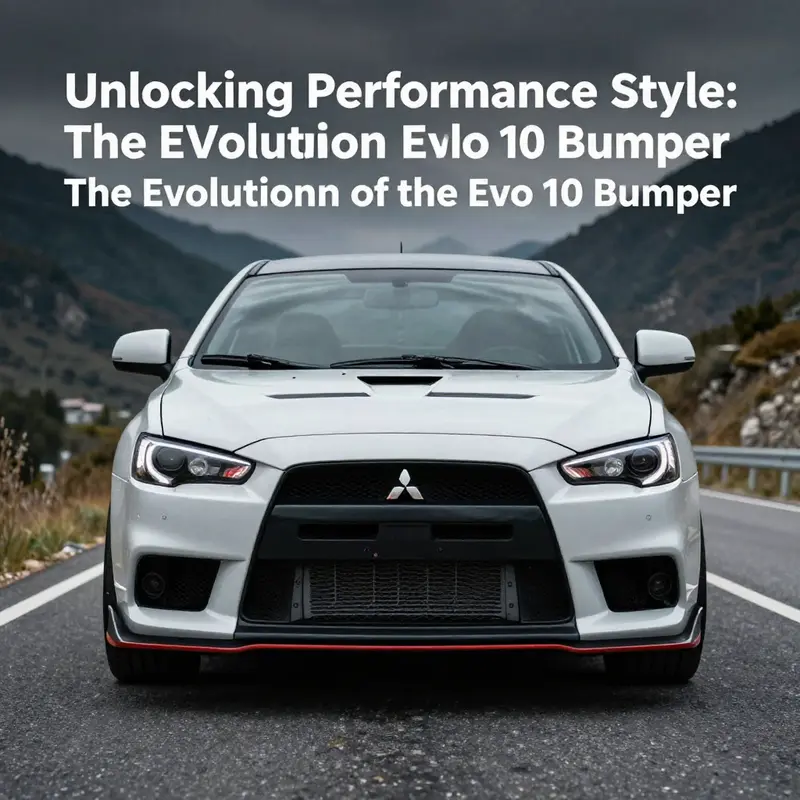

The Mitsubishi Lancer Evolution X, popularly known as the Evo 10, captivates automotive enthusiasts with its high-performance capabilities and striking aesthetics. One of the most significant components contributing to its allure is the front bumper. This article delves into the intricacies of the Evo 10 bumper, covering its aerodynamic design features, the variety of aftermarket options available, sourcing and manufacturing practices in Guangdong Province, performance improvements from upgrades, and the unique aspects of the Final Edition bumper. Each chapter builds on the understanding of how the Evo 10 bumper enhances both performance and visual appeal, providing crucial insights for business owners looking to tap into this market.

Front-Row Aerodynamics: Unpacking the Evo X Bumper’s Role in Grip, Cooling, and High-Speed Stability

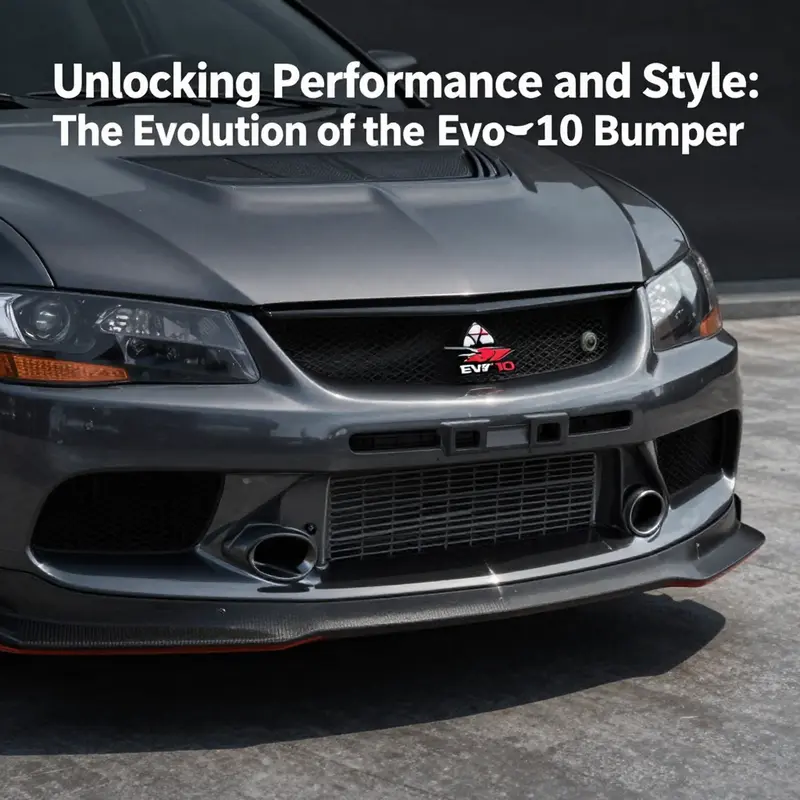

The front bumper of the Mitsubishi Lancer Evolution X sits at a clear crossroads between aggression and function. It is not merely a face for the car; it is a carefully engineered surface that shapes the air velocity, pressure distribution, and thermal pathways that define how the car behaves at the limit. In high-speed driving, where every kilometer per hour translates into measurable grip and predictable response, the bumper becomes a central actor in a broader aerodynamic system. The way air is invited into the engine bay, how it is guided along the undercarriage, and how turbulence is tamed at the leading edge all converge to determine how quickly the car can accelerate, brake, and find its balance through a corner. The Evo X front bumper embodies this integration, combining a bold silhouette with a suite of features that work together to produce measurable gains in performance and a coherent, track-ready feel on the road. Its visual impact is the first signal of its deeper purpose: a design that can transform front-end behavior without sacrificing the visual identity that enthusiasts crave.

A critical element is the aggressive front splitter paired with integrated air dams. This duo bites into the air as the car moves forward, funneling a portion of the boundary layer out from beneath the car and directing the rest toward channels that feed the underside with carefully pressed, controlled airflow. The splitter creates a targeted pressure gradient at the front, which helps to push the nose down and generate downforce. The air dams act as channels that guide air away from the tires and over the low-slung undertray, reducing lift where the car would otherwise become light and unpredictable. On a vehicle built for track work, this subtle redistribution of pressure translates to improved front-end grip and a more planted entry into corners at high speeds. The effect is rarely dramatic in isolation, but when the splitter, the dams, and the underbody topology work in concert, the front end contributes to a noticeably more confident front axle—an essential quality for confident maneuvering when the stakes are high.

Beyond the visible lip, the Evo X bumper features airflow channels that are shaped to minimize turbulence around the producing facets of the nose. These channels act as efficiency rails, guiding high-energy air away from the centerline where it could spark eddies that disrupt the smooth flow over the hood and into the upper grille. The result is a reduction in parasitic drag and a more coherent wake downstream. This optimized guidance is particularly important on a car designed for both street and track duty. At speed, the clean separation of air and the reduction of turbulent pockets along the sides and near the wheels contribute to more predictable yaw stability and a steadier steering feel. The bumper’s role becomes most evident when the car is pushed into the mid to high-speed range, where every incremental gain in aero efficiency translates into a measurable advantage in cornering consistency and brake confidence.

Thermal management is another essential duty of the Evo X bumper. Large intake openings are not just for show; they are designed to feed substantial quantities of cool air directly to critical components—the engine bay and the brakes. When a car spends long sessions on a track or is driven aggressively on a hot day, thermal load becomes a limiting factor. The bumper’s openings optimize the thermal pathway, ensuring that the engine breathes cleanly and the braking surfaces remain within their ideal temperature windows. Efficient cooling supports sustained performance, helping to prevent heat soak that would otherwise degrade power output and pedal feel. In this way, the bumper doubles as a shield against thermal bottlenecks, allowing the driver to preserve tempo through a stint or across a demanding sequence of corners.

Another architectural stride is the wide arch design found in many modern Evo X body kits. Expanding the wheel arches not only accommodates wider tires but also contributes to lateral stability. The broader track enhances cornering grip, and the reinforced structure associated with these designs increases chassis rigidity. The upgraded rigidity improves steering response and tire feedback, making the car feel more communicative to the driver as the limits are approached. In tandem with the bumper’s aero features, this increased rigidity helps distribute aerodynamic loads more evenly across the front of the car, reducing the tendency for the nose to squat under hard braking and allowing for cleaner weight transfer through cornering sequences. This combination is especially advantageous for track-focused builds, where precision and repeatability are prized above all.

The integration of the front bumper with other aero components—side skirts and a rear diffuser—forms what engineers and drivers often describe as a continuous aero flow. When the bumper, side skirts, and diffuser work in harmony, air travels smoothly from the front of the car to the rear, with minimal turbulence along the seams and underbody. The result is a cohesive aero package that minimizes drag while maximizing downforce where it matters most. The underbody becomes more of a controlled air system than a simple flat plane, and the overall aerodynamic footprint is more predictable across a wider range of speeds and attitudes. This holistic approach is essential for a vehicle designed for diverse applications, from daily driving to track sessions where repeatable handling is the objective.

Beyond the structural and aerodynamic logic, the Evo X bumper speaks to a broader philosophy of performance where aesthetics and function are not at odds but mutually reinforcing. The glossy, shadowed finish that has come to symbolize a certain era of performance cars is not merely cosmetic; it reflects how the bumper’s lines are intended to manage the eye as well as the air. The clean, linear geometry of the intake openings and the directional cues in the bumper design help the driver read the vehicle’s intent at a glance—the car is built to be fast, precise, and controlled. For enthusiasts pursuing the most ambitious visual statement, aftermarket options that emphasize carbon fiber—known for potential mass savings and stiffness—offer further opportunities to tune the car’s weight distribution and cooling capacity. Carbon variants, in particular, can reduce mass significantly while preserving strength, a combination that enhances acceleration, braking, and steering response. Venting integrated into such designs can further aid engine bay heat management, an important consideration for sustained performance during track driving.

All of these features underscore a central point: the Evo X bumper is a performance device as much as a styling element. Its primary objective is to shape the air that meets the car with surgical precision, guiding it where it can do the most good and where it will not impede the car’s balance. This is why considerations of material choice matter. While carbon fiber is celebrated for its strength-to-weight benefits, alternatives such as high-quality plastics and composites offer robust impact resistance and cost-to-performance advantages. The choice of material influences not only mass and rigidity but also how the bumper interacts with the rest of the body kit and how easy it is to install and align with other components. Proper fitment is crucial; even the best aero philosophy falters if mounting points are off, if the panels do not align cleanly with the fenders, or if gaps invite unwanted air leakage that spoils the intended flow. For those who pursue the most rigorous performance ethos, the path often involves a measured blend: the aerodynamic logic remains constant, while material choices are tuned to balance weight savings, durability, and cost.

In the broader ecosystem of Evo X customization, this front bumper’s role goes beyond the moment of entry into a corner or the moment of straight-line speed. It is a cornerstone of a carefully balanced system, one that can be tuned to different goals—track focus, drift setups, or show-stopping street machines—without sacrificing the underlying aero philosophy. For the engineer, it is a reminder that aero design is iterative and collaborative, built on real-world testing as well as computer modeling. For the driver, it offers a tangible sense of cohesion: the front end feels connected to the rest of the car, and the car responds to steering, throttle, and braking with predictable discipline. The result is not just faster lap times but a more confident vehicle in which the driver can trust the front end to behave as expected when the pace climbs.

External reference: For a broader perspective on bumper design and aero performance, see MotorTrend’s bumper guide: https://www.motortrend.com/cars/mitsubishi/lancer-evolution-x/bumper-guide/.

Forged for the Fast Lane: FRP and Carbon Front Bumpers Redefining the Evo X

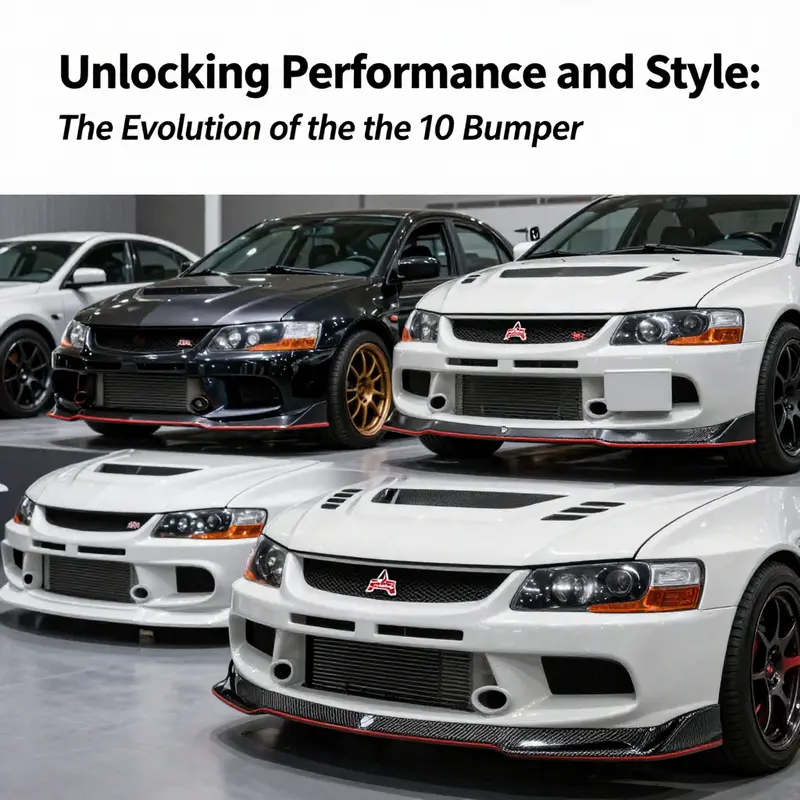

The front bumper is more than a face for the Evo X; it is a carefully engineered gateway to airflow, cooling, and stability at speed. In the world of performance tuning, the bumper sets the baseline for how a car slices through air, how heat moves away from the engine bay, and how confident the driver feels when the track becomes the primary stage. When enthusiasts turn their attention to the Evo X, they often arrive at two broad paths for the bumper: durable FRP options that balance cost and practicality, and high-spec carbon fiber versions that emphasize weight savings and precision aesthetics. The choice matters not only for looks but for how the entire chassis communicates with the road at high velocity. The journey from OEM form to aftermarket function begins with a clear understanding of what each material can deliver in real-world driving, and how that translates into trackability, daily usability, and the kind of build the driver wants to pursue over time.

Fiberglass-Reinforced Plastic, or FRP, remains a cornerstone in the aftermarket bumper world because it blends resilience with value. A bumper crafted from FRP is known for its impact resistance and durability, an important consideration when a car is driven aggressively on street courses or windy backroads where debris and curbs do their own form of testing. FRP bumpers often come with aerodynamic features that respond to the Evo X’s street and track needs in practical ways: functional ducts that help move air to the radiator or intercooler, dive planes that manage front-end lift, and adjustable splitters that tune undertray flow. These design elements aren’t decorative; they channel air to reduce stagnation, improve high-speed stability, and help keep the engine bay cooler during sustained performance driving. The manufacturing approach behind FRP allows for relatively straightforward customization, so builders can tailor ducting and splitter geometry to their specific track config or weather conditions without inflating costs. In terms of fitment and integration, FRP bumpers tend to be more forgiving in terms of minor variances, which can be a practical advantage when completing a full body kit or working within a tight project timeline.

On the other side of the spectrum sits carbon fiber, the material that has become synonymous with lightweight performance and refined aesthetics. Lightweight bumpers crafted from carbon fiber can substantially reduce mass, which matters when every gram counts for acceleration, braking, and steering response. The weight advantage is more than a number on a spec sheet; it translates into quicker turn-in, sharper throttle steering, and a more immediate sense of balance through transitions. Carbon fiber bumpers also lend a distinct, track-ready look that accentuates the Evo X’s aggressive stance, offering a premium visual punch that many drivers associate with purpose-built machines. Beyond appearance, carbon fiber can be engineered with vented sections to further improve engine bay cooling, a feature that becomes especially valuable on extended track sessions or in hot climates. For drivers who want a bolder aero statement and are building a dedicated track or drift-focused project, carbon fiber often becomes the preferred path because it aligns performance gains with a more aggressive, race-inspired silhouette.

The practical benefits of these aftermarket options extend beyond weight and airflow. A well-chosen bumper can contribute to improved high-speed stability through better front-end geometry and cooling efficiency. When air is directed efficiently, engine temperatures remain within optimal ranges, intercoolers stay cooler, and the driver benefits from more consistent power delivery and throttle response during demanding runs. The design language of FRP bumpers can be tailored to deliver improved cooling without sacrificing structural integrity, while carbon fiber options can capitalize on their intrinsic stiffness to maintain consistent geometry even under the duress of high-speed cornering and aggressive braking. This interplay between material choice and aero design is what elevates a bumper from a cosmetic upgrade to a performance-focused component that supports the Evo X’s dynamic balance.

However, material choices should be contextualized within the broader upgrade ecosystem. A bumper is rarely a standalone upgrade; it is often part of a larger aerodynamic strategy that may include a full front-end refresh, side skirts, a rear diffuser, and an aero-inspired hood. In this sense, the bumper’s job is to harmonize with the vehicle’s overall airflow architecture. For drivers planning a complete visual and performance transformation, a full body kit—front bumper, rear diffuser, side skirts, and aero-optimized hood—offers the most cohesive evolution of the Evo X’s appearance and handling characteristics. The integration process demands careful attention to fitment with other components and an understanding of how changes at the front influence brake cooling, radiator airflow, and the vehicle’s balance under load. When a bumper is paired with a properly calibrated splitter, vents, and canards, the car’s ability to manage front-end turbulence improves markedly, helping to keep the chassis planted as speeds rise.

From a practical standpoint, cost and installation realities inevitably shape decisions. FRP bumpers tend to be more budget-friendly while delivering solid performance and durable shell construction. Carbon fiber options, while lighter and often stiffer, come with higher price tags and a requirement for precise installation to maximize performance gains. The critical step in any material selection is to assess the expected use case. A street-driven Evo X with occasional track days may benefit from FRP’s balance of cost, durability, and customizable aerodynamic features. A track-focused build, where every gram matters and sustained high-speed runs are common, will more readily justify the investment in carbon fiber. The installation process for both materials benefits from careful prep and attention to mounting points, wiring, and paint matching. Some aftermarket bumpers require adaptations to the vehicle’s wiring or sensors, so a professional fitment or thorough hand-tolerance checking becomes essential to ensure that safety systems and lighting continue to function as intended.

The aesthetic dimension deserves consideration as well. Carbon fiber’s natural weave and gloss can deliver a high-contrast, motorsport-inspired look that enhances the Evo X’s already aggressive presence. FRP, by contrast, can be finished and painted to a wide range of colors and textures, offering opportunities to tailor the bumper to the vehicle’s overall color scheme or to emulate a particular race-inspired look. In both cases, achieving a seamless paint match and maintaining the bumper’s pristine appearance over time demands proper surface preparation, paint quality, and attention to finish durability against road rash and track debris. A well-executed paint and clear-coat job can help protect the chosen material from UV exposure and thermal cycling, preserving both the appearance and the integrity of the aero geometry for years to come.

For the driver who seeks authenticity without sacrificing fitment precision, there are foundational options that emphasize a factory-like fit and a high level of aftermarket compatibility. One authentic option can be seen through the CZ4A Lancer Evolution X Front Bumper – Genuine. This path emphasizes alignment with the car’s original geometry while still allowing for aftermarket refinements in ventilation and splitter design. The choice to pursue a genuine front bumper, as opposed to a purely aftermarket alternative, depends on the driver’s priorities: whether they value near-perfect OEM fit, ease of installation, and a predictable paint-match outcome, or whether they prioritize the weight and cooling benefits that come with a purpose-built aftermarket piece. The balance between these considerations often defines the overall project’s trajectory and sets the tone for how the Evo X will perform on the track and on the street.

As with any substantial upgrade, the small practicalities deserve attention. Some installations may require wiring adjustments for sensors or lighting, and paint matching can present a challenge when color codes or finishes differ from the factory look. Safety standards and compatibility with other body kit components should be verified as part of the planning process. While FRP and carbon fiber bumpers share the core objective of improved aerodynamics and cooling, the best results come from a thoughtful, integrated approach that respects the car’s intrinsic balance and the driver’s ambitions.

For readers seeking deeper technical guidance, there is a broader reference that covers how to choose the right Evo X bumper and what to expect from different aftermarket configurations. External resources can provide practical checklists for fitment, paint, and installation nuances. For a detailed overview, you can consult the external guide at https://www.carinterior.com/evo-10-bumper-guide-how-to-choose-the-right-one/.

In the end, the Evo X bumper choice is a statement about how much the owner values weight savings, cooling efficiency, and aero precision versus budget and practicality. FRP offers solid, versatile performance at a more accessible price point, while carbon fiber carries the promise of performance gains through reduced mass and enhanced rigidity. The decision should align with the driver’s intended use, the track environment, and the broader aero strategy. When integrated thoughtfully with the rest of the body kit and tuned for the specific handling goals, the bumper becomes a pivotal part of the Evo X’s evolving identity on both road and racecourse. The resulting package is not merely a cosmetic update but a strategic upgrade designed to deepen grip, sharpen response, and sustain performance as speeds climb and corners tighten.

From Guangdong’s Foundries to the Track: The Sourcing and Manufacture of Evo X Front Bumpers

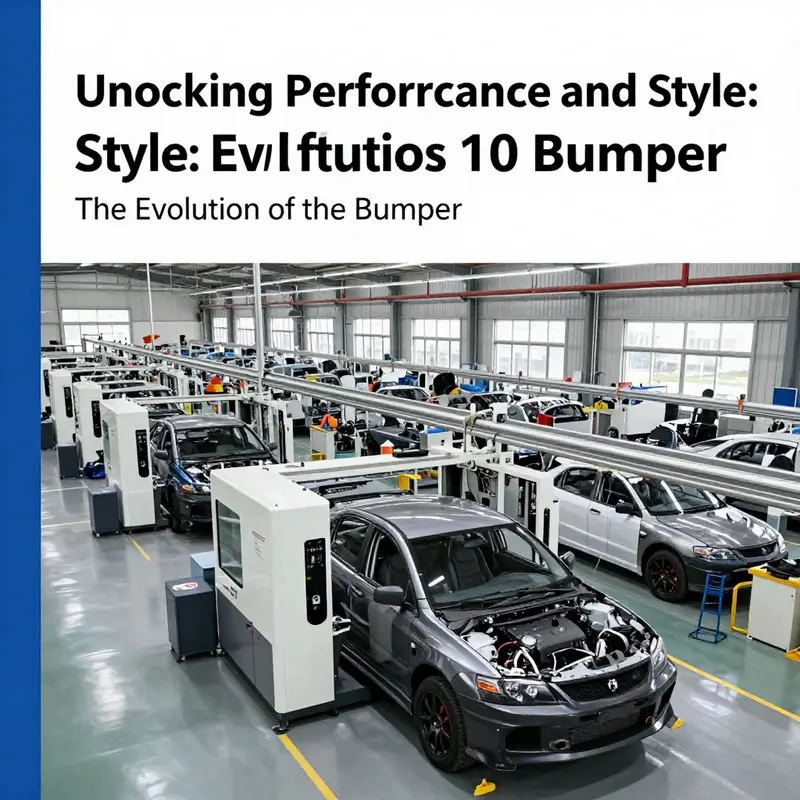

Guangdong Province sits at the crossroads of global automotive refinement, where design intent, material science, and manufacturing prowess converge to shape the front bumpers that define the character and performance of high end performance cars. In the ecosystem centered on Guangzhou and Foshan, suppliers operate at scale with a discipline for precision, repeatability, and rapid response. The region’s ports – Shenzhen, Yantian, and Nansha – serve as gateways for parts and as logistical arteries that keep the market stocked with new designs, refinements, and variants tailored to different performance targets. For buyers and builders, this geography matters because it translates into shorter lead times, more reliable delivery, and the ability to react quickly when a new aerodynamic idea or cooling solution proves its merit on the track.

The actual production lines in this region leverage a triad of materials and processes that suit both OEM and aftermarket demands. ABS plastic remains the backbone for many bumper covers, prized for its balance of impact resistance, tooling flexibility, and cost efficiency. Where stiffness and rigidity are paramount for high load front end panels, polyurethane formulations justify their weight and performance advantages, especially when finished with UV-resistant coatings that keep color and gloss stable under track exposure. For enthusiasts seeking weight reduction, carbon fiber composites are a mature option, offering substantial mass savings while maintaining the rigidity needed for aggressive aero schemes. Ventilation channels and vented sections are often integrated to improve engine bay cooling during sustained track driving, helping preserve performance and reduce heat soak.

Manufacturers in Guangdong operate with a breadth of capabilities to support both base bumpers and performance variants. The region’s know-how extends from rapid prototyping and mold design to painting, surface finishing, and packaging, all within a local ecosystem. This lowers complexity, shortens lead times, and helps control tolerances and fitment, which are crucial when a bumper must align with larger body kit components and sensor arrays. MOQs in Guangdong tend to reflect the scale of tooling and the breadth of customers, with flexibility often higher for established players and more modular for smaller shops pursuing track builds. Even so, the supply chain remains adaptable enough to accommodate shifts, enabling builders to stage production windows that match development calendars.

At the center of the Evo X style discussion is a design ethos that blends aggressive front end geometry with practical performance goals. The bumper’s large intake openings and integrated aero elements are not mere styling cues; they are calibrated to manage front end turbulence, reduce drag, and channel air toward intercoolers and radiators while preserving high speed stability. In Guangdong tooling rooms, engineers translate these aerodynamic objectives into tooling paths, resin systems, and lay up schedules that optimize strength without sacrificing weight. The carbon fiber variants require careful considerations of weave orientation, resin infusion, and curing cycles to achieve the intended stiffness and dimensional accuracy, ensuring the bumper contributes meaningfully to a vehicle’s balance on the track as air resistance and underbody flows become more critical with wider tires and more aggressive suspension tuning.

Sourcing these parts in a market that emphasizes performance also means evaluating supplier capability beyond unit cost. The most capable factories in Guangdong emphasize on-time delivery, consistent reorder rates, and high-response communication as markers of reliability. The data points that matter include on-time delivery rates, reorder frequencies signaling steady demand, and responsiveness that translates into swift clarifications on fitment, coatings, or sensor integration. The backdrop is a culture of continuous improvement—lean manufacturing, meticulous QC, and a willingness to adapt features to evolving regulatory and performance requirements. All of this matters when a bumper is intended to work within a full aero package on a race-prepared chassis.

For buyers seeking a window into the sourcing landscape, digital marketplaces play a pivotal role. Platforms list verified suppliers from Guangdong and provide buyers with specifications, pricing, and protection policies. These marketplaces enable direct connections to capable manufacturers, allowing buyers to verify prototypes, request samples, and scale production in step with development timelines. Transparent documentation such as material data sheets, coating specifications, and dimensional tolerances helps ensure fitment margins stay tight. Some suppliers also offer adjustable MOQs to accommodate smaller teams or one-off builds, depending on complexity and material used. A genuine front bumper from the CZ4A lineage can illustrate how Guangdong suppliers deliver authentic pieces that align with OEM specifications while maintaining flexibility for aftermarket projects.

The geographic advantages extend to logistics. Guangdong-based suppliers leverage mature export channels, established freight paths, and the ability to consolidate shipments for multi-part kits. This is particularly relevant for complete aero packages that require harmony between front bumpers, rear diffusers, side skirts, and aero-focused hoods. The network supports quick shipping to international markets, enabling builders to test aero configurations with fewer friction points. Suppliers often provide installation support documentation and fitment data to ensure that the bumper, sensors, and other components align correctly, preserving performance and safety margins during aggressive driving scenarios.

Within this ecosystem, the most refined collaborations are those that offer OEM-level fit and the installation support required to ensure that high-demand performance parts can be relied on in real competition. Authentic components come with detailed technical data, and many suppliers advertise direct assistance with installation, torque specs for mounting points, and recommended fasteners to maintain structural integrity under load. The practical takeaway is that Guangdong’s manufacturing and sourcing networks do not merely supply a part; they provide the framework for a coherent aerodynamic program. This reduces the friction that usually accompanies upgrades and helps ensure that a full body kit—front bumper, rear diffuser, side skirts, and an aero-focused hood—can be integrated with confidence, even inside a tight testing schedule.

The Guangdong story also heckles with the nuance that not all products are created equal. Even within the same chassis family, there are iterations—different weave patterns in carbon fiber, alternative resin systems, and variations in coating quality—that influence weight, stiffness, and optical finish. The Final Edition styling touch, for instance, demonstrates how a limited run can create added value and exclusivity through finishes and branding. In practice, the decision to pursue a particular bumper option is not just about aerodynamics; it is a balance of weight savings, cooling capacity, color and finish fidelity, and the availability of installation and warranty support. It is this mix of engineering rigor, regional specialization, and global accessibility that makes Guangdong a pivotal nexus for Evo X era bumpers and their broader aero ecosystems, a narrative that naturally aligns with the next chapter’s deeper dive into how these components are integrated into a complete performance build.

Front-Forward Force: Elevating Aerodynamics, Cooling, and Handling with Evo X Front Bumper Upgrades

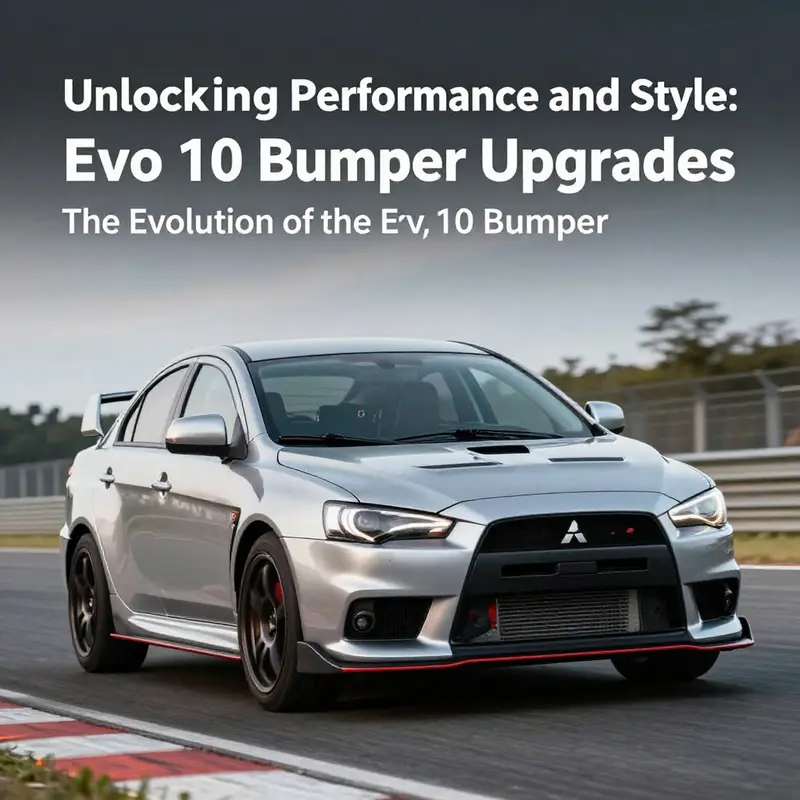

The front bumper on the Lancer Evolution X sits at a crossroads of performance and presentation. It is not merely a weathered shield against wind and road spray; it functions as a carefully engineered interface between the car and the air that rushes toward it at speed. In the Evo X, the bumper helps manage the boundary layer, reduce drag, and shape the flow that wraps around the nose to the underbody and the splitter. When you consider upgrading this part, you are really stepping into a broader program of aerodynamics, cooling strategy, and chassis balance. The goal is not to make the car look aggressive alone; it is to give the driver more usable grip, more predictable behavior, and more confidence when pressing into corners at track speeds. The design philosophy of an upgraded Evo X bumper is to channel air efficiently toward the radiator and intercooler while stabilizing the front end under lift. A bumper engineered with a well-thought-out intake channel or ducting system can deliver high-density air where it matters most, feeding cooling systems that fight thermal buildup during sustained driving or competitive sessions. In this sense, an upgrade becomes a functional enhancement rather than a cosmetic makeover, and the evidence of that effectiveness reveals itself in the car’s stability, cooling margins, and perceived throttle response when the boost comes on hard in mid-c corner exits.

A primary payoff from a redesigned front end is improved airflow management. A bumper that incorporates refined air dams and strategic ducting can direct larger volumes of air toward the radiator and intercooler while reducing parasitic turbulence around the leading edge. In a turbocharged setup, that air has a twofold impact: it helps regulate engine temperature and it preserves turbocharger efficiency by maintaining denser intake conditions at critical moments. When air flows cleanly into the engine bay rather than swirling in a chaotic wake, the temperature envelope becomes more forgiving. That translates to more consistent power delivery, fewer heat soak concerns on long straights or multi-lap stints, and a lower likelihood of power dips during high-demand driving. The result is a more linear, confidence-building experience that keeps a driver planted to the topic at hand: pace and control, not just speed.

Downforce is another nuanced benefit of thoughtful bumper design. The front end, when sculpted to offset lift through a shaped air inlet and careful under-bumper geometry, can press the nose toward the tarmac more effectively at elevated speeds. This enhanced downforce augments cornering grip and steering feel, especially when the car is already balanced by a tuned suspension and a properly sized tire setup. The effect is not simply about sticking to the pavement; it is about reducing the phenomena that undermine corner exit traction, such as front-end chatter or light steering feel as the car unloads and loads during turn transitions. In practical terms, that means more predictable turn-in, steadier mid-ccorner acceleration, and a reduced tendency for the nose to twitch as weight shifts away from the front wheels.

A modern Evo X bumper upgrade also speaks to synergy with other performance modifications. The bumper can be part of an aero package that includes a refined hood, a diffuser, and side skirts designed to harmonize airflow along the full length of the car. When a bumper is designed with integrated channels or vented sections, it can complement a cold air intake or a high-flow intercooler setup by preserving stagnation-free air paths to the turbocharger. The consequence is more stable air density entering the compressor, which supports more consistent boost levels and a more immediate throttle response. It is this cohesive aerodynamic ecosystem—front, midsection, and rear—that allows drivers to exploit other upgrades without creating conflicting airflow patterns. A well-integrated front end makes the entire car feel more linear in its power delivery and more composed through complex corners where grip is influenced as much by aero balance as by tire construction.

The aesthetic and functional attributes of a bumper upgrade are often intertwined in the decision-making process. Yes, the Evo X’s front fascia is aggressive by any standard, but a bumper that manages airflow while showcasing precision engineering underlines an important truth: performance upgrades must work in concert with the vehicle’s original design language. For those who care about OEM compatibility and long-term reliability, there is value in sourcing a front bumper that aligns with factory geometry and mounting interfaces. This ensures that the installation not only preserves fitment across the entire body kit but also minimizes the risk of misalignment that could degrade aero performance. When fitment is precise, the surface you see—the smooth transition between bumper and fenders—becomes a living indicator of the engineering behind it. The result is a coherent silhouette that maintains the Evo X’s identity while enabling tangible improvements in track performance and on-road stability.

Alongside these performance dimensions, the choice of material and construction plays a pivotal role in how a bumper behaves under load. Carbon fiber, a material frequently favored in performance builds, offers a dramatic weight reduction compared to conventional composites and metals. This mass savings translates into quicker front-end response, lighter steering effort, and improved braking performance due to the lower unsprung weight and overall mass that must be controlled by the suspension. The benefits are magnified on track, where every millisecond of response and every ounce of weight shaved from the front can contribute to crisper turn-in and quicker recovery from mid-corner adjustments. Venting within carbon fiber bumpers also supports engine bay cooling, a feature that becomes increasingly important as drivers push engines and turbos to the limit. The engineering logic is straightforward: lighter components improve inertia, while intelligent venting maintains thermal margins that keep power steady and reliability high during demanding sessions.

Beyond material choice, the market offers a spectrum of aftermarket bumpers designed to preserve OEM-fitment while delivering enhanced aerodynamics. Choices range from lightweight composite blends to full carbon fiber assemblies and, in some cases, hybrid constructions that blend a structural backbone with carbon surfaces for aesthetics and weight savings. In a well-planned installation, the bumper can align with a broader aero strategy that includes diffuser and underbody kit alignment, ensuring the nose-to-tail airflow remains coherent at high speed. Buyers doing their homework may weigh factors such as material quality, tolerances, and the bumper’s compatibility with existing side skirts, a lip, or a hood with an aero emphasis. The goal is a seamless integration where the added front-end performance is not offset by new gaps, misalignments, or wind noise at high velocity.

Culturally, the Evo X bumper also reflects a broader trend in the community: enthusiasts increasingly see the bumper not just as a performance part but as a visual signature of intent. Some builds celebrate the aesthetic of a race-inspired front, while others emphasize subtlety and balance with a gloss or matte finish tailored to a particular colorway. Even in limited editions, high-quality front bumpers carry badges that signal a collector’s value, reminding builders that performance and provenance can coexist. In these contexts, choosing the right bumper is about balancing the desire for a sharper look with the practical realities of track-day durability, daily-drive reliability, and the finite budget of a build.

For those who are committed to OEM-style authenticity or exacting fitment, genuine front bumper components exist as an option, and sourcing can be part of a broader strategy to preserve the car’s original character. For OEM-like compatibility, a genuine CZ4A Lancer Evolution X front bumper can be sourced from established suppliers, ensuring that mounting points align with the factory geometry and that the surface treatment integrates with existing panels and trim. This approach provides a sense of reassurance for builders who want predictable installation outcomes and predictable alignment with adjacent parts. CZ4A Lancer Evolution X front bumper genuine.

As the discussion above suggests, the payoff from Evo X bumper upgrades extends beyond mere looks or the bragging rights of a sharper profile. The strategic combination of improved airflow, enhanced downforce, and cooling efficiency yields measurable gains in track performance, handling fidelity, and driving confidence. It is a holistic upgrade, one that asks the driver to consider how a front-end component interacts with every other element of the chassis and powertrain. The effect is a more cohesive and responsive machine, one that can maintain solid pace through complex corners, resist heat buildup during repeated laps, and return consistent performance across a session. In the context of an overall build, the bumper becomes a focal point around which aerodynamic, thermal, and structural enhancements converge, delivering a tangible reward: a car that communicates its intent clearly to the driver and rewards precision and commitment with steadier balance and more confident, repeatable performance.

External resource for further detail and practical guidance can be found here: Lancer Evo X Front Bumper Guide: How to Choose the Right One.

The Final Edition Front Bumper: Aerodynamic Precision, Dark Aesthetics, and the Legacy of Evolution

The final edition front bumper embodies more than a visual cue in a celebrated lineage; it is the culmination of aerodynamic intent and design discipline, a component engineered to manage airflow, cool critical systems, and stabilize the chassis at high speed while remaining visually cohesive with the car’s silhouette. Its central features include a pronounced central air dam, integrated side intakes, and recessed fog-light pockets that preserve the clean lines and minimize drag, delivering predictable cooling and maintained downforce as the car enters corners at speed. The bumper’s deep, uniform black finish creates a high-contrast frame for the sculpted surfaces, enhancing the perception of aggression while avoiding glare that can distract the driver at night. A centrally mounted badge marks the edition’s provenance, linking the front end to the model’s broader history and signaling collectability and care in engineering. In sum, the final edition bumper is not merely cosmetic; it is a carefully integrated element of the aero kit and powertrain calibration, designed to work with other components to preserve steering feel, stability, and driver confidence across a range of driving contexts.

Final thoughts

The Evo 10 bumper is more than just a visual upgrade; it serves as a pivotal development in automotive design that enhances performance and aesthetic appeal. Understanding its aerodynamic design, exploring various aftermarket options, and recognizing the manufacturing landscape in Guangdong Province allows business owners to seize opportunities in this niche market. The impressive upgrades available, along with the unique characteristics of the Final Edition bumper, further underline the value these components bring to performance car enthusiasts. With a knowledgeable approach, businesses can effectively engage with the Evo 10 community and meet their specific needs.