For business owners in the automotive market, the demand for high-performance parts continues to grow, particularly for enthusiasts seeking to enhance their Mitsubishi Lancer Evolution X. The introduction of a brand new original carbon fiber bonnet hood presents compelling benefits that cater not only to performance enhancement but also aesthetic appeal. This innovative upgrade offers weight reduction, improved aerodynamics, and enhanced structural rigidity, allowing vehicles to perform at their peak. Each chapter in this article will dissect these aspects, providing valuable insights into compatibility, installation, market availability, and technical specifications, ultimately equipping you with the knowledge to make informed decisions regarding this exciting aftermarket enhancement.

null

null

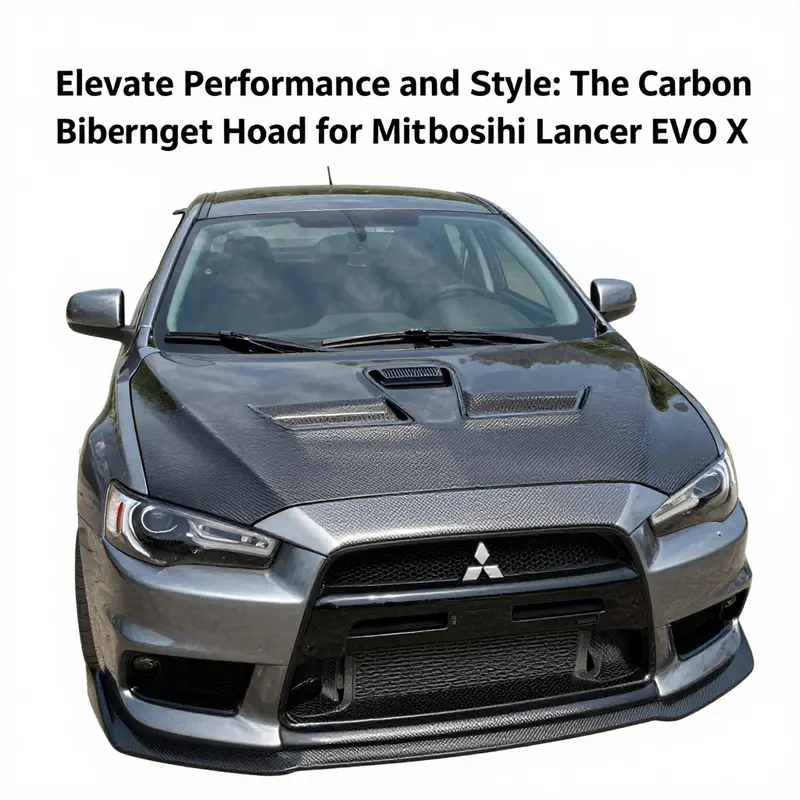

Face of Velocity: Aesthetic Mastery with the Brand-New Carbon Fiber Hood for the Lancer EVO X

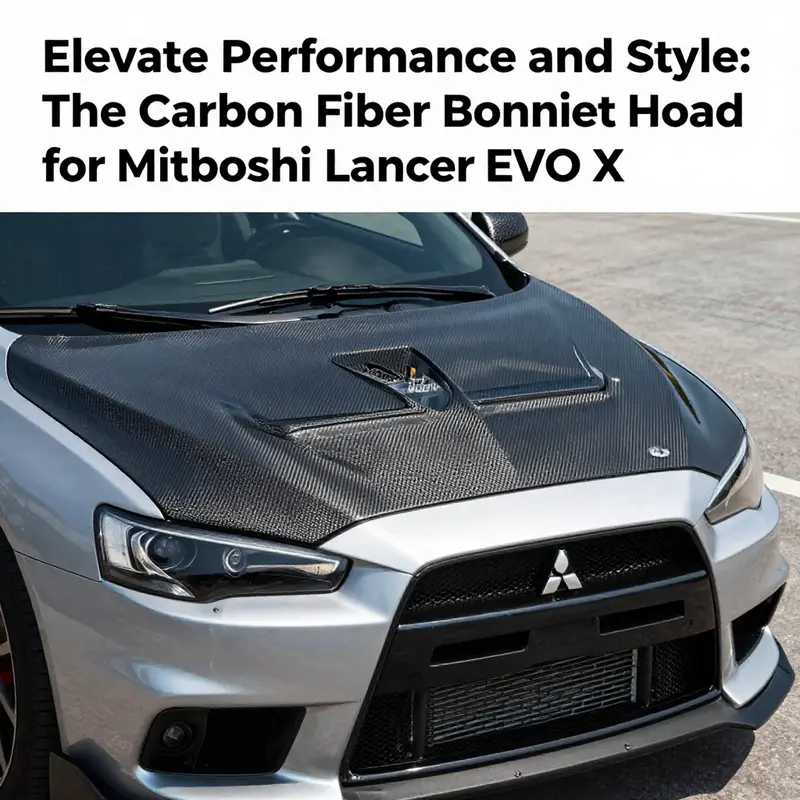

The Mitsubishi Lancer Evolution X has always invited a conversation between power and poise. When a brand-new original carbon fiber bonnet hood arrives for this chassis, the first conversation shifts from raw numbers to a more nuanced dialogue about presence. The hood itself becomes a canvas where engineering intent and design language converge. Real carbon fiber, with its signature weave, is not merely a material choice; it is a statement about how a modern performance sedan wants to be perceived as it sits at the curb or hammers down a back road. The visual texture of the weave catches light in a way that steel simply cannot reproduce, offering a tactile reminder that the front end of this car is engineered for more than protection. It signals readiness, not just resilience, and that distinction matters when a car is judged by both its track credentials and its street charisma.

To the eye, the hood presents a refined, race-inspired silhouette that cleanly mirrors the factory contours. The molded lines follow the EVO X’s front-end geometry with a precision that suggests it was designed alongside the car from the start. This is not a heavy, overbearing modification; it is a direct-fit replacement that respects the vehicle’s original chassis geometry while substituting a lighter, stiffer skin. The result is an integrated, cohesive front face that looks purpose-built rather than aftermarket. The aero-conscious observer notes how the hood borrows from the car’s own aerodynamic language, with subtle creases that guide attention to the car’s width and stance rather than dividing it. In this sense, the aesthetic upgrade doubles as a visual cue to performance, reinforcing the perception that the EVO X is a machine built for speed, even when it sits still.

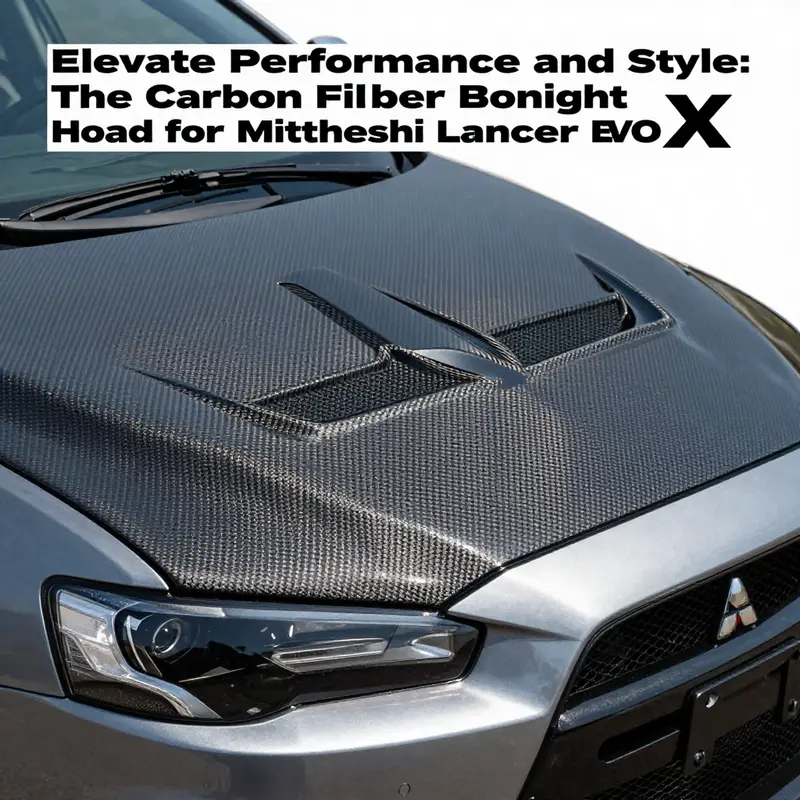

Among the most striking elements is the EVO-style design language that this hood carries forward. The lines are restrained, purposeful, and confident, emphasizing a muscular front without shouting. There is a quiet aggression here, the kind that suggests the car is ready to unleash, not just for show. A notable feature in the design vocabulary is the presence of functional elements that blend smoothly into the surface. Central vents or side louvers break up the front plane in a way that communicates cooling as a design principle, not merely a practical afterthought. These vents serve a dual role: they channel cooler air into the engine bay, reducing intake air temperature and improving turbo efficiency, while also enriching the hood’s visual texture. The eye perceives movement even when the EVO X is stationary, as if the hood itself anticipates the roar of the engine and wants to be part of that moment before ignition.

Among the design stories the hood tells is a nod to iconic styling cues that add personality without compromising restraint. The possibility of a Jackie Chan Style inspired hood is more than a marketing flourish; it becomes a narrative device that personalizes the vehicle while aligning with a broader culture of performance car aesthetics. Such design accents can make a big difference on a crowded street or a quiet track paddock, because they signal a certain philosophy: performance with a sense of drama, discipline, and provenance. It is not only about looking fast; it is about a front end that communicates a track-leaning intent at a glance. This is important for owners who want their EVO X to be recognized not just for its speed, but for its confident statement that speed is a lifestyle choice as well as a capability.

The aesthetic impact extends beyond mere surface appearance. Carbon fiber has a way of elevating the entire front fascia into a more cohesive identity. The weave acts as a visual reminder of engineered sophistication, while the gloss or satin finish can intensify the sense of depth across the hood’s surface. The hood’s curvature and stance also contribute to a more integrated profile; the front end appears more compact, with the carbon fiber skin harmonizing with the car’s overall geometry. This helps the EVO X convey a unified, purpose-built look that resonates with enthusiasts who appreciate the marriage of form and function. In practice, this translates into a presence that is both arresting and credible, a combination that enhances the vehicle’s overall driving experience by aligning the eye with the car’s actual performance capabilities.

The functional details deserve more than a passing mention. The central vents and side louvers do more than ventilate; they read as deliberate design moves that communicate airflow science. When air is drawn efficiently through the engine bay, cooler air can reach the turbocharged 4B11T setup with less resistance, which supports higher power outputs and greater reliability under sustained track conditions. This is not a mere improvement in cooling; it is a causal relationship between airflow management and engine performance, one that owners notice when they push their Evo X to its limits. The hood’s geometry—slightly raised sections, tapered edges, and carefully placed vents—also tangentially supports ride feel. The reduction in front-end weight can contribute to sharper steering response, reduced moment of inertia, and a more eager turn-in. In combination, these effects give the EVO X a more communicative front axle and a keener sense of agility, particularly when balanced with appropriate suspension tuning. The aesthetic virtues thus dovetail with practical performance gains, creating a holistic upgrade that appeals to both the eyes and the driving reflexes.

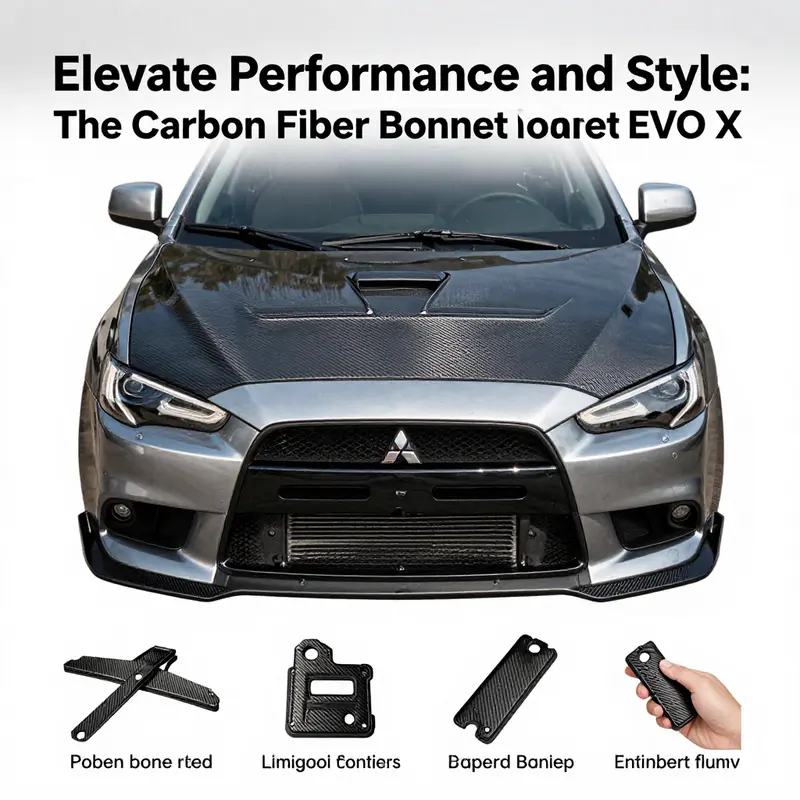

Selecting a carbon fiber hood as a direct-fit replacement for the 2008–2015 Mitsubishi Lancer Evolution X is a decision grounded in compatibility and longevity. The hood’s compatibility is a practical reassurance for enthusiasts who prefer a straightforward installation without major modification. The real carbon fiber construction is not just a material choice but a performance orientation. It reduces the vehicle’s front-end mass by as much as a significant percentage when compared with steel, improving how the car responds to steering inputs and brake performance. The lighter front end means the car can rotate more readily, benefiting both acceleration and braking dynamics. While the numbers vary with configuration and weight distribution across the entire vehicle, the qualitative effect is clear: a more responsive, more eager-to-turn chassis that rewards precise driver input. This sense of immediacy is part of what makes the upgrade feel like a true overhaul rather than a cosmetic enhancement. In a market saturated with cosmetic add-ons, a new carbon fiber hood offers a tangible, measurable impact on the Evo X’s performance envelope, reinforcing the car’s identity as a precision instrument rather than a mere engineered showpiece.

Sourcing and authenticity matter in equal measure when pursuing this upgrade. Genuine, brand-new carbon fiber hoods for the EVO X are available on multiple platforms, with emphasis on real carbon fiber construction and model-year compatibility to ensure a flawless fit. The purchasing process invites careful verification of materials, finish, and certifications. While the hood’s visual appeal is immediate, the long-term value rests on the hood’s ability to maintain its appearance under heat, humidity, and road grime, all while resisting warping and delamination. For those seeking a direct-fit option online, a notable listing highlights a phantom-black OEM U02 hood for the EVO X range, underscoring the emphasis on color consistency and precise fitment. If you want to explore a specific option that aligns with the Evo X’s styling cues while preserving the car’s original lines, you can visit the EVO-X hood phantom black OEM U02 listing here: 08-15 Mitsubishi Lancer Evolution EVO-X Hood Phantom Black OEM U02.

The broader discussion of carbon fiber hoods for the EVO X also touches on sourcing, certification, and the assurance of craftsmanship. For buyers who want to triangulate authenticity, many trusted suppliers emphasize CE, BV, and ISO certifications, along with documented real carbon fiber construction. The goal is to provide not only a look that commands attention but a build that endures. In a world where the aesthetic upgrade can sometimes outpace the engineering, the best options marry outward beauty with inner strength. The result is a hood that remains visually striking through hundreds of miles behind the wheel and through countless sessions on asphalt and track. The car ceases to be just a mode of transport; it becomes a statement of craft, a declaration that speed can be paired with artistry without compromise.

For those who want an additional frame of reference beyond direct purchasing, trusted online marketplaces and supplier portals offer a window into what credible, authentic carbon fiber hoods look like in practice. They provide not just product photos but context on fit, finish, and compatibility with the EVO X platform. The visual and tactile experience of a carbon fiber hood—the weave, the gloss or satin treatment, and the subtle integration with the car’s lines—helps owners envision the transformation before it happens. When the hood arrives and is installed, the EVO X reveals a new level of visual cohesion with the rest of the silhouette, a front end that looks ready to attack, whether the driver is on a race track or a city street. It is a reminder that aesthetic upgrades for performance machines are not merely about vanity; they are part of a larger ethos of precision, balance, and mastery of the machine.

External reference for product specifications and certifications can be found here: https://www.alibaba.com/product-detail/Carbon-Fiber-Hood-Bonnet-for-Mitsubishi-Lancer-EVO-X_1600574273948.html

Bolt-On Performance: Mastering Compatibility and Installation of a Carbon Fiber Front Hood for the EVO X

A carbon fiber front hood designed for the Lancer Evolution X embodies a precise balance of weight reduction, aerodynamics, and visual aggression. For the chassis and engineering team behind the EVO X, the front end is a critical module where weight, stiffness, and cooling converge. When a direct bolt on replacement is chosen, the goal is to maintain the integrity of the original mounting points while unlocking the performance gains that carbon fiber can deliver. In practice, this means selecting a hood whose outer geometry, hinge locations, latch fit, and corner radii align with the factory design. The EVO X has a well defined hood line, and any departure from that geometry can impact how the hood sits along the fenders, how the front edge meets the bumper, and how the hood closes with consistent gaps. The promise of a real carbon fiber hood rests not only in the dramatic reduction of front end mass but in the potential to sharpen steering response and front axle dynamics through a more favorable front weight distribution. A direct-fit hood of this kind is engineered to drop onto the car without modifying the mounting points or the structural attachments, which is essential for preserving both safety and longevity under track or street use. This is not the time to improvise; the design intent is to preserve, not to alter, the fundamental geometry of the EVO X front end. In practice, customers often appreciate a clean, factory-like integration that allows the vehicle to remain road legal and compliant with local inspections while still delivering the visual and thermal benefits of a lighter, stiffer structure. The direct bolt-on concept also gives a sense of confidence when it comes to resale value, since a properly fitted hood maintains the integrity of the original body lines and does not require invasive bodywork or nonstandard fasteners to achieve a secure installation. The nuance here is that fitment is not simply a matter of bolt counts. It hinges on the exact thickness, perimeter shape, vent position, and the subtle tolerances that accompany each batch of carbon fiber parts. As with any advanced composite component, dimensional variances between production lots can introduce small alignment differences. Knowing this, the installer should approach the task with measured expectations and a plan that includes thorough checks of the hood sit, gap uniformity, and latch engagement before finishing the job. For those who are moving from a steel hood to this lightweight alternative, the process is a reminder that performance upgrades are a blend of engineering precision and hands on care. The goal is not to force the part to fit, but to guide it into its designed envelope with as little compromise as possible. The user benefits from this approach with a hood that closes consistently, aligns with the front fenders, and presents a uniform, race-inspired silhouette at rest or in motion. A key element in achieving this outcome is attention to the hood’s vents and scoops, which on many models are not cosmetic extras but functional channels for heat extraction and intake air management. When a hood features integrated vents, their alignment with the engine bay components and the radiator core support becomes a determinative factor in both function and efficiency. Proper alignment ensures that cooling performance is optimized and that the intake system receives the intended airflow for turbocharged operation, particularly in hot climates or during sustained high-load driving. This alignment is not a one off check. It requires a careful re-seating of the hood, verification of hood gaps along the leading edge, and a test of the latch mechanism under several load conditions to ensure there is no binding as the hood travels from closed to open. A small misalignment can disrupt airflow patterns around the radiator and intercooler ducts, potentially undermining the cooling advantage that carbon fiber construction affords. Throughout the installation, attention to detail remains the guiding principle. Minor deviations in the hood’s edges or hinge prep can appear as minute gaps at the corners. These are not cosmetic flaws to be ignored; they are signs that the hood has not yet found its neutral resting position against the rest of the bodywork. In such cases, simple shimming, hinge adjustment, or a slight realignment of the latch can restore symmetry and ensure consistent closure. This is where the simplicity of a bolt-on exchange becomes an advantage. The absence of major cutting, welding, or riveting keeps the process aligned with the vehicle’s original architecture, which translates into both mechanical reliability and peace of mind for the owner. For the EVO X, the compatibility window typically covers model years from 2007 to 2015. This range encompasses small production variations that can affect mounting tolerances, wedge fits, and the exact height at which the hood sits above the bumper. Prospective buyers often verify fit against official fit guides or documented OEM-like references, ensuring that the chosen hood, while aftermarket, adheres to the OEM opening and latching geometry. In practice, a careful verification step involves comparing the new component to the existing hood in the open position, checking that the hinge pins seat properly, and confirming that the latch engages with a clean catch every time. If the hood has functional vents, a simple mock closure with the hood partially open helps gauge whether air channels align with the intercooler and radiator plumbing. The alignment process, while straightforward in concept, requires patience and a steady hand. Minor alignment adjustments after installation are common and should not be viewed as a defect. Rather, they reflect the natural variance in composite production and the realities of field installation. The aim is to minimize time spent chasing perfect zero gaps and to maximize functional performance with consistent, repeatable closure. From a documentation standpoint, manufacturers and authorized suppliers typically provide clear guidelines on fitment and installation. These guides often include torque specifications for the original bolts, the order of tightening to preserve even clamping forces, and cautions about over-tightening which can deform the lightweight panel. Following these requirements is essential to sustain the hood’s shape and the integrity of the fiber layup. It is also prudent to consult a qualified technician with experience in aftermarket bodywork. A trained professional understands how material properties interact with the EVO X chassis and can anticipate issues such as paint prep, clear coat protection, and micro-movements that may occur after the hood is driven for an extended period. The technician can also facilitate functional testing, including ensuring that the hood venting does not create unwanted turbulence around the headlights at high speed or during cornering where air flow shifts rapidly. The broader value of compatibility and installation is more than just a mechanical success; it is about achieving a cohesive sense of performance that sits at the intersection of form, function, and reliability. When done correctly, the car exhibits a lighter front end, lower inertia in the nose, and a more precise steering feel under braking and during midcorner transitions. The aesthetic payoff, with its exposed carbon weave and sculpted venting, complements the performance characteristics by presenting a coherent, race-inspired stance that signals capability to onlookers and judges alike. In the spirit of practical research and real world fitment, readers can reference a detailed guidance resource that outlines OEM style fit and compatibility considerations for this platform. A direct look at the 2008-2015 EVO X hood OEM fit and other fit notes is often included in product documentation and retailer pages, such as the item referenced here: 2008-2015-mitsubishi-lancer-evo-x-hood-phantom-black-oem-u02. This particular guide helps verify mounting points, hinge spacing, and latch alignment against the EVO X family across those years, providing a practical assurance that the chosen hood will blend seamlessly with the vehicle’s original design intent. It is important to treat such references as validation tools rather than as a replacement for hands on inspection and professional installation. Finally, the broader conversation around compatibility and installation benefits from looking beyond the immediate product description. The front end of a modern turbocharged Lancer gains a meaningful advantage from a hood that is not merely lighter but also better cooled and more rigid. The improved heat extraction potential and the reduced mass contribute to a more responsive chassis, particularly in spirited driving or on the track. Yet these benefits sustain only when the hood is properly matched to the car and installed with care. Attention to batch differences, a measured approach to alignment, and a commitment to professional diligence all converge to deliver a result that remains faithful to the EVO X’s original design aspirations while pushing its capabilities forward. For readers who want to expand their understanding of carbon fiber hood compatibility and engineering nuance, a detailed external resource offers a broader context on OEM style fit for this platform. External reference: https://www.carbonfiberhondas.com/mitsubishi-lancer-evolution-x-carbon-fiber-hood-oem-fit

null

null

null

null

Final thoughts

Upgrading to a brand new original carbon fiber bonnet hood for the Mitsubishi Lancer EVO X offers performance, aesthetic appeal, and compatibility that aligns perfectly with market demands. The improvements in weight, aerodynamics, and structural rigidity significantly enhance the vehicle’s performance parameters, making it an ideal choice for automotive enthusiasts and business owners alike. As the automotive aftermarket continues to evolve, staying ahead with premium parts like the carbon fiber bonnet hood will ensure vehicle performance reaches new heights, capturing the essence of racing and precision engineering.