The Mitsubishi Lancer, a well-respected name in the automotive industry, offers an exceptional range of engine technologies that cater precisely to the diverse needs of business owners. Understanding the engineering prowess behind this vehicle is vital for fleet managers and business professionals looking to maximize efficiency and performance. This article details the core engine technologies that define the Mitsubishi Lancer, explores the various engine options by displacement, and discusses performance enhancements and modifications that can elevate the Lancer’s capabilities. Each chapter will enhance your grasp of what makes the Lancer an ideal choice for professionals seeking reliability and performance in their vehicles.

Heart and Craft: How Mitsubishi Lancer Engines Balance MIVEC, Turbo Power, and Everyday Driveability

Core engine technologies define how a Mitsubishi Lancer feels, responds, and performs. At the center of that engineering philosophy sits a variable valve-timing system that reshapes the engine’s personality across the rev range. But the Lancer’s appeal goes beyond a single innovation. Its family of engines ranges from fuel-frugal four-cylinders for daily commuting to rally-bred turbocharged units built for speed and control. The result is a lineup engineered to suit different priorities while sharing a commitment to durability and usable performance.

Mitsubishi’s valve-timing system is the most visible technological thread across many Lancer engines. This system optimizes valve opening and closing events to match engine speed and load. At low rpm it improves torque and drivability. At higher rpm it allows the engine to breathe more freely and extract more power. The benefit is not just peak figures on a dyno. It is a flatter torque curve, smoother throttle response, and better fuel economy across mixed driving. For drivers who want crisp city manners and capable highway passing, this variable timing gives a single engine the flexibility to perform both roles convincingly.

Beyond valve timing, Lancer engines use modern combustion and breathing strategies. Dual overhead camshaft heads appear on several mid-sized engines. They allow more precise valve control, reduce valvetrain inertia, and help the variable timing system operate more effectively. Intake and exhaust port shapes are tuned to give strong midrange torque without sacrificing high-rpm power. Direct and multi-point fuel injection strategies improve atomization and reduce fuel consumption. Combined with the variable timing, these measures yield engines that are both responsive and efficient.

The Lancer’s engine architecture covers a practical range of displacements and configurations. At the economical end sits a compact 1.6-liter four-cylinder. Its double-overhead-cam layout and advanced timing deliver surprisingly smooth low-rpm behavior. This engine is built for daily use and commuting. It emphasizes fuel economy, low emissions, and minimal maintenance. With power figures in the lower triple digits, it is not designed for spirited driving. Yet its lightness and efficiency make it an ideal choice for urban drivers who value running costs and reliability.

Stepping up, the naturally aspirated 2.0-liter four bridges comfort and capability. It often represents the sweet spot for many Lancer owners. With stronger midrange torque and a broader usable power band, the 2.0 delivers confident highway merging and relaxed overtaking. Fuel economy remains competitive for the class, but the real advantage lies in drivability. This engine’s tuning favors a balance between responsiveness and refinement. It benefits from the variable timing system, which lifts low-rpm tractability and delivers a livelier throttle feel at higher revs. For families and daily drivers who expect versatile performance, the 2.0 is the practical choice.

For performance-focused models, turbocharging transforms the engine’s character. A turbocharger compresses intake air, allowing more fuel to be burned. The result is a dramatic rise in power and torque without increasing engine displacement. In sport-oriented Lancer variants, the turbocharged two-liter engine produces significantly higher output and a far more aggressive throttle response. It is built to tolerate higher cylinder pressures and increased heat, requiring reinforced internals and robust cooling. These performance engines also pair with advanced drivetrain systems to ensure traction and control under load.

One example of rally-derived engineering appears in the high-performance two-liter inline-four used in certain Lancer models. That engine is designed for sustained force across a wide rpm range and couples with a full-time all-wheel-drive system. The drivetrain balances torque delivery among the wheels, improving traction in low-grip situations and during spirited cornering. Performance diff systems further refine torque distribution, reducing wheelspin and improving turn-in behavior. These features transform a powerful engine into an effective tool on winding roads and loose surfaces alike.

Valve timing and turbocharging are not the only considerations. Engine mounts, throttle bodies, and ancillary systems play important roles in how an engine communicates with the car and driver. Mount design affects vibration, NVH, and perceived solidity. Hydraulic mounts provide a smooth, quiet ride by damping vibrations with fluid chambers. Solid rubber mounts are simple, durable, and cost-effective. For drivers who want a firmer connection and improved response, polyurethane mounts are a common upgrade. They reduce compliance at the cost of transmitting more vibration into the cabin. For a balance of comfort and control, many owners accept the factory hydraulic mounts or choose a progressive aftermarket option.

The throttle body is another piece that influences engine behavior. Modern throttle bodies integrate electronic controls for precise management of airflow. A well-engineered throttle body has a smooth bore and a valve designed to minimize turbulence. Corrosion-resistant materials extend service life and help maintain consistent airflow over time. Improvements in throttle design can raise engine efficiency and slight increases in power by improving how the engine breathes. For tuners and enthusiasts, aftermarket throttle bodies can provide measurable gains, especially when matched with other intake and tuning upgrades.

Cooling and lubrication systems are equally vital for long-term engine health, especially in higher-output variants. Turbocharged engines operate at higher temperatures and require robust cooling circuits, larger radiators, and often upgraded oil pumps. Heat management extends beyond radiators; it includes intercoolers to reduce the temperature of compressed intake air. Cooler air increases density, allowing safer ignition timing and better power. Oil coolers and high-flow oiling systems help preserve bearing and piston ring integrity under sustained loads. These enhancements become essential when an engine is tasked with sustained high power or track use.

Chassis integration magnifies the effect of engine improvements. A reinforced chassis reduces flex under load, allowing suspension geometry to remain consistent. That translates to sharper handling and more precise feedback from the tires. In performance Lancer models, engineers increased body rigidity and upgraded suspension components to match higher engine outputs. Those chassis upgrades ensure power is usable and predictable. They also help maintain alignment and tire contact during hard cornering, improving lap times and safety.

Maintenance and reliability are central to the Lancer’s appeal. Engines designed with conservative thermal and mechanical limits often last longer with routine care. The variable timing system demands proper oil quality and timely changes, because timing mechanisms rely on clean oil for precise operation. Regular inspections of mounts, belts, and cooling components prevent small failures from escalating. For turbocharged engines, paying attention to oil temperature and pressure is especially important. Warm-up and cooldown routines help preserve turbo bearings and reduce thermal stress.

The tuning potential of each engine varies. Naturally aspirated engines offer predictable gains through intake, exhaust, and camshaft work. Turbocharged engines respond well to boost, fueling, and timing adjustments, but they require supporting upgrades to remain reliable. Forged internals, reinforced cooling, and improved fueling are common steps on the path to higher outputs. Electronic engine management, whether through a standalone controller or a recalibrated factory unit, allows precise control over ignition timing and fuel delivery. Tuning must respect the engine’s mechanical limits to preserve longevity.

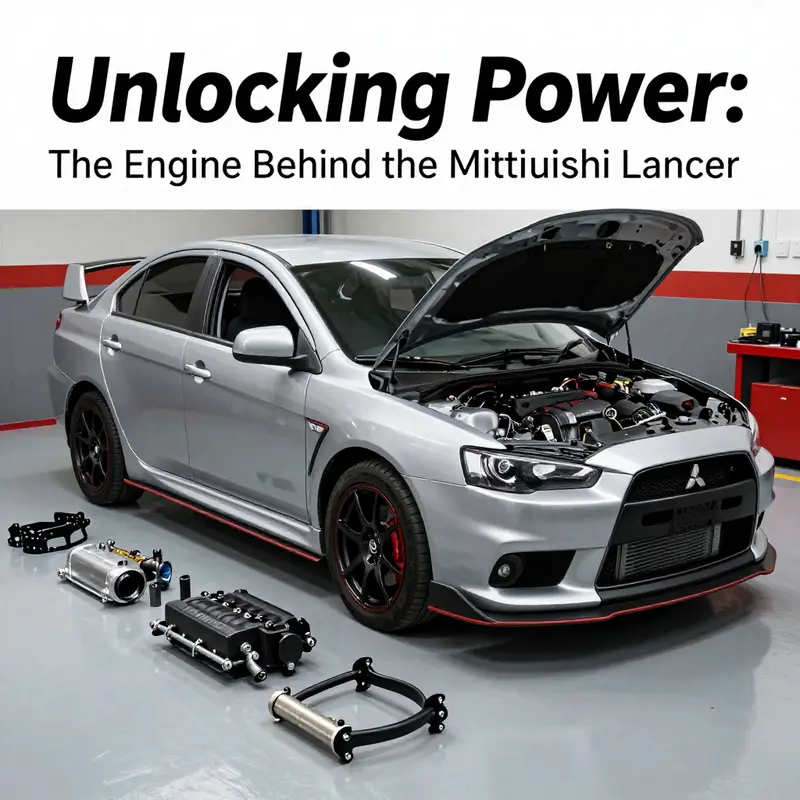

Owners often choose upgrades that reflect how the car will be used. For street-driven Lancers, improvements that enhance throttle response and midrange torque are popular. On-track or rally use demands heavier investment in cooling, oiling, and drivetrain components. Suspension and brake upgrades complement engine work, ensuring the car can harness additional power safely. A holistic approach yields the best results: power gains without corresponding improvements in control and cooling can create weak points and raise safety concerns.

Parts availability and aftermarket support have shaped how the Lancer evolves in the hands of enthusiasts. High-performance engines attract strong parts ecosystems. Rebuildable short blocks, strengthened connecting rods, and upgraded cams are common items. For the more modest engines, bolt-on upgrades can yield enjoyable real-world improvements without drastic expense. The presence of an active aftermarket makes it easier to tailor a Lancer to individual priorities.

Despite the emphasis on performance, fuel economy and emissions control remain central design goals. Technologies that improve economy often benefit emissions simultaneously. Variable valve timing, refined combustion chamber geometry, and precise fuel injection reduce unburned hydrocarbons and improve efficiency. Manufacturers tune engines to meet regulatory requirements while retaining character. That balancing act explains why many Lancer engines feel lively, yet remain practical for everyday use.

Every engine in the Lancer family is a compromise between power, economy, durability, and cost. Engineering teams optimize each unit for its intended role. The compact 1.6 offers low running costs and adequate performance. The 2.0 provides flexibility for families and commuters. Turbocharged units deliver exceptional performance and benefit from tougher internals and enhanced systems. Across all variants, core technologies like variable valve timing and modern fuel injection create engines that are efficient, responsive, and reliable.

For enthusiasts seeking a historically significant high-output example, there are authentic sources for the rally-proven engine found in earlier high-performance Lancer models. These listings help preserve and restore classic performance vehicles. One such listing details a genuine JDM 4G63T 2.0L DOHC turbo engine that includes transmission and ECU. That resource is useful for restorations and engine swaps. genuine JDM 4G63T 2.0L DOHC turbo engine listing

For a deeper technical read on valve-timing systems and engine technologies that complement them, consult the manufacturer’s engine technology overview. It provides insight into how modern timing strategies, fuel systems, and materials work together to balance performance and efficiency. https://www.mitsubishi-motors.com/engines/technology.html

Displacement Dialogues: Tracing the Lancer’s Engine Range from City Runabouts to Rally-Bred Power

Across generations, the Mitsubishi Lancer has carried a quiet, persistent argument about what a car’s heart should do. It should sip fuel when the road calls for economy, yet roar with purpose when the need for speed arrives. Displacement became the guiding thread through that argument. It shaped how engineers balanced daily practicality with the brand’s rally heritage, how markets with different needs perceived value, and how enthusiasts learned to listen for a particular cadence in the engine’s note. The Lancer’s engine lineup spans a spectrum—from compact, city-friendly mills to high-spirited, turbocharged powerplants—each tuned to a different mood and a different choreography of throttle, torque, and efficiency. The result is a lineage that reads like a map of driving intent: from the hum of a small, economical four to the thunder of a boosted engine that can punch well above its weight in the right hands. This chapter threads those options together, showing how displacement becomes not just a number on a spec sheet but a narrative of how the Lancer evolved to meet evolving roads and ambitions.

At the base of the spectrum sits the smallest, most economical end of the family. In early models, a 1.3-liter configuration was common in markets that valued affordability and low running costs over outright performance. These units emphasized reliability and efficiency, delivering modest horsepower and torque that kept urban commuters moving with minimal fuel bills. The goal was simple: keep the car light, keep the power modest, and let the chassis and gearing do the rest. As the Lancer lineage matured, the engine choices broadened, and the 1.3-liter option became a reference point for what a practical, reachable daily driver could be. It was never about thrilling acceleration, but about a predictable, economical rhythm for daily life.

As the early generations progressed, the 1.6-liter class emerged as a practical bridge between economy and everyday livability. Within this displacement band, Mitsubishi introduced more advanced valve timing strategies that optimized how and when the engine breathed. In practical terms, this meant crisper response at light throttle, better mid-range pull, and improved efficiency across typical driving cycles. The 1.6-liter family bridged the gap between the smallest urban mills and the larger, more aggressive engines that would follow, proving that modest displacement could still deliver a welcome mix of driveability and economy. The essence of this era was not merely a shift in numbers but a refinement of how the engine delivered power under real-world conditions—more torque where you needed it, without a heavy appetite for fuel at the pump.

But the Lancer’s story is not a straight line toward larger numbers. It also charts how engineers refined breathing and timing to extract usable performance from the same block. Enter the 1.6-liter DOHC variants that carried with them a higher degree of control over valve timing. This approach improved throttle response and low-end torque, letting the Lancer feel more eager in city streets and on back roads alike. Yet these gains did not come at the expense of efficiency; the aim was to remain docile at ordinary speeds while offering a meaningful uptick when the accelerator’s tempo quickened. Such duality—quiet efficiency at one end, satisfying liveliness at the other—became a recurring theme in the Lancer’s engine narrative.

Moving up the scale, the 1.8-liter class offered a more engaging balance. In many markets, this displacement found itself in a sweet spot where power and economy coexist with sensible daily practicality. The 1.8-liter engines provided a noticeable performance lift over the smaller mills, producing enough torque for confident highway merging and spirited weekend driving while still returning respectable fuel economy. What mattered most in this middle ground was not simply the peak horsepower figure but the character of the engine’s delivery: a smooth, progressive pull that broadened the usable torque band and kept the car feeling responsive across a broad range of speeds. The Lancer could feel lighter on its feet thanks to a more favorable torque curve, enabling relaxed cruising in everyday use and a touch more zest when the road demanded it.

The centerpiece of the broader displacement narrative, however, is the evolution of the 2.0-liter family. The naturally aspirated 2.0-liter option became the mainstream backbone for many Lancer models, delivering a robust and balanced blend of power, torque, and efficiency. This mill offered a confident mid-range surge and a refined top-end character that appealed to drivers who wanted more than just comfortable daily transport. In practice, it translated to solid midrange acceleration, quick response in overtaking maneuvers, and a level of smoothness that made long trips more wearable. The 2.0-liter NA variant proved that displacement on its own, when paired with modern valvetrain technology and precise engine management, could deliver a broad, well-rounded driving experience that suited a wide audience—from busy families to weekend explorers.

Yet perhaps the most consequential leap within the Lancer’s engine family is the rise of the turbocharged 2.0-liter configuration. Turbocharging transformed the displacement story from a matter of simple balance into a study in riotous potential. The turbocharged two-liter engine unlocked rally-inspired throttle response and a surge of power as the revs rose. It made the Lancer feel lighter, more agile, and unexpectedly quick when the throttle was pressed. The engineers faced a delicate balancing act: how to harness the turbo’s power without compromising the efficiency and smoothness that modern buyers expect. The solution lay in a combination of robust internals, refined intake and exhaust paths, and a sophisticated engine-management strategy that could modulate boost, air-fuel mixture, and timing across driving regimes. The result was a powerplant that could deliver a strong, usable punch in daily driving and unleash a more aggressive character for spirited driving or performance-focused applications. The turbo era also played a pivotal role in cementing the Lancer’s association with performance culture, even as the base models retained their practical appeal.

Accompanying the displacement-focused evolution were parallel improvements in how the engine communicated with the rest of the car. The Lancer’s era-wide adoption of advanced valve timing control systems meant engines could breathe more efficiently at both ends of the rev range. This control translated into real-world benefits: steadier idle, smoother transitions, and more predictable behavior when coming off idle or applying load during climbs or overtakes. In practical terms, this meant fewer abrupt surges or lurching transitions, which can unsettle drivers and passengers alike. The engineering mindset here favored a broad, usable torque band over a single burst of peak power. The trade-off—slightly more complexity and cost—was justified by improved drivability and efficiency across the board. The result is a family of engines that could accommodate a wide range of buyers, from those seeking reliable daily transportation to those chasing a more exhilarating, turbocharged driving experience.

Within the spectrum of discrete displacement choices, there are also less common, yet notable, configurations that contributed to the Lancer’s diversity. In some markets, smaller, entry-level variants pushed even lower power outputs while emphasizing low running costs and ease of maintenance. In other markets, larger displacement options occasionally appeared, offering more outright power, refined refinement, and a greater sense of distance-covering capability. A handful of engines in this extended family leaned on legacy architectures derived from earlier generations, adapting to modern demands with updates to timing systems, combustion efficiency, and cooling. A few of these variants were even adapted to meet special-market needs, where the combination of affordability and driveability defined the product offering. The overarching theme remains: the Lancer’s engine lineup was designed to be adaptable, scalable, and broadly appealing, rather than narrowly optimized for a single use case.

This adaptability is perhaps most evident when considering how the Lancer’s engines interface with other critical components that shape the driving experience. The choice of engine displacement interacts with the chassis’ weight, suspension tuning, and gearing. It also interacts with the car’s aero profile, exhaust routing, and intake paths—factors that influence how power translates into speed and how efficiently that power is sustained on longer trips. The end result is a car that can feel at home in a crowded city, carve a canyon twist, or keep up on a highway with steady confidence. The engine is not an isolated artifact but a partner to the whole vehicle, tuning its voice to complement the chassis and the driver’s intent. In this sense, displacement is not just a measure of size; it is a language through which the entire Lancer communicates with the road.

To illustrate the practical impact of these displacement choices, it helps to anchor the discussion in real-world expectations. A modern 1.6-liter variant tends to deliver excellent efficiency for daily commutes, with smooth operation that makes city driving almost effortless. Its low-end torque, when supported by advanced valve timing management, makes stop-and-go traffic feel less tiresome and enhances fuel economy on mixed routes. A step up to the 1.8-liter range yields a more confident feel in highway cruising and a quicker response in overtaking situations, while still maintaining reasonable consumption. At the 2.0-liter mark, the natural aspiration delivers a well-rounded package—strong mid-range performance that remains practical for daily use. For enthusiasts who crave something more, the turbocharged 2.0-liter option offers an appreciable leap in performance, delivering a surge of thrust that changes the character of the car, especially on winding roads or when merging with faster traffic. The higher-displacement 2.4-liter variants, present in select markets or configurations, further reinforce the idea that you can have more power without abandoning the fundamentals of reliability and everyday usability.

Every step in this displacement ladder comes with its trade-offs, and the Lancer’s engineering team weighed these carefully. Turbocharging, for instance, introduces thermal and mechanical engineering challenges that demand stronger cooling, tighter tolerances, and more robust rotating assemblies. The payoff, however, is a car that can deliver a more exhilarating experience when needed without forcing drivers to accept punitive fuel economy in normal use. Similarly, moving to a larger displacement often yields more immediate torque and easier acceleration at modest revs, but it can also increase fuel consumption if the driver habitually operates at wide-open throttle. The beauty of the Lancer’s approach is that it presents a spectrum—a menu of choices rather than a single recipe. That gives buyers and enthusiasts the opportunity to select a car that matches their preferred balance of practicality and gusto, and it lets the model stay relevant across a broad range of markets and lifestyles.

In the realm of performance-oriented builds and enthusiast readiness, the displacement story intersects with aftermarket and tuning culture. The turbocharged 2.0-liter family, in particular, has long invited experimentation because the core concept—a compact, high-revving engine boosted by a controlled air boost—lends itself to predictable upgrades and scalable performance. For those who want to push the envelope, the path from a stock, street-friendly daily driver to a weekender-ready machine is paved with choices about internals, boost management, and cooling. An informed approach emphasizes reliable, deliberate upgrades that respect the engine’s fundamental design while extracting more performance without compromising daily usability. In this space, even a seemingly small change to the block or associated components can ripple through the car’s behavior, altering torque delivery, response times, and the way the car feels at different speeds and temperatures. Although the exact configurations vary by market and generation, the principle remains enduring: the Lancer’s engine range is a platform for both dependable transportation and the thrill of performance engineering, depending on how the owner chooses to tune and drive it.

One can glimpse the broader pattern by noting how the displacement ladder interacts with the car’s drivetrain architecture and its control systems. The amount of air the engine can pull in, the timing of the valve opening and closing, and the engine-management software all converge to determine the power curve. In a naturally aspirated setup, the emphasis lies on optimizing airway efficiency and combustion quality to maximize usable power across the rev range. In a turbocharged configuration, the emphasis shifts toward managing boost, heat, and spark timing so that the engine remains tractable and predictable, even under heavy throttle. Across these conditions, the car’s weight, chassis stiffness, and tire grip all influence how displacement translates into the actual driving experience. It is here that the Lancer’s engine philosophy reveals itself as pragmatic engineering—an approach that respects everyday duty while still offering room for emotion and excitement when the road invites it.

For readers who want to connect the learning from this displacement-focused narrative to practical, device-level choices, consider how the engine’s breathing and timing might be adjusted within reasonable limits to improve a specific aspect of performance. The concept of a more efficient valve-timing system, which can modulate when intake and exhaust operate, is central to how modern engines deliver both power and efficiency. When this concept is applied to different displacement classes, the result is a distinct character shift: a smaller mill becomes noticeably more willing to climb into higher revs with minimal throttle, while a larger unit gains an unmistakable, confident torque feel that helps the car pull strongly from lower speeds. In short, the Lancer’s engine family demonstrates how displacement, breathing, and control systems cooperate to deliver a coherent driving experience across a wide spectrum of use cases.

To tie this collective arc back to practical ownership, the story of the Lancer’s engines is really a story about choice. Buyers could prioritize economy and daily comfort, selecting the smaller, efficient mills with refined valve timing management. Or they could opt for a more dynamic experience by selecting the 2.0-liter turbo variant, which reshaped the car’s personality for those who wanted more immediate, rally-like intensity. The mid-range options offered a balanced compromise, ideal for daily driving that still permitted engaging performance when the moment demanded it. In all cases, the displacement strategy was not just about pushing more power out of a bigger engine; it was about sculpting the power to fit a wide range of road situations, driver expectations, and ownership realities. The engine options by displacement in the Lancer thus become a philosophy of accessibility and depth, a reminder that engineering can deliver both practical reliability and the spark of excitement—often in the same chassis, under the same doors, and with the same four wheels taking you wherever you intend to go.

For readers curious about how high-performance enthusiasts approach the more capable end of the spectrum, a deeper dive into how the turbocharged 2.0-liter family can be enhanced is available. In particular, there are upgrade avenues that focus on strengthening the foundation while preserving daily usability. These options—from reinforced blocks to precision balancing and optimized turbo components—are designed to preserve reliability even when boosting power. If you’re exploring performance-oriented upgrades, you can consult specialized resources that document the technical paths available for these engines. For a detailed look at one such upgrade possibility, you can explore a source dedicated to high-strength performance blocks designed to handle boosted operation. This option represents a logical step for those who want more from the turbocharged configuration without compromising everyday drivability. 4b11t billet block offers a concrete example of how the displacement-driven performance story can be extended through careful engineering choices.

Across this broad landscape, the Lancer’s engine family stands as a demonstration of how a car can be engineered to respond to the needs of diverse drivers. The displacement choices, coupled with modern valve timing systems and intelligent engine management, create a vehicle that is not only capable and efficient but also adaptable. In this sense, displacement becomes a language that speaks to everyday practicality while still leaving room for the exhilaration that comes from a well-tuned turbocharged engine. The Lancer’s journey through its engine options by displacement, across generations and markets, reflects a philosophy of balance and breadth—one that has helped the model endure and connect with a wide spectrum of drivers who want something more from their car than simply getting from A to B.

External reference for deeper technical context and standards: a detailed overview of the valve-timing strategies and engine management approaches used in modern Lancer variants can be found in official technical literature published by the manufacturer. This source provides a thorough explanation of how modern valves, timing, and control systems contribute to performance and emissions, reinforcing the idea that displacement is just one axis among several that define the Lancer’s engine character. https://www.mitsubishimotors.com/technical/lancer-mivec-engine-explained/

Power Under the Hood: A Cohesive Journey into Tuning the Mitsubishi Lancer’s Engine for Performance and Longevity

The engine of the Mitsubishi Lancer has always carried a dual identity: it must serve as a reliable daily companion and, for many buyers, be a capable performer with a spark of rally-blood in its veins. Across generations, the Lancer’s powertrain has evolved from efficient, compact four-cylinders to more sophisticated, turbocharged setups that balance torque, response, and efficiency. At the heart of that evolution sits a concept that transcends parts lists: the harmonious integration of air, fuel, timing, and mechanical robustness. When we speak of performance enhancements for the Lancer, we are not simply chasing peak numbers. We are designing an engine experience—one that breathes easier, tunes itself to different conditions, and remains reliable under spirited use. The discipline begins with recognizing what the factory engineers built and where the margins exist for thoughtful, safe improvement. In this sense, performance is not a blind sprint toward horsepower; it is a careful, patient dialogue between the engine’s breathing, its timing, and how the drivetrain handles the resulting forces. From the well-proven basics to the more advanced powertrain changes, the philosophy is consistent: improve efficiency where possible, increase airflow where it matters, manage heat, and tune control systems so that every added gram of air or fuel translates into actual performance rather than just noise and temperature rise.

Starting with the basics, the engine’s ability to breathe cleanly and consistently is foundational. A clean, properly rated air intake is more than a matter of top-end power. It reduces the likelihood of lean conditions and detonation, helps the throttle respond crisply, and preserves stability when the engine is under load. A simple air-filter upgrade, when matched with a well-designed intake tract, can yield meaningful gains in response and throttle manners, especially in urban and mid-range driving where the engine operates most often. Yet the improvements are subtle and must be balanced with filtration efficiency and dust exposure. The next layer, the lubricating system, protects those moving parts under higher stress. High-performance oils do more than reduce friction by texture and viscosity; they form a film that resists thermal breakdown when the engine is working harder than usual. In practice, this means selecting an oil with the right viscosity for the climate and the engine’s tolerance to heat, then changing it at intervals that reflect the extra stress of spirited driving. Spark plugs, too, deserve respect. Worn or fouled plugs alter combustion speed, promote misfires under boost, and blunt mid-range torque. Maintaining fresh plugs tailored to the engine’s compression and ignition strategy ensures that the air-fuel mixture is converted into usable power consistently. These maintenance steps have a compound effect: they preserve shutdown fuel economy, reduce unexpected knock, and preserve a healthy baseline for any further modifications. They also set the stage for more ambitious gains because the engine’s actual condition matters as soon as you begin to push air and fuel limits higher.

Beyond breathing and combustion, the intake side of the equation deserves careful attention. Modern Lancer engines rely on electronically controlled sensor input and precise timing to manage air mass and mixture. A properly selected intake upgrade—paired with a high-quality throttle body and uninterrupted air path—offers a more dense charge into the cylinders. The benefit is not only a higher peak horsepower figure, but a more usable mid-range torque character. A cold air approach, when implemented thoughtfully, provides cooler air that is denser and less prone to pre-ignition in hot conditions. The gain tends to show up as better throttle response and more predictable power delivery in everyday driving as well as in spirited scenarios. Importantly, a larger intake must be matched with exhaust and fuel-system adjustments to avoid an unintended lean condition, particularly when boost is introduced or increased. An integrated approach—air, fuel, timing—yields a cohesive improvement rather than a series of isolated tweaks.

For turbocharged variants, the performance story deepens. A turbocharger expands the engine’s breathing dramatically, but it also raises the stakes in terms of heat, fuel demand, and structural stress. The broad path toward meaningful gains starts with aligning the turbo’s size and the boost level with the engine’s internal strength and the fuel-system’s capability. Upgrading to a larger unit can unlock more air and greater potential, but it must be accompanied by a corresponding fuel-system upgrade to prevent a lean condition. In practical terms, a higher-capacity fuel delivery setup, paired with an appropriate back-pressure management strategy, ensures that more air does not outrun the supply of fuel. This balance is critical because the real power of a turbo lies not only in the turbo’s capability to push air but in the engine’s capacity to burn it safely across the entire RPM range.

A calibrated engine-management strategy is essential when boost becomes part of the equation. An external tuning solution allows real-time adjustments to ignition timing, fuel delivery, and boost pressure. The intent is to maintain a safe, efficient relationship between air, fuel, and timing so that the engine remains robust under higher stress while unlocking the intended performance. The tuning process is iterative and data-driven, relying on a mix of wideband feedback, temperature monitoring, and mechanical health checks. It is not a ritual of cranking up numbers; it is a disciplined refinement that keeps friction and heat in check while extracting the maximum usable power from the air mass flowing through the system. The boost control strategy, too, matters. A dedicated controller tailored to the engine’s particular boost curve can provide fine-grained management of how quickly boost rises with RPM and load, preserving tractable throttle feel and drivability at lower speeds while still delivering the rush when the pedal goes to the floor. The objective is smooth, predictable power delivery rather than sudden surges that disrupt traction or overwhelm the drivetrain.

Exhaust flow is the natural counterpoint to intake and boost. A performance exhaust system reduces backpressure and encourages freer exhaust gas evacuation. The result is not only more power and torque but improved exhaust scavenging, which helps the engine breathe at higher RPMs. The exhaust path, including the header design and pipe diameter, shapes the engine’s torque curve and its character across the band. In a well-balanced setup, the added flow produces a more aggressive engine note without becoming a drone in daily driving. The exhaust strategy, however, should be harmonized with the intake and boost approach. In practice, that means considering the entire exhaust length, catalytic efficiency, and the impact on emissions. While the aim is to maximize performance, the approach should still respect local rules and the vehicle’s overall integrity.

With more air and fuel moving through the engine, the drivetrain receives the added loads. Strengthening the clutch ensures the increased power is translated to the wheels without reliability concerns. A heavy-duty clutch can handle higher torque levels but must be chosen with an eye toward pedal effort and daily usability. Transmission lubrication is another non-glamorous but vital piece of the puzzle. Upgrades to oil pumps and cooling lines help protect the geartrain during sustained high-performance driving. The goal is to manage heat and wear so that the driver does not reach a point where repeated launches or hard shifts become expensive or risky. These considerations highlight a core theme: performance is a system property. Upgrading the engine without protecting the clutch, gearbox, and differential can shift the problem from mere horsepower to driveline fatigue and reliability questions.

For those seeking more extreme performance, the concept shifts from optimization within the existing architecture to deeper engineering changes. Engine transplants from more powerful variants, while a significant undertaking, illustrate how modern Lancers can be reimagined as the result of carefully planned powertrain swaps. Such an approach requires careful matching of engine electronics, mount points, cooling capacity, and supporting systems. It is not a casual upgrade; it is a full integration project that demands technical depth, precise fabrication, and a clear plan for calibration and emissions considerations. Similarly, internal upgrades such as forged pistons or stronger connecting rods can bolster reliability under higher boost and compression. These components, however, carry implications for lubrication, cooling, and the engine’s overall balance. When paired with a comprehensive ECU reprogramming strategy, the engine management system can align timing maps and fuel tables to the new hardware, ensuring a harmonious relationship between all parts. It is this level of integrated thinking that separates a mere modification from a true performance upgrade.

In the real-world application of these enhancements, safety and reliability must remain guiding principles. The temptation to chase mythic numbers can overlook the practical realities of everyday driving, weather, and maintenance accessibility. A well-planned upgrade path starts with a clear objective—whether it is to improve daily drivability with better mid-range torque, to achieve a more engaging driving experience at higher RPMs, or to pursue track-focused performance while keeping emissions within reasonable bounds. The steps should be staged: refresh basic maintenance first, then address intake and exhaust balance, then consider fuel and timing controls, and finally, evaluate the stiffness and heat management of the drivetrain for sustained intervals of high-performance operation. Each stage should be validated with measurements—the air-fuel ratio, manifold pressure, ignition timing, and engine temperature—to ensure the changes deliver the intended benefits without compromising engine life. A practical takeaway is that modest, well-aimed improvements often yield more usable performance than large, isolated gains that destabilize the engine’s operating envelope.

In practice, the pathway to enhanced performance can be viewed as a dialogue between the engine’s foundational design and the owner’s goals. The Lancer’s engine family was designed to offer a broad spectrum of experiences—from efficient daily commuting to assertive mid-range power and, in the turbocharged variants, rally-inspired performance. The modern approach to upgrades respects that spectrum. It starts with dependable maintenance and controlled improvements to air intake, ignition, and lubrication, and then expands into coordinated fuel, boost, and exhaust strategies. The most compelling outcomes come not from chasing peak horsepower alone but from the engine’s ability to deliver more usable power across the RPM range, smoother throttle response, and consistent performance under varying conditions. When done thoughtfully, such upgrades can preserve the engine’s reliability while elevating the overall driving emotion—more immediate acceleration, cleaner throttle response, and a deeper sense of connection between the driver and the road.

For readers who want to explore a practical upgrade path that aligns with the Lancer’s engineering heritage, consider a focused upgrade that enhances the core block’s performance characteristics. Upgrading the block itself to a stronger variant can provide a robust foundation for higher power targets. This is a strategic choice that supports future enhancements while maintaining the engine’s structural integrity under higher loads. To learn more about a concrete pathway for strengthening the engine block, you can explore the 4b11t billet block option, which represents a targeted approach to improving durability and reliability in higher-performance applications. 4b11t billet block.

As the chapter closes on this subject, the practical takeaway is clear: power is earned through a disciplined blend of breathing, fueling, timing, and heat management. Each piece of the system matters, and the most satisfying builds honor the Lancer’s original design intent while enabling a more engaging, responsive driving experience. The journey from a factory baseline to a refined, performance-oriented engine is not about cutting corners; it is about thoughtful integration, measured testing, and respect for the engine’s life—the kind of respect that keeps a tuned Lancer reliable, maintainable, and exciting to drive on every road, every day.

External reference: https://www.mitsubishicars.com/en-us/performance-parts/lancer

Final thoughts

The Mitsubishi Lancer represents a smart investment for business owners who value both efficiency and performance in their vehicles. With a versatile lineup of engines and cutting-edge technologies like MIVEC, the Lancer caters to a wide range of driving needs—from city commuting to open highway cruising. The ability to choose from different engine displacements allows businesses to tailor their fleet for fuel efficiency or high performance, depending on their specific use cases. Furthermore, considering performance enhancements can optimize vehicle performance, making the Lancer not just a car, but a robust business asset. Understanding these dimensions is key for any business looking to leverage the advantages offered by Mitsubishi Lancer.