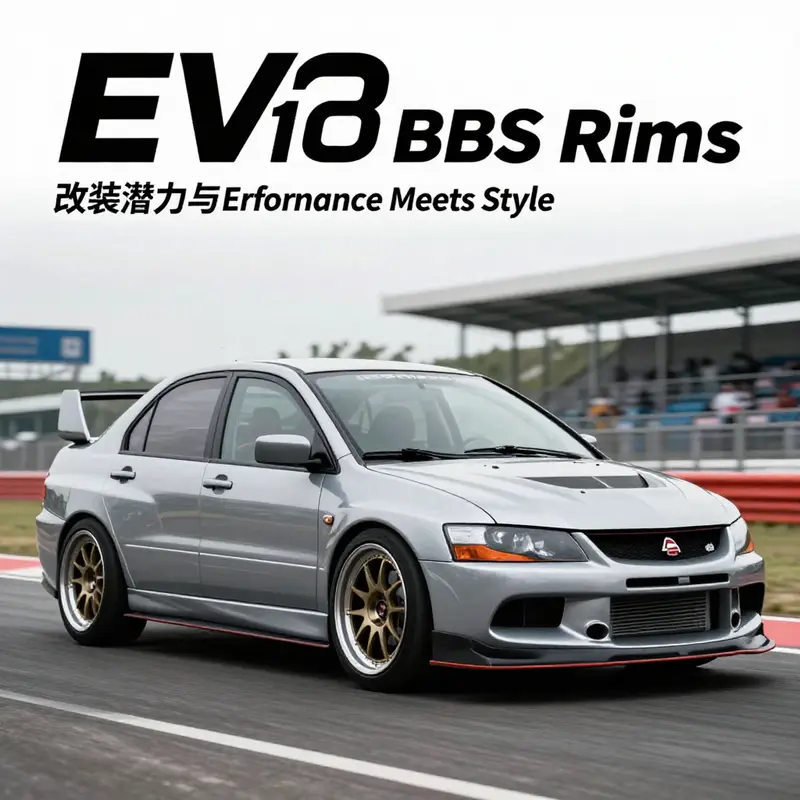

The EVO 10, introduced in 2007, epitomizes high-performance engineering, notably with its BBS rims that enhance both functionality and aesthetics. This article delves into the original equipment’s compatibility and performance advantages, explores the materials and manufacturing processes behind these iconic rims, examines their adaptability and competitive edge in the market, and discusses the vast potential for modifications that can enhance vehicle performance further. Each chapter offers insights that empower business owners to appreciate the value behind EVO 10 BBS rims, whether they operate in sales, customization, or performance upgrades.

Forged Precision: How the EVO X’s Original-Equipment Wheelset Shapes Grip, Alacrity, and On-Track Identity

The Mitsubishi Lancer Evolution X has long stood as a benchmark for how a compact sedan can feel purpose-built for the race track. In its factory configuration, the vehicle carries a wheelset that is more than a visual signature; it is a carefully calibrated part of the chassis’ behavior. The 18-inch forged wheel package, offered in a variant distinguished by its exacting wheel and tire pairing, embodies a philosophy: lightweight, rigid, and precisely matched to the car’s suspension and braking systems. For owners and enthusiasts who want to understand what makes the EVO X handle with such immediacy, the wheel choices—especially the forged, 5×112, 18-inch configuration—are a central piece of the story. On the surface, this is about wheels, but at deeper levels it is about how a performance car translates power into controlled movement through the road. The two versions that appeared in the market—the BBS-equipped version and the ENKEI version—illustrate how the same platform can be tuned for slightly different driving experiences, while still remaining faithful to the core mindset of the EVO X: the car is meant to respond without delay and to reward precise inputs with clean, predictable lines through corners and straights alike.

The core technical merits begin with weight. Forged construction is the cornerstone of the difference. In forged wheels, aluminum alloys are formed under high pressure to create a dense, homogeneous structure. The resulting weight savings are not just a number on a spec sheet; they translate into tangible, on-road performance gains. With less unsprung mass—the portion of the vehicle not supported by the suspension—the tires can better maintain contact with irregularities in the road. The suspension itself encounters less inertial resistance as the wheel rotates, so the car’s natural steering rate and primal feedback feel more instantaneous. In track terms, the car reacts to steering inputs with less delay, and the tires can follow the intended line with greater fidelity. The impact is visible in how quickly the EVO X can change direction after a corner entry and how cleanly it settles into an apex under throttle and brake modulation. These responses are not merely a matter of grip; they are the outcome of a system where the wheels are a pivotal actuator, translating engine torque into motion with surgical efficiency.

The 18-inch diameter and the 5×112 bolt pattern anchor the wheel in a familiar European performance language. The bolt pattern is not incidental; it is a practical gateway to both strength and compatibility. The EVO X’s chassis geometry and brake package were tuned around this wheel size, and that tuning matters when the car is pushed toward limit grip. A 5×112 interface is robust, supports large vented brake rotors, and offers a wide array of high-performance tire options that can be paired without sacrificing balance. The choice of 245/40 R18 tires, initially deployed by the OEM pairing, is itself a decision that harmonizes sidewall rigidity with contact patch area. The taller sidewall on a 18-inch wheel helps absorb road texture, while the relatively low aspect ratio keeps the tire’s footprint crisp enough for confident steering through high-speed sections. The result is not just grip in a straight line, but a communicative, linear feel when the car transitions from one axis to another. When a driver presses harder into a corner, there is an unambiguous line: the chassis leans, the tires bite, and the wheel returns a precise, immediate sense of the road’s topology. The overall effect is that the car feels both planted and alive, a balance that is no accident but the fruit of careful factory pairing.

Beyond the material choice, the forged wheel’s geometry complements the EVO X’s suspension architecture. The unsprung mass reduction interacts with a multi-link or MacPherson-based layout in ways that improve wheel hop control, damping efficiency, and steering feedback. Because the wheel is lighter, the suspension has to absorb smaller inertial forces, allowing dampers to work more predictably. The result is enhanced mid-corner grip and quicker recoveries when the car is placed back onto the throttle after a brake corner. The difference is not simply a faster car; it is a car that communicates more clearly with the driver. The steering wheel doesn’t merely convey road input; it conveys the degree of grip available at the contact patch. The driver can time throttle modulation and braking with greater confidence because the wheel’s mass and the tire’s behavior feel integrated with the car’s chassis dynamics. This is the essence of a performance wheel that serves as an extension of the driver’s intent rather than as a separate, isolating mass at the corner.

The historical nuance here matters too. The EVO X was designed to be a benchmark in part because its wheel and tire package spoke to a broad consensus about what a performance sedan should deliver: immediate response, linear grip, and a chassis that communicates in clear, quantifiable terms. The BBS version of the wheel package, in particular, has become a touchstone for enthusiasts who seek the purest expression of the car’s handling potential. The genuine forged wheel is not merely a lighter part; it is a statement about engineering discipline and brand philosophy—the idea that performance begins with the wheel and ends with the road’s acknowledgement of driver intent. In this context, the “ENKEI version” represents a complementary approach, preserving the same wheel diameter and bolt pattern while allowing for different rim geometries or finishes that can subtly shift feel without altering the fundamental balance that makes the EVO X so engaging to drive. For a reader curious about the breadth of wheel options without straying from the EVO X’s core tuning, it is instructive to consider how a forged wheel set acts as a platform for further experimentation. A useful point of comparison can be found in broader wheel-market discussions that examine how forged wheels influence cornering behavior, throttle response, and braking transition in high-performance cars. A look at broader wheel options such as a range of forged designs for similar platforms can illuminate the degree to which the EVO X’s baseline is a starting point rather than a destination. For example, one could explore more about the practicalities of aftermarket forged wheels in similar chassis configurations at this reference: brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans.

In everyday use, the distinction between OEM and aftermarket forged wheels often comes down to the balance of cost, weight, and accountability to the vehicle’s original purpose. The EVO X’s factory wheelset is a designed integration, not an afterthought, aligned with the car’s duty cycle—quarter-mile sprints, twisty canyon roads, and track sessions alike. The forged construction ensures that this alignment lasts under heat and fatigue, resisting deformation that could otherwise alter brake bias or steering geometry. The caliper and rotor package can be pushed to the limit because the wheel’s mass does not demand excessive energy to change speed. In practice, that translates to shorter stopping distances for a given tire and better modulation of brake pressure, because the wheel’s rigidity sustains a consistent tire contact patch as heat builds and laps accumulate on a track.

From a handling perspective, the EVO X’s wheel choice also underscores a subtle truth about modern performance cars: chassis dynamics are a system, and every component from tethers to tires to rotors contributes to a single arc of performance. The wheel is the interface between the car’s mechanical heart and the road that heart beats upon. A forged, properly sized wheel with a high-quality tire can sharpen steering feel without making the ride punishing. It keeps the car’s natural balance intact while allowing the driver to exploit peak grip more reliably as speed increases. Enthusiasts who ultimately choose to run wider tires or larger diameter rims often confront a delicate trade-off. While a move to 20 inches or beyond can improve cornering grip and reduce susceptibility to tire roll, it also increases unsprung weight and can alter the suspension’s ability to follow the road’s irregularities. The EVO X’s factory alignment around 18 inches represents a deliberate curb between performance and practicality. The wheel’s weight, stiffness, and diameter interact with the tire’s profile to create that signature sense of immediacy in steering, a precise throttle response, and a braking balance that remains predictable under load. This synergy—between wheel, tire, brake, and suspension—offers a glimpse into why the car has endured as a performance reference for so many enthusiasts.

The practical implications for owners are equally important. If one contemplates a wheel upgrade or a return to a factory-equivalent setup for a track day, the forged wheel offers a strong baseline for maintaining vehicle behavior. A broader discussion about wheel choices reveals that while the 5×112 pattern provides compatibility with a range of European performance platforms, the EVO X’s design team tuned the offset, spoke geometry, and center bore to work in concert with the car’s braking system and the dynamics of its transfer case and all-wheel-drive torque distribution. The result is a cohesive, track-ready character that remains accessible to everyday driving. It is this careful balance that frames the EVO X’s reputation for rewarding precise inputs and disciplined driving, rather than simply offering a high top speed or an aggressive look.

For readers who want to explore more diverse wheel configurations without losing sight of the EVO X’s core strengths, there is value in examining how forged wheels from established manufacturers interact with the car’s chassis over time. The community often highlights how enthusiasts select a forged wheel in a way that preserves the original braking clearance, maintains correct wheel speed sensor alignment, and respects the suspension’s travel and bump steer characteristics. The fact that the EVO X offers two close-but-distinct wheel options underscores how even within a single platform, the wheelset can shape the driving experience in meaningful, measurable ways. When the objective is a balanced, track-ready car that remains compliant on public roads, the factory forged wheel arrangement represents a thoughtful, well-executed solution that many drivers come to trust and respect. The awe of the car’s performance arises not from a single sensational feature but from the clarity with which its entire wheel-system package communicates the driver’s intent and the road’s reality.

External resource: For deeper technical context on forged wheel construction and quality standards, see a technical details resource from the wheel maker: https://www.bbs-rims.com/technical-details

Forged Precision: Materials and Craftsmanship Behind EVO 10 BBS Rims

Material and Craftsmanship of EVO 10 BBS Rims

The defining hardware under the fenders of a high-spec EVO X is the wheel. BBS wheels specified for the tenth-generation model are not a cosmetic afterthought. They are engineered components that combine material science, manufacturing discipline, and vehicle integration. The MR and other higher-trim versions shipped with 18-inch BBS wheels made from forged aluminum alloy. That simple fact hints at a deliberate design choice: keep unsprung mass low while preserving structural strength for aggressive driving.

Forged aluminum alloy is central to the wheel’s performance identity. In forging, a billet or preform of aluminum is heated and then compressed in a die under massive pressure. This process realigns the metal’s grain structure, squeezes out porosity, and increases internal density. The result is a component that delivers higher yield strength and better toughness than cast alternatives of similar weight. For a car like the EVO X, that translates into wheels that resist impact and fatigue without the weight penalty of a heavier design.

A forged wheel’s benefits show up in everyday dynamics. Lower rotating mass improves the car’s ability to accelerate and to decelerate. Reduced unsprung mass makes the suspension more responsive, allowing it to follow road contours more precisely. On the street, that means quicker turn-in and a firmer, more controllable response under braking. On a track, the advantages compound because heat cycles and repeated loading reveal weaknesses in inferior materials. Forged BBS wheels tolerate those cycles while maintaining consistent behavior.

Beyond forging, manufacturing tolerances and finishing steps matter. OEM BBS pieces for the EVO are produced to tight dimensional tolerances. The wheel center bore, bolt pattern, and offset are specified to fit the vehicle without modification. For the EVO X, commonly used spec is 18×8 with offset near +38 and a bolt pattern of 5×112. Those numbers are chosen to balance wheel arch clearance, scrub radius, and brake package fitment. Accurate machining preserves hub-centric fit and minimizes runout, reducing vibration and improving bearing life.

Surface treatments are another integral part of wheel engineering. Forged wheels often receive precise machining to meet visual and clearance requirements, followed by coatings that protect the metal. Powder coating or specialized paints provide a durable cosmetic finish. Clear coats and protective sealants combat brake dust and road salts. Anodizing or bead-blasting can be used where texture and a performance aesthetic are desired. Those layers add negligible mass but greatly extend life and ease maintenance.

A lot of performance value stems from the improved strength-to-weight ratio of forged alloys. Manufacturers can remove material where stresses are low and keep metal where strength is required. That sculpting reduces moment of inertia without compromising safety. It also allows designs that clear larger brake calipers and rotors while maintaining structural integrity. For an EVO running upgraded brakes, this flexibility allows owners to fit bigger hardware without resorting to heavy, aftermarket cast wheels.

Fitment options and interchangeability play into why these BBS wheels are popular beyond Mitsubishi owners. The 5×112 bolt pattern is common on many European brands, which broadens the wheels’ aftermarket appeal. For tuners, the OEM BBS rim is a reliable baseline for further upgrades, such as wider widths or different offsets. Some enthusiasts choose to move up to 19- or 20-inch diameters, or to wider 9-inch and 10-inch widths. Doing so changes tire geometry and handling balance, so decisions should be guided by clear goals: improved lateral grip, altered steering feel, or aesthetic proportion.

When increasing wheel diameter or width, one must consider the tire profile. The EVO X commonly left the factory on 245/40 R18 tires matched to the 18-inch BBS wheels. Upsizing to lower-profile tires like 265/35 R18 or 245/35 on larger rims affects ride comfort and effective gearing. Wider tires increase contact patch area and potential grip, but they also increase rolling resistance and unsprung mass if the wheel is heavier. This is why many enthusiasts retain or seek forged wheels for larger sizes, to preserve weight advantages while gaining rubber footprint.

Manufacturing choices also influence repairability. Forged wheels have an edge in being repairable after curb strikes or localized damage. The denser grain structure lets trained technicians machine out small defects and restore roundness. Repair limits depend on severity and location of damage. Structural cracks through spokes or the barrel are often beyond repair and warrant replacement. Preventive maintenance and careful inspection after hard impacts extend service life and preserve safety.

Fatigue resistance merits emphasis. Wheel assemblies experience cyclic loads from bumps, braking, and cornering. Casting defects such as micro-porosity or inclusions can initiate cracks under repeated stress. Forging reduces these defects and creates a more uniform material. For a car that sees track days or spirited driving, that mean fewer unexpected failures and more predictable performance under repeated loading.

The OEM relationship between BBS and the manufacturer is important. When a wheel is an OEM-specified part, it is engineered to the vehicle’s geometry and tested as part of the car’s system. That ensures appropriate offsets and load ratings for normal and sport use. It also ensures that the wheel’s original finishing and balance settings are optimized for the vehicle. For those interested in original equipment quality, OEM BBS wheels provide assurance that aftermarket copies may not match.

For consumers deciding between forged and other processes, it helps to understand where each process fits. Cast wheels are cheaper and allow complex shapes, but they sacrifice density and resistance to impact. Flow-formed or semi-forged wheels offer a middle ground. Flow-forming stretches and compresses the rim area to increase tensile strength and reduce weight, without the full expense of forging. These can be solid choices for budget-conscious drivers seeking some benefits of lighter wheels.

Designers also balance stiffness and compliance. Too stiff a wheel can transmit harshness into the suspension and reduce the tire’s ability to conform to the road. Too compliant a wheel may flex under cornering loads, disturbing alignment angles and handling precision. Forged wheels allow targeted stiffness: spokes can be shaped and hollowed to tune flex characteristics. The finished wheel thus becomes part of the vehicle’s chassis tuning, not just an attachment.

Finally, practical considerations matter. Matching wheel offsets to brake calipers prevents interference. Ensuring correct hub-centric fit mitigates runout and bearing stress. When changing wheel sizes, fender clearance and speedometer calibration need checking. And surface protection reduces corrosion and simplifies cleaning. For owners seeking a used set, look for signs of repair, check for straightness, and confirm mounting specifications. A verified OEM set often carries a premium but also fewer unknowns.

The BBS wheels that came with the EVO X represent a purposeful fusion of material science and manufacturing. From forging to finishing, each stage aims to yield a wheel that supports the car’s dynamic goals. For owners and builders, understanding these choices clarifies trade-offs and helps guide upgrades. Whether preserving an OEM set or moving to a broader, lighter wheel, the underlying principles remain the same: control mass, manage strength, and match the wheel to the car’s intended use.

For those looking to source original-spec wheels, consider checking listings for an OEM BBS R18 wheel set to confirm fitment and condition. See a reputable supplier for an example of an OEM BBS wheel set here: 原厂BBS R18轮毂套装.

For a technical overview of forging and alloy wheel properties, further reading is available from general materials references and technical resources on forging processes: https://en.wikipedia.org/wiki/Wheel(device)#Alloywheels

Market Fit and the Competitive Edge of EVO X Forged Wheels

Wheels are more than circular metal; they are a critical interface between a car’s power, its handling, and the road under the driver’s control. In the era of the Evolution X, a generation defined by its aggressive stance and precise mechanical tuning, the choice of wheel became a practical extension of the car’s performance philosophy. The OEM approach toward forged wheels for that era demonstrated a balance between strength, weight, and reliability. Forging and high-grade aluminum alloys enabled a reduction in unsprung mass, which in turn sharpened every facet of the driving experience—from initial turn-in to mid-corner stability and stop-and-go steering feel. The 18-inch wheel diameter that accompanied the top trims was not incidental; it reflected a designed compromise. The larger contact patch of a high-performance tire could be paired with an even lighter, stiffer wheel to maximize acceleration, braking, and damping response, all while preserving ride quality. The chassis, suspension, and brake system were calibrated to work with tires in the 245/40 R18 range, a combination that offered both robustness and a performance envelope wide enough to accommodate spirited driving and daily usability. This fusion of engineering intent and material science created a beginning point for a broader dialogue about market fit and what constitutes a meaningful competitive edge in the high-end wheel segment.

When one surveys the aftermarket landscape in this space, the most consequential factor is not simply the wheel’s diameter or its visual appeal. It is the breadth of the wheel’s compatibility—the ability to scale from the OEM spec to larger diameters and wider widths while preserving the essential performance characteristics. A premium forged wheel line in the market today is designed with an expansive size matrix, typically offering dimensions from the high teens to the low twenties in diameter, and a spectrum of widths that accommodate various tire configurations. The practical consequence is clear: a wheel set can serve diverse vehicles across multiple regions, from premium European sedans to high-performance coupes and even certain Japanese performance models that share common hub patterns and bolt circles. The chromatic silhouette of such wheels—whether finished in machine-polished, hyper-dark, or a machined contrast—contributes to the vehicle’s aero and brake-cooling presentation, yet the core value rests in the engineering that makes the fitment robust across platforms. A single, well-calibrated wheel family can significantly reduce the complexity of sourcing for enthusiasts who own multiple cars or who frequently experiment with fitments for track days, street performance, and spirited weekend runs.

From a technical standpoint, the most compelling advantage lies in the material choice and the forging process. Forged or semi-forged wheels derived from high-strength aluminum alloys explain much of the performance premium. The manufacturing approach—often described in industry terms as using advanced aluminum alloys and optimized heat treatment—delivers a combination of stiffness, resilience, and lightness that is difficult to achieve with cast wheels. A typical forged wheel line emphasizes the conversion of alloy into a structural form that aligns with the car’s load paths. This structural efficiency translates into reduced unsprung weight, which directly affects how quickly the suspension can respond to road irregularities, how sharply the car can change direction, and how quickly it can brake without the wheel’s inertia fighting the driver’s input. In performance contexts, lighter wheels not only help the engine deliver power more efficiently but also improve braking dynamics by reducing inertia in the rotating assembly. The effect is a more responsive, communicative feel through the steering wheel, with quicker throttle response during acceleration and a more predictable chassis attitude under braking and cornering. The consistent mechanical properties of forged wheels also raise confidence in high-rate braking scenarios where thermal loads demand robust heat dissipation and resistance to fatigue. This is where the market’s premium forged wheel families justify their higher price points: the engineering discipline behind the design ensures predictable performance over time, even as the car is pushed toward the limit on a track or a spirited canyon road.

A salient feature of market-ready forged wheel lines is their breadth of bolt patterns and hub bore accommodations. Although the European performance car ecosystem has long favored the 5×112 bolt pattern for its combination of strength and versatility, modern performance segments increasingly demand compatibility with multiple PCDs and center bore diameters. A wheel line engineered to cover a wide range of patterns and offsets effectively reduces the friction and frictional cost for enthusiasts who own multiple vehicles or who want to repurpose a set for another high-performance model. The practical upshot is a practical universality: the ability to preserve performance while switching vehicles, tires, or driving styles without a costly wheel swap each time. This universality matters because the modern enthusiast market is not monolithic. It spans owners who track their cars, daily commuters who demand predictable handling, and weekend warriors who crave a tactile sensation of speed. A wheel family with broad compatibility can bridge these use cases, delivering consistent performance across the spectrum and enabling a coherent upgrade pathway for drivers who want to move beyond stock configurations.

From the customer’s perspective, a durable forged wheel offers several benefits that compound over time. First, there is the weight difference relative to a cast alternative. Even modest reductions in weight per corner can accumulate into noticeable gains in initial acceleration, braking onset, and corner-exit speed. In a vehicle like a high-performance compact, these improvements are not merely theoretical; they translate into faster lap times, more predictable brake bias, and improved throttle modulation when exiting corners. Second, the stiffness and fatigue resistance granted by a well-engineered forging process contribute to longer wheel life under demanding use. The wheels retain their shape under high-load events, reducing the risk of localized deformation that could compromise alignment or brake clearance. The third advantage is corrosion resistance and environmental durability. Wheels built with aerospace-grade aluminum alloys undergo rigorous surface treatment and testing cycles to withstand road salt, humidity, and heat. The ability to survive salt spray and aggressive corrosion tests ensures that the wheel’s structural integrity remains intact across seasons, an important consideration for drivers who live in climates with harsh winters or salted roads.

In the marketplace, the competitive edge is not merely about raw numbers. It is about delivering a coherent package that aligns with the vehicle’s performance character and the owner’s expectations for daily usability, track capability, and long-term reliability. The blend of a broad fitment range with a disciplined material strategy and an emphasis on heat management makes a forged wheel line attractive to a wide audience. For those who want to push a car toward higher performance, a wheel that can maintain rigorous tolerances at higher speeds and temperatures becomes more than a tool; it becomes a central element of the car’s overall dynamic balance. A well-chosen forged wheel, matched with an appropriate tire, can optimize grip, steering feel, and suspension compliance. It smooths the transition from on-ramp poise to track-day aggression, all while preserving ride quality on everyday roads.

The market narrative around such wheels also hinges on accessible, practical references that help enthusiasts make informed decisions. For example, a dedicated product page illustrating a set of forged wheels with 18-inch sizing and a multi-spoke design can be read as a case study in how a wheel line translates its engineering principles into real-world performance. The page demonstrates the alignment of size, weight, and spoke geometry with the car’s brake clearances and tire choices, providing a tangible template for fitment decisions that a reader can compare against their own vehicle and driving goals. If readers want to see how a specific wheel family approaches fitment for L-class sedans and similar platforms, they can explore the reference page that focuses on a forged rim set for the Lancer family. The link is intentionally descriptive, enabling readers to understand the context and the logic behind the fitment decisions without needing to guess at the technical details. brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans.

On the broader stage, the competitive landscape for forged wheels is shaped by the synthesis of size flexibility, compatibility breadth, and material performance. A company that can offer a seamless range—from 19 inches to 21 inches, with widths that span from a compact 8J to a wide 12J, and that can accommodate a broad spectrum of bolt patterns such as 5×112, 5×120, and others—gains a legitimate edge. The advantage is twofold: it lowers friction for the consumer who wants to upgrade a single vehicle or multiple vehicles, and it reduces the risk of misfitment, which can be costly and time-consuming to correct. Forging technology, with its emphasis on the EN AW-7000 series and advanced heat-treatment schedules, provides the backbone for this reliability. The end result is a wheel that is not only lighter and stronger but also more consistent across production batches, a factor that matters when evaluating long-term ownership costs and performance endurance on a track or during daily use. In this sense, the EVO X-era wheel narrative becomes a snapshot of a broader principle: market fit is about delivering a product family that can scale with a driver’s ambitions, while maintaining the fundamental performance promises that defined the vehicle’s character from the factory.

The discussion would be incomplete without acknowledging the environmental and lifecycle considerations that increasingly define consumer choices. A forged wheel’s longevity, its resistance to corrosion, and its ability to retain performance characteristics over time can contribute to a lower total cost of ownership when compared with more disposable, lower-quality alternatives. The engineering approach—emphasizing lightness, strength, and durability—also dovetails with broader industry goals toward efficiency and responsible manufacturing. In brief, the market’s appetite for a versatile forged wheel line is driven by a combination of practical fitment, performance benefits, and long-term value. This convergence of factors helps explain why a wheel family built around these principles remains a cornerstone for enthusiasts who seek credible improvements without compromising reliability on either road or track.

External resource for deeper understanding: https://en.wikipedia.org/wiki/Forging

锻造极致:EVO X的BBS轮毂潜力与改装潮流的推广

当人们谈到 EVO X 的改装潜力时,思路往往从马力和扭矩的提升开始,但真正改变日常驾驶体验的,往往是车轮与悬挂这对看不见的“脚手架”。在这套思路里,原厂的18英寸锻造轮毂承担着一个关键的角色。它们采用的5×112螺栓孔距,是一条通往欧洲高性能车型的共同语言,也正因为此,轮毂在改装市场上显得不再是单纯的“美观件”而是与整车性能紧密绑定的要件。原厂提供的245/40 R18高性能轮胎组合,与轮毂的轻量化设计共同作用,降低簧下质量,使得加速、制动、转向的响应都显得更为线性和敏捷。这一切并非偶然,而是厂家在性能定位上对整车系统理解的直接体现。为了理解 EVO X 的改装潜力,必须把轮毂从“外观件”升格为“性能元件”来审视。通过锻造或半锻造工艺制造的轮毂,往往在强度与重量比上占优,能在高速行驶或激烈弯道中稳定传递路感,减少传动系统与悬挂的额外负担。用更轻的轮毂来承载同样的轮胎尺寸,实际上是在降低簧下质量,提升制动的即时性和弯道的追踪能力,这对于追求“街道赛道化”体验的车主来说,是直接可感的改动。正因如此,5×112 这一欧洲高性能车型的共用螺栓孔距,也使得 EVO X 的改装潜力具备跨品牌兼容的现实基础,车友们往往在这一规格上进行更广泛的轮毂与轮胎组合尝试。对于热爱驱动的玩家而言,轮毂并不仅是提升外观的装饰,更是提升整车动态极限的关键部件。此处对轮毂的重视,与整车从静态美学走向动态性能的转变相呼应。若从更宏观的改装路径看,BBS 等顶级锻造轮毂在圈内长期被视为性能起点。这不仅因为它的结构强度与轻量化带来的综合效益,更因为它提供了一种“可验证的工程范式”,即通过精密的制造工艺降低簧下质量、提升传动效率,从而让车辆在快速通道转向、刹车热衰减与穹顶下的稳定性之间取得更好的平衡。这样的技术逻辑,与 EVO X 的全轮驱动底盘、刚性车身与高响应悬挂系统共同构成了一条清晰的改装路径。换言之,轮毂的改动,能以较低成本带来显著的综合性能提升,这是任何打算在赛道与日常之间取得平衡的车主不应忽视的要点。与此同时,轮毂的材料与制造工艺选择,也直接决定了未来扩展性的空间。锻造轮毂往往具备更好的强度重量比,允许在不显著增加簧下质量的前提下,承载更大尺寸的轮胎和更强的制动配置。随着改装目标从“单纯追求马力”转向“综合性能提升”——包括操控、散热、耐用性与外观的一体化美感——镶嵌在 EVO X 的改装蓝图中的便是这组轻量化、坚固且耐用的轮毂。对许多车友而言,18英寸的原厂轮毂是一个值得尊重的性能起点,他们会以此为基点,逐步探索更宽的轮胎与更强的悬挂系统的协同效应。关于这方面的思考,亦可在改装圈中看到类比的案例:在许多街道与赛道的实际改装中,锻造轮毂被视为“极限驾驶体验的起点”,因为它们在保持强度的同时显著降低了簧下质量,从而提升了对路面的小范围干扰的敏感度与反应速度。这种“轻量化、刚性、低惯量”的组合,是 EVO X 在高性能改装领域的天然优势,也是持续推动改装热潮的核心动因。为了充分理解这一点,可以把轮毂看作整车性能的一个放大镜:它放大了你对悬挂、制动、转向的感知,也放大了你在赛道或日常道路上对极致操控的追求。若你愿意进一步探索这条路径,便会发现,选择一个高强度、轻量化的锻造轮毂,是把“潜力”变为“可用极限”的关键一步。与此同时,广阔的改装市场也提供了多样的路径,以满足不同车主对美学与性能的综合诉求。从宽轮胎到改进的制动系统,从优化的进排气到更极致的涡轮增压配置,任何一个环节的提升都可能在实际驾驶中以更显著的方式体现,而轮毂的角色作为将这些改变物理化、可感知化的载体,不可小觑。对 EVO X 的拥趸而言,BBS 这一类的锻造轮毂不仅是性能的符号,更是一种改装文化的标记——它象征着对轻量化、强度与可靠性的共同追求,也代表着对“驾控边界”不断突破的精神。通过将轮毂重量降至最低、承载更大尺寸轮胎以及提升制动的响应性,车手可以在多种驾驶场景中实现更稳定的线性表现。这不仅在理论层面有益,在实际路感与弯道贴地性的体验中更是直观可感。 EVO X 的改装社区经常以此为出发点,逐步探索更高的动力输出与更极致的底盘调校。即使动力的提升可能会带来复杂的热管理与可靠性挑战,良好的轮毂选择与合适的轮胎搭配仍然是确保改装成果稳健性的第一道防线。未来的推广也会围绕“高强度、轻量化、易维护”的核心理念来展开——强调轮毂在整车性能提升中的核心地位,并通过实际案例展示其在动力、操控与耐用性方面的综合收益。对于热爱改装的车迷来说,选择合适的锻造轮毂,就是在为未来的改装蓝图奠定物理基础。若把目光从单次改装的结果延展到长期的改装文化,便能看见一个持续扩展的生态:从工艺精度的提升、对路面信息的更敏感传递、到在不同气候与路况下的可靠性表现,所有这些都指向同一个核心——以高强度、低簧下质量的轮毂为起点,推动整个 EVO X 改装生态向更高的水平前进。对追求极致驾驶体验的人来说,这种推广不仅是商业活动,更是一种对性能边界的持续挑战。学习和借鉴原厂对轻量化、刚性结构的思路,结合更成熟的悬挂与制动升级,便可在日常街道和赛道之间找到一个更能被信赖的“中间地带”。最终,EVO X 的改装潜力将不再仅限于少数“极客级”的改装者,而是逐步成为广大车迷可理解、可落地、可共享的驾驶哲学。正是在这条路线上,锻造轮毂成为了一个不可替代的推进器,它让每一次踩下油门都更具信心,让每一次进入弯角都更从容,也让整车的潜在力量得以在实际场景下被充分释放。若你愿意进一步了解相关的轮毂选择与搭配,可以参考某些锻造轮毂在实际应用中的案例,帮助你在遵循安全与法规的前提下,做出更适合自身驾驶风格的选择。对于热衷于 EVO X 的玩家而言,这正是一个值得持续探索的领域:在灯光与涡轮声浪之外,轮毂带来的直观体验,往往是你日复一日对车库驱动的最忠实回报。

Final thoughts

The EVO 10 BBS rims represent a fine blend of performance engineering and aesthetic appeal, highlighting critical factors such as original equipment configuration, material quality, market adaptability, and modification potential. For business owners in the automotive industry, understanding these aspects enables them to make informed decisions in offering products that not only meet performance standards but also attract enthusiasts. Leveraging the reputation and benefits of BBS rims opens numerous opportunities for partnership and innovation within the automotive landscape.