Maintaining a Mitsubishi Galant involves understanding the critical components that ensure optimal performance. For business owners in the automotive sector, knowledge of these essential car parts can significantly impact service quality and customer satisfaction. This article delves into three key components: the water pump, rear shock absorbers, and engine overhaul gasket kits, detailing specifications, customization options, and reliable suppliers. By exploring each of these aspects, you will gain valuable insights that can help you in procurement, installation, and customer consultations, ultimately strengthening your business’s service portfolio.

Cooling Currents: A Comprehensive Exploration of the Water Pump Landscape for Mitsubishi Galant (2004–2012)

The water pump sits at the quiet center of a car’s cooling system, yet its role governs the engine’s life and the driver’s comfort in thousands of small, unseen ways. For the Mitsubishi Galant produced between 2004 and 2012, with the 2.4-liter four-cylinder heart that powered many midsize sedans of its era, the water pump is more than a mere accessory. It is a calibrated piece of engineering designed to move coolant with just the right balance of flow and resistance, ensuring the engine maintains its optimal operating temperature under a wide range of speeds and conditions. The pump’s performance threads through every drive—from early morning commutes to long highway stints in hot weather—and its reliability anchors the Galant’s reputation for steady, predictable operation. When the pump fails or falters, the consequences ripple outward: overheating, a rise in belt tension irregularities, and the potential for downstream damage to gaskets, seals, and the broader cooling circuit. Understanding this component in context means appreciating not only its technical specifications but also the ecosystem of parts supply that supports maintenance, repair, and long-term ownership of these vehicles.

In the landscape of replacement parts, the water pump for this Galant era is defined by a handful of design imperatives. First, compatibility with the 2.4-liter engine family is non-negotiable. The pump must align with the original mounting points, belt routing, and overall length so that it sits in harmony with the alternator pulley, the timing belt or chain geometry where applicable, and the radiator assembly. This alignment matters because even a minor deviation in length or mounting position can shift the belt tension or belt path, potentially leading to accelerated wear on adjacent components or, in a worst-case scenario, reduced cooling efficiency. The housing itself is generally crafted from aluminum, chosen for its light weight and corrosion resistance, helping to extend service life under the heat and thermal cycling that engines routinely endure. The impeller, shaft, seals, and bearings are engineered to withstand a working life that matches or exceeds the original component, while maintaining steady flow across the engine’s temperature spectrum.

A practical hallmark of the water pump’s design in this category is its adaptability to both pulley-included configurations and setups sold without a pulley. Buyers are often cautioned to verify whether the listing includes the pulley or requires a separate purchase, because that small packaging detail directly affects the installation steps and the exact fitment in the engine bay. The OEM-style fitment angle is equally important: the new pump should mirror the original’s bolt pattern and gasket interface so that it can be mounted without improvisation, preserving the integrity of the coolant ports and sealing surfaces. In this sense, the water pump becomes a small, highly precise module that embodies the broader engineering philosophy of the Galant: straightforward, reliable replacements that preserve the car’s long-term performance without demanding specialized adaptation.

The quality story behind these pumps extends beyond the mechanical fit. Reputable manufacturers emphasize stringent quality control across the production chain, from casting and machining to assembly and packaging. The materials chosen—high-grade aluminum for the housing, robust impeller materials, and seals designed to resist coolant degradation—are selected to resist the corrosive and thermal demands of long-running cooling circuits. In practical terms, this means a replacement part that, when installed correctly, behaves like the original in both performance and reliability. It also means guidelines for installation and initial operation are straightforward: a properly seated pump with clean mating surfaces, a fresh gasket or O-ring where required, and careful attention to torque specifications on mounting bolts to prevent leaks while avoiding warping the housing.

A broader description of the water pump’s role reveals how its success hinges on a few interlocking factors. The pump must deliver sufficient volumetric flow to the engine core across a broad range of engine speeds. If the flow declines, the coolant warms, and the engine’s thermal management system works harder to remove heat—potentially triggering a cascade of alerts, reduced efficiency, or, in the worst case, engine hotspots that stress head gaskets and seals. At idle, city streets, and highway cruising, the pump’s duty remains the same: create a dependable, continuous loop that keeps the engine within its ideal temperature window. The design intent behind the common OEM-style pumps is to preserve that window with predictable, steady flow while enabling straightforward installation for a quick replacement.

In terms of practical procurement, the water pump ecosystem for the Galant’s 2.4-liter lineup often presents a spectrum of options. One category focuses on OE-style replacements designed to replicate the original dimensions and mounting geometry as closely as possible. These pumps aim to minimize surprises during installation, offering a drop-in experience that mirrors the factory part’s fit. A second category emphasizes compatibility-focused units that may adopt slightly different casings or seals but claim equivalent performance, calibrated to meet or exceed OEM specifications. These options appeal to buyers seeking a balance of price and reliability, with post-purchase support that covers compatibility and warranty terms. A third category includes more value-oriented units from regional manufacturers that still honor essential design constraints—clearances, seal materials, and flow rates—while delivering cost-effective alternatives for budget-conscious repairs. Across these categories, the common thread is fidelity to the engine’s cooling requirements and the belief that a well-chosen replacement can restore the Galant’s cooling performance without introducing new mechanical uncertainties.

The reliability narrative for the Galant water pump is closely tied to the broader maintenance philosophy that drivers bring to their vehicles. Regular coolant changes, using appropriate coolant formulations compatible with aluminum components, contribute to the pump’s longevity by minimizing corrosion and scale buildup that can impede flow or create abrasive wear on seals. Attention to belt condition is also critical. The water pump shares a belt with the alternator and sometimes the power steering or air conditioning depending on the exact configuration, making the belt’s health a proxy for the pump’s operational environment. A frayed or glazed belt can inadvertently alter the pump’s pulley alignment, generate excess noise, or even cause a temporary slip that affects cooling capacity during peak loads. In this sense, the water pump’s reliability is inseparable from routine maintenance practices that also safeguard the engine’s overall thermal management system.

From the consumer’s vantage point, choosing a water pump for the Galant involves evaluating several practical criteria. First is compatibility: confirm the vehicle’s exact year, engine code, and emission specification, because the Galant’s 2004–2012 window encompasses a variety of drivetrain configurations; some engines used in related models might share common parts names but diverge in mounting details. Second is the inclusion of the pulley. If a separate pulley is required, buyers should factor that into their total replacement cost and ensure the pulley’s balance and alignment are preserved. Third is the warranty and return policy. A typical OE-style or compatible pump may come with a warranty period—often ranging from one year to several years depending on the supplier—and a reasonable replacement or credit policy if a defect is discovered within the coverage window. Fourth is lead time. Stock items tend to ship quickly, while customized production can extend lead times. Buyers who plan long trips or frequent highway driving should plan accordingly, ensuring they have the replacement on hand or schedule the installation to avoid cooling-system downtime in advance of high-demand seasons.

The supply chain story behind these pumps is also telling. In today’s markets, parts sourced from diverse regions can meet stringent performance and durability criteria if the manufacturer adheres to robust process controls and uses consistent materials. The critical takeaway for the Galant owner is that a water pump purchased from a supplier with a clear commitment to OEM-style fitment, marked quality assurance, and transparent warranty terms will likely deliver the most predictable outcome in terms of both installation and long-term reliability. In addition, written installation instructions, a clean gasket interface, and a careful torque protocol for mounting bolts contribute to a durable seal that helps the new pump integrate smoothly with the cooling system’s existing hoses, clamps, and radiator connections. Even without perfect visibility into every step of the production line, these indicators—aluminum housing, proper fitment, robust seals, and a stable belt-driven interface—signal a pump designed to be a faithful heir to the original design.

In discussing the water pump’s practicalities, it is helpful to keep in mind the Galant’s maintenance arc. The cooling system has multiple components, and while the pump’s failure can be abrupt, the symptoms often emerge gradually. A slight whine from the pulley or a faint coolant odor near the timing belt area can herald a developing issue. A sudden loss of coolant, a visible puddle under the vehicle, or continuous overheating after a short drive typically points to a pump problem or a related seal or hose issue. In diagnostics, a technician will assess pump operation by monitoring the coolant flow and pressure, inspecting the seals for leaks, and verifying that there are no obstructions in the radiator or blocked passages in the thermostat housing that could emulate a pump fault. A well-chosen replacement—installed with careful attention to cleanliness, gasket integrity, and hose connections—restores the cooling system’s equilibrium and preserves the Galant’s performance envelope.

Beyond the mechanical and procedural realities, the water pump episode for the Galant invites reflection on how modern vehicles balance performance with serviceability. The pump is a relatively small component in the grand scheme of the engine’s ecosystem, yet its influence on reliability, efficiency, and even driving pleasure is disproportionately large. A vehicle that maintains stable temperatures under diverse driving conditions tends to deliver more consistent fuel economy, steadier emissions performance, and longer life from other cooling-system components. The purchase and installation decision—whether opting for a near-identical OE-style unit or a compatible alternative—will shape the owner’s experience of maintenance, repair, and everyday use. In that sense, the water pump becomes a case study in how modern automotive parts sustain a long-running relationship between machine and driver, built on predictable performance, transparent information, and a shared expectation of value over time.

For those who want to explore further, the broader literature on water pump design and reliability offers a deeper dive into the engineering choices that underlie these seemingly simple devices. While the Galant’s era may have its own unique engineering fingerprints, the fundamentals—materials selection, lubrication and seal integrity, bearing life, and proper fitment—resonate across many OEM and aftermarket platforms. Each replacement pump is not just a component to be swapped; it is a careful rebalancing act that preserves the cooling loop’s harmony and, by extension, the entire engine’s health. This is why, at the end of the day, the water pump is less a standalone part and more a keystone in the Galant’s ongoing relationship with reliability, economy, and everyday driving satisfaction.

External perspective often frames the water pump within the broader automotive supply ecosystem: a reminder that the car’s performance is amplified when the right piece—matched to its precise design language and installed with care—enters the system. The Galant, with its 2004–2012 window and 2.4-liter four-cylinder heart, embodies that principle. As owners weigh options, the question becomes less about chasing the lowest price and more about securing a component whose fit, build quality, and governance reinforce the car’s long-standing reputation for steady operation. In this light, the water pump is not merely a spare part but a small investment in the vehicle’s future—one that pays dividends in reliability, peace of mind, and the comfort of knowing that the engine’s cooling system will continue to perform under the pressures of daily driving and periodic highway expeditions alike.

For readers seeking a broader context on cooling-system components and reliability considerations, a relevant external resource provides a complementary perspective on how engineers approach pump design, seals, and flow dynamics in modern engines. This resource helps illuminate why the seemingly modest water pump commands such careful attention in both design and replacement decisions. https://www.amazon.com/dp/B0XXXXXXX

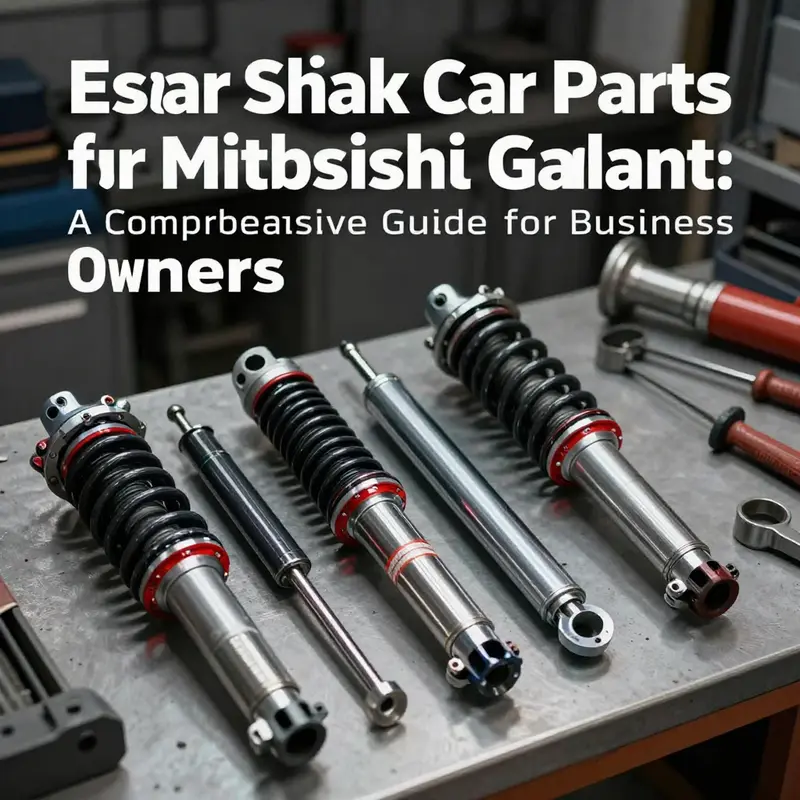

Rear Shock Absorber Options for Mitsubishi Galant: Design and Availability

The suspension system in a Mitsubishi Galant is a quiet architect of everyday driving comfort and everyday safety, yet it often hides in plain sight until a worn component reminds the owner of its importance. Among the most impactful elements in this system are the rear shock absorbers. They govern how the car responds to road irregularities, how it settles into a corner, and how predictably it preserves its line when the pavement surprises with a sudden dip or a slope. As with many car parts, design choices and supply realities shape what an owner can realistically install, what a workshop can tune, and what a driver can expect in terms of feel, durability, and return on investment. The discourse around rear shock absorbers for the Galant thus sits at the crossroads of engineering, user needs, and the practicalities of global supply chains that now move more quickly than ever before.

The most enduring conclusion about rear shocks is that there is no one-size-fits-all solution. The Galant, with its lineage of daily-driver comfort tempered by occasional spirited driving, benefits from a spectrum of design approaches that balance ride quality, handling, and budget. At the heart of this spectrum are three predominant designs that dominate aftermarket offerings: monotube shock absorbers, twin-tube shock absorbers, and coilover systems. Each design speaks to a different philosophy of how a car should respond to force and how heat should be managed when the car is driven through long stretches of potholes or pushed a little harder on winding roads.

Monotube shock absorbers, by virtue of their single cylinder and a high-pressure gas chamber, excel at heat dissipation and consistent response under repeated loading. In everyday terms, they tend to stay firm and linear even as the miles accumulate, which translates to stable handling and controlled body movement after pothole hits or when the Galant is cornering on a wet surface. Enthusiasts or drivers who frequently traverse challenging road surfaces will notice that monotubes resist the fade that can plague twin-tube designs after successive bumps and repetitive compression. A monotube configuration often provides a more immediate and precise steering feel, because the internal gas acts as a separate chamber that suppresses the foaming of hydraulic fluid during rapid cycling. The result is a shock that responds with less delay and maintains its damping characteristic as the suspension traverses rough terrain, which can be especially appreciated during spirited highway stints or occasional track-oriented sessions.

Twin-tube shocks, on the other hand, remain a stalwart of the mainstream aftermarket due to their cost effectiveness and broad compatibility. They tend to deliver a smoother ride on typical city streets and highways, with a slightly softer character that many daily drivers value. The twin-tube design generally features two cylinders, which can translate to a different heat management profile and, in some cases, a slightly cushier damping response at lower speeds. For the Galant owner who prioritizes comfort and quiet confidence over relentless performance, twin-tube units offer a compelling blend of affordability and practicality. The availability of these designs is vast, with a global supply chain that ensures replacement options for a wide range of model years and trims, often at a price point that makes regular maintenance more approachable.

Coilover systems introduce a newer layer of customization. They combine the shock absorber with an adjustable coil spring assembly, enabling users to alter ride height and damping characteristics with a single kit. For those who want a more individualized stance or who wish to dial in a stiffer setup for specific driving conditions, coilovers offer a path to a tailored suspension feel. The downside is that coilovers can be more expensive and may require more hands-on setup to reap their full benefits. They are particularly attractive to enthusiasts who want to fine-tune the balance between ride comfort and cornering capability, especially on Galants that see both daily driving and occasional spirited driving in varied weather conditions.

In the context of the Galant, the practical question then becomes not only which design best suits a given driver’s needs but also how readily available the chosen solution is across the globe. Availability is now defined as much by the reach of online marketplaces as by the reach of traditional auto parts stores. Global suppliers, particularly those operating through electronic marketplaces, present a robust spectrum of rear shock options that claim compatibility with a broad array of Mitsubishi models, including variants that share platform characteristics with the Galant. This means that a panel of options—ranging from monobloc, gas-charged monotubes to more economical twin-tube assemblies—can be sourced from multiple regions, often without the long lead times that once characterized aftermarket parts for older sedans.

A practical illustration of availability emerges from current listings that target a wide model year window. One representative example notes a set of rear shocks designed to fit a Galant within a particular generation span, typically marketed as a left-and-right pair to simplify installation. Such listings commonly specify compatibility with non-adjustable suspension configurations, a reminder that some newer shock technologies may require careful matching to the vehicle’s original geometry and damping needs. The point is not to imply that every option is a perfect plug-and-play fit, but rather to underscore that a variety of configurations are reachable through reputable suppliers without the long wait times that used to accompany specialty parts.

Another facet of availability is the role of part numbers and warranty. In the aftermarket world, part numbers commonly align with the intended vehicle family and the particular shock design. A widely cited example, though originating from a manufacturer with a broader off-road and SUV application, shows how a gas-filled, high-performance shock can be catalogued for a set that matches a mid-2000s Galant range. The warranty attached to these products typically mirrors typical aftermarket terms, offering around one year of coverage or a mileage cap between thirty thousand and sixty thousand kilometers, whichever comes first. This warranty structure provides a degree of confidence for the buyer who may be weighing the longer-term costs of replacement against the upfront price of a more sophisticated shock option.

Logistically, the availability story extends to how the parts are shipped. Sellers of aftermarket suspension components frequently offer a mix of express air freight and sea transport to accommodate the needs of buyers across different continents. For larger orders or non-stock items, manufacturers commonly provide longer lead times, with manufacturing or customization taking place to match the requested specifications. The possibility of customization is particularly relevant for those who seek non-standard damping curves or those who want to tailor the unit to regional driving conditions—for example, harsher roads, higher speeds, or more extreme weather patterns that can influence damping performance.

In practice, choosing between monotube, twin-tube, and coilover options becomes a decision guided by personal driving goals and by the reality of what is physically obtainable for the specific Galant in question. If the aim is to maintain a conventional daily-driver experience with a slight edge in steering precision and consistent ride control, a well-matched monotube or a high-quality twin-tube with robust seals and a proven damping profile can deliver the best balance. If, however, the driver’s calendar includes more demanding road surfaces, or if there is a keen interest in a precise, adjustable setup for cornering, coilovers may justify the extra complexity and cost. Either way, the landscape today supports a broad spectrum of choices that can be aligned with the Galant’s chassis geometry and the driver’s expectations.

When assessing any rear shock option, there are a few practical steps that help ensure a successful match. First, verify compatibility not only with the Galant’s model year, but also with the specific trim and suspension configuration. Even within the same generation, subtle differences in mounting points or spring rates can influence fitment and ride. Second, consider the intended use and climate. A daily commuter in a region with rough roads benefits from a shock that maintains damping integrity under repeated fatigue, while a weekend enthusiast might prioritize a design with a more linear response and reduced fade. Third, check the warranty and service support. A robust warranty, easily accessible customer service, and clear documentation greatly aid the maintenance path over the life of the vehicle. Fourth, factor in the ease of installation. A pair of rear shocks should come with straightforward hardware and clear guidance, especially for the home mechanic who wants to complete the job in a weekend without surprising alignment or mounting issues.

The broader takeaway is that rear shock absorbers for the Galant now exist within a mature aftermarket ecosystem. The ecosystem is characterized by a blend of traditional, reliability-focused designs and newer, tunable options that empower drivers to tailor the vehicle’s behavior to the road and to their preferences. The practical upshot is that owners who approach replacement with a clear sense of how they drive—and how they want the car to respond—can more confidently select a design that harmonizes with the car’s overall character. This is not about chasing the latest buzzword in suspension tech; it is about aligning damping performance with the Galant’s chassis dynamics so that every mile, whether it is a routine commute or a winding road, feels controlled, predictable, and comfortable.

To widen the practical lens further, consider the example of a model year window that has historically presented a target for many replacement parts catalogs. A commonly listed configuration targets the 2004–2012 Galant 2.4L 4-cylinder ES variant, where the rear shock assembly is often presented as a complete left-and-right kit. This packaging approach is convenient because it ensures symmetric damping behavior and simplifies installation, reducing the risk that an out-of-spec pair could upset the balance of the car’s rear end. The reality is that this kind of listing is a strong reminder of how the aftermarket supports the Galant across multiple markets, enabling owners to source a matched set that aligns with their driving style, climate, and road conditions. The availability narrative is not about a single, universal answer but about a spectrum of viable solutions that can be chosen and adapted over time.

Across all these considerations, it helps to keep a few guiding questions in mind. What is the daily driving pattern, and how much time is spent on roads that test damping performance? Is the owner seeking a subtle improvement in everyday ride quality or a more pronounced upgrade in handling for occasional spirited driving? What is the budget, and how much value is placed on durability, warranty protection, and service support? And finally, what is the level of comfort with car maintenance tasks, including alignment checks and potential readjustments after installation? By answering these questions, a Galant owner can navigate the list of rear shock options with a sense of purpose, selecting a design that complements the vehicle’s personality and the owner’s expectations, rather than chasing a trend.

The conversation about rear shock absorbers for the Galant is inseparable from the broader theme of reliable, predictable performance. The right shock, installed with care and matched to the car’s geometry, keeps the rear end composed when the pavement bites back. It preserves tire contact with the road, supporting both braking stability and cornering grip. It helps ensure that when the car is loaded with passengers or luggage, it remains balanced rather than adopting an unsettled, pogo-stick feel. In that sense, the rear shock absorber is not a cosmetic upgrade but a fundamental stability component that quietly guards comfort, safety, and confidence on every journey.

For those who want a tangible touchstone as they explore options, a representative reference point to a broader ecosystem can be found in one of the catalog pages that describes an Evo-series shock component. The page presents a glimpse into how shock design can be aligned with a particular performance philosophy without straying from the practical realities of replacement parts for a sedan like the Galant. While the Galant and the Evo lineup are not the same vehicle family, the shared engineering language—tighter damping control, robust construction, and a willingness to meet a range of driving scenarios—offers a useful perspective on what is possible when a driver ventures beyond stock hardware. The principle remains consistent: the best rear shock choice is the one that preserves the vehicle’s intended handling balance while delivering reliable, predictable performance across a spectrum of road conditions.

In closing this contemplation of rear shock options, the emphasis rests not on chasing a trend but on cultivating a compatible, durable, and well-supported upgrade path. The Galant, with its balanced roots in everyday usability and occasional sportier expression, benefits most from a choice that preserves its inherent stability while offering the flexibility to adjust for personal taste and local conditions. The availability narrative—through global suppliers that offer sets designed for mid-2000s Galant generations, packaging as complete pairs, and warranty terms that provide a reasonable horizon—rounds out the practical picture. Buyers and enthusiasts alike can approach the decision with confidence, knowing that a thoughtful selection can sustain comfortable, controlled, and engaging driving experiences for years to come.

As a practical next step, readers might consider tracing the broader suspension ecosystem across Mitsubishi models to understand how related platforms approach damping and chassis tuning. This cross-model perspective often reveals common design threads that inform compatibility and upgrade paths for the Galant. The journey through the rear shock absorber landscape thus becomes part of a larger exploration of how a well-balanced suspension translates into everyday reliability and driving enjoyment.

Internal reference for further nuance and a sample product narrative can be found here: Evo 4-9 shock block product page. This link offers a window into how related shock configurations are documented and marketed within the Mitsubishi aftermarket ecosystem, illustrating how a broad family of shock designs is organized and described for various models and requirements. In parallel, readers can explore external catalogs and supplier portals to compare pricing, lead times, and warranty terms across different regions, ensuring an informed choice that matches the Galant’s dynamics with practical procurement considerations.

External resource for broader context: https://www.alibaba.com

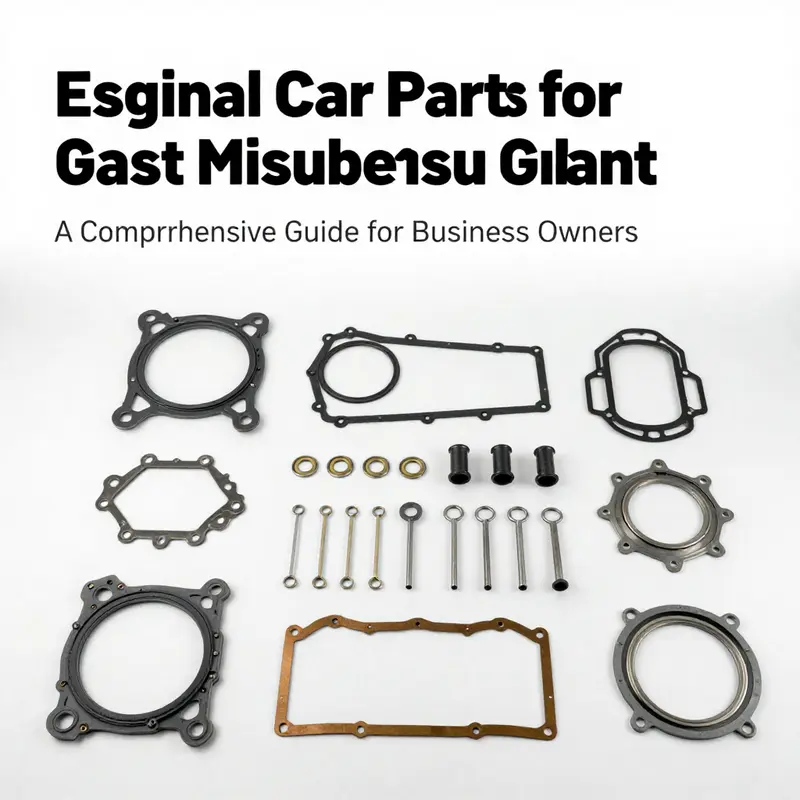

Engine Overhaul Gasket Kit for Mitsubishi Galant: Details and Customizations

When rebuilding the heart of a Mitsubishi Galant from the early 1990s, particularly the 1992–1996 E52A generation equipped with the 4G93 engine, the gasket kit you choose can determine the difference between a reliable restoration and a recurring slate of leaks and overheating problems. The engine overhaul gasket kit, in this context, is not a mere collection of individual seals but a carefully engineered assembly designed to restore the integrity of the powerplant as a cohesive whole. For mechanics and enthusiasts alike, the kit represents a focused synthesis of compatibility, durability, and installation convenience. It is a reminder that the Galant’s enduring reputation rests not only on its chassis balance and drivetrain layout but on how well the engine seals perform under the demands of repeated starts, high-temperature cycles, and the unforgiving conditions of real-world driving. An overhaul kit tailored to the 4G93’s architecture offers a path to a rebuild that feels like factory refresh rather than a patchwork of disparate components. The essence of this approach is engineering discipline: every gasket, every seal, and every corresponding o-ring is specified to fit with the engine’s unique bore, valve timing, and lubrication pathways. In practice, that means choosing a kit that is designed for the exact model year and displacement, ensuring not just a physical fit but a sealing performance matched to the engine’s thermal and mechanical profile. The 4G93’s cylinder head, intake and exhaust interfaces, valve train oil passages, and crankcase seals all demand a coordinated sealing strategy. A well-designed overhaul kit provides that strategy in a single, coherent package. It reduces guesswork for the technician and minimizes downtime, which matters when a workshop must turn around a Galant for a customer or fleet vehicle in a predictable maintenance window. The emphasis is not on novelty but on fidelity: a gasket kit that mirrors the OEM layout and tolerances, while incorporating modern materials and high-temperature formulations, can deliver a rebuild that withstands the heat, pressure, and cyclic stresses of typical daily use, even in regions with colder starts or higher altitude driving. In the Galant’s case, the kit’s value proposition rests on three pillars: material excellence, comprehensive coverage, and installation clarity. Material quality is not merely a matter of selecting a gasket made from a durable composite or rubber. It is about selecting compounds that resist corrosion and shrinkage over time, while withstanding the engine’s exposure to thermal cycling, oil immersion, and fuel-related contaminants. A modern overhaul kit uses corrosion-resistant materials and high-temperature-resistant synthetic compounds that retain elasticity and sealing force across a wide temperature band. This is essential for the Galant’s 4G93, which experiences rapid heat rise during operation and must maintain a seal as the engine returns to ambient temperatures. The durable rubber formulations and synthetic seals are designed to resist cracking, hardening, or swelling in response to oil contaminants or coolant exposure. The goal is a sealed environment that keeps compression within the cylinder head gaskets stable, oil seals dependable, and valve covers free of seepage. The comprehensive design aspect of the kit is particularly important. Rather than purchasing gaskets and seals piecemeal, the overhaul kit bundles a complete set of gaskets and seals that cover all the critical interfaces: cylinder head gaskets, valve cover gaskets, oil seals, cam seals, crank seals, and any other seals essential to the engine’s lubrication and sealing pathways. This approach is efficient because it prevents the common pitfall of overlooking a small but critical seal during a rebuild. When a mechanic follows a single, all-encompassing kit, the risk of gaps diminishes and the rebuild workflow becomes more predictable. The result is a rebuild that behaves like a well-tuned, original engine. The installation experience is where the benefits become tangible. A high-quality overhaul kit is designed with the installer in mind. Components arrive pre-assembled in a logically organized fashion and are labeled to indicate their position and function. Industry-standard practices—such as color-coded trays or grid layouts for easy identification of cylinder head gaskets versus valve seals—reduce misidentification and assembly errors. For the technician, this translates into a smoother procedure, fewer missteps in torque applications, and a shorter window of downtime. In addition, the packaging often reflects an intention to assist both professionals and home mechanics, with clear documentation that outlines the required torque sequences, gasket compression ranges, and any specific installation notes that apply to the Galant’s 4G93 configuration. The practical payoff is the confidence to proceed without having to consult multiple sources mid-rebuild, which can dramatically speed up the turnaround time and minimize the chances of rework. Behind the scenes, the engine overhaul gasket kit is rooted in a careful balance between OEM compatibility and modern material science. The existence of a kit designed for the 4G93-based Galant signals attention to the engine’s original architecture—its bore spacing, head gasket profile, oil passage routing, and coolant channels. When designed with OEM alignment in mind, the kit helps preserve the engine’s thermal management, lubrication efficiency, and mechanical interface with the rest of the drivetrain. This degree of fidelity matters because an engine rebuild is not merely about sealing; it is about preserving the precise geometry that allows the engine to maintain compression, avoid oil leaks, and sustain proper oil pressure during high-load operation. A kit that respects the engine’s original geometry supports consistent valve timing seals, a reliable oil control system, and stable cooling gallery seals, all of which play into the Galant’s long-term reliability and performance. An important, often overlooked aspect of choosing and using an overhaul gasket kit is the consideration of climate and operating environment. Cold-start conditions at high altitude can put unusual stresses on seals, particularly along temperature-shift cycles that drive oil viscosity changes and shrinkage of rubber compounds. A kit that anticipates these conditions—through stronger, temperature-tolerant compounds and robust elastomer profiles—can deliver better sealing performance when the engine first fires up in a chilly morning or after a long climb into thinner air. This type of customization is not about chasing formal novelty but about ensuring reliability where it matters most. Customization in this context can include materials with thickness tolerances that suit particular rebuild goals or service expectations. Some kits offer an adjustable tolerance band (for example, ±5% in material thickness) to accommodate variations that arise from different manufacturing batches or from specific engine variants. For shops that service a mixed fleet of Galants or that handle related platforms with the same engine family, having the option to tailor the gasket materials to climate or fuel quality can translate into longer seal life and reduced call-backs. While the Galant’s 4G93 engine is relatively simple in its overall architecture compared with modern engines, it still benefits from thoughtful customization. In practice, the customization might involve selecting a gasket kit with variants that accommodate slightly different head gasket thicknesses or seal hardness, ensuring that seals maintain proper seating pressure across the engine’s temperature range. The choice of a kit designed for the 4G93-based Galant should also take into account the engine’s lubrication regime and oil viscosity under typical driving conditions. The right seals will tolerate synthetic or conventional oil blends and will maintain effective sealing even as oil pressure fluctuates during start-up or high-RPM operation. The holistic view is that the system’s integrity—coolant channels, oil passages, valve-train interfaces, and piston rings—must all work in harmony with the kit’s components. This reduces the chance that a rebuild will be compromised by an overlooked or mismatched seal, and it increases the likelihood that the Galant will perform reliably after the rebuild under a broad spectrum of driving scenarios. For practitioners who also work across a broader Mitsubishi parts ecosystem, a practical reminder is that the underlying principle of an effective overhaul gasket kit remains constant: alignment with the engine’s original design, robust materials, complete coverage, and installation simplicity. In this sense, the Galant’s rebuild becomes a model for how modern gasket solutions should behave under real-world use—delivering predictable performance, minimizing maintenance surprises, and supporting long-term ownership experience. To illustrate a practical touchpoint in the broader parts ecosystem, consider how such a kit aligns with standard packaging and labeling practices commonly observed across Mitsubishi-part catalogs and workshops. Although the specific catalogs vary, the principle remains: clear labeling, correct part positioning, and precise part-to-engine matching. This alignment matters not only for new-build projects but also for routine maintenance of aging Galants that have accumulated mileage and wear. It reinforces the broader narrative that automotive parts, even those as seemingly simple as gaskets and seals, deserve the same level of attention given to more visible components like pistons or camshafts. For readers exploring related parts in the same maintenance ecosystem, a catalog entry from the broader Mitsubishi parts catalog demonstrates the same attention to position, labeling, and compatibility that a high-quality overhaul gasket kit embodies. See an example of catalog clarity here: 03-06-mitsubishi-evolution-8-9-jdm-rear-bumper-oem, which, while focusing on a different component, echoes the same spirit of standardized part presentation and ease of integration that benefits engine rebuilds across model lines. This internal cross-reference highlights how standardized packaging and consistent labeling contribute to smoother maintenance workflows, whether you are rebuilding a Galant’s engine or replacing a rear bumper on a related model. The takeaway is not to chase brand prestige but to pursue a reliable, properly matched kit that makes the rebuild predictable, durable, and repeatable. When the job is done, the Galant that rolls out of the shop with a refreshed 4G93 engine gains more than new gaskets; it gains a renewed sense of reliability and a return to everyday drivability. The engine no longer carries the burden of uncertain seals and inconsistent compression. Instead, it returns to the road with confidence, ready to meet the demands of highway cruising, city commutes, or spirited weekend drives. The overhaul kit is, in essence, a compact investment in the Galant’s future, a safeguard against the small, often overlooked leaks that can escalate into more significant mechanical issues if left unaddressed. It represents the culmination of careful engine design understanding, quality material science, and practical installation considerations that together preserve the vehicle’s original balance and the owner’s peace of mind. External resource: https://www.alibaba.com/product-detail/KOWZE-MD970445-Car-Engine-Overhaul-Gasket-Kit-for-Mitsubishi-Galant-4G93-1992-1996.html

Final thoughts

Understanding the essential car parts for the Mitsubishi Galant, such as water pumps, rear shock absorbers, and engine overhaul gasket kits, equips business owners with the necessary knowledge to make informed decisions. By collaborating with reputable suppliers and leveraging customization options, you can greatly improve the service offerings of your business. Each of these components plays a fundamental role in vehicle performance and reliability, which in turn, enhances customer trust and satisfaction. Stay ahead in the competitive automotive market by integrating these insights into your procurement strategies.