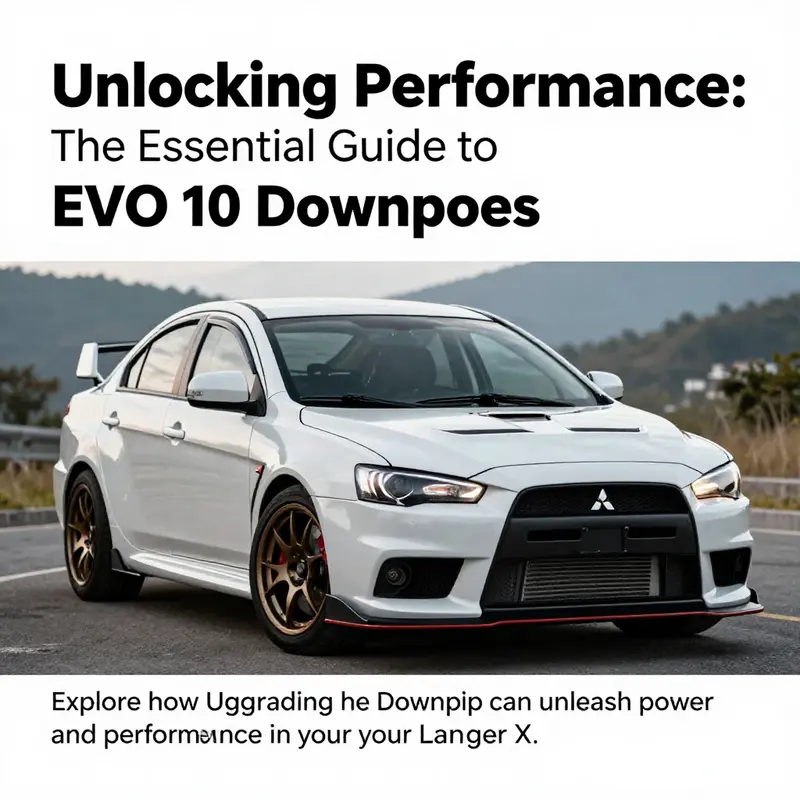

The Mitsubishi EVO 10, a beloved staple of the high-performance automotive community, often requires meticulous attention to key components for optimal enhancement. Among these, the Downpipe serves as a critical element connecting the turbocharger to the exhaust system. Not only does it affect sound and emissions, but it also plays a pivotal role in boosting engine performance. In this comprehensive guide, we will delve into the Downpipe’s functionalities and its imperative role in enhancing performance, examine the materials and manufacturing techniques that define high-quality options, discuss installation considerations for compatibility and optimization, and explore real-world enhancement cases. By the end of this article, business owners will gain valuable insights into the potential benefits of choosing high-performance Downpipes for the EVO 10.

Unlocking the Turbo: How the EVO 10 Downpipe Transforms Power, Response, and Sound

How the Downpipe Works and Why It Matters

The downpipe on an EVO 10 is a short component with outsized influence. It links the turbocharger outlet to the rest of the front exhaust. Despite its modest size, its geometry, diameter, and internal finish determine how easily exhaust gases escape the turbine. That escape governs turbo speed, spool time, and the pressure environment the engine breathes against. Changing this link from a restrictive production piece to a purpose-built performance component reshapes the car’s response, peak power, and acoustic character.

A factory downpipe balances emissions, noise, and everyday drivability. To satisfy regulations, it often includes flow restrictions and catalytic elements. These work for street refinement, but they create backpressure. In turbocharged engines, backpressure fights turbo acceleration. It slows spool and reduces the turbine’s efficiency. A well-designed aftermarket downpipe reduces that resistance. With lower backpressure the turbo spins more freely, torque builds sooner, and power delivery becomes more linear under load.

Material and manufacturing quality matter as much as shape. Performance downpipes typically use thick-gauge stainless steel alloys. These resist high exhaust temperatures and avoid warping under thermal cycles. Some advanced designs incorporate composite heat-resistant materials in non-structural areas to cut weight. Flange fitment and weld quality affect leak tightness and long-term durability. Poorly executed flanges or low-grade bolts can lead to exhaust leaks, failed sensors, or stripped threads during installation. Attention to these details prevents issues that would otherwise negate the power gains the pipe promises.

Reducing backpressure delivers measurable gains. Properly matched downpipes commonly yield a mid- to high-range power increase. Real-world cases often show double-digit gains at the crank or drivetrain, depending on supporting mods. The exact amount varies with the rest of the system. A larger turbo or aggressive boost program will generally reveal a larger absolute benefit. Conversely, if the intake and fueling systems remain restrictive, downpipe gains will be smaller but still noticeable in throttle response and transient behavior.

Choosing pipe diameter requires balancing low-end response and high-end flow. Smaller diameters can preserve low-speed exhaust velocity, supporting spool and torque below midrange. Larger diameters reduce restriction at higher flow rates, supporting top-end power but risking softening of low-speed response. On the EVO 10, common performance diameters sit in a range that balances both demands. Select a diameter that aligns with your torque and horsepower goals, the turbo size you run, and whether the car will see street or track duty.

The internal path and transitions are as crucial as diameter. Smooth bends and gradual transitions reduce turbulence. Mandrel-bent sections maintain constant cross-section through curves and avoid choke points. A straight-through path to the front pipe minimizes reflected pressure waves that can induce turbo surge or flow separation. Designers also consider the wastegate flow and placement relative to the main pipe; a poorly located or obstructed wastegate path undermines the whole system’s ability to control boost and heat.

Wastegate handling is an important variation to weigh. Some designs route the wastegate to the atmosphere, while others merge it back into the exhaust stream. Dumping wastegate gases to the atmosphere can reduce backpressure further and create a more aggressive sound. However, it increases local heat and complexity and may complicate noise or emissions compliance. Returning the wastegate flow to the main pipe offers a cleaner legal footprint and smoother sound, but it may slightly increase backpressure, depending on the merge geometry. Choose the approach that fits your performance targets and the regulatory environment you must operate in.

Beyond raw flow, a downpipe affects thermal dynamics. Faster gas evacuation lowers turbine temperatures and can reduce heat soak in the turbo and nearby components. That benefits durability under high-load use. Yet increased flow also means hotter oxygen sensors and catalytic components if fitted. High-quality thermal protection, such as heat shielding and proper wrap for adjacent wiring and hoses, is essential. Heat management extends component life and keeps engine bay temperatures within safe limits for sensors and electronics.

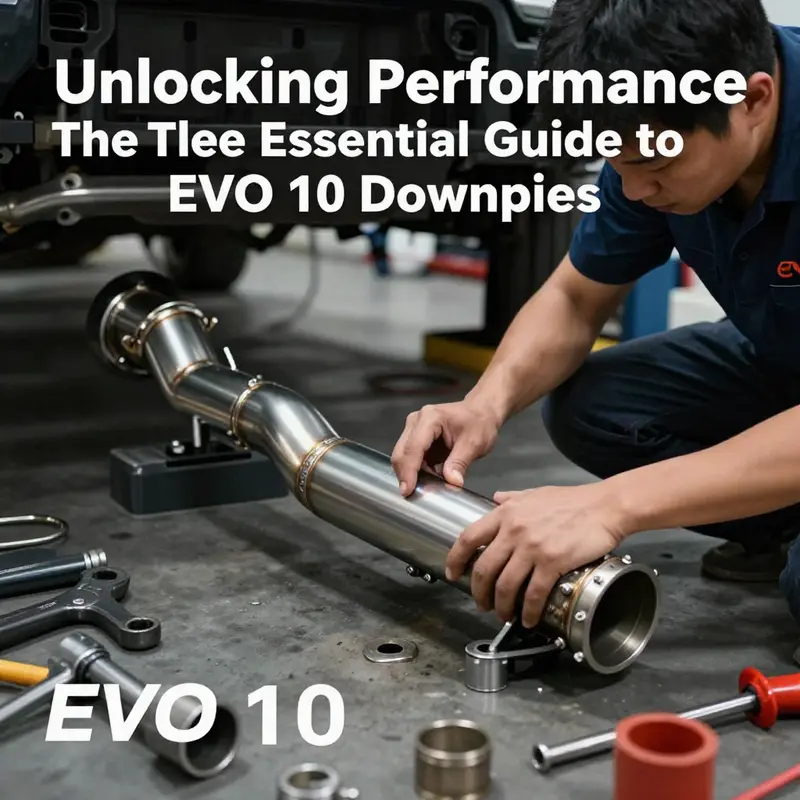

Installation challenges are often underestimated. The EVO 10’s engine bay is tightly packaged. Turbo housings, steering linkage, drive axles, and heat shields crowd the workspace. Bolts exposed to long-term heat cycles can be brittle or corroded. During replacement, it is common to encounter seized hardware, small bolt holes, or weakened threads. Professional tools and techniques, such as penetrating lubricant, controlled heating, and proper torque sequences, reduce the risk of damaging fasteners. In extreme cases, peripheral components must be removed for access. Experienced technicians will plan for possible halfshaft or bracket removal to complete a safe installation without rush or improvisation.

Tuning and system matching are essential after a downpipe upgrade. Removing restriction changes exhaust backpressure and the oxygen sensor environment. Engine control systems see different feedback and may run suboptimal if left unchanged. A recalibration to adjust fueling and timing is typically required to reap full benefits. Ignoring tuning can leave the engine susceptible to knock, incorrect fueling, or reduced efficiency. A calibrated program will exploit the freer flow, restoring safe air-fuel ratios and optimizing boost control across the rev range.

Sound is both an emotional and technical outcome of a downpipe swap. A less restrictive route allows the exhaust note to broaden and gain presence. At light throttle the change can be subtle, but under full throttle the car sounds more direct and aggressive. If the design uses a wastegate-to-atmosphere path, the character becomes sharper, with distinct bursts when the wastegate vents. That sound can be thrilling, but it also transmits more noise and harshness into the cabin. Some owners find the added acoustic energy rewarding. Others find it intrusive during long drives. Consider how the vehicle will be used and whether additional measures to damp cabin noise are desirable.

Compatibility with downstream components is a final, practical consideration. The downpipe must join cleanly to the front pipe and rest of the exhaust. Misaligned diameters or mismatched bends cause stress, leaks, and drivability issues. Keep in mind that changing the downpipe often exposes the limitations of stock components. A full exhaust system designed for higher flow complements the downpipe and avoids bottlenecks. The same goes for intake plumbing and intercooler efficiency. A holistic approach prevents chasing single-part gains and ensures each part performs in service of the whole.

There are trade-offs worth accepting and some to avoid. Gains in throttle response and peak power come at the cost of increased sound and potentially higher emissions. Material choice and build quality mitigate risks of premature failure. Professional installation reduces the chance of stripped bolts and exhaust leaks. Planned tuning prevents engine management problems. Lastly, consider the vehicle’s future upgrades. A high-quality downpipe lays a strong foundation for larger turbo kits, higher boost levels, or competition use. It is often the first step in a staged upgrade path because it unlocks the turbo’s ability to operate at higher efficiency.

For those who approach the EVO 10 as a platform, the downpipe is a critical early investment. It shapes how the turbo interacts with the engine, alters thermal behavior, and brings tangible gains in drivability. When selected with attention to diameter, internal finish, wastegate routing, and material quality — and when paired with proper tuning and heat management — it becomes a multiplier for subsequent modifications. If you need a reference for a full car partial teardown or component fitment during major upgrades, consult a dedicated EVO X halfcut resource for layout and compatibility guidance: EVO X halfcut reference.

Reference:

https://www.c-dubtech.com/products/ets-08-16-mitsubishi-evo-x-dump-downpipe

EVO 10 Downpipe: Materials and Manufacturing Craft for Maximum Flow and Durability

Across the EVO 10 tuning journey, the downpipe acts as more than a simple connector. It is the gatekeeper of how quickly exhaust gases leave the turbine housing and how cleanly they travel toward the front pipes. In performance conversations, this component is often one part of a larger design philosophy: reduce flow resistance without sacrificing durability in the intense heat of a turbocharged engine. The material choice and the manufacturing craft behind a downpipe shape how readily the turbine can respond to throttle input and how far the power curve can be stretched across the rev range. In that light, the downpipe becomes a quiet but decisive lever in the quest for a more responsive, more brutal, and more cohesive driving experience.

Materials start with the obvious choices. Stainless steel remains the workhorse for many high‑performance downpipes because it blends cost, strength, and resilience. The common grades used—stable, heat-tolerant variants—deliver dependable performance under the corrosive and hot exhaust environment. The ability to withstand repeated heat cycles without hardening, cracking, or warping is essential, because a downpipe sits where temperatures surge and where the gas stream can twist and turn with every turbo surge. Wall thickness matters too. Thick walls resist physical deformation and sustain form through life in heat, yet add weight and may slightly alter the internal geometry. The real trick is balancing rigidity with an unobtrusive flow path. In a well‑engineered piece, the bore remains smooth, the walls steady, and the flanges sealing without hesitation through countless boost cycles.

For builders seeking lighter weight and even greater high‑temperature tolerance, titanium alloys enter the conversation. Titanium offers a meaningful reduction in mass and an excellent heat profile. The lighter assembly reduces the overall drivetrain inertia, which can translate to quicker throttle response and a more agile feel under load. The caveat is cost and fabrication nuance. Titanium welds demand technique and specialized considerations to avoid cracking under heat cycling. In practice, only a subset of high‑end or track‑oriented builds opts for titanium downpipes, but the payoff in weight savings can be significant when the rest of the package is scaled to match the performance intent.

Manufacturing pathways for high‑performance downpipes blend precision and durability. A seamless tube is often preferred because it eliminates the seam weakness that can become a hotspot for fatigue under exhaust temperatures. CNC bending ensures bends are placed with surgical precision, preserving a smooth interior bore and avoiding abrupt changes in diameter that would create turbulence or pressure peaks. Where joints are necessary, high‑quality welding with deep penetration and a clean, continuous seam provides both seal reliability and structural integrity. Surface finishing matters as more than just aesthetics. A polished bore reduces roughness that could disturb the boundary layer, while a brushed or coated finish adds corrosion resistance and can help manage heat load. In service, a well finished downpipe resists discoloration, cracking, and pitting, maintaining performance and appearance through miles of track work and street duty.

Design choices extend beyond material to geometry. The inside of a downpipe is often finished with a uniform bore designed to minimize turbulence. OEM designs may employ subtle diameter transitions that can create unintended backpressure, especially as boost curves rise. In performance iterations, engineers frequently favor a consistent diameter for a more linear flow profile. This is not without trade‑offs; a pipe that is too large early can hamper mid‑range torque if the rest of the exhaust and intake are not aligned. The right balance is a function of the whole powertrain script: turbine size, intercooler efficiency, intake design, and engine management strategy. To translate theory into practice, the best products emerge from fluid dynamics simulations and iterative testing, where the tiniest change in flange quality, seal fit, or weld smoothness can ripple through the entire system’s performance.

Surface finishes play a subtle, often underestimated role. A bore that gleams through heat cycles is not just about looks. A high‑quality finish can reduce parasitic drag inside the pipe and limit heat soak in nearby components. Protective coatings add a barrier to corrosive exhaust byproducts, while still preserving the bore’s smoothness for gas flow. In track or winter climates, coatings that resist oxidation and corrosion extend service life and maintain flow characteristics even after repeated heat cycling and exposure to road salt. The combination of material choice, seamless manufacturing, precision bending, and thoughtful finishing underpins a downpipe that survives harsh conditions while delivering predictable flow benefits.

Weight considerations frame another core decision. Stainless steel offers a predictable performance envelope with robust durability at modest weight penalties. Titanium, by contrast, can shave kilograms off the package, which matters in a light‑on‑weight strategy aimed at sharper throttle response and more aggressive transient behavior. Yet every gram saved on the downpipe must be paid back in other areas of the system—flanges, bolts, gaskets, and the surrounding heat management plan—to avoid creating new weak links. The upshot is that the best downpipes are designed with an eye toward overall system coherence rather than isolated gains. The inline fit between turbine outlet and subsequent exhaust segments hinges on flange planarity, gasket sealing, and the absence of misalignment that could generate leaks or uneven flow.

Matching the pipe to other parts of the exhaust and engine management is crucial. A widely observed guideline in high‑performance setups is to select a diameter that harmonizes with the rest of the system. Common choices hover around mid‑ to large‑scale diameters that optimize the trade‑off between mid‑range boost response and top‑end flow capacity. The wrong pairing can cause resonant issues or a perceptible drop in acceleration when the engine is pushed hard. After installation, recalibrating or re‑mapping the engine control strategy is often necessary to align the turbo’s behavior with the new pressure characteristics. The goal is not to force a larger pipe to deliver immediate gains without regard to the engine mapping; it is to unlock the latent potential of the turbocharged flow path through coherent orchestration of hardware and software.

Real‑world benchmarks illustrate the potential of a well‑chosen downpipe. In elaborate performance programs, a high‑flow system paired with a larger turbo and a tuned intake can push peak power toward the upper end of the spectrum, with torque gains that become tangible in the mid‑range. The actual gains depend on the entire upgrade package—intercooling efficiency, air intake design, and fuel and ignition management all contribute. In some cases, the power bump is accompanied by a broader, more usable torque curve and a quicker spiritual response from the accelerator pedal. However, these benefits are contingent on careful coordination; a downpipe on its own cannot conjure feats of horsepower without the rest of the system being tuned to exploit the enhanced flow. If the engine is pushed to extremes without corresponding cooling and management, the gains may plateau or even worsen overall driveability.

Beyond the numbers, a downpipe upgrade affects the car’s feel and daily usability. A freer exhaust path allows the turbine to spool more eagerly, which translates into quicker throttle response and a more aggressive exhaust note under acceleration. The engine bay, however, will radiate more heat and, for some drivers, a touch more cabin resonance. Heat shielding, strategic routing, and, at times, improved engine mounts help balance the increased performance with acceptable NVH levels. In some builds, adjacent components are upgraded to better withstand the added heat and vibration, ensuring the chassis remains composed and the road feedback remains precise. The aim is a coherent upgrade that improves responsiveness without turning the car into a noisy, unsettled companion on daily commutes.

From a materials and manufacturing perspective, the downpipe represents a convergence of metallurgy, mechanical engineering, and quality fabrication. It is a conduit that must tolerate extreme heat, resist corrosion, and endure the mechanical demands of boost, exhaust gas pulsations, and track‑driven vibrations. A well‑made downpipe preserves the energy of the exhaust stream as it transitions from turbine housing to the rest of the exhaust tract. The result is a more immediate throttle response, a cleaner power delivery, and a broader usable RPM range. The craft involved is not a matter of aesthetics alone; it is an engineering discipline that translates into real, repeatable on‑road and on‑track performance.

To connect this discussion to practical integration within the EVO X tuning ecosystem, consider a related component that interlocks with the same chassis and performance goals. For those exploring practical upgrades that complement the downpipe, a nearby option worth exploring is the evo-x-halfcut, which provides a critical subset of the car’s drivetrain components suitable for a serious performance build. See evo-x-halfcut for more on how these parts can come together in a coherent package.

Finally, as with any major performance modification, the path to reliability is paved with careful planning, quality workmanship, and attention to matching the rest of the system. The downpipe is not a magic wand; it is a carefully engineered enabler that can unlock additional potential when paired with the right intake, intercooling, and engine management. The story of a well‑chosen downpipe is the story of engineering discipline meeting real‑world driving, where a car becomes more responsive, more eager to climb through the revs, and more alive with the freedom of a freer exhaust path. It is a testament to the idea that performance gains are rarely the product of a single part but the sum of meticulous design, precise fabrication, and thoughtful integration.

External reading and deeper technical context can provide further insight into how these systems are engineered and tested. For readers seeking more background on high‑performance exhaust systems from a manufacturing perspective, a detailed resource offers broader perspectives on materials choices, fabrication practices, and testing methodologies. This can help drivers and builders understand why certain choices are made and how to evaluate potential products beyond surface‑level specifications. https://www.jomoperformance.com/products/evo-10-downpipe

Navigating EVO X Downpipe Installations: Compatibility, Fitment, and Tuning for Peak Power

Understanding the EVO X downpipe upgrade requires attention to three interconnected areas: compatibility, fitment, and tuning.\n\nCompatibility ensures the downpipe matches your year, market, and emission specifications so that the exhaust plumbing, turbine outlet, and O2 sensor sockets align correctly.\nFitment focuses on the physical clearance in the engine bay, clearance with heat shields, and proper gasket and flange seating to prevent leaks.\nTuning addresses ECU recalibration and fueling strategy to leverage reduced backpressure while maintaining reliability and drivability.\n\nA coordinated upgrade plan that sequences compatibility, precise installation, and calibration tends to deliver the best results in throttle response, midrange torque, and peak power, without compromising daily usability.

Unleashing the EVO X: Real-World Impacts of a Downpipe Upgrade

Between the turbocharger and the forward section of the exhaust, the downpipe sits at the critical junction where flow meets heat, pressure meets patience, and the true character of a tuned engine begins to reveal itself. In performance work, replacing a stock downpipe with a purpose-built, high-flow alternative is often the first meaningful step toward unlocking what lies beyond the factory tune. The stock design tends to balance emissions, sound, and smoothness for daily driving. It often treats the exhaust as a broader system where a long, labyrinthine path can introduce mild bottlenecks. When an upgraded downpipe is installed, the dynamics shift. The exhaust gas stream meets less backpressure, which can accelerate turbine response, improve throttle immediacy, and set the stage for higher revs where peak power typically resides. This is not a myth or a fantasy; there are real, measurable changes that enthusiasts can feel behind the wheel and see on the dyno. In many cases, the improvement is enough to transform midrange torque and mid-to-high end pull, turning what once felt like a gentle curve into a more confident, linear rise in power as the revs climb. The downpipe is not a lone hero, but it is the crucial gatekeeper that decides how freely the engine can exhale after boost has done its job, and how quickly the turbo can respond to throttle input before conditions outside the engine even get a say in the power curve.

A practical way to think about the downpipe upgrade is to picture the exhaust as a two-part system: the turbocharger’s outlet and the pipe that carries exhaust to the rest of the exhaust tract. The stock pipe is typically designed to meet a broad set of constraints—legislation, noise limits, and a need for low-end tractability. In a performance build, those constraints become the risk factors to be managed, not merely accepted. A well-chosen downpipe aims to minimize flow resistance without compromising reliability. In the context of the EVO X, this means a pipe that preserves the structural integrity of the exhaust system while increasing the velocity of the gases as they leave the turbine housing and head toward the front section of the exhaust. The result, in simple terms, is a more efficient turbocharger: quicker spooling, less lag, and more eager acceleration as boost builds and the engine reaches into higher RPM ranges where the power is most capable of surprising a stock-oriented observer.

Materials and engineering choices play a decisive role in how an upgraded downpipe behaves under heat and pressure. High-performance versions typically use materials that resist heat distortion, corrosion, and warp at the elevated temperatures produced by forced induction and rapid exhaust gas movement. Stainless steel is a common choice because of its balance of strength, durability, and manufacturability, while some premium variants lean toward lighter, advanced composites or specialty alloys that can further reduce weight and improve heat handling. The construction quality matters just as much as the material itself. Precision-toleranced bends, clean welds, and reinforced joints ensure that the pipe can withstand repeated, high-heat cycles without leaking or deforming. A well-made downpipe also minimizes the risk of backflow or resonance that can complicate the exhaust’s acoustic signature and potentially disrupt exhaust scavenging at certain RPM windows. These aren’t merely theoretical claims. In real-world builds, drivers report a smoother, more assertive presence as the engine breathes more freely, especially in the midrange where turbocharged power is often most usable for street and track driving alike.

The observable benefits are not limited to a single, dramatic number on a dyno chart. A common, well-supported outcome is a more responsive throttle feel and a broader, more usable torque band. When the backpressure is reduced, the turbo can move air more readily, which translates into faster and more consistent throttle response. On the street, that translates into crisper acceleration, a more confident surge as you step into the throttle, and a noticeable shift in the way the engine pulls through the gears. On a highway ramp or a load test, you can feel the engine pulling with less hesitation as boost climbs and the exhaust breathes easier. In more ambitious builds—where the engine may be kept in high-boost territory for longer periods—downpipes can contribute to a more consistent power delivery, helping to tame some of the abruptness that accompanies aggressive tuning. The numbers that enthusiasts chase—gain figures in the 20–40 horsepower range at the wheel, or an even more dramatic shift when paired with other upgrades—are not unusual, and in certain combinations, a dyno may record peaks in the low 400s wheel horsepower. While those numbers are exciting, the practical takeaway is the enhanced driveability and the foundation they provide for further iterations of the powertrain.

An illustrative thread running through multiple real-world projects is how a downpipe interacts with other components of a performance package. The reduction in exhaust backpressure works best when the rest of the system is aligned to take advantage of the freed-up flow. A downsized or mismatched pipe can introduce strange resonances that create new and unwanted harmonics or even choking in parts of the spectrum where the engine would otherwise benefit from smoother gas expulsion. Consequently, many builders treat the downpipe as the starting point of a broader cascade of upgrades. They plan a staged approach: downpipe first, followed by careful tuning of the engine control system, and then matched improvements to induction and intercooling, always with an eye toward fuel delivery precision and ignition timing stability. The ECU, in particular, must be reconsidered in light of the altered exhaust flow. A reflash or a recalibration of fueling, timing, and boost targets is essential to avoid lean conditions, detonation risks, or misfiring in high-load regimes. This holistic approach helps to maximize the downpipe’s potential and ensures that the vehicle remains reliable in daily use while it explores the edge of its new capability.

Case studies from the field underline this point with tangible details. In a couple of popular narratives, enthusiasts have described how a high-flow downpipe, when combined with a broader exhaust strategy and a tuned ECU, can push wheel horsepower up meaningfully while preserving drivability. The gains are not limited to numbers; the driver’s perception of engine response changes in a meaningful way. The turbo spools more quickly, reducing the perception of lag, and the engine pulls with a more linear and accessible powerband. This is especially relevant for the EVO X, where the turbo’s response and the midrange torque are central to everyday performance and track readiness. The practical takeaway is clear: a downpipe upgrade is a gateway to broader performance improvements, but it performs best when integrated with a coherent plan that respects mechanical limits, emissions considerations, and the intended use of the vehicle.

Of course, every upgrade carries potential caveats. The improved flow and power come with changes to exhaust tone and vibration levels that some drivers may notice more readily. A more aggressive exhaust path can translate into a louder, more aggressive soundtrack, particularly at higher RPMs. For some users, this is a welcome feature; for others, it may demand additional attention to cabin isolation or minor adjustments to the chassis mounts and bushings to maintain a balanced ride quality. In parallel, the removed or altered backpressure can have knock-on effects on other subsystems. If the engine management is not tuned to the new airflow characteristics, you risk misfires, ECU watchdog alerts, or a less-than-optimal air-fuel ratio. The prudent path is to view the downpipe as part of a system rather than a standalone upgrade. It deserves integration with tuned fuel delivery, a calibrated ignition map, and a plan for fueling and cooling upgrades, so the resulting power is both strong and sustainable across a wide range of operating conditions.

The alignment of the downpipe with the rest of the exhaust and propulsion system is an important practical consideration. Not all downpipes are created equal, and the degree to which the pipe’s diameter, the length of the run, and the type and location of any catalytic components influence the final result. A larger diameter is not a universal answer; if the downstream piping, mounts, and turbomachinery are not designed to work with that increased cross-sectional area, you can inadvertently create resonance problems or turbulence that undermines the intended benefits. The most successful configurations maintain a careful balance: a tube diameter that complements the turbocharger’s characteristics and the engine’s breathing across the entire RPM range, a path that minimizes sharp elbows and abrupt changes in direction, and a robust mounting strategy that keeps the system quiet and stable at full boost. In practice, this means selecting a downpipe that preserves critical alignment with the turbo outlet, avoids interference with neighboring components, and includes reliable sealing and heat management features. The heat soak management is not a trivial detail; faster gas movement can mean more intense heat in proximity to the turbine housing and surrounding components, which is why attention to heat shielding, clamping, and routing cannot be overlooked.

As with any performance modification, legality and warranty considerations must be part of the planning. Depending on jurisdiction, certain exhaust configurations may affect emissions compliance or vehicle inspection requirements. A well-informed project will consider these aspects early, ensuring that the long-term ownership experience remains smooth and free from regulatory surprises. In some cases, choosing a downpipe with a catalytic element or a compliant design can help maintain road legality while still delivering meaningful performance improvements. The objective is to achieve a balanced tune that respects the rules of the road while expanding the vehicle’s capabilities in a controlled and repeatable way.

For builders who are looking to push beyond a single upgrade, the downpipe sets the stage for a staged upgrade path. If the goal is more extreme performance, many teams plan subsequent steps: a larger-turbo or twin-scroll approach, a more ambitious intercooling strategy, enhanced fueling, and a more aggressive ECU strategy. Each step amplifies the previous ones, but it is essential to retain a coherent, test-driven approach to avoid creating unmanageable heat, fueling imbalances, or reliability compromises. In this sense, a downpipe is not merely a piece of metal; it is the first domino in a sequence whose fall leads to a broader, more purposeful evolution of the vehicle’s power, sound, and behavior.

For readers who want to connect this discussion to broader practical resources, consider the EVO X ecosystem and its modular upgrade paths. When planning a multi-part upgrade, it helps to map out the components that will work most harmoniously together. A well-chosen downpipe pairs naturally with an upgraded intake and front-mounted intercooler, and it benefits from a calibrated exhaust map that reflects the new gas dynamics. In addition, a compatible fuel strategy and ignition timing plan complete the foundation necessary to exploit the improved flow without compromising reliability. If you’re curious about how such upgrades are discussed in broader resources, you can explore a technical analysis of downpipe benefits from reputable sources that review real-world test data and explain how the changes translate into measurable performance gains. See the external resource linked at the end of this chapter for a detailed, data-driven look at the topic.

To keep the discussion grounded and actionable, consider the practical step of researching and selecting a downpipe that fits the vehicle’s platform and your goals. It is important to verify that the chosen pipe aligns with the rest of the exhaust system, the engine’s management approach, and the planned level of power. The goal is not simply raw numbers but a reliable, repeatable performance profile that translates into a more satisfying driving experience. When done thoughtfully, the downpipe upgrade becomes a meaningful stepping stone toward a more capable and responsive vehicle, one that feels alive in each gear and measurable in each dyno session. From a driver’s perspective, a well-tuned downpipe can transform the car’s character: the turbo spools with a more immediate snap, the midrange pulls with more authority, and the high-RPM crescendo comes alive with a freer, more deliberate breath. The car behaves with a new sense of confidence, inviting you to push further and to align your driving style with the enhanced capabilities now waiting under the hood.

If you want to explore a related piece of the EVO X platform in more depth, the EVO X halfcut page offers a useful reference point for understanding how different chassis components are designed to integrate with performance upgrades. This page provides context on how the broader vehicle architecture supports or constrains aftermarket parts choices, which can help you plan a cohesive upgrade plan rather than chasing piecemeal gains. For a more technical, data-driven look at the broader topic of downpipe upgrades, refer to the external resource below that outlines the measurable benefits observed in real-world testing and the considerations that come with high-flow exhaust work. The discussion there emphasizes how downpipe improvements, when paired with proper tuning and complementary hardware, can shift the power delivery and throttle response in meaningful ways that persist across different driving scenarios.

Internal link for further reading on EVO X platform integration: EVO X halfcut page

External resource for deeper technical context: EVO X downpipe upgrade benefits

Final thoughts

Investing in a high-quality Downpipe for the Mitsubishi EVO 10 can profoundly impact not only engine performance but also future modifications. As we explored, this single upgrade contributes to reduced backpressure, improved turbo response, and potential increases in horsepower. By ensuring thoughtful selection of materials and skilled installation, businesses can enhance the driving experience of EVO 10 owners while laying the groundwork for subsequent upgrades. Equip your customers with the knowledge and tools to elevate their performance game with a reliable Downpipe.