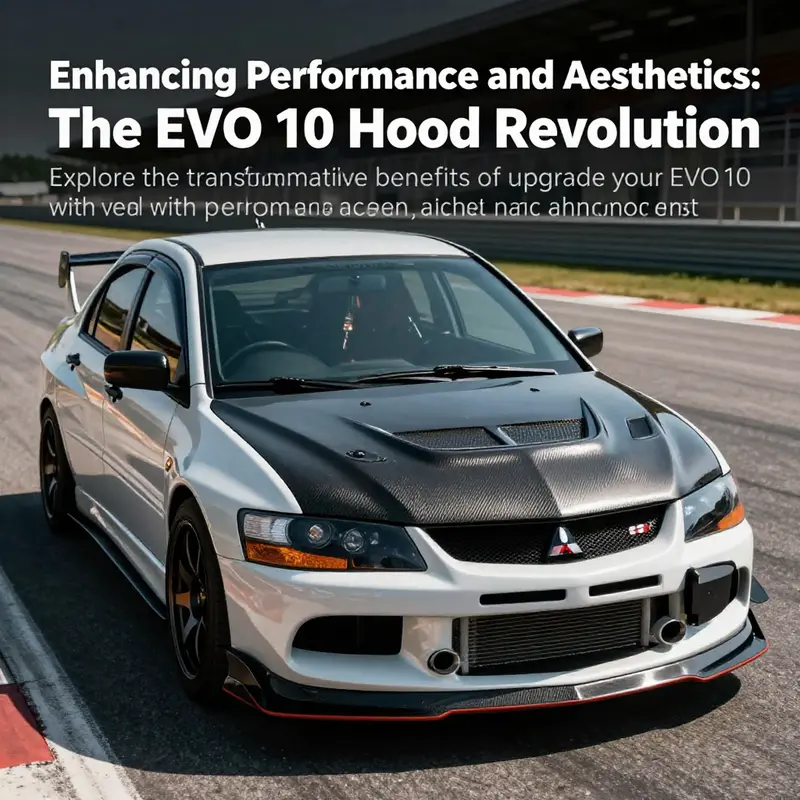

The Mitsubishi Lancer Evolution X, commonly referred to as the EVO 10, has firmly established itself as an icon in the automotive world, revered for its performance and style. One of the pivotal components contributing to both its aerodynamics and visual appeal is the vehicle’s hood. Upgrading to a carbon fiber hood can significantly enhance performance through weight reduction, improve cooling efficiency, and present a striking appearance. This article delves into three key aspects: the performance enhancements provided by the EVO 10 hood, the benefits of using advanced materials like carbon fiber, and the market availability of these products for business owners looking to tap into the aftermarket modifications sector.

Hooded Precision: How the EVO X’s Carbon Hood Shapes Performance, Handling, and Heat

The engine bay is more than a mechanical compartment; it is the beating heart of a car’s performance narrative. For the Mitsubishi Lancer Evolution X, the hood—often dismissed as a simple cover—plays a surprisingly influential role in how the car behaves on street streets and on the track. The move from a heavy, factory steel hood to a carbon fiber alternative embodies a philosophy: every gram counts when the aim is to sharpen reflexes, balance, and confidence at the wheel. In this chapter, we explore how a carbon fiber hood functions as a performance lever for the EVO X, not through a single decisive data point, but through a cascade of beneficial effects that accumulate under the right driving conditions. The idea is straightforward: if you reduce front-end weight, you change the way the car rotates, brakes, and plants itself on the road. Those changes become most evident in aggressive cornering, in rapid direction changes, and in sustained, high-load driving where thermal limits come into play. The hood’s primary mechanical job remains protection and enclosure. Yet when you replace the OEM sheet with a lighter, stiffer composite, you tilt the wheel of balance in favor of the driver. The weight savings are not just about shedding mass; they are about relocating it in a way that favors handling fidelity. In the EVO X, where the chassis is tuned around precise weight distribution and nuanced steering feel, shaving the front end can translate into more immediate turn-in, quicker nose response, and a more linear transfer of load through the chassis during braking and cornering. The magnitude of the change is not a single metric, but a composite improvement built from several interlocking parts of the vehicle’s dynamic system. The carbon hood is typically a sprung, laminated part that replaces the OEM metal panel. Unlike the stock lid, a carbon composite can weigh a fraction of the original, sometimes reducing front-end sprung weight by a meaningful margin. This reduction lightens the moment of inertia at the car’s front, allowing the car to pitch into corners with less effort from the driver and with less scrubbing of speed before the apex. The result is a feeling of lighter steering, more immediate response to steering input, and a chassis that communicates better what the front tires are doing. It does not make the car a miracle machine, but it does help the EVO X express its cornering character more faithfully. The practical consequence is a more balanced front-to-rear weight distribution, which fosters improved balance under braking and enhancing mid-c corner stability. In practice, this can translate into more confident throttle application as the front tires settle into traction rather than fighting against a heavy front bias. The hood’s effect on front-end weight distribution interacts with the car’s suspension tuning. A lighter hood reduces the load that the suspension must manage at the car’s most forward point, allowing the springs and dampers to respond more freely to road texture. This is particularly noticeable on uneven surfaces or during aggressive track sessions where heat, braking, and tire temperatures push the chassis to its limits. The EVO X, with its turbocharged heart and sophisticated all-wheel-drive system, relies heavily on precise weight transfer to keep balance stable as boost comes on. Lightweight hood panels help the front wheels connect with the road more cleanly, which can appear as crisper turn-in and a more controllable understeer/oversteer balance across different corner radii. The narrative of performance improvement is thus not a single mechanical spec but a chain of subtle shifts in how the car behaves after the click of a wheel and the press of the accelerator. Beyond weight, heat management is another cornerstone of hood-driven performance. The forward compartment of the EVO X is where air must travel swiftly to remove heat from the engine, turbochargers, and intercooler. A well-designed carbon hood often features air vents, scoops, or channels that guide cooler air into the bay and extract hot air more efficiently than a flat, unvented panel. In hot weather or during high-speed driving, engine temperatures rise quickly; heat soak can erode performance and throttle response. By accelerating heat removal, a vented carbon hood helps sustain engine performance, maintain intake efficiency, and prevent heat-induced power drop-offs during repeated, high-load bursts. The installation of vents is not a cosmetic flourish; it is a performance-centric design choice. The vents create a controlled pathway for air to escape the engine bay, which lowers the density of hot air around the intake and exhaust system. The benefits are twofold: cooler air helps the manifold and intercooler operate with less resistance, and the cooler environment reduces the likelihood of heat soak in the intake system that can rob horsepower during long sessions on a circuit. In other words, a carbon hood can act as a passive thermal management ally. Visual appeal, while secondary to function, is also a meaningful part of this upgrade. The look of exposed carbon weave—paired with the aggressive linework of the EVO X silhouette—conveys a distinct, performance-oriented attitude. It signals a driver who values both speed and polish, a balance that many enthusiasts seek when they contemplate the next step in their car’s evolution. The subjective lift in presence, however, demands practical caution: carbon fiber is strong, but it is not invincible. Like any aftermarket component, the hood must be selected with an eye toward quality, craftsmanship, and compatibility with the hood latch, hinge alignment, and the surrounding structure. A hood that does not line up flush with the fenders or interferes with the radiator support can undermine the entire dynamic package. Fitment is not merely a matter of aesthetics; it’s a cornerstone of performance reliability. The manufacturing method matters too. Carbon fiber hoods tend to use resin-rich laminates laid into a mold, then cured under heat and pressure. The result is a panel that is stiff and light, but also more brittle in some impact scenarios than metal. For this reason, many builders emphasize a protective clear coat to guard against UV exposure, stone chips, and environmental elements. The finish matters not only for longevity but for ergonomics—how the hood responds to temperature cycles, how it feels when you shut it, and how it aligns with the hood latch and secondary safety catches. If the hood does not sit securely, the risk of flutter at high speeds or under heavy braking rises, and that undermines both safety and performance. This is where the practical, almost ritualistic side of upgrading to a carbon hood comes into play. Enthusiasts invest time in verifying fitment, performing alignment checks, and ensuring the latch mechanism remains robust after removing the factory hood. The investment is not merely in a lighter piece of carbon; it is in the confidence that the new hood will behave as the driver expects under race conditions or spirited drives. The interplay with other performance upgrades further shapes the overall effect. A carbon hood on its own can deliver weight savings and heat control, but those benefits are magnified when paired with compatible upgrades—like a stiffer front-end brace, a revised radiator or intercooler setup, and carefully tuned aero elements that work in concert with the hood’s venting strategy. In a broader sense, this is an exercise in balance: you are not simply removing mass; you are rebalancing the front end to improve steering response, turn-in aggression, and the overall tactile feel of the steering wheel. This is why many EVO X owners approach hood upgrades as part of a holistic chassis refinement rather than a single, standalone modification. The movement toward carbon fiber hoods reflects a philosophy of functional advantages anchored in material science rather than mere fashion. Yet the aesthetic improves the driving experience in another, subtler way. When a car looks fast, it tends to feel faster, and that perception reinforces the driver’s behavior behind the wheel—more precise inputs, more deliberate corner entries, and a more disciplined approach to throttle modulation. All of these intangible benefits contribute to the practical reality: a carbon hood can enhance the EVO X’s driving experience in ways that are felt in the cockpit as much as they are measured on the dyno. In a world where small improvements compound into measurable performance gains, the hood’s role emerges as a telling example of how thoughtful modification can elevate a vehicle’s character without altering the fundamental architecture. For readers who want to explore a practical path to this upgrade, a targeted, high-quality carbon hood option is worth considering. Choose one that emphasizes a good balance of light weight, stiffness, venting strategy, and robust finishing. A compatible hood should align with the hood’s mounting points, not interfere with the latching system, and provide a protective surface that ages gracefully under sun and road debris. In the context of the EVO X, where chassis tuning and turbocharged performance already demand precise control of weight and heat, the hood upgrade becomes a strategic step toward a more responsive, composed, and engaging driving experience. For those who want to see what a specific carbon hood option looks like in practice, a representative product entry demonstrates how a hood’s properties translate into real-world benefits. The page describes a hood that is designed to appeal to the enthusiast who values both form and function, offering a weight reduction paired with a venting approach that targets engine bay cooling while preserving the structural integrity required for spirited driving. In this sense, the hood upgrade is not merely a feature; it is a strategic component of the EVO X’s ongoing development, one that respects the car’s heritage while embracing a modern approach to materials and engineering. Relevant sources on the broader performance implications of hood design corroborate this logic, underscoring how weight reduction, heat management, and aerodynamics converge to shape driving dynamics. For a practical starting point, readers can explore a carbon fiber hood option that emphasizes both lighting-fast heat dissipation and a visually assertive presence. The narrative of performance here is incremental and cumulative, but it is precisely that accumulation of small, deliberate steps that often yields the most meaningful gains on track or in spirited road sessions. If the goal is to refine the EVO X’s handling envelope without reinventing the entire suspension or drivetrain, a carbon hood offers a measured, accessible route to tangible improvements in front-end behavior, thermal stability, and steering feel. Internal links can connect the reader to a product page that presents a carbon fiber bonnet hood appropriate for the EVO X, helping bridge the gap between concept and purchase. For those who want to study the phenomenon from a broader automotive perspective, the linked resource below provides a detailed evaluation of how the Evolution X performs in stock and in modified contexts, offering insight into the relative impact of weight, heat, and aero on overall performance. Anchor text for the internal link: brand-new original carbon fiber bonnet hood for Mitsubishi Lancer Evo X. External resource for broader context: MotorTrend’s Evolution X review and analysis. External link: https://www.motortrend.com/cars/evolution-x-review/.

Lighter, Faster, Cooler: The Material Truth Behind the EVO X Hood

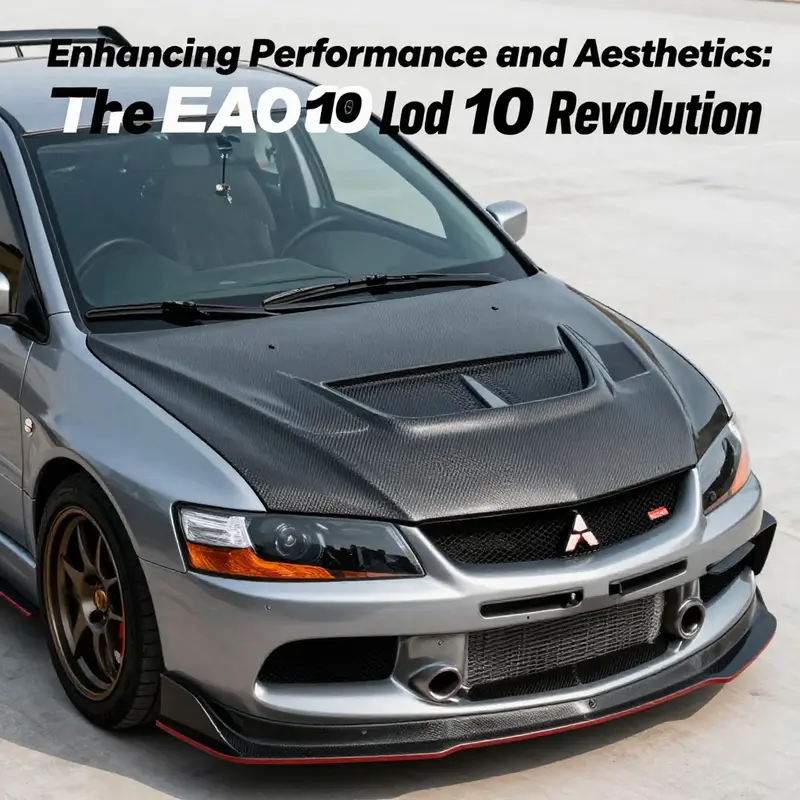

The EVO X hood sits at a crucial junction where performance meets perception. It is not merely a cover for the engine; it is a functional element that influences weight distribution, thermal management, aerodynamics, and the car’s visual stance. When a hood is tuned for performance, every microgram matters, and the choice of material becomes as strategic as the shape of the vents or the curvature of the panel. In the world of high-performance Mitsubishis, the path from steel to carbon fiber or other advanced composites is less about trend and more about a deliberate engineering choice that echoes through the handling on a racetrack and the confidence felt in daily driving. The EVO X hood, in particular, becomes a case study in how material science translates to measurable, tangible gains in momentum, balance, and reliability under demanding conditions.

Weight reduction sits at the heart of the material argument. Carbon fiber hoods, for instance, can slash weight by as much as sixty percent compared with traditional steel panels and offer a substantial edge even when compared with aluminum equivalents. That difference is not just about a number on a spec sheet; it manifests in a lighter front end, which improves the car’s weight distribution and steering feel. For a car like the EVO X, where front-biased mass is inherent to its design, shaving pounds from the hood translates into more balanced corner entry, crisper turn-in, and a more predictable ride height under hard acceleration and braking. In practical terms, this kind of weight reduction helps the vehicle rotate more readily around its front axle, enabling quicker direction changes and more precise throttle modulation through turns. The payoff surfaces in both track performance and street confidence, with the front wheels doing less work to overcome inertia and more work to communicate what the driver intends.

The benefits extend beyond weight alone. Structural rigidity is another hallmark of high-performance composites. Carbon fiber, for example, delivers exceptional tensile strength and stiffness per unit weight. This means a hood designed with carbon fiber maintains form under high-speed aero loads and aggressive driving without the sag or flex that can plague thinner or poorly supported panels. A stiff hood reduces panel motion and accompanying rattles, so the engine bay feels more solid at highway speeds and during rapid braking sequences. A well-engineered hood also resists deformation under heat soak and engine-induced vibrations, which matters because the EVO X chassis thrives on precision and responsiveness. When you couple the rigidity with lighter weight, you end up with a hood that stands up to the stresses of spirited driving while preserving the clean, predictable geometry that the car’s suspension and steering geometry depend on. The result is a front end that remains consistent as temperatures rise or as tire pressures shift under different driving scenarios.

Ventilation and thermal management are closely linked to the hood’s geometry and the material’s ability to conduct and channel heat. A number of carbon fiber hoods are designed with integrated vents, ducts, or sculpted channels that actively move cooler air in and hot air out of the engine bay. In the context of the EVO X, a well-designed venting strategy can influence charge air density, throttle response, and combustion efficiency. The hood vents are not mere cosmetic flourishes; they are aerodynamic tools that work in concert with the car’s intercooler and intake system. When hot air is evacuated efficiently, the engine can maintain safer operating temperatures during sustained runs or hot-lapping sessions, which helps prevent heat-induced detonation tendencies and keeps timing curves more stable. The cohesive effect is a drivetrain that can sustain higher performance without the fuel-air mix deteriorating as the metal cools unevenly or the intake air becomes heat-soaked. In everyday terms, this translates to a more linear power band and a more confident boost response that remains consistent as you push the car harder.

The aesthetic and tactile appeal of carbon fiber also deserves attention. The woven texture and the premium sheen of carbon fiber convey a motorsport lineage that resonates with enthusiasts who track days as well as those who simply want a car that looks purpose-built. That visual identity matters because it communicates a philosophy of performance even when the car is parked. The gloss and weave catch light in a way that signals the vehicle’s intent—speed and sophistication—without saying a word. It is a rare combination: a material that can be both functionally superior and visually compelling. While some drivers prioritize performance metrics above all else, a hood that looks and feels premium can reinforce confidence, which in turn influences how a driver approaches a corner and how smoothly they carry speed through the apex.

Of course, durability remains a practical consideration. Carbon fiber, while exceptionally strong per unit mass, can be more susceptible to impact damage if not protected properly. The protective clear coat and resin matrix help mitigate minor abrasions and environmental exposure, preserving the hood’s appearance and structural integrity for longer. On the flip side, fiberglass presents itself as a durable alternative with excellent weather resistance and a more forgiving surface in some respects, especially in terms of impact resistance and long-term resistance to weather and chemical exposure. For owners who live in regions with extreme weather or who routinely navigate rough roads, the longevity of the hood’s surface finish and its resistance to cracking or delamination can be decisive factors when choosing a material. Each option has its own set of advantages, and the choice often comes down to how the hood will be used: daily driving with a taste for performance, or dedicated track use where every gram of mass savings compounds into measurable lap time and improved cornering stability.

What makes the EVO X hood decision more nuanced is how market availability intersects with engineering goals. The broad market offers carbon fiber and fiberglass hoods in a range of designs, from simple bases to vented configurations that emphasize heat management, downforce, and aerodynamics. The availability of vented or ducted models is a key factor for performance-minded drivers. These designs are often tailored to enhance engine cooling by drawing cooler ambient air into the engine bay while expelling hot air more efficiently. The integration of vents must be considered in conjunction with the hood’s stiffness, as the vents alter the hood’s structural path and influence how it deforms under load. In short, a well-integrated vent system paired with a strong, lightweight hood can contribute to a more controlled thermal environment inside the engine compartment, which in turn supports consistent power delivery and a reliable throttle response—two critical attributes for the EVO X on track days or enthusiastic street drives.

The decision to upgrade a hood is also about the total package—the balance of weight reduction, rigidity, ventilation, and aesthetics—rather than any single feature. A carbon fiber hood, when chosen with care, aligns with the EVO X’s engineering ethos: maximize performance with minimal compromise. The weight savings ease the burden on the front suspension, enabling smaller, more compliant springs or more precise damping without increasing stiffness to an uncomfortable level. It reduces the front-end load transmitted through the steering system, allowing for more direct and intuitive steering feedback. In addition, the heat management benefits protect the turbocharged powerplant from heat soak, supporting sustained power output during spirited driving. This synergy matters because the EVO X platform rewards consistent performance—a hood that helps keep the engine cool, reduces mass, and preserves chassis balance can help a driver exploit the car’s potential more effectively through successive laps or a sequence of highway pulls that test both power and control.

Market availability and decision-making for EVO X owners also extend into the realm of sourcing and compatibility. The best choices come from sellers and catalogs that emphasize fitment and engineering quality. Hood panels must align with the hood hinges, latch geometry, and the engine bay’s contours to maintain a snug, secure closure and proper seal against environmental intrusion. A well-fitted hood reduces wind noise and prevents wind-driven debris from finding its way into the engine bay—an important consideration for longevity and reliability. The practical aspects—ease of installation, verified fitment, and a robust finish—are not merely conveniences; they are prerequisites for a conversion that delivers on its performance promises year after year. When buyers approach a project like this, they weigh the cost against the potential gains in acceleration, braking efficiency, and cornering with the added intangible of improved aesthetics. In the end, the decision to upgrade the hood for the EVO X is a statement about intent: it is a choice to pursue speed with discipline, to reduce mass where it matters, and to refine the car’s overall balance so that the chassis responds more linearly to the driver’s input.

For readers seeking a concrete link to one of the primary sources of information on carbon fiber hoods for performance applications, you can explore a dedicated reference page that discusses the material and its applications in this context. See the internal resource here: carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x.

Beyond the technical and practical considerations, adopting a hood made from advanced composites also has implications for maintenance and longevity. Carbon fiber itself is highly resistant to corrosion and weather-induced degradation, which is a meaningful advantage in varied climates. However, it is not immune to all risks. The surface protection from UV exposure and road debris protection through a quality clear coat plays a critical role in maintaining gloss and structural integrity over time. The hood’s finish must be robust enough to withstand cleaning, exposure to road salts, and the occasional impact from stones or debris. The fiberglass alternative offers its own durability profile, often performing well in harsh environments and offering a different balance of stiffness and flexibility. The choice between carbon fiber and fiberglass thus depends on the owner’s driving patterns, climate, and willingness to invest in ongoing care. The highest-performing setups typically pair a well-designed vented hood with a protective surface under a clear coat, ensuring that both the heat management benefits and the durable external appearance endure through seasons of use.

In the broader arc of the EVO X’s evolution, the hood stands as a microcosm of the engineering mindset: lightweight, stiff, thermally efficient, and visually assertive. It embodies a philosophy that prioritizes how a single component can influence dynamic behavior, cooling efficiency, and the perception of speed. The chassis responds to mass reductions with a more agile poise, while the cooling system benefits from an air-management strategy that keeps the turbocharged powertrain operating within its optimal thermal envelope. Enthusiasts realize that these modest weight savings and aerodynamic refinements compound, producing a more responsive, more predictable car that behaves with greater precision in demanding conditions. This is the essence of upgrading the EVO X hood: not just to shave seconds off a lap time, but to cultivate a more coherent and confident driving experience, one that aligns the vehicle’s mechanical performance with the driver’s intent at every turn.

For those who wish to dig deeper into the material science underpinning these benefits, there are comprehensive guides and analyses that explore carbon fiber’s performance characteristics, manufacturing processes, and real-world applications in automotive exteriors. While the hood is only one piece of the broader performance puzzle, it offers a tangible, accessible entry point into understanding how material choice translates into measurable driving advantages. As with any upgrade, the goal is to maximize the sum of its parts—weight, rigidity, thermal management, and aesthetics—so that the EVO X can deliver a more engaging and confident ride, whether on open roads or in the controlled environment of a race track.

External resource for deeper context: https://www.evo10performance.com/carbon-fiber-guide

null

null

Final thoughts

Investing in a carbon fiber hood for the Mitsubishi EVO 10 not only enhances the car’s aesthetics but significantly improves performance through weight reduction and efficient cooling. Business owners in the automotive aftermarket sector will find a growing opportunity in this niche, as demand for performance upgrades continues to rise. With the availability of various options across different platforms, catering to the customization needs of EVO 10 owners can solidify a competitive edge in the market.