technical documentation is maintained, and how post-sale support is structured to address questions about fitment, materials, and expected wear. The broader lesson for readers of a premium auto parts review is clear: reliability arises from the blend of material integrity, process discipline, and supply chain agility. The most dependable suppliers are those that can articulate a coherent value proposition built on standards compliance, manufacturing capability, and logistics readiness. They are the kind of partners that enable a repair or upgrade to maintain its premium character over time, rather than simply delivering a one-off performance spike. When a buyer looks at the landscape, there is value in seeing how these elements come together in practical terms. For instance, a premium product page can illustrate the provenance and quality emphasis that marks successful premium parts. The page showcases the carbon-fiber bonnet for a high-end compact sport model, highlighting its origin, the materials used, and the testing it has undergone. The legitimacy of such an item is more than its weight reduction or stiffness. It is a signal of the supplier’s willingness to invest in material science, manufacturing precision, and a rigorous inspection regime. A buyer who understands this signals that the supplier is capable of delivering not just a single component but a trusted supply chain that can sustain an assortment of performance upgrades or OEM-equivalent replacements. Because the premium auto parts market often hinges on long-term ownership cycles and the need for consistency across service intervals, the clinician-like attention to process and provenance becomes a selling point in its own right. It helps shift the conversation from “what is this part capable of today?” to “how reliably can this part perform over multiple years and multiple service events?” This shift in thinking is what separates boutique offerings from durable, practical investments. Fleet managers and performance enthusiasts alike benefit from partnering with suppliers who can demonstrate ongoing quality assurance, transparent material specifications, and a coherent approach to post-installation support. The credibility of a supplier is reinforced by visible QA protocols, third-party certifications where applicable, and a willingness to collaborate on custom projects without sacrificing standardization. It is also helpful to acknowledge consumer-facing platforms that give buyers peace of mind through user feedback and professional guidance, much as AutoZone’s Premium Parts Selection provides a curated spine of high-performance components backed by technical support and compatibility tools. The practical take-away for readers remains straightforward: seek suppliers that consistently align with international standards, demonstrate robust manufacturing capability, and maintain logistics that can scale with demand. In the end, premium is not a buzzword but a promise backed by a network that supports it every step of the way. The most reliable suppliers are those that combine technical sophistication with practical reliability, enabling you to enjoy performance, safety, and longevity without compromise. And as the market evolves, the best partnerships will be those that maintain a shared commitment to quality, transparency, and continuous improvement. For readers composing their own premium parts shopping list, the implication is clear: prioritize suppliers with a proven quality framework, a track record of on-time delivery, and the capability to support both small, bespoke orders and large-volume requirements with equal reliability. The result is not merely a safer or faster car, but a vehicle that can retain its premium character across miles and years. External sources corroborate this market dynamic, underscoring the importance of regional manufacturing ecosystems and integrated logistics in delivering premium parts with consistent quality: https://www.sourcingmag.com/china-automotive-supply-chain-guangdong-premium-parts/

Final thoughts

Navigating the landscape of premium auto parts is essential for business owners looking to optimize vehicle performance and safety. High-performance engine components and superior brake systems are critical in achieving customer satisfaction and ensuring reliability on the road. By investing in high-quality products from trusted suppliers, businesses can extend the lifespan of their vehicles while enhancing their reputation. Remember, the key to long-term success in the automotive industry lies in prioritizing quality over cost. Elevate your offerings by choosing premium auto parts today.