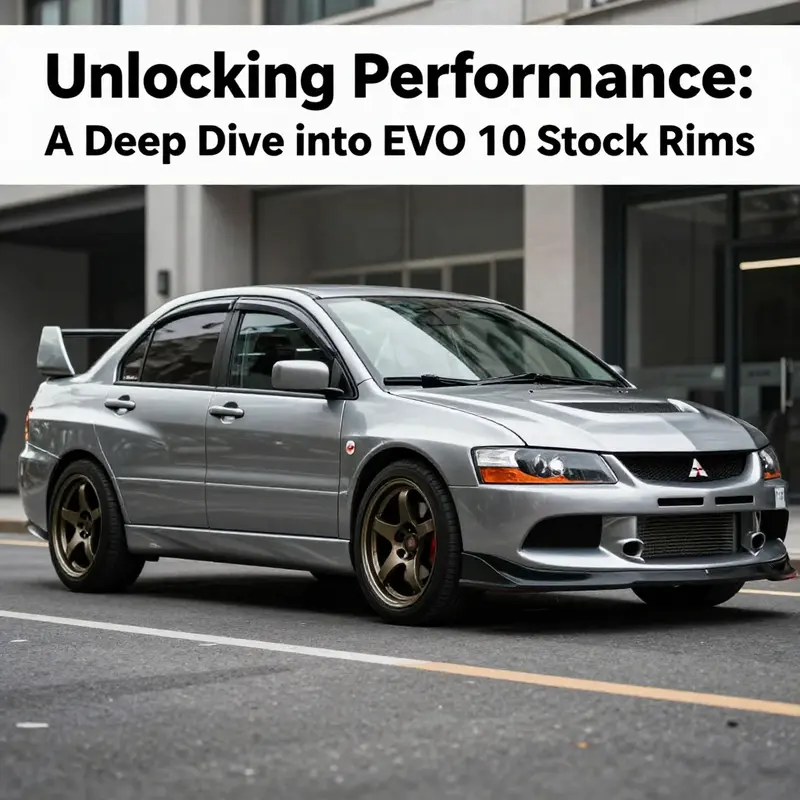

Mitsubishi’s EVO 10, recognized for its sheer performance and engineering excellence, features stock rims that are meticulously crafted for an optimal driving experience. The original 18-inch BBS forged rims, paired with high-performance 245/40 R18 tires, are not just aesthetic choices; they play a crucial role in the vehicle’s overall dynamics. Each chapter of this article will delve deeper into the specifics of these stock rims, starting with their original configuration and specifications, exploring their performance characteristics, comparing them to aftermarket options, providing essential maintenance tips, and understanding their critical impact on vehicle dynamics and handling. Business owners looking to invest in or maintain this iconic vehicle will find this comprehensive guide invaluable.

Factory-Forged Wheels and the EVO 10: How the Stock Rims Shape Performance

Factory-forged wheels are an integral part of the EVO 10’s identity, and the stock rims fitted to the tenth-generation Lancer Evolution were chosen for more than looks. They represent a balance of strength, weight, and geometry tuned to the car’s all-wheel-drive chassis and high-performance ambitions. Understanding the original configuration and specifications of these wheels explains why they remain a common reference point for owners who value handling precision and mechanical balance.

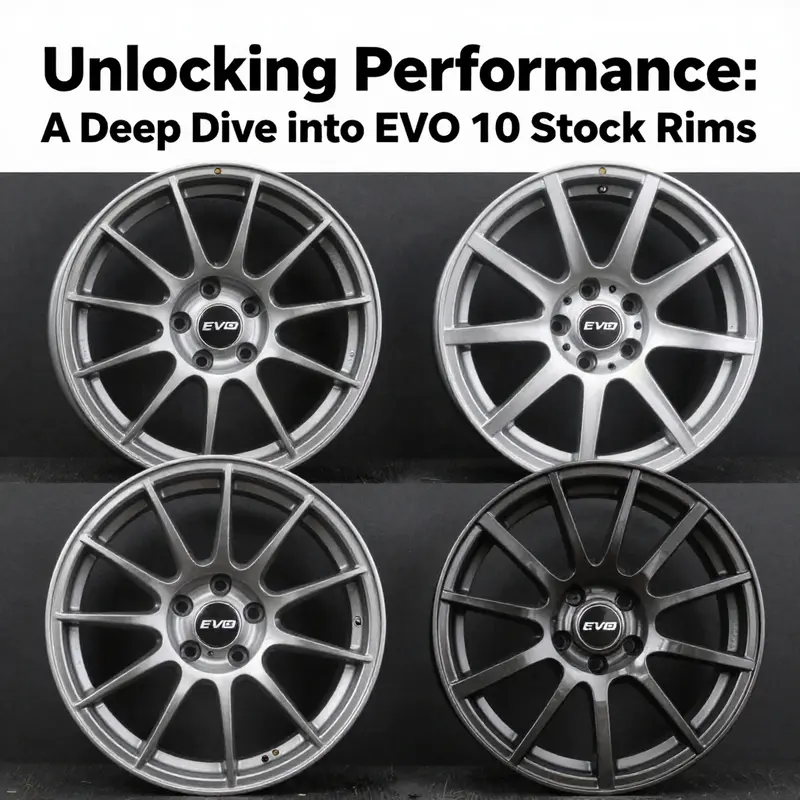

From the factory, the EVO 10 rolls on 18-inch forged alloy wheels measuring 18 inches in diameter and 8 inches in width. This size establishes the geometric baseline for tire choices, brake clearance, and suspension tuning. The standard tire pairing for these wheels is 245/40 R18, a profile that preserves predictable sidewall compliance while offering a broad contact patch for grip. That 245 width works with the 8-inch rim to deliver a stable footprint in both steady-state cornering and rapid transitions.

A defining characteristic of the stock wheel is its negative offset, specified at -15mm for the standard model. Offset determines how the wheel sits relative to the hub mounting surface and fender line. In the EVO 10’s case, the negative offset pushes the wheel in a geometry that the factory intended to optimize weight distribution and steering feedback. The wheel placement works in concert with the car’s suspension rates and steering geometry to provide a responsive, communicative front end and a planted rear axle under load.

Rather than casting for economy, the stock wheels are forged from high-strength aluminum alloy. Forging aligns the metal grains and removes internal voids, producing a wheel that offers greater rigidity at lower weight than a comparable cast wheel. For a performance car, lower unsprung mass yields clear benefits: quicker suspension response, reduced rotational inertia at the wheel, improved acceleration, and more consistent braking under repeated loads. Drivers feel the difference as sharper turn-in, improved mid-corner stability, and crisper feedback at the limit.

The aesthetic design and spoke geometry of the stock wheel complement its mechanical role. Spokes are arranged to balance stiffness and damping, routing loads from the hub to rim efficiently while allowing just enough flex to absorb harsh inputs. The open spoke pattern assists brake cooling. On a car engineered for spirited driving, heat management is not an afterthought; lighter wheels that encourage airflow reduce fade and keep pad and rotor temperatures in check.

Compatibility was another practical consideration. The specified wheels and tires are a direct fit for EVO X models produced from 2008 through 2015. This factory-matched setup simplified build and service decisions and ensured consistent behavior across trim levels. For owners, keeping the original wheel dimensions preserves the drivetrain geometry and electronics calibration that rely on the factory wheel diameter and rolling circumference. Deviating significantly from these specs can alter speedometer readings, ABS and stability control thresholds, and even the effective final drive feel.

Beyond pure fitment, the manufacturing quality of the factory-forged wheels matters for long-term integrity. Forged alloys resist the micro-cracking and fatigue that can afflict lower-grade cast wheels under severe service. This is particularly relevant for an all-wheel-drive vehicle that experiences high lateral and drive loads in performance use. Careful inspection of wheel faces, inner barrels, and spoke junctions will reveal the telltale hallmarks of a wheel built to a higher standard: uniform finish, clean machining marks, and consistent weight distribution across the set.

When owners consider upgrades, they often measure options against the original specification. An aftermarket wheel that keeps the same diameter and width but reduces unsprung weight can deliver tangible performance gains. Maintaining the -15mm offset or choosing a compatible offset preserves handling balance. However, changes to width or offset require attention to fender clearance, hub centering, and suspension geometry to avoid unintended effects such as steering kickback or altered scrub radius.

Tire choice is equally important. The factory pairing of 245/40 R18 is a compromise between performance and everyday usability. The profile keeps sidewall flex in a range that supports mechanical grip while allowing a degree of ride compliance. When swapping tires, choosing a size that matches the rolling circumference helps maintain driveline behavior. Performance tires with a similar contact patch but different construction can change turn-in and mid-corner behavior without any wheel modification.

Maintenance and preservation of the original wheels also influence longevity and value. Forged wheels are not immune to corrosion or curb damage. Regular cleaning with non-acidic solutions preserves protective coatings. Periodic inspections of the inner barrel for pitting or cracking are recommended, especially for cars driven in harsh conditions. Re-finish or repair should be performed by specialists experienced with forged alloys to preserve structural properties and finish quality.

Collectors and enthusiasts sometimes seek replacement sets that match factory specifications exactly. Sourcing OEM-style forged wheels ensures that the car retains the intended handling characteristics and appearance. When purchasing a used set, verify fitment numbers, visual condition, and whether balancing or remanufacturing work has been done. A matched, balanced set keeps rotational harmony across all four corners, which matters to both ride quality and component wear.

For those who plan to push the chassis on track or to build a more aggressive street package, the original rim size and offset provide a clear starting point. Engineers and tuners often use the stock wheel as a benchmark: preserve the diameter to keep gearing and electronics predictable, then marginally adjust width and offset if wider rubber is required. Suspension and brake upgrades usually precede radical wheel changes because they alter the forces the rim must handle. In many builds, keeping a forged wheel philosophy—prioritizing strength and low weight—remains a guiding principle.

Even as aftermarket wheel styles evolve, the philosophy behind the EVO 10’s stock rims endures. The factory choice favored a forged construction, a moderate but capable width, and an offset tailored to the car’s suspension geometry. Those elements combine to make the wheels an active, functional component of performance, not merely a cosmetic choice. For owners seeking to maintain, restore, or refine the driving character of their EVO 10, the original wheel specifications are an essential reference.

If you want to see a replacement set that follows the factory form factor, the listing for a brand-new original set gives a clear picture of fitment and finish; it also underscores why owners often prefer OEM-forged wheels when preserving handling and authenticity. For detailed source information on factory wheel listings, see the related external reference below.

For parts and accessory context, an internal resource showing original rim sets can be useful when considering replacements or spares: brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans.

External reference: https://www.ebay.com/itm/364947322181

Forged Precision: How the EVO X’s 18-Inch BBS Stock Rims Shape Performance

The Mitsubishi Lancer Evolution X is defined in part by its engineering philosophy as much as by its rally-bred soul. Among the many elements that contribute to the car’s fierce, laser-focused character, the stock wheels stand out not merely as cosmetic accents but as a core performance component. When the Evolution X rolled off the line in 2007, it did so with 18-inch BBS forged aluminum alloy wheels matched to 245/40 R18 tires. This pairing was more than a design choice; it was a deliberate balance of lightness, strength, and responsive handling that underpins the car’s dynamic personality. The wheels do not exist in isolation. They interact with the suspension geometry, the tire compound, the brakes, and the chassis tuning to create the Evo X’s renowned turn-in sharpness and the sense of immediacy that defines high-performance all-wheel-drive machines. In that sense, the stock rims are a foundational piece of the EVO X’s on-road behavior, a reason the car feels eager to steer and fearless in the corners even on a factory setup.

Forged aluminum wheels, by their very nature, are a different breed from their cast cousins. The manufacturing process, which compresses and shapes a single piece of aluminum under immense pressure, yields components with superior strength-to-weight ratios. In practical terms, this translates to lower unsprung weight—the weight unsuspended by the suspension that directly responds to road irregularities. When a wheel is lighter, the suspension can react more quickly to bumps, ruts, and cambers, translating into crisper tire contact and a more immediate wheel response. The EVO X takes advantage of this, allowing the suspension to better manage wheel hop and maintain tire contact through transitions. This improves acceleration feedback, braking modulation, and the overall sense that the car is wired to the driver’s inputs rather than fighting them.

Weight reduction is not the only benefit. Forged wheels are inherently stiffer than cast wheels. The rigidity of the wheel itself matters in the way forces from cornering transfer into the tire patch and how smoothly those forces are distributed across the rim. The EVO X’s chassis benefits from this rigidity because the wheel’s ability to resist deformation translates into more predictable steering return, more consistent contact patch geometry under load, and less parasitic flex during aggressive mid-corner throttling. The result is a chassis that feels more planted, more communicative, and more willing to carry speed through apexes. It is this combination—lightness paired with high rigidity—that helps explain the EVO X’s sharp turn-in, a trait that has delighted enthusiasts who crave a precise, almost surgical steering experience.

The choice of 18 inches for the stock setup is particularly meaningful. In the wheel-tire package, size acts as a lever that affects several interacting systems. A larger wheel can offer stiffer sidewalls and more braking surface, but it also risks increased mass and reduced ride comfort if not paired with a suitable tire. The EVO X’s 18-inch diameter is a compromise that respects the car’s suspension tuning and adaptive characteristics. The 245/40 R18 tires provide a balanced footprint with enough width to deliver solid grip while maintaining a sidewall height that preserves ride quality and helps the suspension absorb road imperfections without transmitting excessive harshness. This synergy between wheel diameter and tire profile is a subtle but essential part of the EVO X’s perceived performance. The tire itself is a high-performance radial designed to work with the forged wheel’s rigidity, offering consistent grip across a broad temperature range and during sustained hard driving. The net effect is a package that remains approachable for enthusiasts while still delivering the track-ready bite that Evo buyers expect.

Beyond the mechanical advantages, the stock BBS forged rims contribute to the car’s visual and psychological identity. The intricate machining, the clean lines, and the understated yet purposeful presence of forged rims speak to a philosophy of performance with restraint. They tell a story of engineering excellence and purpose, rather than flashy ornamentation. In that sense, the wheels become part of the Evo X’s storytelling: a compact symbol of light, strong, and precise engineering that aligns with Mitsubishi’s emphasis on balancing performance, reliability, and daily usability. There is a consistency between the wheel’s physical properties and the EVO X’s broader dynamics, a cohesion that makes the car feel well-sorted from the moment you step on the gas and push into the first corner.

The interaction between wheel and tire is more nuanced when one considers braking performance. A lighter wheel with reduced rotational inertia means the brake system has less mass to slow down during deceleration, which translates into more efficient braking and reduced heat build-up under pressure. This is especially important on a car like the EVO X, whose performance credentials often push the limits of braking endurance on winding roads or track days. The forged wheel’s reduced inertia complements the high-friction tire compound, allowing the braking system to deliver more immediate bite and more consistent pedal feel as speeds increase and temperatures rise. In practice, this means fewer instances of brake fade during a spirited session and more reliable, predictable stopping power when the road demands it.

The EVO X’s packaging of forged rims to match the suspension’s stiffness and the tires’ performance envelope creates a holistic system. It is not simply about removing weight or increasing strength in isolation; it is about how each attribute magnifies the rest of the setup. The driver experiences this as a more direct connection to the road, where steering input translates into proportional tire grip, wheel rotation, and chassis reaction. That bond between the wheel, tire, and suspension is perhaps the most compelling argument for the value of a sophisticated stock wheel program. It helps explain why enthusiasts often praise the EVO X’s handling characteristics as a product of careful, integrated engineering rather than a series of discrete performance tweaks stitched together post-factory.

The role of the wheel in everyday driving should not be overlooked either. Forged wheels, while optimized for performance, must still be compatible with the real world: road surfaces, potholes, and curb threats. The EVO X’s wheel design acknowledges these realities by providing a robust yet lightweight platform that resists typical fatigue under aggressive driving. Forged rims can tolerate high loads that would deform or fracture a weaker, cast wheel, offering a degree of confidence to drivers who push the limits of grip in dynamic driving conditions. At the same time, regular inspection for potential curb impact or small bends remains a prudent practice. The stock setup represents a well-balanced compromise between track-capable resilience and day-to-day practicality, which is part of why it remains a reference point for owners and restorers who prize the original EVO X experience.

Within the broader ecosystem of the Evolution X, wheel choice also communicates a certain technical ethos. The BBS forged rim embodies a tradition of precision engineering and high-performance materials that aligns with the vehicle’s turbocharged powertrain, all-wheel-drive dynamics, and active safety systems. It is a reminder that the car’s speed is not merely a function of horsepower and torque but also the efficiency with which that power is delivered and managed through the drivetrain and braking system. The 18-inch wheel size is not an arbitrary detail; it is a carefully chosen parameter that helps the EVO X maintain traction, stability, and control at the limits, a necessity for a vehicle that has always inhabited the edge between street legality and track-ready aggression.

In the context of a modern automotive landscape where wheel options proliferate and aftermarket choices abound, the stock EVO X wheels maintain relevance precisely because they are forged for performance rather than flash. They offer a data-driven proposition: reduced weight, increased strength, improved handling response, and better braking efficiency—all wrapped in a package that preserves the car’s balance and ride characteristics. This is not merely a tale of a factory component; it is a study in how a single design choice can influence the feedback a driver receives, how the car behaves under load, and how it thrives at the edge of adhesion. The EVO X’s factory wheels crystallize a philosophy of performance where every gram saved and every rigidity gained translates into measurable gains on the road and the track.

For readers curious to explore the broader implications of forged wheels on performance cars, a comparative look at similar setups across rally-inspired vehicles can offer further insight. The concept remains consistent: lighter, stronger wheels enable quicker suspension response, sharper steering, and more efficient braking, creating a more engaging driving experience without sacrificing durability. The EVO X demonstrates how a well-chosen wheel—ferociously engineered and meticulously matched to tires—can become a central actuator of the car’s dynamic repertoire. As owners contemplate upgrades or restorations, the message from the stock configuration is clear: cherish the wheel as a true performance element, not merely a cosmetic footnote.

To connect this discussion to real-world options without straying from the spirit of the original equipment, consider how the wheel’s heritage informs the choices available to enthusiasts today. The original BBS forged rims represent a benchmark against which contemporary wheel technologies are measured. While aftermarket offerings can promise dramatic weight reductions or bold styling, the EVO X’s stock 18-inch forged wheels stand as a testament to a design that harmonizes weight, strength, and ride quality in a way that remains relevant decades after the model first debuted. This coherence between wheel and chassis continues to be a touchstone for both owners seeking authenticity and engineers studying the evolutionary arc of high-performance AWD platforms. Within this framework, the EVO X’s stock rims are more than a piece of hardware; they are a narrative thread that ties the car’s driving experience to a tradition of precision engineering and disciplined engineering practice.

Internal link reference: brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans

External resource: https://mitsubishiautopartsshop.com/mitsubishi-evolution-evo-4-9-shock-block-short-motor-engine-complete-4g63-1000b075/

Evo X Stock Rims: The Quiet Foundation of Performance and Potential

When the Mitsubishi Lancer Evolution X rolled off the line, it carried a chassis and powertrain philosophy built for balance rather than brute flamboyance. The stock rims that came with the Evo X were an 18 inch forged aluminum wheel paired with a wide, high performance tire that embodied that philosophy. They were not just wheels to fill the wheel wells; they were engineered components meant to harmonize weight, rigidity, and heat management with the car all wheel drive dynamics. The standard setup described in factory specifications centers on a tire size of 245/40 R18, a choice that preserves a careful compromise between grip, ride comfort, and steering feel. It is easy to overlook how consequential this pairing is, because the stock rims read as quiet, dependable hardware. Yet they are the foundation upon which the Evo X practical performance rests, a baseline from which enthusiasts measure every tweak and upgrade that follows.

To understand why stock rims matter beyond their appearance, it helps to think in terms of the car motion physics. Un sprung mass the weight of the wheel and tire that sits directly on the suspension plays a central role in how quickly the suspension can react to bumps and how abruptly the tire can respond to steering input. The Evo X stock assembly is calibrated to deliver a balanced feel: enough mass to maintain composure over imperfect pavement, but not so much that acceleration, braking, or cornering feel sluggish. The forged construction of the wheel contributes to this balance by offering strength without an excessive weight penalty, a design choice that aligns with the Evo X ethos of delivering confident usable performance rather than chasing raw numbers. When the car is pressed into a turn, the wheel inertia interacts with the suspension geometry to set the rate of load transfer. The goal is to preserve grip while maintaining a predictable, communicative steering experience. The stock 18 inch diameter is a sweet spot that respects tire sidewall stiffness and contact patch economics, ensuring the tire can do its job without demanding extravagant alignment or suspension geometry changes to compensate for the wheel.

Yet the reality of the market is that many owners weigh the tradeoffs of keeping stock rims versus venturing into aftermarket territory. The most common arguments for upgrading hinge on weight, design, and customization. Aftermarket wheels crafted through advanced forging or high precision casting often offer lighter weights than the original equipment. Lighter wheels reduce unsprung mass, which can translate into quicker suspension response, sharper throttle application, improved braking feel, and more immediate turn in. The most enthusiastic wheel buyers also chase style and rigidity, seeking spokes and patterns that can enhance heat dissipation from the brakes and improve stiffness under load. Those mechanical advantages, when paired with appropriate tires, can yield a tangible uptick in perceived performance. However, this is not a free upgrade. Lighter, more aggressively styled wheels routinely carry higher price tags, and the tradeoffs may include a stiffer ride or reduced durability under harsh road conditions. A wheel that is optimized for track work can feel too firm for daily driving, while a wheel designed purely for aesthetics can invite curb damage or durability concerns in winter climates.

The discussion about stock versus aftermarket rims must remain anchored to practical needs. For many Evo X owners, the factory wheel represents a reliable starting line, especially for daily commuting. The combination of a forged wheel and a 245/40 R18 tire provides a comfortable compromise: it accommodates a broad spectrum of driving styles, accommodates a reasonable range of alignment and suspension settings, and maintains compatibility with the car four wheel drive system and differential behavior. This is not a limitation but a design choice. The wheel and tire package works within a defined envelope that ensures predictable behavior in a wide variety of conditions, from wet roads to brisk highway runs. It is a configuration tuned for reliability and consistent performance over time, which is why factory rims often remain a preferred choice for owners who value steadiness and practicality as much as potential speed.

Customization is another thread in this ongoing dialogue. When owners venture beyond stock, they often explore fitment, offset, and width that can subtly or dramatically alter the car stance and tire contact. Wider tires can improve grip at the limit, provided clearance and suspension geometry allow it. Reduced weight, achieved through advanced alloys and forging methods, can sharpen throttle response and cornering precision, especially when the tires are matched with properly tuned suspension geometry. The design language of aftermarket rims whether higher rigidity through optimized spoke patterns, or more elaborate geometries aimed at heat management, offers a canvas for personal expression and performance tuning. The visual impact matters, too; wheel aesthetics have become a key part of the Evo X identity for many owners. But the most meaningful changes come when the wheel geometry is paired with a thoughtful tire strategy and an aligned suspension setup. In other words, the right combination of wheel, tire, and suspension is not simply about speed; it is about the vehicle overall behavior and the driver confidence in it.

Alongside this internal evaluation of rim choices, external resources can broaden understanding by offering an overview of wheel design and how variations in weight and rigidity influence performance. A broad overview of wheel design helps ground the discussion in fundamental principles, allowing readers to connect the Evo X context to the universal mechanics of wheels, tires, and suspension. In the end, the choice between stock rims and aftermarket options comes down to a balance between reliability and customization, between daily usability and track potential. The Evo X invites both approaches, and the decision rests on what the driver values most: the quiet confidence of a proven setup, or the precision and personality that come with a more tailored, purpose built wheel package.

Preserving the Evo 10’s Stock 18-inch Forged Rims: Practical Care for Long-Term Performance

Maintaining the stock 18-inch forged alloy rims on an Evo 10

The factory wheels on an Evo 10 are a core part of what makes the car both precise and confidence-inspiring. These 18-inch forged alloy rims are engineered to balance strength, weight, and appearance. To keep their structural integrity and finish, a deliberate, consistent maintenance routine is essential. This chapter walks through the practical steps that protect the rims from everyday wear, winter hazards, and the occasional mishap, while preserving ride quality and safety.

Start with the basics: cleaning. Dirt, brake dust, and road grime are more than cosmetic problems. Brake dust contains metallic particles that, left in place, will etch clear coats and accelerate corrosion. Use a wheel cleaner formulated for alloy wheels and avoid acidic or abrasive formulas. Apply cleaner while the wheels are cool; heat causes rapid evaporation, leaving residue and making the cleaner less effective. Spray the cleaner, let it dwell briefly, then agitate with a soft nylon brush in the spoke areas and a gentle pad on the rim barrel. Rinse thoroughly and dry with a microfiber towel to prevent water spots. Make this process part of your regular wash schedule—ideally every one to two weeks, depending on driving conditions.

Minimizing physical damage begins before you turn the first corner. Curb rash, parking-stop gouges, and stone chips are common causes of cosmetic and structural damage. Stay mindful when parking and take wider lines in tight spaces to keep distance from curbs. When you do brush a curb, stop and inspect the rim edge immediately. Small scuffs can be sanded and repainted before corrosion begins. Larger gouges or deep nicks may need professional attention; continuing to drive on a rim with compromised coating may expose bare metal to salts and moisture.

Tire pressure and balance tie directly to wheel longevity. Underinflation increases sidewall flex and transfers more load to the rim lip during cornering and impacts. Overinflation reduces the tire’s ability to absorb shock, transferring harsh loads to the wheel and suspension. Maintain the recommended tire pressure for your vehicle and driving conditions, and check it weekly. Dynamic wheel balancing should be performed whenever you notice vibration, during tire replacement, or at routine service intervals. Unbalanced tires create uneven stress on the rim and hub assembly, which can accelerate wear and lead to fatigue.

Fastener torque is another frequently overlooked factor. When tires are changed or wheels removed, always use a calibrated torque wrench and tighten lug nuts to the vehicle manufacturer’s specified value. Both over-tightening and under-tightening have consequences. Excess torque can warp rotors, damage wheel studs, and stress the wheel mounting area. Insufficient torque risks loosening under load, which can lead to rattles, uneven load transfer, or loss of a wheel. Check torque after the first short drive following any wheel service and again at regular intervals.

Regular inspection rounds out preventive care. Examine the rim for hairline cracks, bends, or corrosion at least every few months. Pay special attention after hitting potholes or encountering heavy curbing. Cracks, especially around the spoke-to-hub junction, indicate structural compromise. Deformations may be subtle but observable by runout checks at a service shop. If you find any structural damage, cease normal operation and have a qualified technician evaluate the rim. Cosmetic defects can often be repaired; structural failures cannot be safely ignored.

Seasonal considerations matter. In regions that use road salt and de-icing chemicals, metal corrosion accelerates quickly. If you drive through salted roads, rinse the wheels more frequently during winter. After extended winter storage, perform a deep clean and inspect the wheel finish for trapped salt or moisture. For vehicles stored long-term, remove wheels and store them in a dry, cool place on soft padding. Avoid direct sunlight and temperature extremes to preserve coatings and prevent seal deterioration.

Small repairs and touch-ups extend the useful life of the finish. For shallow scratches and chips, clean the area, lightly sand to smooth edges, and apply touch-up paint designed for alloy wheels. Finish with a clear protective coat where needed. For more extensive cosmetic restoration, professional refinishing services can repair curb rash, refinish barrels, and reapply protective coatings. Keep in mind that repeated refinishing changes wheel dimensions and surface tolerances only slightly, but professional work maintains balance and fitment.

Emergency measures after impact: if you hit a curb or pothole, slow down and pull over safely. Inspect the wheel for visible cracks or bends and look for sudden tire pressure loss. If the tire holds air and there are only minor scuffs, drive carefully to a service point for a thorough check. If the rim is visibly bent or the tire loses pressure, avoid driving. A compromised rim can fail unpredictably under load, endangering you and other road users.

Proper tool selection helps both do-it-yourselfers and professionals. A torque wrench calibrated to the vehicle spec prevents over- or under-tightening. A non-acidic wheel cleaner and a pair of soft brushes reduce the risk of finish damage. Microfiber towels absorb water without scratching. Consider a dedicated wheel sealant or ceramic-based coating to add a hydrophobic layer that repels grime and reduces brake dust adhesion. These coatings are not replacements for regular cleaning but lengthen intervals between intensive detailing.

Wheel repairs and refurbishment deserve careful thought. Cosmetic refurbishments typically restore finish and appearance. Structural repairs, such as straightening a bent rim, should only be performed by specialists with wheel-straightening equipment. Heat-based repairs and welding can alter metal properties, so ensure the shop follows approved procedures and then re-balance the wheel. If a rim shows hairline cracks, replacement is often the safest option.

Maintenance frequency is a practical balance. Clean wheels every one to two weeks under normal conditions. Inspect visually monthly and perform torque checks after any wheel service. Balance tires at least annually or when vibrations develop. After winters or extended storage, perform a full inspection and cleaning. This cadence keeps appearance, handling, and safety aligned without excessive effort.

Preserving the stock wheels supports more than looks. Properly maintained rims maintain tire seating, correct balance, and consistent unsprung mass, all of which influence handling and brake cooling. Treat the wheels as a system component rather than a mere cosmetic accessory.

For parts, service intervals, and torque specifications, consult the official owner guidance. For additional reference on manufacturer maintenance guidelines, see the owner’s manuals page: https://www.mitsubishicars.com/owners/manuals. For replacement wheel sets and compatible options that fit the Evo X R18 specification, consider reviewing product listings like the brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans for fitment details.

Following these practices will keep the Evo 10’s original 18-inch forged rims performing and looking their best. Consistent cleaning, mindful driving, correct torque, and timely inspections prevent small issues from becoming safety risks. Preserve the wheels, and they will preserve the car’s handling and character.

How Evo 10 Stock Rims Shape Handling: The Real Effects of Size, Weight, and Design

How Evo 10 Stock Rims Shape Handling: The Real Effects of Size, Weight, and Design

The factory wheels fitted to the Evo 10 do more than fill the wheel arches. They are a key interface between suspension, brakes, and road. On this generation, the original equipment wheels are 18-inch forged alloy pieces paired with 245/40 R18 tires. That combination sets a baseline for how the car responds to driver inputs, how it accelerates and stops, and how the suspension controls vertical and lateral load transfer. Understanding why those factory rims matter requires looking at weight, rotational inertia, stiffness, heat management, and the way tire geometry interacts with chassis systems. The result is a coherent picture of why the stock rims were chosen and what their presence means for handling.

At the core is unsprung weight. The mass of wheels, tires, brakes, and a portion of suspension that is not supported by the springs is called unsprung mass. Lower unsprung weight allows the suspended parts of the car to stay more isolated from road irregularities. When a wheel is lighter, the suspension can react quicker and keep the tire in contact with uneven surfaces. That contact equals grip. Forged 18-inch alloy wheels, like those supplied originally, reduce unsprung weight compared with heavier cast or steel wheels. The lighter rim improves the suspension’s ability to control vertical movement, which leads to more consistent traction during cornering, braking, and acceleration.

Rotational inertia is the next fundamental concept. Wheels are rotating masses, so their resistance to speed changes affects acceleration and braking. A heavy rim demands more energy to spin up and more effort to slow down. Conversely, a lighter wheel reduces rotational inertia, improving throttle response and reducing brake load. In practice, an 18-inch forged rim significantly lowers rotational inertia relative to heavier alternatives. That change translates into quicker acceleration from corner exit and crisper braking feel at the pedal. For a performance car that relies on precise modulation, the difference becomes tangible during repeated high-load maneuvers.

Wheel design and structural stiffness also shape handling. Multi-spoke forged wheels deliver more than cosmetics. Thoughtful spoke geometry spreads load through the wheel while resisting deformation under cornering forces. When a wheel flexes, it can change tire contact patch shape and steering input translation. Stiffer wheels keep the tire footprint stable, improving steering precision and predictability. The stock rims balance stiffness with controlled flex, preserving compliance where needed while ensuring stability at higher lateral loads. This structural behavior supports the Evo 10’s active chassis systems, allowing them to operate within expected parameters.

Tire selection and rim diameter define the contact patch and sidewall behavior. The stock pairing of 245/40 R18 is a compromise between sidewall height and overall diameter. A 40-profile sidewall on an 18-inch rim provides enough cushion to absorb impacts without overly blunting steering feedback. It also maintains a consistent rolling diameter that aligns with the vehicle’s gearing and stability control calibrations. Lower-profile tires on larger rims sharpen response, but they make the ride harsher and increase the risk of rim damage. Taller profiles soften response and reduce steering precision. The factory spec aims for a balance

between agility and real-world comfort.

Brake cooling and thermal management should not be overlooked. Forged alloy rims typically offer better thermal conductivity than steel or heavier cast wheels. The spokes and open design facilitate airflow to the brake rotors. Under repeated hard braking, this leads to reduced brake fade and steadier pedal feel. The wheel itself can act as a heat sink, drawing heat away from the caliper and rotor assembly. In track or spirited driving, this effect helps preserve braking consistency across laps, which is important for both performance and safety.

Wheel offset and width further influence handling by changing scrub radius and track width. The stock rim dimensions were chosen to work with the Evo 10’s suspension geometry. An appropriate offset maintains predictable steering effort and minimizes torque steer and steering kick from bumps. Increasing wheel width can increase mechanical grip by allowing wider tires, but it also changes scrub radius and suspension loadings. Owners who alter wheel width or offset must account for how these changes affect steering weight, bump steer, and roll behavior. The stock setup is a calibrated compromise that preserves balance across a range of driving conditions.

All-wheel drive systems respond differently to wheel-related changes than two-wheel-drive cars. Diameter differences or mismatched rolling circumferences between front and rear tires can upset torque distribution and slip sensors. The factory 18-inch wheels and matched tire sizes create consistent rolling diameters that keep differential behavior and stability systems within expected limits. When wheels or tires deviate too far from stock, the car’s traction algorithms may compensate in ways that alter understeer or oversteer tendencies.

Ride comfort and NVH are subtle but real factors. A wheel with the right balance of stiffness and damping can reduce harshness transmitted to the cabin. Forged wheels with controlled mass distribution reduce unsprung oscillations, which in turn reduces high-frequency vibrations. The 18-inch size and 40-series tire help shield occupants from smaller road imperfections while keeping a sport-oriented ride character.

Maintenance and longevity also affect long-term handling. Forged wheels resist cracking and often show greater tolerance to impacts than thin cast wheels. They can maintain true shape under load, supporting consistent tire wear. Proper wheel care—correct tire pressures, periodic balancing, and inspection for bends or cracks—preserves the handling traits the factory intended. Neglect in these areas can quickly erode the advantages of well-engineered rims.

Upgrades and changes should be considered with systems thinking. Replace wheels for lighter forged alternatives, and handling improves. But the whole chain must be considered: tires, brakes, alignment, and dampers. A lighter wheel will change suspension dynamics and may reveal limitations in other components. Alignment settings that worked with the stock wheel-tire package might not suit a different combination. Owners aiming to improve handling should pursue complementary changes rather than isolated swaps.

Finally, the choice of OEM forged wheels reflects compromises between cost, durability, and performance. The stock 18-inch forged wheels deliver reduced unsprung mass, lower rotational inertia, efficient brake cooling, and predictable stiffness. Those traits directly affect steering precision, grip consistency, braking stability, and ride quality. For most drivers, the factory combination of 18-inch forged wheels and 245/40 R18 tires offers an effective and balanced platform. Enthusiasts who seek marginal gains can improve specific areas, but only by understanding the interplay between wheel attributes and vehicle systems.

If you are evaluating wheel options or considering replacement parts, comparing new wheels against the original design helps reveal whether a change will be beneficial. For those interested in OEM-style wheels, a direct match to the factory forged R18 set provides similar dynamic characteristics and preserves the design intent. See an example of OEM-style forgings in this listing for brand new original BBS R18 rims for Lancer sedans: https://mitsubishiautopartsshop.com/brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans/. For technical background on how alloy composition and design influence performance, refer to the in-depth review on wheel materials and properties from the industry resource below.

External reference: https://www.insiderims.com/integra-rims-composition-properties-applications/

Final thoughts

The Mitsubishi EVO 10 stock rims represent more than just wheels; they are engineered components that enhance the vehicle’s performance, handling, and aesthetics. Understanding their specifications, benefits, and maintenance can help business owners and automotive enthusiasts maximize their investment. By weighing the stock options against aftermarket alternatives, one can make informed decisions that align with driving goals and performance expectations. Preserving the integrity of these stock rims not only prolongs their life but also ensures the EVO 10 performs as intended, providing an exhilarating driving experience that enthusiasts expect.