The term ‘EVO’ evokes a sense of evolution in both automotive and cycling sectors, particularly with the Mitsubishi Lancer Evolution and the Specialized Stumpjumper EVO. This article delves into the integration of innovative bumper designs and advanced geometries that cater to enthusiasts of both high-performance cars and mountain bikes. Each chapter will dissect how the design, application, and technology surrounding ‘bumper evo’ play a crucial role in enhancing safety, performance, and market competitiveness in their respective fields.

From Guard to Glide: The Silent Evolution of the Performance Bumper

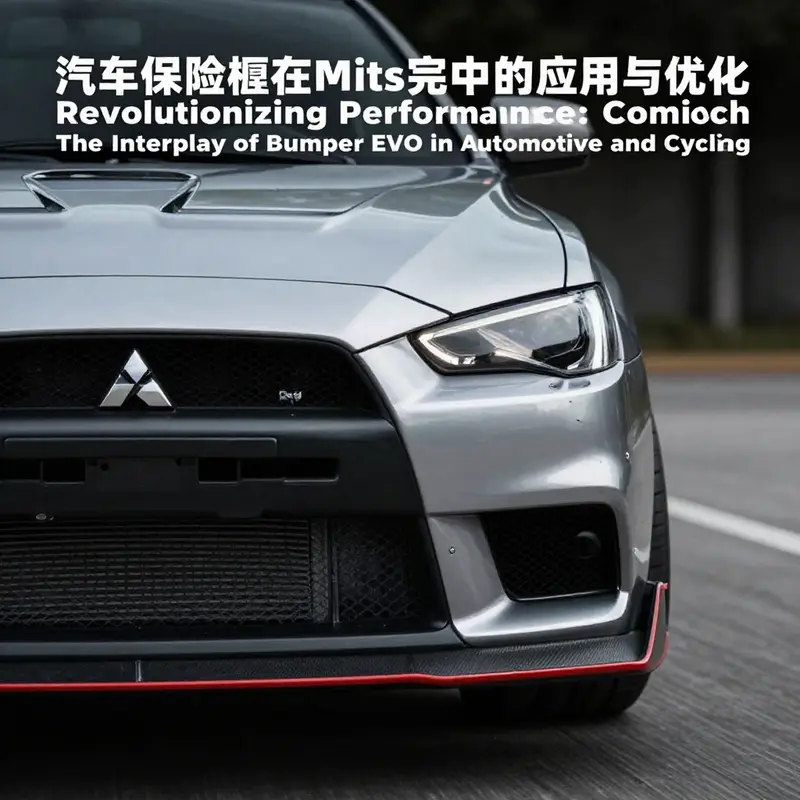

A bumper is rarely the loudest voice in a car’s performance story, yet it anchors the dialogue between machine and air. In a lineage of high-performance sedans that prize speed, balance, and reliability, the front bumper has quietly transformed from a simple guard into a shaped conduit for heat, air, and downforce. This evolution is more than cosmetics; it is a careful orchestration of stiffness, venting, and flow that helps the car breathe, cool, and stay planted at speed. The journey mirrors how geometry evolves in performance engineering: small, deliberate adjustments ripple through the dynamics of the car, broadening the range of control without demanding heroic skill from the driver. In the bumper’s case, those adjustments translate into airflow channels, cooling paths, and underbody interactions that separate a vehicle that merely reaches performance from one that sustains it under duress. Across generations, the bumper’s role grows more complex. Early iterations prioritized protection and basic aerodynamics, but engineers now recognize that every contour affects the boundary layer, so designers shape the front end to choreograph the air more deliberately. The result is a bumper that does more than look aggressive; it acts as an active partner in heat management, drag reduction, and stability. The design language shifts from blunt surfaces to sculpted lips, ducts, and hollows that guide air where it matters and minimize turbulence where it does not. It is a quiet season of refinement with tangible consequences on power delivery, throttle response, and highway stability. One core aim is cooling: engines and ancillaries demand steady thermal management under high load, such as spirited driving or long uphill pushes on winding roads. The bumper now integrates with the front fascia to channel fresh air toward radiators, intercoolers, and brake ducts. The balance between large openings and controlled channels helps prevent hot pockets and keeps cooling aligned with demand. As a result, the vehicle can maintain stronger performance for longer with less risk of thermal throttling. The bumper’s evolution also constrains the wake around wheel arches and underbody, reducing drag and increasing downforce where it matters. Subtle changes—a lip radius, a vent angle, or a fog-lamp opening—can shift downforce, yaw stability, and tire contact quality, making the bumper a key node in the aerodynamic system that connects the splitter, cooling architecture, and overall handling envelope. Material choices have also evolved toward lightweight, stiff composites and thermally stable resins to reduce unsprung weight and preserve structural integrity under high loads. UV resistance and longevity are not afterthoughts; they ensure performance remains reliable after exposure to sun, heat, and debris. Coupled with coatings that resist fade and cracking, the bumper contributes to a durable platform suited for track and daily driving alike. The bumper embodies the idea that performance is a system quality. In mature designs it ceases to be a passive barrier and becomes an active designer of aerodynamic and thermal behavior, integrating with grille architecture, headlights, and front aerodynamics to deliver a coherent, purposeful front end. The honeycomb grilles, sculpted air inlets, and flush surfaces collectively communicate capability and efficiency. The evo mindset rests on incremental gains that cumulatively redefine what a front end can do: better heat margins, cleaner air, and more confident handling across conditions. In practical terms, small bumper refinements can yield measurable improvements in performance, durability, and everyday drive quality. For enthusiasts, engineers, and designers, the upgrade path remains open as new materials and computational tools refine what the bumper can do. The broader dialogue on design language suggests bumpers once stood apart but now participate in a performance network that includes chassis, cooling, and suspension tuning. The story continues as materials advance and simulation becomes more precise, keeping the bumper at the center of a car that breathes easier, sits more confidently at speed, and signals performance at a glance. This synthesis of aesthetics and function defines the bumper evo: a discipline that respects form and function in equal measure, and a reminder that even modest changes can deliver meaningful gains in heat management, stability, and drive confidence. For readers curious about practical examples, a curated collection of bumper designs and their front-end implications can illuminate how modern design balances protection, cooling, and aero refinement without compromising usability. The ongoing dialogue between constraints and creativity is the heart of bumper evo, inviting designers and drivers to imagine the next steps in air, heat, and speed management.

EVO-Driven Geometry: Innovations in Bumpers and Mountain Frames That Redefine Performance

The word EVO carries a stubborn echo across two corners of the automotive and cycling worlds. In cars, it signals a lineage of raw, uncompromising performance. In mountain bikes, it marks a philosophy of adaptive geometry that can be tuned to conquer any trail. This chapter follows that shared thread of evolution, showing how the bumper evo ethos translates from the front end of a high‑performance sedan to the cockpit and suspension of a flagship enduro bike. It is a narrative of design as response—how parts and geometries bend to rider and terrain, how local ecosystems and global ideas converge, and how a single concept can push boundaries in seemingly unrelated domains until the lines between road and trail blur into a continuum of performance optimization.

On the automotive side, the Mitsubishi Evo family has long stood for precision engineering aimed at both daily reliability and race-inspired capability. The front bumper, more than a cosmetic element, is a modal part of that philosophy. Recent discussions around bumper procurement emphasize two intertwined realities. First, there is the geography of supply: Guangdong and Zhejiang have matured into global centers for post-market automotive parts, with a native ecosystem that handles everything from initial prototype validation to mass production at a scale that can reach hundreds of units per month. This localized manufacturing complexity translates into tangible advantages for performance-oriented builds. Shorter lead times, tighter feedback loops, and closer collaboration across mold design, surface finishing, and packaging all combine to shave weeks off a typical cycle. In this sense, bumper evo is not merely about a replacement piece but about an adjustable boundary layer between a car’s performance envelope and the world it navigates.

Second, the technical standards surrounding these bumpers reflect a careful calculus of endurance. Ultraviolet exposure protection is a common requirement, safeguarding resin and color stability through long exposure to sun and heat. The resulting parts also tend to be lighter than their polyurethane predecessors, aligning with the broader industry push toward weight reduction without compromising impact resistance. The upshot is a bumper that wears the marks of performance—durable under a variety of conditions, responsive to the vehicle’s shifting dynamics, and capable of integration into a broader, modular aftermarket ecosystem. In this way, bumper evo aligns with the car’s mission: a front end that can withstand aggressive driving, track-inspired handling, and daily usability while preserving the aesthetic and aerodynamic integrity of the chassis.

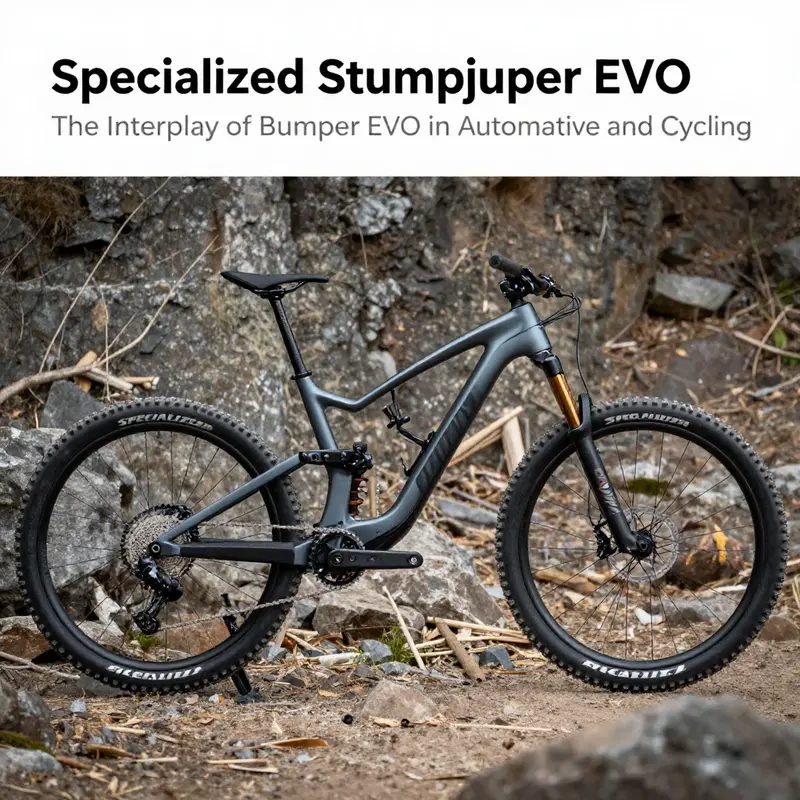

The automotive narrative of bumper evo sits comfortably alongside the mountain bike story, because both domains are animated by the same core impulse: to maximize control and confidence through geometry that can be tuned to context. Here, the parallel with mountain bikes becomes especially instructive. The Specialized Stumpjumper EVO is not merely a trail bike with a sophisticated suspension. It is a manifesto about how geometry can be actively managed to widen a rider’s comfort zone and, by extension, their potential on the trail. The S-Sizing concept, which moves away from traditional sizing anchored to leg length, instead tunes bike fit to rider style and terrain demands. A six-size family ensures that each rider finds a geometry posture that preserves balance, line of sight, and weight distribution across a spectrum of body types and riding preferences. This approach mirrors the automotive emphasis on modular design and adaptable manufacturing that we see in bumper ecosystems: both sectors acknowledge that one size rarely serves all journeys.

The heart of Stumpjumper EVO’s revolutionary geometry is perhaps most clearly expressed through its multi‑modal head tube angle system. By switching interchangeable top cups, the rider can access three distinct head angles—63°, 64°, and 65.5°. Each angle shifts the bike’s steering feel and stability in ways that matter on the trail. The steepest angle sharpens handling for climbs and tight switchbacks; the flattest angle grants stability on high‑speed descents and technical sections where a rider needs to feel planted and predictable despite rock gardens or roots. The ability to swap angles without a complete frame overhaul embodies the evo mindset: geometry is a tunable parameter that can be dialed in as conditions change. Complementing this is the Horst Link flip chip, which adjusts the bottom‑bracket height across a 7 mm range. A lower BB height reduces the vehicle’s moment of inertia during rough terrain, enhancing cornering grip and line tracing through broken ground. A higher setting raises the center of gravity to improve clearance and mid‑corner balance, a practical tool for grenade-like obstacles in the forest without sacrificing the bike’s composure on smoother stretches.

Another facet of the EVO design, the mullet configuration option, speaks to a broader theme in performance engineering: the deliberate use of wheel size to shape response while preserving other essential characteristics. The MulletLink allows riders to pair a 29‑inch front wheel with a 27.5‑inch rear wheel, changing how the bike rides over obstacles and how it accelerates out of technical sections. The larger front wheel delivers smoother rolling over rough terrain and superior steering feel, while the smaller rear wheel improves activity in tight turns and helps the rider keep pace on switchbacks. Crucially, this is not a wholesale wheel‑size revolution but an option within a controlled, predictable framework. The frame geometry, suspension kinematics, and tire selection all stay coherent, so the rider can choose the mullet setup with confidence rather than uncertainty. The final piece of the puzzle, the S‑Sizing family, ensures that this geometry is not only flexible but forgiving: riders can select a size that keeps fore and aft weight balanced, head angle appropriate for their riding goals, and reach and stack that place their body into an efficient riding posture.

Where bumper evo and evo geometry converge most clearly is in the philosophy of tuning for context. Both domains prize a design language that respects the variability of real-world conditions—road and trail alike. In automotive practice, a bumper is often engineered to absorb energy efficiently, to maintain aerodynamic integrity, and to ride with the vehicle’s weight distribution without introducing flutter or drag penalties. In mountain biking, geometry is tuned to preserve pedal efficiency, enhance traction, and maintain control under abrupt transitions between森林 floor and exposed rock. The Stumpjumper EVO’s testing program—encompassing more than a thousand hours of field and lab work—underscores this: the geometry is not a static target but a living protocol for achieving consistent performance across dozens of terrains and ride styles. Pedaling efficiency improves as the frame geometry minimizes unwanted droop during power application, while the suspension gains a more timely response to impacts, reducing fatigue and enhancing rider confidence across long climbs and fast descents. In both domains, the objective is the same: extract maximum performance by aligning the vehicle’s or the bike’s geometry with how it will be used, the rider or driver’s physique, and the environment it will face.

The narrative of bumper evo also invites a practical, almost craft‑like sensibility. For enthusiasts and professionals alike, the choice of bumper and its integration with the car’s styling, air management, and safety systems matters as much as the choice of suspension, gearing, or tires does for a bike. The fact that regional supply ecosystems can deliver rapid prototyping and short lead times means that enthusiasts can experiment more freely, refining trim lines, airflow characteristics, and weight distribution through iteration rather than through months of wait. The automotive world, historically slow to change, appears increasingly comfortable with modular, scalable approaches that echo the agility demonstrated in mountain bike design. Conversely, the bike world draws inspiration from automotive pragmatism: the ride‑weight balance, the stiffness‑to‑compliance ratio, and the capacity to tailor the ride to a rider’s exact needs are patterns that connect the two disciplines. This is the essence of EVO—an idea that evolution is not a single improvement but a continuous, context‑aware re‑balancing of form and function.

For readers who want to trace a concrete example of the bumper side of this story, a deeper dive into automotive bumpers that exemplify this local, scalable approach can be found in catalogs that highlight front and rear bumper options for various Lancer Evolution generations. See how the parts ecosystem supports rapid adaptation and how UV protection, weight considerations, and surface finishing all align to deliver a bumper that complements performance rather than complicates it. For a direct reference to a bumper catalog that mirrors this philosophy, you can explore the Mitsubishi Lancer bumper range in the automotive part repository that emphasizes both compatibility and customization. While the catalog is broad, the underlying principle remains the same: a bumper evo is a tuned interface between the car’s chassis, its aerodynamic profile, and the dynamic demands of the road.

In sum, the EVO concept—whether expressed through a front bumper that protects and enhances a high‑performance chassis or through a trail bike whose geometry adapts to rider size and terrain—embodies a unifying design language. It treats performance as a system property, a composite effect of material choice, structural layout, and tunable geometry. The capacity to alter head angle, to adjust bottom‑bracket height, to mix wheel sizes, or to rethink bumper construction all amount to a single idea: performance is not a fixed pedestal but a moving target that can be recalibrated by design, manufacturing, and rider intent. As both automotive and cycling cultures continue to embrace modularity, as local manufacturing ecosystems mature, and as riders and drivers demand more personalized control, the bumper evo philosophy will continue to rise as a clear, practical guide for thinking about performance in any platform that carries a name with evo in it.

External resource: https://www.specialized.com/uk/en/stumpjumper-evo

Bumper Evo Across Roads and Ridges: A Market Comparison of Front Guards in Cars and Mountain Bikes

The phrase bumper evo sits at the edge of two worlds that rarely share a single vocabulary. On one side lies the automotive front bumper, a guardian of the vehicle and a doorway to advanced systems shaping the future of driving. On the other side stands a trail ready mountain bike, where a suspension tuned shield under the rider’s weight manages rocks, roots, and ruts with precision that feels architectural. When we speak of bumper evo, we are tracing a common thread: protective geometry, lightweight materials, and integrated performance features designed, sourced, and consumed in two very different markets. The investigation becomes less about identical products and more about parallel design logics, shared pressures from climate and wear, and divergent supply chains that shape what is possible in each domain. As the chapter unfolds, the connection between a front end guard designed to negotiate traffic and a trail guard designed to negotiate terrain becomes a study in how ecosystems, not just components, determine value.

In the automotive portion of bumper evo, the front bumper sits at the junction of aesthetics, aerodynamics, crash resistance, and sensor integration. Modern bumpers are not merely a shell; they are a distributed platform that hosts cameras, radars, and a host of safety features that extend the car’s perception beyond the grille. The core advantage of a robust bumper system lies in its ability to absorb impact, protect critical subsystems, and maintain functional integrity after exposure to sun, salt, heat, and humidity. This is where the regional manufacturing ecosystem becomes a crucial determinant of practice. Guangdong and Zhejiang provinces, with their mature tooling shops, paint shops, and rapid prototyping capabilities, have cultivated an agile post market landscape. The cycle from prototype validation to small batch production and then to scalable output can move with astonishing speed, shaving weeks off lead times that would otherwise come from overseas supply chains. Localized engineering—mold design, surface treatment, packaging—translates into shorter delivery windows and more seamless customization, a practical advantage when a bumper must accommodate different trim levels, sensors, and bumper beams across generations. Yet the value proposition hinges on more than speed. The requirement for UV protection to guard against resin degradation, color stability, and long-term weathering is part of a broader push toward durability under a widening array of driving conditions. This is not merely about keeping a face looking fresh; it is about preserving a shield that shields the car’s most advanced systems. In this sense, the automotive bumper becomes the physical interface through which future safety technologies pass, a frontline of the vehicle’s intelligent evolution.

The bike world offers a different flavor of bumper evo, rooted in geometry, suspension, and the relentless pursuit of rider efficiency. In the realm of high-end mountain bikes, the concept of protection is embodied not in a rigid shell but in a dynamic system that adapts to trail conditions and rider size. The flagship model under discussion here is defined by a geometry system that redefines what a single frame can achieve. The essence of this approach is a holistic retooling of how geometry can be adjusted on the fly. Six distinct riding geometries can be realized within a single platform, enabled by adjustable linkage, selectable head tube angle, and a responsive travel profile. The degree of adjustment—allowing vertical fine tuning and head angle variation—enables a rider to tailor the machine for climbing cleanness, cornering stability, and descending confidence. The research behind this design emphasizes suspension kinematics refined over many hours of real world testing; more than a thousand hours of field and lab validation have been dedicated to ensuring that every shift in geometry translates into improved pedaling efficiency and better handling of sharp impacts through the bike’s travel. The result is a vehicle that remains predictable in the most demanding terrain, with a suspension system that absorbs punishment while preserving momentum and energy return. In this context, the bumper on a mountain bike is not a plastic face but a complex interaction of frame geometry, fork and shock tuning, and chassis stiffness all orchestrated to maintain efficiency and control on rough surfaces.

The comparative landscape reveals a philosophy that binds the two realms: modularity and integration as keys to performance. In cars, a bumper is a guarded interface between the outside world and a network of sensors and safety modules. It must accept external forces without compromising the system beyond repair, and it must accommodate evolving technologies that demand more sensing, more software, and stricter safety standards. The local supply chains strength matters because a bumper’s value is amplified when it can be customized quickly to different models, regional climate exposures, and regulatory regimes. The same modular impulse drives the bicycle side, where the geometry and suspension are designed to be recalibrated for a rider’s weight, style, and the specific terrain. The goal is to keep the rider connected to the ground and to the bike’s response, reducing wasted energy and enhancing control. In both cases, lightweighting is a driving force, but the path to lightness differs. The automotive bumper benefits from advances in resin chemistry and composite materials that deliver stiffness with lower mass, while the bike’s overall mass is shaved through sophisticated carbon constructions and refined alloy practices. The parallel is clear: weight reduction is not an end in itself but a means to sustain performance under real-world stress, whether the stress comes from a highway curtain of debris or a rock-strewn trail bed.

The consumer market for bumper evo, viewed through this cross-domain lens, raises questions about how protection translates into perceived value. In cars, protection is often bundled with perception how a bumper integrates with the car’s design language, how it behaves in a collision, and how safely it houses sensors that guide automated driving. In bikes, protection is measured by how reliably the suspension system can translate ground contact into forward motion, how a rider’s energy is preserved during long climbs, and how confidence on rough sections translates into faster overall times. Both markets reward reliability and consistency, qualities that emerge from disciplined engineering, robust supply networks, and a careful balance of trade-offs. The automotive sector’s reliability is reinforced by the capacity to source materials, process them with consistent finishes, and deliver within tight service intervals. The bicycle sector’s reliability is reinforced by the ability to tune geometry and suspension for varying terrains, ensuring that riders can push farther with less fatigue. The two domains thus illustrate how the same human desire protection, stability, and performance manifests through different mechanisms, each shaped by its own technical vocabulary and distribution system.

To connect the practical with the conceptual, consider how a product line within an automotive aftermarket ecosystem mirrors the way a premium mountain bike platform evolves. In the car world, a bumper line can be adapted to different generations and trim levels while meeting safety and durability standards, with the added complexity of integrating active safety components. In the bike world, the same spirit of adaptability manifests in geometry options and suspension tuning that respond to riders evolving preferences and the changing demands of terrain. The cross-market dialogue reveals the importance of a coherent design narrative that transcends single components. A bumper evo embodies a philosophy of shield, sensor, and system harmony; a Stumpjumper EVO embodies a philosophy of geometry as a tool for controllable, confident motion. The chain of decisions from material selection and tooling to packaging and after sales support forms a continuous loop linking concept to consumer experience. A single part or feature can become a symbol of a broader design ethos when it is embedded in a larger ecosystem capable of rapid iteration and local optimization. The result is a market where value is not defined by a lone component but by the way the component participates in a network of capabilities that extend from design benches to end users on mountain trails or urban arterial lanes.

In a sense, the term bumper evo captures a shared aspiration to make protection and performance inseparable, so that a system can endure the rigors of its environment while enabling more precise, more confident movement. This chapter’s market perspective highlights how different ecosystems cultivate this aspiration through distinct channels rapid prototyping and regionally optimized supply chains on one side, and highly tunable geometry and sophisticated suspension on the other. The outcome is a nuanced landscape in which protection is not merely a passive receptacle for impact but an active enabler of control, efficiency, and enjoyment. For every rider or driver who seeks to go farther with greater assurance, the lesson remains consistent the best front end guard is one that communicates clearly with the rest of the machine, integrating form, function, and feedback into a coherent whole. In that sense bumper evo is less a brand name than a design philosophy that travels across roads and ridges, linking two demanding communities through shared commitments to innovation, resilience, and performance.

For readers who want to explore a concrete automotive example while keeping the broader narrative in view, consider the automotive component page that details rear bumper options for a well known evolution era line. It offers a window into how aftermarket ecosystems operationalize rapid customization and scalable production across generations. The link serves as a tangible illustration of the same principles discussed here—modularity, integration, and the enduring priority of protection linked to overall performance. 2008-2015 Mitsubishi Lancer Evolution X rear bumpers can provide a practical reference point for understanding the balance between protection, styling, and sensor integration within a dense, generation-spanning market. https://mitsubishiautopartsshop.com/2008-2015-mitsubishi-lancer-evolution-x-rear-bumpers/

On the bicycle side, the story remains one of controlled variability how a single platform can be reconfigured to meet different trail demands without sacrificing structural integrity or ride quality. The S-Sizing concept, with its independent adjustments to the geometry and the head angle, invites riders to reimagine how a bike can respond to a single terrain category as it shifts to another. This mobility multiple geometry states in one chassis parallels the automotive push toward modular bumper systems that can accommodate sensors, lighting, and aerodynamic refinements without forcing an entire redesign with every model year. The cross market resonance is clear both domains prize adaptability and sustainability, recognizing that the best products are those that keep pace with user needs and environmental realities. The outcome is a market that rewards thoughtful integration and disciplined engineering, in which the term bumper evo can be used, with care, to describe the enduring collaboration between protection and performance. External reading can deepen this understanding by exploring how advanced driver assist systems shape bumper design and integration, as well as how rider confidence is tied to suspension durability on challenging terrain. https://www.nhtsa.gov/road-safety/advanced-driver-assistance-systems-adas

EVO at the Front: Standards-Driven Evolution for Bumpers in a Smart, Sustainable Era

The front bumper is no longer a mere shield against minor impacts. In the evolving language of vehicle design, it has become a lever that multiplies safety, efficiency, and visual identity. The chapter you are about to read unfolds the trajectory of bumper evolution, framed by developing technical standards and a broader push toward smarter, greener mobility. As the global ecosystem of regulation, testing, and manufacturing becomes more tightly coupled, the bumper, once a simple sheet of plastic, is pressed into service as a high‑function, high‑visibility node in a complex, data‑driven vehicle architecture. This shift is not restricted to cars alone. In another realm of the EVO family, a different kind of chassis geometry—the mountain bike’s adjustable, adaptive frame—exemplifies the same core principle: evolution through configurability and precision. Taken together, these domains illuminate how the modern concept of Bumper EVO is less about a single part and more about a tightly integrated system in which form, function, and foresight align with a rapidly changing safety and sustainability agenda.

Within this broader shift, standards act as the invisible conductor that coordinates development across borders and disciplines. The next generation of safety specifications no longer treats the bumper as a passive shell. Instead, it defines how the bumper must interact with sensors, actuators, and the vehicle’s decision‑making systems. International and regional bodies are knitting together requirements for crash energy management, pedestrian protection, and the reliability of sensor data during collision events. This cross‑pollination pushes bumper design toward harmonized interfaces, guaranteed performance under varied climates, and predictable integration with active safety features. The result is a propulsion toward a more holistic, cradle‑to‑grave approach to the bumper, where design, materials, and processing are judged not only by how they perform in a test but by how they contribute to a safer, more trustworthy vehicle ecosystem.

The impact of this regulatory convergence is visible in the way engineers conceive a bumper’s energy management, not merely its outer contour. The traditional objective of absorbing impact while protecting the passengers remains paramount, but the means are increasingly defined by an integrated safety chain. When a potential collision is detected, the bumper must not only deform predictably but also facilitate the timely flow of information to the vehicle’s control systems. With advanced driver assistance systems and automated emergency responses becoming standard in many markets, the bumper’s role expands to enable rapid, reliable sensor communication. In practice, this means internal structures that accommodate sensor modules, robust attachment mechanisms, and materials that maintain resilience in a wide temperature range and long service life. The emphasize is on consistency and predictability across different regions, so a bumper designed and tested under one standard can perform with confidence in another, thereby reducing repeat testing and accelerating time to market for safer, smarter vehicles.

In this light, the push toward lighter, stronger materials becomes a practical necessity rather than a stylistic choice. The ongoing material revolution—favoring high‑performance engineering plastics and composite solutions—enables weight reduction without compromising crash integrity. More sophisticated materials also offer better environmental credentials, responding to the growing expectation that manufacturing be less resource‑intensive and more easily recycled at end of life. These shifts are not merely about reducing mass; they are about improving the bumper’s energy absorption characteristics while maintaining functional durability in the field. To stakeholders, this translates into a lifecycle advantage: lighter components can lower overall vehicle energy consumption, while robust, recyclable materials minimize environmental impact and align with tightening sustainability mandates.

Manufacturing practices are catching up with these ambitions. The convergence of digital design tools, topological optimization, and additive manufacturing is reshaping how bumpers are conceived and produced. Engineers can explore continuous optimization of the bumper’s geometry to distribute crash energy more evenly, often with less material, using mathematically driven approaches. This is complemented by iterative simulation that couples crash physics with sensor data fidelity. In parallel, smart manufacturing and near‑shoring trends reduce lead times and enable rapid prototyping, enabling small batches that test new concepts without the burden of large upfront tooling. Such capabilities make it feasible to tailor bumpers for specific regional climates or regulatory regimes while maintaining a coherent global standard. The result is a bumper evo that is not only safer and lighter but also more adaptable to local needs and preferences.

The concept of EVO, however, transcends automotive engineering. In mountain biking, a flagship frame family has demonstrated a parallel philosophy: configurability that redefines how a rider experiences terrain. The frame geometry can be adjusted in multiple ways to accommodate different riding styles and landscapes. This cross‑discipline resonance—where a high‑adjustability design principle informs a front‑end component—highlights a broader ethic of engineering that prizes versatility, precision, and user‑specific tuning. The bike’s expansive geometry system, with its adjustable parameters, demonstrates how modular, reconfigurable design unlocks performance across diverse conditions. When translated back to bumpers, the message is equally clear: the best bumper evo will be one that can adapt its protective behavior to a range of scenarios—urban commuting, highway cruising, and off‑road or extreme weather conditions—without sacrificing integrity or reliability. The bumper therefore becomes a dynamic interface, not a static façade, capable of accommodating different sensor packages, airflow needs, and energy absorption profiles as dictated by the vehicle’s mission and the environment in which it operates.

The practical upshot of these developmental currents is a set of design imperatives that push the bumper evo toward a future where safety features are embedded as a matter of course, where materials and processes support sustainable production, and where configurability enables a universal fit across markets. One can imagine a bumper that hosts not only passive foam or structured energy absorbers but also integrated micro sensors, heat‑management channels, and modular air ducts that adjust to driving conditions. In a test environment that mirrors real‑world variability, such a bumper would be evaluated not just for deformation under a standard impact but for how quickly and accurately sensor data can be relayed to the vehicle’s safety systems and how effectively the energy is redistributed to protect occupants and vulnerable road users. This is the essence of the future: a bumper evo that is intelligent in its behavior as well as in its construction, capable of evolving with evolving regulations and evolving technologies.

The transition toward this vision is not purely technical. It relies on a shared language across manufacturers, suppliers, and regulators. Standards bodies are increasingly calling for common data formats, traceability in material provenance, and lifecycle reporting that captures both performance and environmental footprints. Designers respond with digital twins that simulate every stage of a bumper’s life—from design and crash testing to manufacturing yield and end‑of‑life recycling. These digital ecosystems enable continuous improvement, allowing teams to validate new materials or geometry changes against a common reference and to assess how such changes might influence sensor performance or regulatory compliance across multiple regions. The result is a more resilient, transparent, and capable supply chain, where a change in a single parameter can be traced through a well‑understood impact on safety outcomes and environmental impact.

From a consumer perspective, the bumper evo promises a more coherent experience: safer driving, less weight, lower operating costs, and a style that remains consistent across markets while still allowing for local customization. This is not about chasing trendiness alone; it is about delivering reliable, measurable improvements in safety and efficiency that endure as regulations tighten and technology accelerates. It also invites a narrative of continuous improvement, where the bumper evolves alongside the vehicle’s other systems. When the vehicle learns to interpret sensor inputs, anticipate hazards, and coordinate protective responses with the help of its bumper’s energy management, the entire driving experience becomes more confident and less stressful for the driver.

For practitioners and readers curious about practical references beyond theory, a broader body of industry knowledge on bumper components and fitment can be explored through generic resource pages that discuss front bumper considerations and compatibility. This page offers a way to connect the design philosophy described here with tangible product details and installation considerations. front bumper page. While the specifics of any one model are not the focus, the underlying principles—fit, safety performance, and material behavior—remain highly relevant across brands and regions. In parallel, external standards organizations remain the ultimate arbiters of how these ideas are validated in the real world. For a trusted overview of how modern vehicle safety testing evolves and coordinates across markets, the European test and rating framework provides a representative lens into how the industry translates concept into comparable, rigorous results. See https://www.euroncap.com/en/ for authoritative context on safety ratings and testing methodologies.

In sum, the future of bumper evo is defined by standardization that travels with innovation, by materials and manufacturing that respect both performance and planet, and by a design ethos that treats the bumper as an intelligent, configurable interface rather than a passive shell. The convergence of these strands—intelligent safety integration, green production, and adaptive geometry—points toward a safer, lighter, and more versatile automotive future. The bumper evo thus embodies a forward‑looking integration of protection, perception, and practicality, anchored by shared standards and accelerated by digital manufacturing. As industries continue to learn from each other—whether in the motor car’s front end or a mountain bike’s evolving frame—the idea of evolution becomes not a slogan but a proven path to safer, smarter, and more sustainable mobility.

Bumper Evo: Weaving Aerodynamics, Safety, and Handling into High-Performance Front End Design

Bumper Evo sits at a pivotal crossroads of performance engineering and everyday practicality. When engineers shape a vehicle’s front end, they are not merely crafting a cosmetic face; they are directing the language of air and impact, stability and friction, perception and protection. The front bumper assembly, often bundled with a front lip, lower splitter, and related panels, becomes a functional aerostructural system. Its purpose extends beyond shielding the engine bay and fascia. It acts as a conductor for airflow, a buffer in collisions, and a contributor to the vehicle’s dynamic personality. In high-performance contexts, where the line between street manners and track capability is fine, the evolutionary path of the bumper design—what we call here Bumper Evo—embodies a careful negotiation between reduced drag, increased downforce, weight management, and sensor integrity. The discussion that follows treats the bumper not as an isolated part but as an integral element that shapes how a car breathes, grips, and responds to the road’s demands.

From a purely aerodynamic standpoint, the front end is the first major interface between the car and the surrounding atmosphere at speed. The bumper’s geometry—its curvature, its cutouts, its under-body channels—plays a decisive role in how air flows around the wheel arches and across the radiator. A purpose-built front lip and splitter can guide air to remain attached to the surface longer, delaying flow separation and, in turn, reducing the wake that creates drag. The addition of air curtains, carefully contoured side ducts, and a central lower diffuser can help channel inflow into zones that either feed cooling requirements or generate subtle downforce. In a well-engineered system, these elements do not merely “look fast.” They actively shape the pressure distribution at the car’s nose, smoothing the otherwise abrupt transition from the vertical grille plane to the horizontal undertray. The result, in high-speed conditions, is a more predictable front end that remains stable as wind forces intensify. A car that maintains a clean separation bubble and a well-behaved pressure gradient tends to exhibit less buffeting, especially during high-speed cornering where the front wheels and tires endure elevated loads.

Yet, the pursuit of aerodynamic efficiency is a constant trade-off. Reducing drag might come at the cost of underbody lift, and adding aggressive ducts or a deep splitter could increase lift in certain yaw angles if not harmonized with the rest of the bodywork. The Bumper Evo philosophy, therefore, emphasizes cohesive integration rather than piecemeal enhancement. A high-performance bumper system should harmonize with the undertray, side skirts, and rear components to form a coherent aerodynamic narrative. This is where wind-tunnel-informed design becomes indispensable. The aim is not simply to shave drag but to shape an overall flow field that lifts the car’s grip on the road without compromising efficiency. In practice, this balance shows up as improved high-speed stability, more confident mid-corner transitions, and a plateau of tire contact that remains accessible to the driver’s inputs.

The handling benefits are not purely about lift and downforce. The bumper’s influence penetrates the steering feel and the chassis’ dynamic balance. A front end that communicates with the tires through well-managed aero loads enables the driver to demand sharper turn-in without sudden, unsettled responses. In other words, when the front end presents a clear beeline for the air, the steering wheel speaks with more fidelity. The chassis can allocate grip where the driver intends, and the car becomes more tolerant of mid-corner disturbances. This is particularly meaningful on street-legal high-performance machines, where road irregularities and variable grip conditions coexist with the demands of high-speed cornering. The overall effect is a more planted front axle, a more confident entry, and a vehicle that responds to steering and throttle with a sense of purpose rather than abrupt, unsettled motion.

Weight considerations form a counterpoint to aerodynamic gains. A bumper assembly that includes a front lip, additional diffusers, and composite panels may yield improved performance under the right conditions, but it also adds mass. For a performance-oriented car, every gram matters, especially when we consider unsprung weight and the moment of inertia around the vehicle’s front axle. The chosen materials—whether advanced composites, reinforced plastics, or carbon-infused formulations—contribute to stiffness, energy absorption, and durability while pursuing a leaner overall package. In a mature Bumper Evo approach, designers mitigate weight while preserving function. They streamline the bumper’s internal cavities, optimize mounting strategies, and incorporate lightweight structures that still meet the protective and energy-absorbing requirements of safety standards. The result is a system that does not merely look lean or aggressive but truly behaves lean and aggressive in the wind and on the road.

Ground clearance is another practical constraint that heavily influences design decisions. A front bumper that hugs the underside of the car or integrates a particularly aggressive splitter risks frequent contact with speed bumps, driveways, and rough pavement. In a city or on a winding mountain pass, the risk of scrapes and scoring wears down aesthetics and, more critically, can compromise the bumper’s integrity or the sensor field of view. A balanced Bumper Evo approach acknowledges this reality. It preserves a usable approach angle, shields critical components, and uses protective elements like skid plates or abrasion-friendly coatings in high-wear zones. The goal is not to pretend the road is perfectly smooth but to design for the realities of everyday driving while preserving the gains earned at the track. This philosophy also ties to maintenance: a bumper that is easier to inspect for cracks or UV degradation—thanks to modular fasteners, accessible joints, and clearly visible impact zones—encourages timely care and prolongs the life of the system.

Safety, of course, sits at the core of any performance enhancement, and bumper systems are no exception. The bumper’s ability to absorb energy in a collision contributes to a vehicle’s overall safety performance. A well-engineered bumper acts as a first line of defense, dissipating some of the crash energy through its engineered deformation. It can reduce the severity of damages to the rigid chassis and protect critical components beneath the skin. However, this protective role must be balanced with the realities of pedestrian safety and urban driving. Pedestrian impact standards demand certain deformation characteristics and surface smoothness for exterior panels, which constrain how aggressively a bumper can be shaped. The same constraint extends to safety sensors—radar, lidar, cameras, and ultrasonic devices used for adaptive cruise control, automatic emergency braking, and parking assistance. A bumper that interferes with sensor lines can degrade the performance of these systems, potentially creating blind spots or false positives. The Bumper Evo concept therefore insists on sensor-preserving geometry and clearances. It encourages designers to route sensor fields and dedicate cutouts that keep detection ranges intact while enabling aggressive styling. The consequence is a bumper that protects on impact, supports driver-assist features, and still communicates a visual message of speed and precision.

The interplay between aerodynamic performance and safety is nuanced. For example, components that guide air toward cooling channels must avoid blocking cameras or radar sensors. Similarly, a bumper that includes aggressive aero elements must be anchored securely to prevent loose or flapping during high-speed runs, which could create hazard or degrade performance. In practice, designers validate these interactions through a cycle of computational simulations, wind tunnel tests, and real-world driving evaluations. They examine multiple yaw conditions, road textures, and weather influences to ensure the bumper’s behavior remains predictable and controllable. The final configuration emerges from this iterative process—a system that improves high-speed stability, enhances cornering confidence, and preserves critical sensor functionality. The result is a vehicle that feels composed and communicative at the limit, offering a safety margin that complements the driver’s intent.

In contemplating the broader implications, it is evident that Bumper Evo is not about pushing out a single, louder signature into the wind. It is about cultivating an integrated sense of vehicle behavior—how the front end communicates with the road, how weight and aerodynamics share the load, and how safety and performance coexist without compromise. This holistic view supports a practical guideline for enthusiasts and engineers alike: pursue aero gains that translate into tangible handling benefits, but never at the expense of essential safety systems or everyday usability. The best bumper evolutions emerge from this balance, delivering steadier high-speed behavior, cleaner transitions through corners, and a robust barrier against minor road hazards, all while preserving the driver’s confidence in the car’s responses.

For readers seeking practical anchors in this conversation, the baseline of OEM standards offers a useful reference point. While performance-focused expressions of bumper design push the envelope, understanding how a factory-integrated system behaves under everyday conditions helps contextualize the gains. In addition, exploring OEM and aftermarket integrations through curated examples can illuminate how to achieve a similar balance in different platforms. A relevant example of a practical reference that illustrates bumper integrity and fitment considerations can be found in the discussion of rear bumper OEM kits for certain generations of performance-oriented models, which provides a baseline for safety-compliant integration and installation quality. See the discussion titled “03-06-mitsubishi-evolution-8-9-jdm-rear-bumper-oem” for a concrete reference point in how a base bumper architecture is approached in a closely related context.** 03-06-mitsubishi-evolution-8-9-jdm-rear-bumper-oem.

In closing, the Bumper Evo concept highlights a design philosophy where aerodynamic performance and safety are not at odds but are complementary. The front end becomes the car’s active contributor to stability, grip, and predictability, while still offering protection and a clear, confident presence on the road. The most successful implementations are those that validate their gains through careful testing, maintain compatibility with driver-assist technologies, and respect the practical realities of everyday driving. When these conditions are met, the bumper ceases to be a mere cosmetic tool and evolves into a sophisticated module that helps translate driver intent into measurable, repeatable performance on any road the vehicle dares to conquer.

External resource: https://www.autohome.com.cn/news/20251114/897642.html

Final thoughts

The discussions surrounding ‘bumper evo’ illustrate the critical role that design and technology play in enhancing performance and safety in both the automotive and cycling industries. As market demands evolve, manufacturers must continue innovating within the framework of safety standards while maximizing performance efficiencies. The insights explored in this article reinforce the interconnectedness of automotive and bicycle designs, providing business owners with valuable knowledge to navigate future trends.