The Mitsubishi 3000GT, known as the GTO in Japan, was a significant player in the automotive scene of the early ’90s, renowned for its innovative engineering and striking design. As aftermarket modifications surged in popularity, the evolution of carbon fiber hoods became integral to enhancing performance and aesthetics. This article delves into the potential role of Advan Velpar Design in this evolution, despite its focus on tires rather than body parts. As we progress through the chapters, readers from the automotive business sector will uncover insights about aftermarket options, the tangible benefits of carbon fiber hoods, and a closer look at the evolving replica market.

Shaping Velocity: Reconsidering Advan Velpar Design and the Carbon Hood for the 1991–1993 Mitsubishi 3000GT

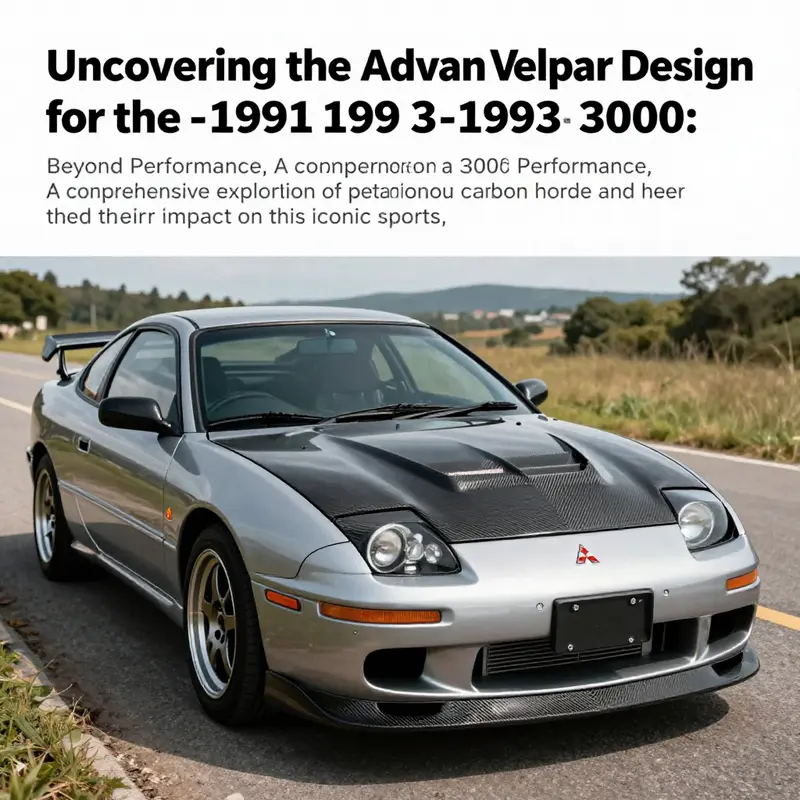

The 1991 to 1993 Mitsubishi 3000GT, known in Japan as the GTO, stands as a milestone in the company’s long arc of engineering ambition. It arrived at a moment when technology and aesthetics began to fuse inside a single frame with the audacious idea that a production sports car could wear a high technology badge as confidently as a racing wind. In the wake of that ambition, the aftermarket landscape followed with equal zeal. Carbon fiber hood upgrades became a shorthand for lightness, heat management, and a more aggressive silhouette. Enthusiasts debated the balance between preserving the 3000GT’s sculpted factory lines and letting carbon fiber bend those lines toward a more lean, track-ready stance. The result was a variety of hood options that promised weight reduction and enhanced engine bay airflow without sacrificing the distinctive profile that made the car instantly recognizable on the street or at a show. In this context, a particular nomenclature has circulated in forums and catalogs that adds a layer of confusion that is worth untangling. The Advan Velpar Design hood, as it is sometimes discussed by enthusiasts, has become something of a touchstone in the conversation about 3000GT carbon fiber upgrades. Yet the reality is more nuanced than a single product line, and the way the Velpar name intersects with hoods from the early 1990s highlights a broader truth about the era: branding from the wheel and tire side of aftermarket culture often bled into body parts in ways that blurred the lines between official catalogs and independent fabrication shops.

To understand the significance of a carbon hood on the 3000GT, one must first appreciate what carbon fiber was offering owners and builders in that era. The material’s promise lay not just in a lighter hood, but in the potential for sharper throttle response, improved weight distribution, and a front-end that felt more responsive to the driver’s input. In straight-line terms, a lighter front portion reduces the load the engine and suspension must carry during aggressive acceleration, cornering, and braking. In the 3000GT’s chassis language, with its front-mid engine layout and complex all-wheel-drive system, even small weight savings at the hood can meaningfully influence steering feel, turn-in, and front axle behavior. In practice, this translates to a more planted front end, a more eager response to steering input, and a front that sits with a slightly more balanced weight distribution under load. The functional benefits are complemented by the aesthetic payoff: carbon fiber effectively communicates speed and precision, a visual cue that signals the owner’s intent to optimize performance without surrendering the car’s iconic form.

From a design perspective, aftermarket carbon hoods for the early 90s 3000GT often sought to preserve the original hood’s sculpted lines while integrating modern, performance-oriented features. Car designers and builders aimed to maintain the centerline geometry, the intake and venting cues, and the signature power-dome or raised center region that helps define the model’s ferocious presence. This careful approach mattered because the 3000GT’s identity rests on more than speed; it rests on a distinctive silhouette that communicates its purpose at a glance. When a carbon hood arrived that could fulfill this need while trimming weight, it offered a rare convergence of form and function. Yet the market’s optimism also carried risk. Without strict standardization in the era before OEM-level carbon components became common, some hoods varied in fitment, weave pattern, resin finish, and venting configuration. This variability is precisely why reputable sources emphasize compatibility, fit, and finish as essential checks before any purchase or installation. A hood may look stunning in photos, but if it cannot align perfectly with the 3000GT’s fenders, latch anchors, or hood pad geometry, the performance benefits can be offset by alignment headaches, wind noise, or hood flutter at speed.

Within this landscape, a particular labeling phenomenon has caused enthusiasts to ask questions about the authenticity and lineage of certain products. The Advan Velpar Design hood is frequently cited in discussions about 3000GT carbon fiber upgrades. Advan, a brand best known for its wheels and tires within the broader umbrella of performance parts, carries a legacy that racers and tuners have trusted for decades. The Velpar designation, associated with high-performance tires, has a brand resonance that naturally carries over into other performance domains in aftermarket communities. That cross-pollination has, over time, led to a perception that there exists a formal Advan Velpar Design carbon hood for the 1991–1993 3000GT. The reality, as many builders and restoration specialists will tell you, is more complex. There is no widely documented official Advan Velpar Design carbon hood produced by Advan or its parent companies specifically for the 1991–1993 Mitsubishi 3000GT. Instead, the Velpar naming has circulated through forums, listings, and gray-market channels, where third-party fabricators and sellers have sometimes marketed hoods under the Velpar umbrella or used Velpar-inspired branding to evoke a performance halo. In other words, the Velpar label in this context is more a marketing echo than an official product line tied to the car from Mitsubishi’s era.

That nuance matters for collectors and restorers because it frames how we assess source material, authenticity, and value. It also frames the broader arc of how the 1990s aftermarket ecosystem operated. Car enthusiasts often seek authenticity, but the line between authentic OEM-aligned parts and high-quality replicas from the same era can blur, especially when the market is flooded with parts that replicate the original’s lines and contours while offering improved materials or lighter weight. A critical takeaway is that the lure of the Velpar label in hood form reflects the era’s appetite for performance upgrades that did not require a wholesale redesign of the car’s front-end geometry. The 3000GT’s hood area was a canvas on which builders could experiment with weight reduction and heat management without altering the vehicle’s recognized face. In practical terms, this means many owners ended up choosing carbon hoods that imitate the factory silhouette with variations in vents, dome shapes, or the density and weave of the carbon itself. The result is a diverse family of hoods, each a little different in character, yet each speaking the language of performance and a modern aesthetic.

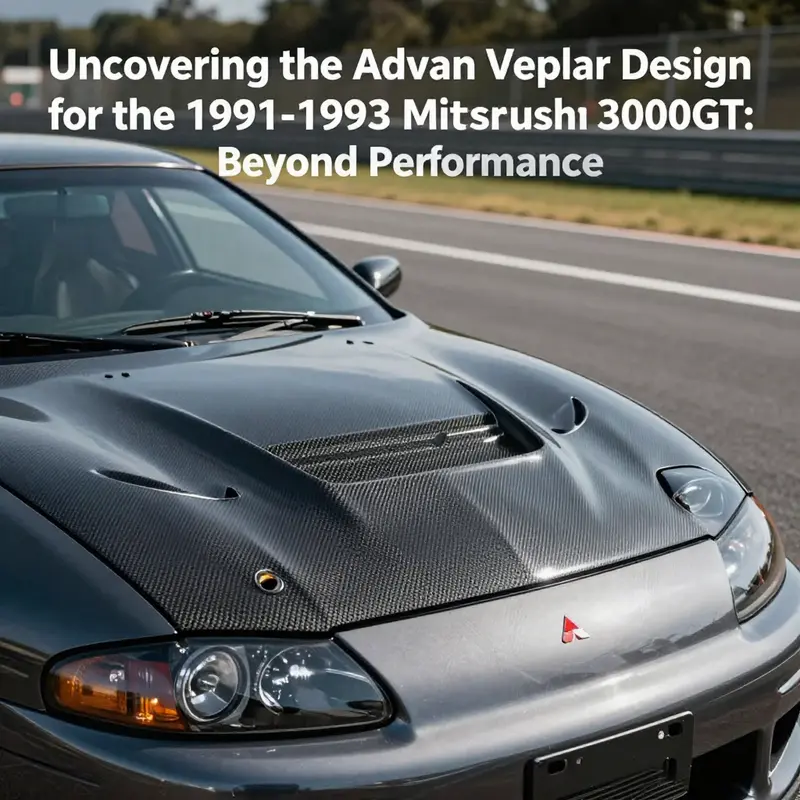

The search for a carbon hood for the 3000GT often leads to three recurring considerations: fit and finish, heat management, and the hood’s ability to maintain a proportionally aggressive look that respects the car’s lines. On the fit side, the hood must align with the hinges, latch points, hood shocks or struts, and the surrounding sheet metal without gaps that would betray its aftermarket origin. A precise fit is not merely about aesthetics; it is a safety and reliability concern. If a hood does not sit flush along the entire front edge, it can lead to air leaks, vibration, or even wind noise at highway speeds. The engineers and fabricators who built carbon hoods for the 3000GT in the early 90s understood that the ideal solution balances exact replication of the factory silhouette with modern manufacturing tolerances. The best examples in the market, whether from a major supplier or a respected restoration shop, feature a surface finish that mirrors the smooth, exacting feel of the original paint edge while delivering a lighter, stiffer panel under tension.

Heat management is another critical factor in hood design. The 3000GT’s engine bay is a relatively compact space, and the front end serves as the primary ducting for air intake and cooling. Carbon fiber does help reduce heat load by trimming weight and allowing for different venting strategies without adding a heavy steel panel. Some variants include a prominent center vent or power dome to facilitate air movement toward the radiator and down to the engine bay, aiding in keeping under-hood temperatures at bay during spirited driving. The science here is straightforward: carbon fiber’s structural properties enable designers to incorporate vent openings without the need for a bulky, heavyweight sheet metal hood structure. Car builders who focus on track readiness frequently advocate this approach as part of a broader strategy to keep the engine bay temperatures within the optimal range even under sustained high rpm. The practical upshot is that the hood becomes not just a cosmetic modification but a functional one with potential cooling advantages that can help sustain performance when the car is pushed hard.

In terms of aesthetics, many owners value carbon hoods for how they reinterpret the 3000GT’s face while preserving its signature stance. The original hood’s strong lines, the curvature around the fenders, and the satin or gloss interplay with the car’s paint all contribute to a unique visual signature. Carbon fiber tends to accentuate those lines by providing a high-contrast texture that reads crisply in photographs and under showroom lighting. The modern owner who chooses a carbon hood often wants that balance between heritage and sport appeal. It is a design choice that says the car remains faithful to its past while signaling a readiness to compete—at car shows, on local hills, or on open roads where the driver feels the weight of speed in the air. The result is a car that looks as if it is ready to accelerate just by virtue of its appearance, even when it is standing still.

From a historical perspective, the aftermarket ecosystem of the early 1990s—especially around performance-focused brands and smaller fabricators—thrived on collaboration and cross-brand signaling. A carbon hood for the 3000GT could be sourced from specialists who also produced compatible components for a range of performance cars. In many cases, restoration professionals and collectors would rely on catalogs that list carbon hoods compatible with a given model. A reputable source to verify compatibility and ensure authenticity for this kind of part is Classic Car Auctions, which lists verified restoration parts including carbon fiber hoods that are compatible with the 3000GT. This kind of sourcing is critical when authenticity and value are at stake, because a hood that looks the part but does not fit correctly can compromise both performance and aesthetics. The emphasis on verified parts helps ensure the piece is suitable for a restoration project and is not simply a generic aftermarket component that happened to fit a similar silhouette.

Community and peer review play significant roles in shaping what counts as a credible option. Enthusiast clubs and forums—such as dedicated Mitsubishi 3000GT clubs and international associations—provide a forum where owners share fitment notes, comparison photos, and installation tips. These dialogues help future buyers understand whether a particular hood is likely to align with their car’s exact configuration, including the model year, door sashes, and weather-stripping tolerances. The practical takeaway for someone who is considering a carbon hood for a 1991–1993 3000GT is to engage with reputable sources, verify the part number or the vendor’s catalog listing, and seek confirmation of fitment on a vehicle with a configuration similar to their own. When available, a seller that can provide a detailed fitment guide, along with mounting hardware and installation steps, offers a more reliable pathway to a successful upgrade.

For those who want to navigate the market with a careful eye, there are reputable suppliers that have maintained a steady presence in the 3000GT ecosystem. These suppliers often produce or stock genuine replacement hoods or high-quality aftermarket variants that respect the original hood’s proportions. In particular, brands that have built a name for themselves in the 3000GT community typically provide internal part numbers and documentation that help buyers verify that the hood will align with the car’s latch mechanism, hinge geometry, and brace attachments. The emphasis on precise fit is not a luxury; it is a practical necessity that prevents misalignment, rattle, and potential damage during high-speed operation. A well-finished carbon hood can be a long-term asset that holds its shape, resists delamination under heat cycles, and maintains an even surface that takes paint consistently. The end result should be a hood that looks integrated with the car’s lines rather than an obvious add-on, preserving the 3000GT’s dramatic front-end character while delivering the benefits of a lighter, heat-tolerant hood.

Throughout this narrative, it becomes clear that the concept of the Advan Velpar Design hood sits at an interesting intersection of branding and aftermarket practice. The Velpar name is historically associated with Advan’s performance tires and wheels rather than a documented, factory-backed carbon hood option for the 1991–1993 3000GT. Yet the Velpar identity—evoked through catalogs, chat threads, and sales listings—has empowered a subset of sellers and builders to reference Velpar in relation to carbon hoods that aim to capture the era’s speed-inflected aesthetics. Enthusiasts should approach such claims with an informed eye, recognizing that the Velpar badge in this context represents a marketing signal rather than a certification of authenticity from Advan itself. In other words, the Velpar moniker has become a cultural artifact within the 3000GT aftermarket narrative, a shorthand for performance aspiration rather than a formal product line linked to the model’s original release.

For those who want to explore the lineage further, there is value in tracing credible sources that discuss carbon fiber hoods and their place in the 3000GT’s evolution. Classic Car Auctions and Mitsubishi 3000GT Club International provide a baseline of documentation and community knowledge that helps separate legend from verifiable product history. These sources remind us that the 1990s were a time when aftermarket culture thrived on experimentation, collaboration, and a shared language about weight reduction, heat management, and aggressive styling. The Advan Velpar Design hood, as a concept, captures that energy—the idea that a car built for speed could be visually and technically enhanced through carbon fiber materials, even if the specific product’s official lineage remains contested. The broader lesson is that enthusiasts who pursue these upgrades should approach the market with a framework of caution and curiosity: verify fitment, inspect the weave pattern and resin finish for consistency, and prioritize a supplier that can demonstrate a track record of quality and accurate documentation.

In practice, the most successful installations balance homage to the 3000GT’s original aesthetics with a clear and measurable enhancement in performance. A hood that is too aggressive in its venting or dome shape can disrupt the car’s front-end wind balance, while a hood that is too conservative may not deliver the perceived benefits of weight reduction. The optimal choice for many restorers is a carbon hood that respects the model’s distinctive silhouette while offering a confident, high-quality finish. The installation journey itself becomes part of the car’s story, a narrative that weaves together the past’s engineering ambitions and the present’s craft. The result is a vehicle that feels as if it has evolved without having to abandon its heritage.

For readers who are curious to explore a concrete example that aligns with the era and the discussion here, one widely referenced option in the aftermarket community is the Pit Fighter carbon fiber hood designed for the 1994–1999 Mitsubishi 3000GT. While not a direct product of the Advan Velpar Design line, this hood demonstrates the characteristics enthusiasts seek: precise fitment, a lightweight build, and a design that echoes the original lines with modern performance cues. Interested readers can learn more through dedicated product pages that catalog this hood as part of the broader 3000GT carbon fiber hood ecosystem. Pit Fighter Carbon Fiber Hood. This reference illustrates how the market in the 1990s often produced hood variants that were compatible across a range of years and configurations, reinforcing the broader lesson that the 3000GT’s hood story is less about a single definitive product and more about a period of intense experimentation and cross-brand influence.

In sum, the Advan Velpar Design hood as a formal, factory-backed option for the 1991–1993 3000GT is not supported by official product histories. The Velpar branding’s appearance within hood discussions reflects a broader aftermarket culture in which the Velpar name carried a powerful association with performance. The hood itself belongs to a lineage of third-party carbon fiber upgrades that sought to preserve the 3000GT’s iconic look while delivering weight savings and improved engine bay cooling. Enthusiasts who want to pursue this path should approach the market with careful sourcing, insist on verified fitment, and consider the role of the hood within a broader approach to performance optimization that respects both the car’s heritage and the practical needs of handling and cooling under load. For those who want to learn more about the Advan ecosystem and its current product direction, the official Advan site offers a window into how the brand frames its performance philosophy today: https://www.advan.com/.

Lighter, Faster, Cooler: The Carbon Fiber Hood’s Quiet Revolution in the 1991–1993 Mitsubishi 3000GT

The Mitsubishi 3000GT, produced during a pivotal moment in sports car history, carried a blend of cutting-edge automotive engineering and a design language that spoke to a generation of enthusiasts hungry for performance with a futuristic edge. Between 1991 and 1993, the car stood out not only for its twin-turbo V6 and all-wheel control but also for the way its silhouette hinted at what a mass-market supercar could be when science and style aligned. In this context, aftermarket carbon fiber hoods emerged as more than mere appearances. They represented a practical, performance-minded approach to modifying a car that already pushed the envelope of what a factory hood could achieve. The chapter that follows examines the performance benefits of carbon fiber hoods on the 3000GT, weaving together weight, heat management, aesthetics, durability, and the broader design ethos of an era when lightness and airflow mattered as much as raw horsepower. It is a story of how a single component—crafted from a lightweight composite—could influence handling, braking, engine reliability, and the visual language of a car that had many drivers looking beyond the showroom floor for a personal sense of speed.

To understand the appeal of carbon fiber hoods on the 1991–1993 3000GT, one must first acknowledge the car’s original engineering philosophy. The factory hood was more than a cover for the engine bay; it was part of a holistic approach to performance that balanced raw power with sophisticated aerodynamics and a chassis tuned for responsive feedback. Enthusiasts in the early ’90s learned to look at the hood not just as a protective shell, but as a weight-bearing, heat-managing, aerodynamically informed component. When carbon fiber emerged as a credible option, it carried a promise that was almost existential for the performance-focused driver: less mass up front could translate into quicker steering responses, more precise weight transfer during cornering, and a less pronounced nose dive under hard braking. In a car like the 3000GT, where front-end weight contributed to understeer tendencies when pushed hard, shaving weight from the hood could offer tangible handling benefits while preserving or even enhancing the car’s iconic stance.

Weight reduction is the most quantifiable and widely discussed advantage of switching to a carbon fiber hood. Replacing the heavier factory sheet with a carbon fiber alternative typically brings a notable mass savings, often in the range of 30 to 50 pounds (roughly 14 to 23 kilograms). That might not sound transformative on its own, but within the front-end dynamic of a front-engine, all-wheel-drive sports coupe, every ounce matters. The front end is the point of first contact with the road; it bears the brunt of braking loads, nose-dive during deceleration, and the initial mass that must be projected into a turn. By reducing front-end weight, the driver experiences crisper steering, a more immediate response to input, and a chassis that is easier to balance as grip shifts during approach and exit from a corner. The acceleration benefits are subtler but real: with less inertia up front, the car can rotate more readily in the mid-corner phase, allowing the driver to preserve exit speed on a varied mix of surfaces.

Bringing down the mass in the hood also has an important cascading effect on braking performance and overall stability. A lighter front end translates to less load transfer into the front tires at the onset of braking, reducing the risk of nose squatting too aggressively and allowing the tires to maintain better contact with the road surface. This improved weight distribution improves brake feel and modulation, which can be especially meaningful in hot weather or during repeated, performance-oriented laps where heat buildup affects pedal travel. The 3000GT’s braking performance, often praised for its strength in stock form, can be refined further with a carbon fiber hood by reducing the load the brakes must control as the front axle carries less mass. In practical terms, a driver can experience a more linear, predictable braking feel, a cleaner line into corners, and a heightened sense of confidence when entering a bend at speed.

The discussion of weight savings is naturally linked to that most visible of benefits: improved handling. Lighter components up front reduce the moment of inertia that the driver must overcome to turn the vehicle. In practice, that translates into quicker turn-in, more immediate steering responses, and a chassis that feels willing to change direction with less effort. For a car like the 3000GT, which already offers a sophisticated suspension arrangement and a well-tuned chassis balance, removing even a portion of the front-end mass can accentuate the car’s ability to respond to abrupt steering inputs without compromising stability. The sensation is subtle but meaningful—the hood’s lighter mass contributes to a more immediate sense of connectedness between driver intent and the car’s rearward momentum, enabling more aggressive but controllable cornering. The result is a vehicle that remains composed at the limit, with less nose heaviness to dampen the driver’s feedback during high-G maneuvers. And while some may assume that carbon fiber simply reduces weight, experienced drivers know that weight distribution is the real game changer: a lighter hood shifts the balance toward a more left-right neutral response, enhancing mid-corner stability and allowing more precise throttle modulation through the apex.

Another critical advantage lies in heat management within the engine bay. Carbon fiber is not just light; it’s highly stiff and thermally efficient in practical automotive applications when paired with correct venting and design considerations. A hood crafted from carbon fiber can be engineered to integrate functional vents or air channels that actively influence airflow across the engine bay. In the 3000GT’s turbocharged setup, cooling is not a luxury but a necessity. The intercoolers and turbo plumbing generate substantial heat, and during sustained high-performance driving, heat soak can compromise efficiency and reliability. A carbon fiber hood with well-designed vents can facilitate improved airflow over the engine and turbo area, promoting more effective heat dissipation. Increased airflow reduces the likelihood of heat soak in critical components such as the intercooler cores, intake manifolds, and valve covers. This is not merely about keeping temperatures within a comfortable range for daily driving; it is about maintaining performance under load, ensuring that the engine can sustain higher boost pressures and consistent power output without the risk of overheating. The improved thermal management dovetails with the car’s broader performance goals, enabling the driver to push closer to the car’s potential in both street and track contexts.

The aesthetic dimension of carbon fiber hoods in the early ’90s bears mentioning as well. The carbon weave, with its distinctive pattern, signaled a commitment to technology and performance that resonated with enthusiasts who valued the engineering behind speed as much as speed itself. The 3000GT, already a visual standout with its aggressive lines and aerodynamic silhouette, gained an extra layer of visual credibility with a carbon hood. The contrast between the dark, glossy weave and the rest of the car’s body color could accentuate the car’s long, hood-forward stance, emphasizing the vehicle’s forward-driving intent. For many owners, this visual upgrade was more than skin deep. It became a statement about the owner’s approach to the car: not merely a consumer of performance but a dutiful steward of engineering, a person willing to invest in materials and fabrication that preserved the car’s edge while simultaneously reducing mass.

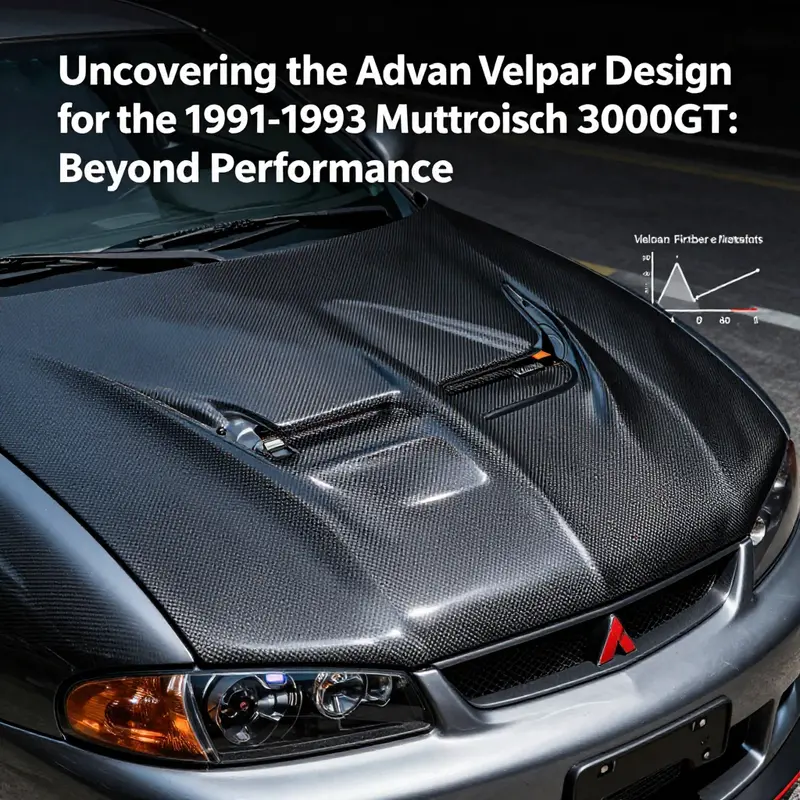

From a quality and durability standpoint, the choice of carbon fiber matters. The best aftermarket hoods—those designed for the 3000GT and built with modern composite techniques—are manufactured using high-grade carbon fiber with a robust resin system and a two-part mold process. Such construction emphasizes both stiffness and a premium surface finish, ensuring that the hood remains visually striking while resisting the wear and tear of daily driving. A well-made carbon fiber hood should maintain a consistent carbon weave pattern, exhibit excellent impact resistance, and lie flush against the factory mounting points, with precise fitment for hood hinges, latch locations, and weatherstripping. The durability question is not merely about the raw material; it’s about the entire manufacturing approach. When a hood is engineered with high-quality carbon fiber and a carefully controlled layup, cured under strict process parameters, it offers long-term resilience in the face of minor flexing, temperature fluctuations, and road-induced vibrations. The result is a product that stands up to the demands of spirited driving while preserving the integrity of the engine bay’s geometry and the car’s signature silhouette. In this light, the decision to adopt a carbon fiber hood becomes a blend of practical engineering and aesthetic preference, anchored in the knowledge that the hood is a critical interface between the driver, the car, and the road.

Yet the story of carbon fiber hoods for the 3000GT in the early 1990s is not simply about the performance numbers or the weave pattern. It is also about the ecosystem of aftermarket parts that formed around the model. Enthusiasts sought reliable sources for fitment and authenticity, often turning to communities and specialized suppliers that could provide hoods designed to replicate the original contours so as to preserve the car’s existing lines while delivering the material benefits of carbon fiber. The authenticity of contour, curvature, and profile mattered as much as the material’s properties. A hood is a defining element of the car’s face; a carbon version that faithfully echoes the factory shape ensures that the car’s identity remains intact even as its performance is enhanced. This balance—between preserving the car’s iconic look and enabling meaningful gains in weight reduction and heat management—helped drive interest in aftermarket carbon fiber hoods during the era. It also required careful consideration of mounting and alignment, since a hood that does not sit correctly or seal well against the cowl can undermine all the potential benefits. The best installations accounted for tolerances, latch performance, and hood alignment to avoid wind noise and rattles at speed, ensuring that the car’s performance gains were not undermined by poor fitment.

In a broader sense, the carbon fiber hood on a classic 3000GT is more than a component; it’s a microcosm of a transitional moment in automotive culture. The early ’90s marked a shift toward highly engineered materials and a willingness to reimagine weight distribution and thermal management as central to a car’s performance identity. The 3000GT, with its complex powertrain and sophisticated chassis, became a canvas for this shift. Enthusiasts who adopted carbon fiber hoods often did so as part of a larger program to optimize weight, aerodynamics, and cooling without compromising the car’s visual appeal or reliability. The result was a nuanced form of modernization: an older platform that embraced new materials and manufacturing techniques to stay relevant in a market that demanded both performance and prestige.

The absence of an official Advan Velpar Design-based carbon hood for the 3000GT is a useful reminder of the era’s realities. Advan Velpar, like many performance-oriented lines of the period, sought to marry high-speed capabilities with a tuned sense of style, but the hood, in this case, was not a product of that specific branding. Nevertheless, the ethos behind Velpar-inspired thinking—weight-conscious design, attention to airflow, and a commitment to athletic, race-inspired aesthetics—echoes in the choices that owners and shops made when selecting carbon fiber hoods for the 3000GT. This is a reminder that, in the early 1990s, the path to improved performance was not paved by a single, branded solution. It was formed by a network of suppliers, forums, restoration shops, and individual enthusiasts who understood that carbon fiber offered advantages beyond a glossy finish. The hood became a tangible expression of a broader philosophy: that every component could be reimagined to shave seconds off lap times, to reduce fatigue on long highway drives, and to heighten the driver’s sense of control when the road demanded precision and poise.

In considering the practical aspects of upgrading to a carbon fiber hood on a 1991–1993 Mitsubishi 3000GT, one cannot ignore the installation realities. A carbon hood requires careful measurement and alignment. The mounting points must be checked for wear and tear, and the hinge and latch hardware should be lubricated and adjusted to accommodate any slight variance in the new panel. The hood’s weight reduction can slightly alter the car’s front-end geometry, which may necessitate a recalibration of the hood alignment and, in some cases, a minor adjustment to the hood supports or gas struts. For some owners, this is a ritual of sorts—a reminder that performance upgrades are not merely bolt-on improvements but opportunities to re-tune the car’s fundamental interfaces with the road. The process is a collaboration between the fabricator, the installer, and the driver, with the goal of achieving a balance between ultimate performance and daily usability. It is this balance that often separates a well-executed carbon fiber hood upgrade from a cosmetic enhancement. The added weight savings and improved heat management come to life only when the hood fits like it belongs there and remains durable under the rigors of spirited driving.

The chapter’s exploration thus far underscores a critical point: carbon fiber hoods for the 3000GT, particularly in the early ’90s, offered a blend of tangible performance improvements and unmistakable visual appeal. They were not universal upgrades, and they required careful consideration of the driver’s needs, the car’s intended use, and the owner’s willingness to invest in a component that sits at the intersection of science and art. The best carbon fiber hoods were more than just lighter panels; they were carefully engineered parts that respected the engine’s cooling demands, the car’s balance, and the cultural moment when performance tuning was becoming a refined, craft-oriented pursuit rather than a simple horsepower race. In that sense, the carbon fiber hood for the 3000GT embodied a broader shift in automotive culture—a shift toward material science as a driver of performance optimization, where weight, airflow, and rigidity were measured with the same rigor as torque curves and drag coefficients.

As readers move forward, they will encounter a more detailed view of sourcing, fitment, and the ongoing dialogue between authenticity and innovation that surrounds these upgrades. The next section will widen the lens to consider how the carbon hood fits within a broader ecosystem of 1990s performance tuning—where forum discussions, restoration parts catalogs, and early specialty shops provided the knowledge base that allowed drivers to plan, justify, and execute such modifications with a sense of confidence and purpose. The conversation about carbon fiber hoods is not simply about material choice. It is about how a generation of enthusiasts imagined speed, how they understood the trade-offs of weight versus stiffness, and how they translated a car’s raw potential into an experience that felt uniquely theirs. In the end, the carbon fiber hood stands as a quiet revolution—a lightweight, heat-conscious, aesthetically decisive upgrade that helped the 3000GT live up to its muscle memory and its futuristic promise at once, while serving as a reminder that true performance upgrades are often about bringing together many small, precise improvements into a coherent, confidence-inspiring whole.

Internal link reference (for further exploration): hello-world

External resource for deeper technical context: https://www.visracing.com/products/vis-carbon-fiber-hood-for-mitsubishi-3000gt-1994-1998-94mt3k2doe-010c

Shaped by Speed: The Carbon Hood Evolution for the 1991–1993 Mitsubishi 3000GT and the Replicas that Carried Its Legacy

In the early 1990s, the Mitsubishi 3000GT stood at a crossroads of performance and futuristic design. Its lines spoke a language of speed before the engine roared to life, and its engineering promised a radar-quiet blend of turbocharged power and precision handling. The hood, as the front face of this performance statement, carried more than a functional purpose; it was a defining element of the car’s stance, airflow management, and the way the chassis breathed. Enthusiasts who sought to push the 3000GT beyond factory limits began to view the hood not just as a cover, but as a component that could influence weight, heat dissipation, and aerodynamics. Carbon fiber, with its lightness and stiffness, offered a compelling path forward. It was a moment when the culture around this car began to align with advances in materials science, and the result was a small but enduring chapter in the broader story of automotive customization.

The notion that the Advan Velpar Design series, associated with high-performance tires rather than body parts, would inherently produce a carbon fiber hood for the era is a helpful reminder of how quickly a market’s memory can misplace historical threads. In reality, there was no official Advan Velpar Design carbon hood released for the 1991–1993 Mitsubishi 3000GT. The series occupied a different corner of the performance world, focused on tires that could translate grip and stability into real-world lap times or street-cred, rather than providing aerodynamic or weight-saving transplantations for the hood. Yet the absence of an official hood from that line did not extinguish the appetite for lightweight, sculpted styling. If anything, it sharpened the distinction between factory lines and aftermarket solutions that promised to respect those lines while offering something lighter and more aggressive.

What followed was a robust aftermarket ecosystem built around the 2-door, 2-wheel-drive era of the 3000GT, as well as its later VR4 configurations. The core idea was straightforward: preserve the hood’s OEM-like silhouette and mounting geometry while replacing the heavy section with a composite that offered meaningful weight reduction and improved heat management. Carbon fiber was the material of choice, not only for its brag-worthy weight savings but also for its unmistakable weave that signaled a serious performance intent. The 3000GT’s hood had already been sculpted to balance the car’s broad haunches and its aggressive glare; any carbon replacement had to respect those contours while delivering true performance gains.

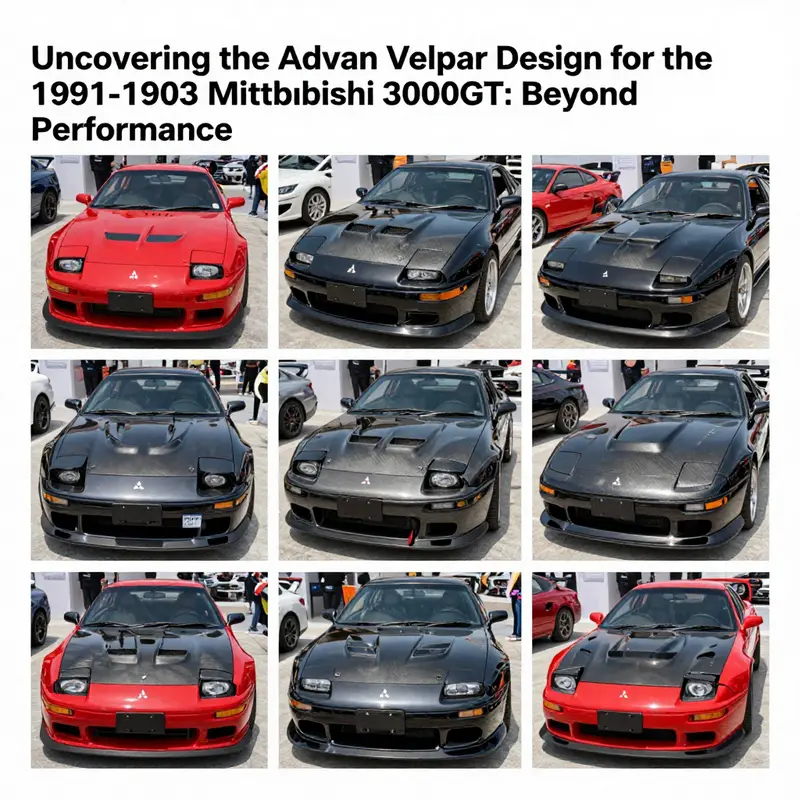

Within this context, a number of reputable manufacturers stepped forward to offer OEM-style carbon fiber hoods designed specifically for the 1991–1993 Mitsubishi 3000GT 2DR configuration. The aim was not to reinvent the wheel but to honor the original geometry—keeping the windage, the hinge placement, and the central profile consistent with the factory design—while providing the benefits of modern composites. The resulting market offered a spectrum of options that catered to different levels of restoration, modification, and budget. For some owners, the appeal lay in the visual drama—the carbon weave peeking through a clear finish, the way light reflected off the surface as the car moved. For others, the draw was functional: a reduction in unsprung weight and a potential improvement in heat dissipation that could help keep a turbocharged engine cooler under track-like conditions.

Among the offerings that followed, the process and the provenance mattered as much as the appearance. The carbon fiber hoods that found a foothold in the market were typically produced with materials and manufacturing methods designed to meet both durability and aesthetic standards. The best examples employed 100% ISO-certified, Grade-A carbon fiber, a level of quality that gave buyers confidence that the material would hold together under the stress of spirited driving and occasional track use. A common manufacturing approach used by reputable suppliers involved a two-part mold system. This technique allowed the hood to replicate the exact contours and styling of the original while ensuring the carbon skin was bonded to a strong substrate that could withstand daily use, road debris, and weather exposure. In other words, the goal was to marry similarity of form with the assurance of modern materials science.

The market’s evolution also mirrored broader shifts in how enthusiasts sourced and evaluated aftermarket parts. Instead of relying solely on brick-and-mortar performance shops, many buyers turned to online marketplaces and enthusiast forums for guidance, installation tips, and reliability feedback. Platforms that hosted owner reviews, fitment photos, and long-term ownership stories became invaluable. The narrative around these hoods grew beyond a simple wish to lighten the car. It became a conversation about authenticity, fitment integrity, and the way a modern composite part could carry the car’s iconic look into a new era of performance culture.

In this context, the carbon hood market for the 1991–1993 Mitsubishi 3000GT did more than offer an appearance upgrade. It created a bridge between the era’s engineering mindset and the evolving demands of modern restoration and performance. Owners who traced the lineage of the car through its design language could now pair that legacy with techniques and materials that the original engineers could only have imagined. The hood, once a single piece of sheet metal shaped by stamping presses, could become a carefully engineered component that lightened the load on the front of the vehicle while maintaining the precise geometry that allowed the aerodynamics to behave as intended at speed. The care with which these parts were designed and manufactured reflected a broader trend: the realization that classic performance icons could live on, not just in pristine showroom condition, but in varied, usable forms that embraced contemporary manufacturing realities.

One of the key dimensions of this story is the balance between authenticity and modern fabrication. Enthusiasts who cared about accuracy often sought parts that matched the OEM hood’s silhouette and mount points. They wanted a carbon replacement that did not require a radical reworking of the fenders or grille, nor a re-engineered hood latch. The two-part mold method, used by many reputable suppliers, was central to achieving this—allowing the carbon layer to be formed around an exact replica of the original hood’s surface, with consistent thickness, and with the ability to be finished to a high gloss or matte clear coat that matched the car’s overall aesthetic. The result was a hood that could look and feel like the original, yet carry the weight savings and heat dissipation benefits that carbon fiber offers. In some cases, the replacement was so precise that it could be installed by the typical hobbyist with basic hand tools, striking a balance between DIY accessibility and professional quality.

Pricing and financing also emerged as practical considerations that shaped the market’s adoption. While the exact numbers varied by seller, region, and finish options, some of the more widely cited price points suggested that the hood could be acquired at a level that made restoration work feasible for a broader community of enthusiasts. The narrative often includes a sense of context: what a typical buyer might expect to pay, and how financing or promotions may have influenced the timing of an upgrade. Even when financing was not available, the relative affordability of carbon hoods, compared with other high-performance modifications, helped fuel interest. Buyers could weigh the cost against the potential benefits, such as improved weight distribution and reduced engine bay temperature, and decide how much of a performance upgrade they wanted to commit to their car’s overall package.

Sourcing and availability added another layer of complexity. The aftermarket ecosystem drew on a combination of established manufacturers and regional suppliers. While reputable brands maintained a steady online presence with product pages that showcased fitment data, sample finishes, and installation guidance, other parts could appear on marketplaces or through regional distributors. Some enthusiasts discovered that Guangzhou-based suppliers offered related accessories or body kits that complemented carbon fiber hoods, though the availability of complete hood assemblies could vary by year, model, and market. In some cases, part numbers and distributors outside the immediate North American market pointed to broader supply networks for carbon fiber components and related hardware. In all of this, though, the fundamental principle remained clear: the best aftermarket hoods preserved the original lines while delivering the benefits of modern composites.

For enthusiasts seeking a direct, reliable source of information about a specific hood that matched the 1991–1993 Mitsubishi 3000GT’s 2DR configuration, the market offered detailed product listings and user feedback on dedicated platforms. These sources provided more than mere price points; they offered installation tips, comparisons of product quality, and perspectives on long-term reliability. The value of a well-documented product page could not be overstated. A reputable supplier’s official listing would typically include the material composition, the exact mold approach used to reproduce the original geometry, and photographs that demonstrated the hood’s finish and weave alignment. The best listings made clear the hood’s compatibility with the factory latch and hinges, ensuring that a buyer could install the piece with minimal modification and maintain the car’s original feel. Such transparency was crucial for restorers who sought to maintain the vehicle’s historical integrity while embracing a contemporary material upgrade.

As the market matured, the community also placed greater emphasis on authenticity. Original equipment and OEM-style replacements carried more weight with collectors and meticulous restorers who wanted to preserve as much of the car’s provenance as possible. Yet there was also room for true performance emphasis. Some buyers looked at carbon hoods not only as a means of saving weight but as a component that could contribute to more efficient engine cooling. The front of the engine bay in turbocharged configurations can accumulate heat, especially during sustained high-speed runs or in hot-weather conditions. If a hood could shed a small fraction of weight without compromising stiffness, the engine bay might experience nuanced improvements in heat management, which in turn can support more stable boost behavior and consistent performance. Even modest gains like these could make carbon fiber hoods attractive beyond their aesthetic appeal.

To understand the broader context of sourcing and availability, it helps to consult the sources that have chronicled these parts in detail. For example, a well-structured overview on a respected aftermarket supplier’s platform offers a glimpse into the materials, molding processes, and finish options that define modern carbon fiber hoods for older performance models. The narrative often includes a description of the two-part mold approach used to reproduce the original hood’s contours, ensuring the replacement looks right from every angle yet benefits from the reduced mass of the composite. It also highlights the importance of proper surface finishing and UV protection to preserve the carbon’s appearance over years of exposure to sun, rain, and road debris. This combination of historical reverence and contemporary fabrication technique is at the heart of why carbon fiber hoods for this era remain a meaningful upgrade for many enthusiasts.

Beyond the technical and practical considerations, the culture surrounding these hoods reveals a community that values peer insights and shared experiences. Enthusiasts frequently turn to forums and social channels to compare fitment results, to verify that a given hood aligns with the factory lines, and to gather advice on installation and alignment. The Mitsubishi 3000GT Forum, for instance, has served as a venue where owners exchange impressions about color matching, weave orientation, and the overall impression of the car’s front-end profile after a carbon replacement. This communal dimension—where a hood is not just a part but a conversation starter—adds texture to the material story. It explains why some owners prefer a well-documented option with robust customer feedback over a cheaper alternative that might promise similar weight savings but fail to deliver on fit and finish.

In terms of sourcing, the market sometimes pointed buyers toward distributors and retailers with direct ties to the car’s model year and body configuration. For anyone chasing a precise fit for the 1991–1993 Mitsubishi 3000GT 2DR, matching the hood to the original geometry was not merely a nice-to-have; it was essential for maintaining the vehicle’s equity—the sum of its appearance, driving feel, and historical footprint. The tension between price and provenance often guided consumers: some preferred a product that carried the exact dimensions and mounting points of the OEM hood, even if it required a premium price and longer lead times; others accepted a close-but-not-perfect replica if the aesthetic result satisfied their immediate restoration or performance goals. The market’s flexibility—and the willingness of reputable suppliers to provide guidance and documentation—helped sustain a steady flow of options for collectors and drivers alike.

The evolution of these hoods thus stands as a microcosm of how classic performance cars have navigated the transition from vintage craft to modern manufacturing. It is about how the chassis, engine, and aerodynamic philosophy of an iconic car could persist through decades by embracing contemporary materials and production methods. It also reveals how enthusiasts balance the desire to preserve a car’s original character with the willingness to adopt innovations that improve daily usability or track reliability. The 1991–1993 Mitsubishi 3000GT, with its complex turbocharged heritage, became a proving ground for a broader principle: that a piece as simple as the hood could still matter deeply in a car’s performance narrative when crafted with care and placed within a community that valued both authenticity and improvement.

For those who want to explore specific examples and the exact options that were available, there is a practical, accessible entry point. A reputable catalog or retailer’s page dedicated to the 1991–1993 2DR variant will often list the hood as OEM-style, carbon fiber, and designed to replicate the factory geometry. These listings typically include the exact surface finish, the thickness range of the carbon layer, and the tolerances related to mounting points. They may also provide high-resolution images that show how the weave aligns with the hood’s curvature, an indicator many buyers use to judge the craftsmanship. The interplay of visual accuracy and functional engineering is a recurring theme in the discussions of these parts, and it is precisely what sustains this niche: the harmony between a car’s storied lines and the modern materials that can responsibly meet today’s performance expectations.

As with any aftermarket upgrade, the decision to install a carbon hood is a statement of intent. It signals a commitment to weight reduction, a willingness to reexamine heat management, and an enthusiasm for a distinctive look that stands out in a crowded showroom or a quiet, winding road. For owners of the 1991–1993 Mitsubishi 3000GT, the carbon hood option represents more than an aesthetic flourish; it is a link to a moment when the car’s designers and the aftermarket community began speaking the same language—one that recognized the car’s potential to accelerate, to corner with confidence, and to carry its own myth into the next chapter of its long life.

To emphasize the practical route for anyone curious about this path, it’s worth noting one particularly useful resource that chronicles the evolution and current state of the market for carbon hoods for the Mitsubishi 3000GT. The resource highlights how aftermarket carbon fiber hoods have been aligned with the original lines of the car, how they are produced using precise two-part molds to reproduce the contours, and how a shift toward authentic materials has helped the community maintain a degree of fidelity to the car’s heritage. For enthusiasts who want to explore a specific model year and body style, this kind of documentation—paired with community feedback and manufacturer specifications—provides a robust framework for making an informed choice about fitment, finish, and long-term durability. Related discussions and product details can be found on dedicated online resources and retailer pages, where the technical particulars are laid out and where a buyer can compare options side by side. The result is a more confident journey from initial curiosity to a completed installation that preserves the car’s iconic silhouette while embracing the benefits of modern composites.

For those who want to dive directly into a concrete example of an available option and see how a contemporary supplier frames its offering, this internal link provides a path to a widely referenced product line that has been discussed within the community for years. The page demonstrates how a carbon fiber hood for the 1994–1999 Mitsubishi 3000GT fits within the same design philosophy as the earlier chassis while accommodating the small but meaningful differences that later years introduced. While the styling and edge details might differ slightly from the 1991–1993 model, the underlying approach—using a proven mold to reproduce the OEM geometry and delivering a high-strength carbon skin—remains a throughline that connects generations of 3000GT restorations and builds a continuous thread through the car’s evolving aftermarket narrative. You can explore that specific option here: 1994-1999 Mitsubishi 3000GT Pit Fighter Carbon Fiber Hood.

As the story of these hoods unfolds, one thing becomes clear: the 1991–1993 Mitsubishi 3000GT’s carbon fiber hood market is less a simple accessories aisle than a testament to how a beloved performance icon can adapt to changing manufacturing realities. It is a story about how enthusiasts, engineers, and fabricators collaborated across borders and generations to retain the car’s distinctive attitude while embracing the advantages of modern composites. It is about the conversations that happen in forums and online marketplaces, the careful comparisons that shoppers make between fitment and finish, and the way a small, meticulously crafted piece of carbon can help a car feel new again without losing the aura that made it special in the first place.

For readers who want to extend their research or confirm details beyond this narrative, a reliable external resource offers broader context on the materials and performance considerations connected with carbon fiber hoods for classic performance cars. See the VIS Racing official product overview for carbon fiber hoods tailored to this model family, which provides technical data, finish options, and mounting guidance that can be cross-referenced with user experiences from the community. This resource complements the hands-on notes and forum commentary by supplying a canonical perspective on how these parts are intended to perform in the real world.

Final thoughts

As we’ve explored, the potential of the Advan Velpar Design concept within the realm of the 1991-1993 Mitsubishi 3000GT sheds light on a broader industry trend toward customization and performance optimization. Aftermarket carbon fiber hoods not only provide aesthetic enhancements but also functional improvements that resonate with car enthusiasts and performance seekers. The evolving replica market offers numerous options for these iconic vehicles, ensuring that they remain relevant in both performance and appearance. Recognizing these advancements highlights the enduring legacy of the Mitsubishi 3000GT in the automotive community.