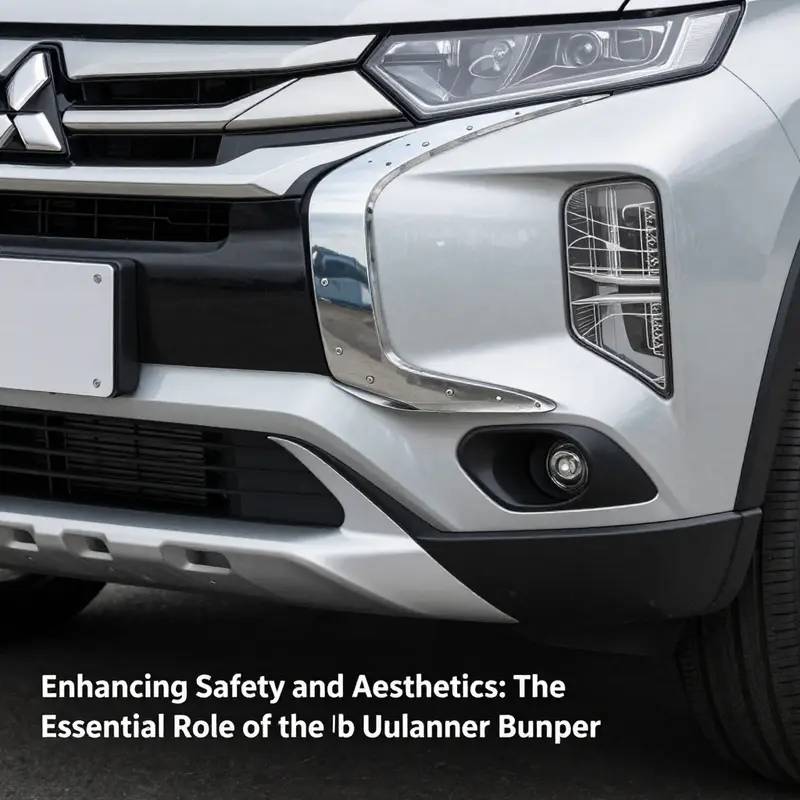

The bumper of the Mitsubishi Outlander is not merely a decorative component; it plays a vital role in vehicle safety and functionality. This article will elucidate the structural and material characteristics of the Outlander bumper, analyze its performance indicators, explore advanced features and technologies integrated into its design, and guide business owners in choosing between original and aftermarket options. Each chapter will build a comprehensive understanding of the importance of this crucial automotive component in maintaining both safety and aesthetics for the Mitsubishi Outlander.

Mitsubishi Outlander Bumper: Structural and Material Characteristics

The front bumper of the Mitsubishi Outlander sits at the crossroads of safety, performance, and visual storytelling. It is not merely a plastic face that greets the eye; it is a carefully engineered system designed to absorb impact, guide airflow, support sensors, and preserve the vehicle’s aesthetic identity through generations. In the Outlander, as in many modern crossovers, the bumper is a composite of layered functions. Its shape is sculpted to reduce drag and to blend with the vehicle’s lines, yet behind that sculpted surface lies a robust architecture built to protect occupants and essential components in everyday mishaps and low-speed collisions. The emphasis on OEM precision—where every contour, seam, and mounting point is calibrated for a specific model year—reflects a broader philosophy: the bumper should integrate with the car’s safety, electronics, and cosmetic systems as if designed as a single, coherent unit. When a replacement is necessary, owners confront choices that ripple through performance, warranty, and future maintenance, underscoring why the bumper is a more consequential part of the Outlander than many drivers first imagine.

Material selection sits at the heart of this balance between protection and weight. The bumper cover is typically crafted from high-grade polypropylene (PP) or acrylonitrile butadiene styrene (ABS). These plastics are chosen for their impact resistance, their lightness, and their ability to be painted to match the vehicle’s color. PP, in particular, offers a favorable blend of toughness and flexibility, allowing the cover to deform under a minor impact and spring back rather than crack. This resilience translates into fewer cracks and less cosmetic damage in low-speed bumps, parking lot scrapes, and incidental contact with curbs. ABS, on the other hand, often finds its way into aftermarket or reinforced variants, where slightly stiffer performance is valued for added protection against deeper impacts. Regardless of the exact material, the bumper cover’s surface is treated to take paint evenly, resist UV degradation, and retain color alignment with the rest of the bodywork. When you see a pristine Outlander with a perfectly matched color, you are witnessing the success of paint compatibility and material stability that underpins long-term aesthetics as well as durability.

The outer cover is only the first line of defense. Immediately behind it lies a network of structural elements designed to distribute and dissipate energy, protect critical components, and maintain alignment under stress. The bumper beam, or reinforcement bar, is the core energy-absorbing element. In the Outlander, this component is typically forged from high-strength steel or a lightweight aluminum alloy, chosen for its superior energy absorption and controlled deformation characteristics. In a collision, the bumper beam undergoes a calculated deformation that lengthens the collision duration within safe limits, lowering peak forces transmitted to the frame, radiator, and engine bay. This energy management is not an afterthought; it is engineered to complement other safety systems, including pedestrian protection features and the vehicle’s crash-test performance ratings issued by authorities and testing organizations around the world. The beam’s material choice reflects a trade-off between weight, rigidity, and manufacturing costs, with the steel variant offering excellent strength at modest weight, and the aluminum option delivering weight savings that slightly improve fuel economy and handling. Both are compatible with the bumper system’s goals: to protect occupants, minimize costly baseline damage, and assist in maintaining vehicle geometry after minor impacts.

Supporting the bumper cover on either side are brackets and mounts that anchor the assembly to the chassis and to the surrounding body panels. These brackets, often constructed from reinforced metal or durable engineered plastics, keep the bumper aligned with the front fascia, fenders, and hood. Their role is not purely mechanical; they dampen low-frequency vibrations and prevent the cover from micromotions that can result in squeaks or gaps when the car experiences the regular stresses of road travel. Properly designed brackets also ensure that the bumper and its associated features—fog lamps, sensor housings, and ladder-like sensor arrays—remain in the correct spatial relationship to one another. In the context of advanced driver-assistance systems (ADAS), such precise alignment becomes critical. Even a slight misalignment of a radar unit, camera, or ultrasonic sensor can degrade performance, trigger incorrect warnings, or cause a temporary loss of functionality. For this reason, OEM bumper components are manufactured and assembled with exact tolerances, and professional installation is often recommended to preserve calibration integrity.

Beneath the surface, the bumper’s internal architecture includes supports intended to preserve the radiator core, condenser, and air intake pathways during a collision. These internal supports help maintain airflow to cooling systems, reducing the likelihood of overheating after an impact that causes minor deformation. The objective is to prevent a cascade effect where cosmetic damage compounds the risk to engine cooling and performance. This is particularly important in the Outlander, a vehicle positioned for practicality and family use, where reliability under varied weather conditions and driving scenarios is paramount. The bumper’s geometry is designed to maximize these protective effects while still accommodating the vehicle’s lighting and sensing features. In practical terms, this means the OEM bumper is shaped to house fog lights and sensor arrays without forcing excessive alterations to the surrounding structure. The integration with sensors, including radar for adaptive cruise control and blind-spot monitoring, makes precise placement essential. When spacing, angles, and mounting positions drift, the sensors’ field of view can be compromised, diminishing the effectiveness of the driver-assist systems that many buyers rely on for safer highway driving.

The Outlander’s bumper is also a stage for performance and style cues. The design takes cues from the fascia’s overall silhouette, ensuring the bumper complements the vehicle’s lines and proportions. This is not merely about aesthetics; it is about a coherent aerodynamic strategy. A well-integrated bumper reduces sear-induced drag, helps to guide airflow around wheel arches, and can influence the path of air toward the radiator and intercooler as needed. The result is a more efficient cooling pathway and a more stable ride at highway speeds, where even small reductions in drag can contribute to improved fuel economy and steady high-speed handling. OEM bumpers are conceived to support these aerodynamic and functional goals while preserving the visual identity of the Outlander—an identity that many owners value when seeking to maintain a consistent look across a model’s lifecycle.

A crucial aspect of bumper design is the way it accommodates additional features that modern vehicles rely on. In the Outlander, and in many contemporary crossovers, the bumper system is not a passive shell but an active interface with lighting, sensors, and sometimes hood-latch mechanisms. The engineering challenge is to keep these elements precisely positioned as the bumper covers are removed for maintenance or replacement. OEM parts are designed to align with the location of fog lamps, bumper sensors, and radar housings from the factory, which minimizes the time and effort needed for inspection and recalibration after reinstall. This alignment is fundamental to a repair plan that aims to restore the car’s pre-accident performance and appearance. For drivers who prioritize safety and reliability, OEM bumpers offer not just a perfect physical fit but a guarantee of compatibility with the Outlander’s ADAS suite, ensuring that parking assist, adaptive cruise control, and collision avoidance sensors work as intended after a replacement. When shoppers weigh the trade-offs between OEM and aftermarket options, the alignment and calibration considerations often tip the scales in favor of original equipment parts, especially for vehicles under warranty or those with active ADAS programs.

The material and structural characteristics discussed here illuminate why the bumper is a critical element of the Outlander’s overall safety strategy. A bumper is not simply meant to absorb energy in a crash; it is the first point of contact that channels that energy away from more fragile components and toward safer deformation paths. This dynamic is central to the vehicle’s crashworthiness profile and the occupant protection story that underpins confidence in daily use as well as in the event of a collision. In practice, that means any repairs or replacements must consider not only the cosmetic restoration of the front end but also the preservation of the bumper’s energy-absorption performance. When a bumper is replaced with OEM components, the vehicle can maintain its protective characteristics with the highest likelihood of preserving the intended crumple zones and load paths that the manufacturer designed into the chassis. It also helps ensure that the Outlander retains its original drive feel, weight distribution, and alignment—a subtle but meaningful set of outcomes that influence everything from steering response to tire wear patterns over time.

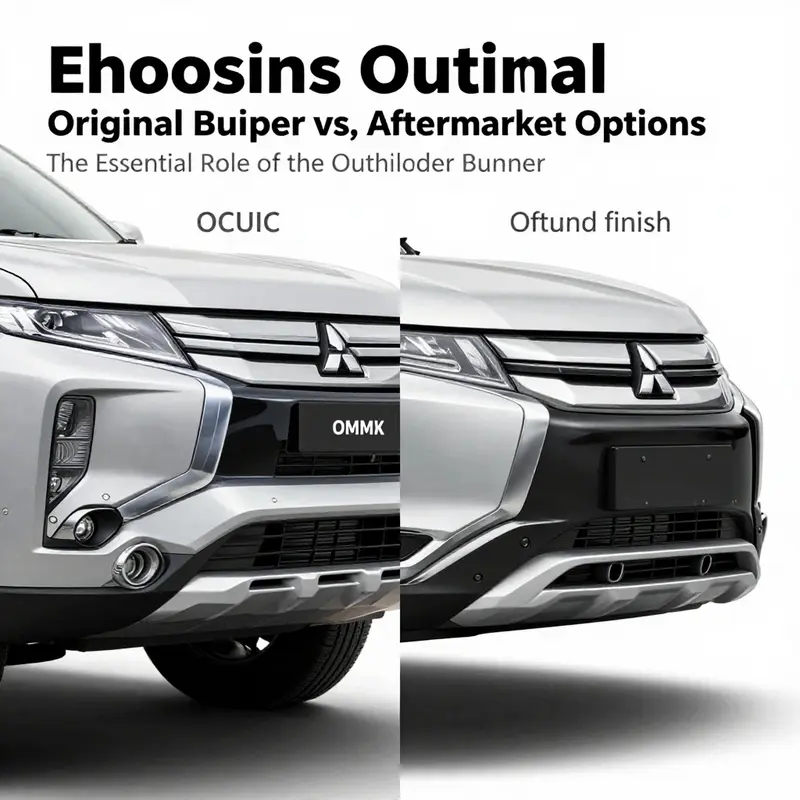

In considering replacement or maintenance options, drivers often ask about the tangible differences between OEM bumpers and aftermarket alternatives. The primary distinctions revolve around fit, safety performance, sensor compatibility, and the preservation of warranty coverage. OEM front bumpers are tailored to the exact generation, which means there is no guesswork about seam lines, mounting points, or the fit of the bumper cover to the fenders and grille. This exactitude translates into fewer adjustments during installation, reduced risk of creating gaps that invite wind noise or water intrusion, and a higher probability that the integrated sensors will recalibrate properly after service. From a safety perspective, OEM components are designed to meet the same standards as the original parts, including the crash-test performance that contributes to the vehicle’s overall rating. For owners who intend to maintain the validity of their warranty or who aim to minimize the probability of misalignment-related issues after an accident, OEM is often the prudent path, even if it requires a higher upfront investment.

The practical implications extend to maintenance and repair workflows. A key takeaway for Outlander owners is that the bumper should be treated as part of the front-end system rather than a standalone cosmetic piece. Replacement work entails more than swapping shells; technicians must verify that the energy-absorbing core and the mounting hardware are in good condition, inspect the bumper beams for any signs of deformation, and re-check the sensors’ positions and calibrations. For vehicles equipped with radar-based systems or camera-based perception, recalibration can be essential following any bumper service. When technicians replace or reinstall an OEM bumper, they typically follow a procedure that re-centers and re-calibrates all integrated components to ensure the system’s performance remains within specification. This process often requires specialized equipment and trained personnel, reinforcing the idea that the bumper is a high-value, safety-critical assembly rather than a quick cosmetic fix.

From a consumer perspective, the decision to pursue OEM components for the Outlander bumper is ultimately about balancing safety, warranty, and long-term value. The precise fit helps to preserve the vehicle’s aerodynamics and its visual appeal, while the energy-absorbing performance of the bumper assembly remains aligned with the expectations of safety authorities and the car’s design intent. The aesthetic benefits—color matching, seamless lines, and an absence of misaligned gaps—contribute to a sense of quality that owners often associate with the overall ownership experience. The functional benefits—reliable sensor operation, consistent ADAS performance, and resilient energy absorption—translate into real-world peace of mind for daily driving and for accidents that, by their nature, are unpredictable. In this light, the bumper emerges as a sophisticated, multifaceted component whose design, materials, and assembly processes reflect a broader commitment to safety, efficiency, and user confidence that defines the Outlander experience.

For readers seeking practical entry points into this topic, a straightforward option is to explore direct replacement pathways that respect the Outlander’s design integrity. For instance, if you are considering the next steps in replacing a front bumper on newer or specific Outlander models, you can rely on the dedicated front bumper offering for the Outlander platform to ensure a precise fit and proper alignment with the vehicle’s sensors and mounting points. This approach minimizes the risk of misfit and the need for subsequent adjustments, while also simplifying the color-matching and finish work. To see a representative example and to understand the形式 of the fitment, refer to the dedicated page for the Outlander front bumper: front bumper for Mitsubishi Outlander.

Beyond the immediate repair considerations, the bumper’s construction echoes a broader philosophy about how modern crossovers like the Outlander manage the balance between rugged practicality and refined engineering. The bumper is the first line in a chain of protective measures that begins at the exterior and ends with the safety systems that respond to a potential collision. It is also a reminder that even seemingly minor replacements can ripple through a vehicle’s performance, calibration needs, and warranty conditions. When owners approach bumper replacement with this holistic mindset, they are more likely to make choices that sustain the vehicle’s safety envelope, preserve its visual identity, and maintain the reliability that has made the Outlander a trusted option for families and adventurers alike.

External resources offer additional context about material choices and industry practices, supporting the conclusions drawn here. For a broader technical reference that aligns with the Outlander bumper material and energy-absorption discussions, you can consult supplier information detailing bumper cover materials and related components. External resource: Alibaba listing for Mitsubishi Outlander Front Bumper Cover.

The Frontline Guard: Interpreting the Performance Metrics of the Outlander Bumper

The bumper on the Mitsubishi Outlander is more than a surface detail or a color match in a showroom photograph. It is a deliberate, technically engineered safety envelope that sits at the front of the vehicle’s architectural integrity. When we talk about bumper performance, we are really describing a system that blends crash energy management, aerodynamics, sensor accuracy, and aesthetic continuity into a single, integrated component. The OEM bumper, designed for a specific model year and generation, embodies a philosophy that values precise fit, predictable behavior under stress, and a seamless interface with the vehicle’s safety systems. In practice, this means every contour, every mounting point, and every embedded feature is calibrated to work in concert with the car’s chassis and its active safety technologies. The result is a unit that not only shields the occupants and critical structure during an impact but also preserves the vehicle’s intended look, feel, and performance envelope after a collision repair or a maintenance cycle.

The core idea behind bumper performance starts with fit. An OEM bumper is crafted to align perfectly with the architecture of a particular Outlander generation. There are no gaps that invite air turbulence or misalignment that could throw off sensor readings. This is not merely cosmetic precision; it is a functional requirement. In a modern Outlander, the front bumper is the first interface between the road and the sophisticated perception and assistive systems that many owners rely on daily. The horizontal line of paint and the vertical faces of the bumper are more than aesthetics; they are the outer boundary of a designed crash pulse. The moment a low-speed collision occurs, the bumper’s ability to distribute and dissipate energy across its geometry, the bumper beam behind it, and the surrounding structure becomes a determinative factor in how much protection reaches the passengers and how much of the underlying frame remains intact.

At the heart of the bumper’s performance is the bumper beam, the energy-absorbing core that you rarely see but feel when you understand how safety works. This component is typically forged from high-strength steel or lightweight aluminum, chosen for its resistance to deformation and its capacity to guide energy away from the cabin. The beam serves as the conductor of the crash energy, guiding the force away from vulnerable points such as the radiator, hood latch, and frame rails, while maintaining the geometry necessary for proper crumple zones to function. In tandem with the beam, the bumper cover—often made from high-impact polypropylene or thermoplastic olefin (TPO)—is engineered to deform in a controlled fashion. This combination allows for a two-stage response: a gentle initial give that absorbs energy and a more pronounced deformation as the load increases, preserving the integrity of the passenger cell.

The materials chosen for Outlander bumpers are selected with both performance and durability in mind. Polypropylene and TPO strike a careful balance between stiffness and ductility. They are tough enough to resist accidental scuffs and light impacts yet flexible enough to yield under stress without cracking. Their resilience contributes to long-term durability, a factor that matters not just in the aftermath of a collision but in the daily grind of road debris, minor scrapes, and the cosmetic wear that comes with years of driving. The OEM choice of materials is part of a broader strategy to preserve the vehicle’s paint-matched finish. A well-matched bumper minimizes corrosion risk at edges and seams, reduces UV-induced fading, and stands up better to the sun’s subtler but persistent effects over time. In practice, that means fewer repairs for the owner and a higher likelihood that the repair, should it occur, will restore the bumper to its original performance characteristics rather than replacing a part that no longer behaves as intended.

Beyond the beam and the cover, the modern Outlander bumper is a hub of integration. It houses or interfaces with a suite of sensors and lighting elements that are critical to the vehicle’s safety and convenience features. Fog lights, parking sensors, and radar units for adaptive cruise control or blind-spot monitoring are commonly embedded or mounted in ways that demand meticulous alignment. The bumper must not impede the correct function of these systems; rather, it should support their operation by providing stable mounting points and calibrated gaps that keep sensors at their designed distances from the vehicle and the environment. This alignment is more than a matter of aesthetics. Misalignment can compromise sensor performance, which in turn can degrade the effectiveness of active safety features, degrade pedestrian detection, or cause nuisance warnings that dull the driver’s trust in the car’s protective technologies. For this reason, many service professionals emphasize that replacing or recalibrating an Outlander bumper is a task that benefits from specialized equipment and expertise.

One important theme that emerges when considering bumper performance is the interface between crash performance and repair quality. Insurance and safety-testing organizations around the world, including bodies that scrutinize pedestrian risk and crashworthiness, evaluate how a bumper behaves in low-speed impacts and how well it preserves occupant safety. In this sense, OEM bumpers are designed to meet or exceed required standards, not just for cosmetic fit but for crash energy management under controlled laboratory conditions and real-world scenarios that reflect common accident sequences. For Outlanders that may face urban parking mishaps or minor tolls on the highway, the bumper’s energy-absorption characteristics and its ability to protect vital structural elements are central to a repair that is both safe and durable.

Color, paint, and finish play a subtler but no less important role in the bumper’s performance narrative. A matched finish is not merely about keeping the vehicle looking pristine; it also supports long-term durability. When the bumper’s surface is properly shielded from the sun’s ultraviolet rays and harsh weather, it resists chalking, fading, and micro-cracking that can propagate through the finish. The paint system often used with OEM bumpers is designed to resist chipping and abrasion in normal use and through the rougher rhythms of winter driving where road salt and moisture are constants. The combined effect is a bumper that remains visually coherent with the rest of the body panels while continuing to deliver consistent performance across its life cycle.

The decision to opt for an OEM bumper rather than an aftermarket alternative carries a cascade of implications for a driver who values safety, warranty, and system integration. OEM parts align with the original crash-test data and the vehicle’s protective architecture, preserving the intended behavior of crumple zones and safety margins when a collision occurs. They also tend to maintain compatibility with the vehicle’s diagnostic and ADAS ecosystems, reducing the risk that sensor calibration drifts or that auxiliary systems require reprogramming after a replacement. This compatibility is particularly meaningful for owners who rely on advanced driver-assistance features in everyday driving. If a bumper is sourced from a different supplier, there is a higher likelihood that sensor housings, mounting points, or even the color match may diverge, necessitating additional calibration sessions and possibly undermining the system’s reliability.

From a repair and maintenance perspective, the choice of bumper influences how a vehicle is returned to its pre-accident state. OEM bumpers carry with them the expectation of a straightforward repair path that mirrors the original design intent. When professionals replace a bumper, they often perform sensor recalibration and alignment checks to ensure that the integrated systems re-synchronize with the vehicle’s electronics. The importance of precise placement cannot be overstated; even a small offset can affect the radar’s field of view, the camera’s calibration, or the proximity readings of parking sensors. This is why many repair professionals prefer OEM components in conjunction with factory-approved calibration procedures and diagnostic tools. While aftermarket parts may offer initial cost advantages, the downstream costs—potential misalignment, reduced sensor fidelity, or compromised safety performance—can erode the savings over time.

For readers seeking to deepen their technical understanding, there is a concrete framework of performance indicators that helps translate this narrative into measurable outcomes. Impact absorption is the headline metric, reflecting how energy is arrested and redistributed during a collision. Material selection and structural design underpin that energy management, while the bumper cover contributes to the controlled deformations that leave the core structure largely spared. Integrated features reveal how the bumper’s role extends beyond protection to actively supporting the vehicle’s sensing and driver-assistance capabilities. Durability, including the long-term finish and resistance to environmental stressors, rounds out the picture by describing how the bumper maintains its protective and aesthetic roles across years of service. In sum, the Outlander’s bumper performance is a composite of energy management, precise fit, and seamless electronic integration—each element reinforcing the others to produce a coherent, safety-forward driving experience.

To connect this narrative with practical steps a consumer might take, consider the following reflection: when a bumper repair or replacement becomes necessary, the choice between OEM and aftermarket should be guided not only by price but by the vehicle’s safety commitments and the long-term health of its ADAS. If the aim is to preserve the car’s original protective envelope, maintain warranty integrity, and keep sensor calibration as straightforward as possible, the OEM path remains compelling. This is particularly true for owners who intend to maximize the Outlander’s reliability and safety profile after an accident or during a major repair cycle. Those who opt for aftermarket parts should ensure that the chosen component is designed for direct compatibility with the exact model year and generation, and they should plan for professional calibration and inspection to verify sensor performance and alignment. The overarching aim is clear: restore the vehicle to a state where its bumper, its energy-absorbing behavior, and its electronic safety systems are harmonized as they were at the factory.

For readers who want a tangible reference to the integration of bumper design and vehicle architecture, a look at the practical modules involved can be illuminating. The bumper’s lines must flow with the grille, the fenders, and the hood, creating a single aerodynamic entity that minimizes drag while inviting a natural ingress of cooling air. The geometry influences how air flows around the front end, which in turn affects fuel efficiency and engine temperature management. While these effects may seem subtle, they are part of the broader performance envelope that every Outlander owner experiences every day. In the end, the bumper is not a standalone piece; it is a module within a larger system that upholds safety, efficiency, and the vehicle’s design language.

For readers who wish to explore the practical options available for Outlander bumper replacements, a relevant product listing for the Outlander’s front bumper provides a direct demonstration of the OEM approach in a contemporary context. You can view a representative page that illustrates how the OEM bumper is positioned within the broader parts ecosystem: front bumper mitsubishi outlander 19.

Beyond the showroom floor, the discussion of bumper performance feeds directly into how owners assess value, safety, and longevity. The bumper’s metrics—impact absorption, material properties, integrated features, and durability—coalesce into a coherent narrative about what keeps a family vehicle safe but also capable of evolving with new safety technologies. The front bumper thus earns its place not as a mere cosmetic factor but as a central pillar of a vehicle’s protective architecture. In a world where technology and design intersect at increasingly complex angles, the bumper stands as a practical reminder that safety is an ongoing, engineered conversation rather than a one-off specification. The Outlander’s bumper, in this light, is a carefully choreographed system that expresses both engineering discipline and a commitment to the driver’s confidence on every mile of road.

External resource for deeper standards and specifications: https://www.mitsubishiparts.com/vehicle/2023-outlander/oem-bumpers

Guarding Innovation: Advanced Features and Technologies in the Mitsubishi Outlander Front Bumper

The front bumper of the Mitsubishi Outlander is more than a guard against minor bumps; it is a carefully engineered interface where safety, aerodynamics, and aesthetics converge. In modern design, this component functions as a gateway for sensing technologies, a convergence point for airflow management, and a canvas that preserves the vehicle’s visual identity. Rather than a single rigid shield, the bumper system embodies a coordinated suite of parts that work together to cushion impacts, guide air, and support the car’s advanced driver-assistance systems (ADAS). The way these pieces interact—the bumper, the surrounding fascia, and the embedded sensors and cameras—determines how effectively a driver can rely on automated braking, lane-keeping, and blind-spot monitoring. This is why the bumper’s precision fit and sensor alignment are not afterthoughts but foundational requirements. When engineers embed radar, lidar, or camera modules behind the bumper’s surface, they must ensure that the housing preserves line-of-sight, minimizes distortion, and maintains calibration under a range of temperatures and driving conditions. Any shift of a sensor position, even seemingly minor, can degrade system performance, which is why the topic of bumper design cannot be separated from the overall reliability of the Outlander’s ADAS suite. The result is a front-end assembly that reads as a coordinated ensemble rather than a collection of discrete protections. In practice, this means the bumper is designed around the sensors and the electronic networks that connect them, so installation and maintenance must be performed with the same attention to accuracy that a mechanic would give to engine management or braking systems. The emphasis on integration is not about conspicuous complexity; it is about ensuring consistent performance across the vehicle’s life, from the first drive off the showroom floor to years of everyday use on bustling city streets and remote highways alike. To appreciate the sophistication of the Outlander’s bumper, one can consider how the system balances three central objectives: occupant protection, sensor fidelity, and vehicle efficiency. Each objective depends on the others, and the bumper sits at the crossroads where protection, perception, and performance intersect. The result is a component that looks simple from the outside but carries a dense layer of engineering nuance beneath the surface. Inside this surface lie the materials, geometries, and connective tissues that enable a high-functioning safety network while preserving the vehicle’s elegant silhouette. The bumper becomes the starting point for a broader conversation about how advances in materials science and sensor technology translate into real-world safety benefits. At its core, the Outlander’s bumper is a shield that absorbs and dissipates energy in a crash, yet it is also a conduit that channels data to the car’s brain, allowing the car to see and react with a precision that would have seemed like science fiction a generation ago. This dual role—protective and perceptive—makes the bumper a prime exemplar of how modern automakers fuse form and function. In this light, the bumper is not a mere accessory; it is a critical platform for safety and convenience features that modern drivers now take for granted. The emphasis on compatibility is equally important. The bumper is designed to accommodate integrated fog lights, radar housings, and camera assemblies while preserving the clean lines of the Outlander’s front end. It is crafted to minimize air turbulence that could interfere with sensor performance or destabilize airflow around the vehicle at highway speeds. The design process takes into account the thermal environment dictated by the engine bay, ensuring that heated exhaust or cooling airflow does not distort sensor readings or degrade the bumper’s structural integrity. The result is a front-end assembly that performs consistently, season after season, under a variety of weather conditions and driving scenarios. To ensure enduring effectiveness, many owners and technicians recognize that the bumper’s calibration is as important as its physical installation. Modern ADAS features often rely on precise sensor placement and alignment; misalignment can erode the accuracy of adaptive cruise control, lane-centering assist, or pedestrian detection. Consequently, the aftermarket choices and maintenance practices surrounding the bumper must be approached with a careful regard for sensor geometry and alignment tolerances. Engineered precision is a core attribute of the Outlander’s bumper system, and it arises from cross-disciplinary collaboration among design engineers, materials scientists, and calibration specialists who must translate real-world driving data into tangible improvements in protection and perception. This collaborative spirit manifests in three interwoven domains: materials selection, structural energy management, and sensor integration. Materials selection in the Outlander bumper tends toward lightweight yet robust plastics, where high-strength polypropylene and thermoplastic olefin (TPO) composites form the skeleton of the fascia and cross-beams. These polymers deliver a compelling balance of toughness, fatigue resistance, and formability, enabling intricate shapes that blend aerodynamics with aesthetics. Not only do these materials withstand low-speed impacts that could otherwise deform the front end, but they also contribute to overall vehicle efficiency. Reducing weight a few kilograms can translate into measurable gains in fuel economy and lower emissions, a modest but meaningful contribution to the Outlander’s environmental performance. Within the bumper’s interior, energy-absorbing structures—often foam inserts and strategically tuned rib networks—absorb impact energy and help protect occupants and critical subsystems. These energy-dissipation elements are designed to engage early in a collision, distributing force away from the passenger cabin while minimizing collateral damage to supporting components such as the engine cradle, radiator, and front-frame members. The placement and density of foam inserts are calibrated to respond predictably across a spectrum of collision severities, aligning with safety standards that mandate effective pedestrian protection and robust restraint of occupant injury. Pedestrian safety has become a focal concern for modern bumper design, and the Outlander’s approach reflects this priority through crumple zones that absorb vertical and horizontal energy and through features intended to reduce the risk of injury to unprotected pedestrians. In some markets, this alignment with safety norms is reinforced by energy-dissipating structures that deform in controlled ways, absorbing energy while guiding the impact around more vulnerable parts of the vehicle. The bumper’s integration with ADAS sensors further extends its safety remit beyond collision energy management. The front bumper houses cameras and radar sensors responsible for adaptive cruise control, forward collision warning, and emergency braking. The precise fit of these sensors relative to the bumper’s contours and the vehicle’s grille ensures that the field of view remains optimal and that sensing algorithms have reliable reference points. If the bumper were to shift due to improper mounting or aftermarket replacement, the sensors could lose calibration and degrade performance. This is why OEM-grade replacements are often recommended and why technicians carefully re-check calibration after any bumper replacement. Aerodynamics is another crucial domain in which the bumper design contributes to overall vehicle performance. The Outlander’s bumper is not simply a shield; it is a carefully contoured surface that harmonizes with air dams, lower valances, and underbody channels to guide air efficiently around and under the car. The objective is to reduce drag, manage lift, and stabilize airflow during high-speed travel. In higher trims or sport-oriented variants, the bumper work can be part of a broader aero package that includes side skirts and roof elements, extending the cohesive visual language of the car while enhancing downforce and stability at speed. This integrated approach—where bumper geometry, grille design, and underbody shaping work in concert—embodies a philosophy that aesthetics and performance need not be mutually exclusive. A factory OEM grille, in particular, plays a dual role. It ensures that engine cooling remains consistent under demanding conditions, such as sustained highway driving or towing. It also contributes to the vehicle’s overall airflow management, shaping how air enters and exits the engine bay without compromising the sensors mounted in the bumper. In more performance-oriented or off-road-oriented variations of the Outlander, the grille may employ mesh patterns that improve heat dissipation or deliver a more aggressive look. However, such choices demand a mindful consideration of sensor placement and fog-light compatibility, reinforcing the idea that the bumper is a living interface rather than a static shell. The engineering story extends to practical considerations about replacement and maintenance. When owners contemplate replacing a damaged bumper, the temptation to choose a less expensive aftermarket option can be strong. Yet the Outlander’s bumper’s value lies not only in its protective capacity but also in its role as a sensor housing and aerodynamic component. An aftermarket substitute that fails to preserve tight tolerances can lead to degraded ADAS performance, misalignment of cameras, or even unintentional changes to the vehicle’s aerodynamic balance. As such, OEM replacements are often the safer path for owners who want to preserve the car’s safety integrity and warranty coverage. This reality does not diminish the value of well-designed aftermarket components, but it does raise the bar for fit and calibration. Professional installation remains essential, not merely to secure the bumper but also to ensure that all integrated devices—sensors, cameras, lights—are precisely positioned and calibrated. The process may include diagnostic checks and reprogramming of the vehicle’s control units to reestablish correct sensor baselines after mounting. The collaborative enterprise of bumper design—spanning materials science, crash engineering, aerodynamics, and software calibration—illustrates how a single, everyday part can embody the best of modern automotive engineering. It is a reminder that the Outlander’s contemporary driving experience—smooth, confident acceleration, stable highway behavior, and proactive safety alerts—rests on a carefully choreographed set of interactions that begin at the car’s nose. For readers who want a tangible sense of how this translates to everyday ownership, consider how the bumper’s design choices influence maintenance and after-sales service. A bumper that is precisely matched to the vehicle’s body lines minimizes the risk of gaps or misalignments that can collect dirt or water, which in turn helps preserve sensor integrity and reduces the likelihood of corrosion around mounting points. This precision also supports paint quality, color matching, and long-lasting appearance, which are important for maintaining resale value and owner satisfaction. When discussing the Outlander’s bumper within a broader article about bumper design, it is important to acknowledge the careful balance between cost and capability. OEM components may entail higher upfront costs, but they deliver consistent fit, safer calibration for ADAS, and a warranty-backed assurance that the vehicle’s safety systems will function as intended. The alternative—aftermarket parts—can offer cost savings but carries the risk of imperfect fit and sensor misalignment that could compromise both safety and reliability. The ongoing evolution of bumper technology continues to push for smarter, lighter, and more integrated solutions. Advances in polymer chemistry, structural foams, and sensor miniaturization point toward bumpers that still provide robust impact protection but partner more intimately with the car’s computing systems. The result is a future where the bumper does not merely cradle the front end but actively participates in the vehicle’s perception and response to the world ahead. As we reflect on the current Outlander generation, it becomes clear how the bumper’s advanced features and technologies illuminate a broader trajectory in automotive design. The front end is no longer a static shield but a dynamic platform that supports perception, protection, and performance. This convergence yields tangible benefits for drivers: more reliable safety nets from ADAS, improved efficiency through refined aerodynamics, and the enduring aesthetic coherence of a vehicle that wears its modern identity with quiet confidence. In this sense, the Outlander’s bumper stands as a practical manifesto of contemporary engineering—an object whose value is measured not just by how it looks, but by how well it preserves life, guides the car’s behavior, and sustains the driving experience over time. For readers seeking to explore OEM options that align with these principles, a representative entry point is the front bumper mitsubishi outlander 19, which exemplifies how an OEM component can be harmonized with the car’s sensor layout and performance goals: front bumper mitsubishi outlander 19. Looking beyond the bumper as a discrete item, the discussion expands to acknowledge how this part fits into the larger ecosystem of safety systems, chassis dynamics, and energy management. Each element—whether a foam insert, a high-strength polymer, or a camera mount—plays a role in a grander objective: enabling a safer, more efficient, and more confident driving experience. The bumper’s story is, therefore, inseparable from the story of the car itself. It is the hinge where engineering rigor meets everyday practicality, where the pursuit of zero-defect sensing meets the reality of road wear, and where style meets substance in a way that complements the Outlander’s core identity. This is the essence of advanced bumper design: not a single feature, but a synchronized ensemble that keeps pace with a rapidly evolving vehicle technology landscape and a driver’s rising expectations for safety, efficiency, and seamless integration of intelligent systems. For readers who want to dive deeper into the official specifications and materials, authoritative details are available from the manufacturer’s resources, which provide deeper context on how these components support the vehicle’s performance targets. External reference: https://www.mitsubishi-motors.com.

Choosing the Right Front Bumper for Your Mitsubishi Outlander: OEM Confidence or Aftermarket Flexibility?

Balancing safety, fit, and cost for the Mitsubishi Outlander front bumper

Selecting a front bumper for a Mitsubishi Outlander requires more than price comparison. The bumper is both a visual anchor and a structural safety component. It sits at the intersection of crash energy management, sensor integration, and vehicle aesthetics. For owners weighing original equipment against aftermarket alternatives, the choice is essentially about priorities: uncompromised crash performance and system compatibility, or cost savings and style options.

Original equipment bumpers are engineered to fit a specific model year and generation precisely. That precision matters. When a bumper aligns perfectly with body panels, it preserves aerodynamic flow. It also ensures that factory fog lamps, grille pieces, and mount points sit where engineers intended. Behind the plastic cover, an engineered energy-absorbing structure—often a high-strength steel or lightweight aluminum beam—controls how force is distributed in a low-speed impact. That beam, together with foam absorbers and mounting rails, is tuned to absorb and dissipate energy without transferring excessive load to the cabin or critical chassis components. Maintaining that tuning matters for occupant protection, and for the vehicle’s ability to perform as tested under international safety assessments.

Beyond structure, the modern Outlander’s front bumper typically houses several active systems. Parking sensors, radar units used by adaptive cruise systems, and cameras for driver assistance are often mounted directly to or behind the bumper. Sensor position and angle are calibrated at the factory to work with other vehicle systems. A replacement bumper must preserve these mounting points with millimeter accuracy to avoid degraded performance. Using an original bumper keeps these tolerances intact. It reduces the chance of an insurance claim denial tied to improper repair and preserves the traceability required by many manufacturer warranties. While original parts generally cost more and can require professional installation, they deliver a straightforward path to restored safety and full system functionality.

Aftermarket bumpers bring clear advantages for certain buyers. They are typically less expensive and may offer alternative styling. Some aftermarket trims add chrome accents or sportier grilles. Others provide options in alternative materials like reinforced polypropylene, fiberglass, or even carbon-fiber composites for specialty applications. For drivers who prioritize appearance or seek a specific modification, aftermarket choices can be attractive. Some kits also include aerodynamic add-ons such as side skirts or diffusers that smooth airflow and potentially improve high-speed stability. These upgrades can appeal to commuters or performance-minded owners looking for small gains in ride behavior.

However, aftermarket parts vary widely in quality. A budget cover that doesn’t match factory dimensions can introduce gaps, misalignments, and stress concentrations at the mounting points. Poor fitment can create unexpected vibration, allow water ingress, and interfere with hood latch sensors. More importantly, an ill-fitting bumper may misalign radar or camera sensors, undermining advanced driver-assistance systems. That misalignment can reduce the effectiveness of automatic braking, lane-keeping assists, or adaptive cruise control. In crash scenarios, a non-compliant support rail or beam may not manage impact forces as designed, risking greater damage to structural components and passengers.

For owners who consider aftermarket options, careful vetting is essential. Seek suppliers that publish engineering data, show material specifications, and demonstrate dimensional tolerances. Replacement support rails and beams that are manufactured to OEM specifications can perform almost identically to factory parts. Ask for certification or test reports when possible. Confirm that the part supports original sensors without requiring extensive modification. Review return policies and warranty terms. If you choose a cosmetic trim or accent piece, consider how it mounts and whether it will require drilling or permanent alteration of factory parts.

Installation and recalibration are crucial topics regardless of part choice. Any bumper replacement that affects sensor position should be followed by professional recalibration. Many modern vehicles require specialized alignment tools and a diagnostic connection to complete the process. Failing to recalibrate can leave ADAS features impaired and expose drivers to safety risk. Further, some manufacturer warranties and insurance repairs stipulate that a trained technician must perform the installation and verify system alignment. If maintaining warranty coverage is important, use a part that conforms to the manufacturer’s requirements and have certified technicians perform the work.

Cost considerations extend beyond the part price. Factor in paint matching, labor for removal and installation, and potential recalibration fees for sensors. Paint matching can be deceptively expensive if the vehicle’s finish has aged or been polished. Primer, base coat, and clear coat layers must match the original color code and gloss. Original bumpers are often available pre-primed or even pre-painted to exact factory standards. This reduces shop time and lowers the chance of noticeable color mismatch.

Resale value and long-term ownership also influence the decision. Vehicles repaired with OEM parts often retain a clearer service history. Prospective buyers and resellers frequently prefer factory-correct repairs. Aftermarket modifications that alter crash structure or sensor performance can complicate future sales. Conversely, thoughtfully selected aftermarket parts that maintain function while improving style can be a selling point for the right buyer. Document all repairs and include invoices that demonstrate parts compatibility and professional recalibration work. That documentation supports future value and shows attention to vehicle integrity.

For owners who prioritize safety and warranty integrity, original parts represent a conservative, sound investment. For budget-conscious drivers or those seeking custom looks, aftermarket parts offer flexibility. The best approach blends both perspectives: when structural or sensor-critical elements are involved, favor the OEM component. For purely cosmetic accents, choose reputable aftermarket manufacturers whose parts fit without alteration. Always confirm compatibility with vehicle systems before purchase.

When evaluating replacement bumpers, use a checklist: verify part numbers against the vehicle VIN, ensure sensor mount points match factory locations, confirm material specifications for energy-absorbing components, and validate paint match capability. Ask the supplier whether the part has been crash-tested or meets recognized structural standards. For installations, insist on a technician familiar with the Outlander’s ADAS suite and factory calibration procedures. If a shop suggests modifying sensor mounts or leaving recalibration incomplete to save cost, seek a second opinion.

A practical example: a front bumper cover might cost significantly less from an aftermarket supplier. But if that cover requires a new support beam or causes sensor misalignment, repair costs can exceed the initial savings. Similarly, a slightly higher investment in an OEM bumper can avoid future diagnostic headaches and preserve system performance. For owners who use the vehicle in family transport or long-distance travel, preserving the designed crash energy management system is especially important.

Quality assurance also matters. Reputable sources provide mounting hardware, absorbent inserts, and precise clips. They back parts with limited warranties and technical support. Lower-cost options may omit these items, leaving the installer to reuse old hardware. Reusing deformed mounts can compromise the repair. When possible, replace mounting hardware to restore original stiffness and alignment characteristics.

Choosing the right bumper for a Mitsubishi Outlander is a decision about priorities. Safety, sensor compatibility, and long-term vehicle value favor original parts. Affordability and unique styling favor aftermarket choices. The recommended path is pragmatic: use original structural components where function is critical, and reserve aftermarket selections for non-structural aesthetic elements. Regardless of choice, engage qualified technicians, confirm calibration of any affected systems, and retain documentation. That approach preserves performance, safety, and resale potential while allowing room for personalization.

For a practical supplier option on replacement bumpers, see this internal reference to a front bumper for Mitsubishi Outlander: Front bumper for Mitsubishi Outlander.

For technical details on factory part design and performance characteristics, consult the manufacturer’s parts guide:

https://www.mitsubishicars.com/owners/support/vehicle-parts-guide-outlander

Final thoughts

The Mitsubishi Outlander bumper is an essential component that ensures both vehicle safety and aesthetic appeal. Understanding its structural integrity, performance metrics, advanced technologies, and the critical decision-making involved in selecting original versus aftermarket parts is vital for business owners. By prioritizing safe and effective bumper solutions, you not only uphold your commitment to quality but also ensure the longevity and reliability of the Mitsubishi Outlander. Investing in the right bumper will ultimately safeguard passengers and enhance vehicle performance.