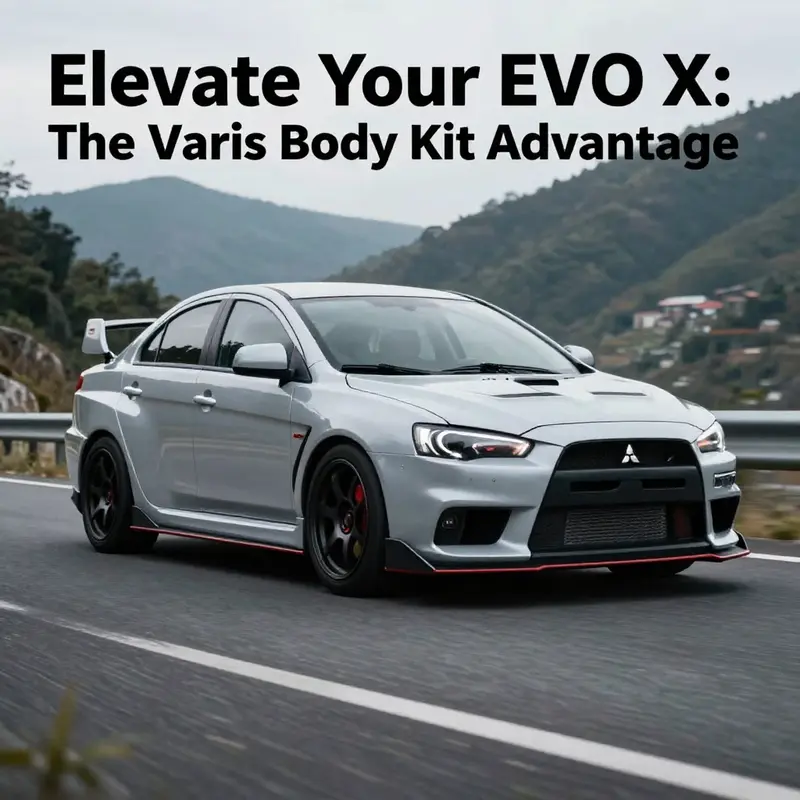

The Mitsubishi EVO X is already a powerhouse in the automotive world, known for its rally heritage and spirited performance. However, the Varis body kit takes this iconic vehicle to a new level, marrying performance upgrades with stunning aesthetic enhancements. This comprehensive guide will delve into the four critical areas where the Varis kit redefines the EVO X: aerodynamic design, material quality and craftsmanship, adaptability for performance enhancement, and suitability for varied driving conditions. By the end of this exploration, you’ll have a thorough understanding of why the Varis body kit is an exceptional choice for business owners and performance enthusiasts alike.

Engineered Aggression: The Full-Body Aero Synthesis that Redefines the Evo X Experience

The evolution of a high-performance sedan into a focused track weapon often hinges on a single, carefully calibrated decision: how to manage air and weight without surrendering usability. In the case of the iconic tenth-generation Evolution, a full-body aero kit embodies this philosophy. It is not merely a visual upgrade; it is a disciplined reengineering of the car’s air handling, weight distribution, and chassis balance. When a renowned aero house designs a complete enclosure around the body, every line, vent, and mounting point serves a purpose. The result is a cohesive package that shifts the vehicle’s relationship with air from a mere fact of speed to an active component of handling, cooling, and stability. The narrative of this kit begins with the exterior, where the lines that once hinted at speed become a full expression of mechanical intent. The widened fenders and flared arches alter the silhouette to accommodate a broader wheel track, a change that carries implications beyond aesthetics. A wider stance provides a larger contact patch, which translates to improved grip in cornering and more consistent tire behavior under load. But there is more than raw width at play. The integrated front lip, optimized underwing surfaces, and a pair of vented front corners are not decorative add-ons. They are aerodynamic devices that shape the path of incoming air, tease out the high-energy boundary layer near the wheels, and help manage lift at the nose. Front air knives, modeled to split and direct air efficiently, reduce under-body disruption and encourage a smoother entry for air into the engine bay. The string of vents and vents’ relationships with the hood and fenders demonstrates a philosophy: every vent is not simply to vent; it is to choreograph air so that it contributes to engine cooling, brake cooling, and overall stability at speed. The hood itself, often a material of choice for weight relief and rigidity, is sculpted with vents that serve both thermal management and the vehicle’s aggressive stance. The interplay of these elements creates a front end that seems to lie in wait for the next corner, a proactive stallion rather than a passive sculpture. This is where the design meets the science of aerodynamics. The wing and the rear diffuser are not about making the back end look dramatic; they are about controlling wake, pushing air downward where it matters, and drawing out the last vestiges of lift that threaten stability at high speeds. An oversized rear wing, with an adjustable angle and a clean, high-rigidity mounting, balances downforce with drag, allowing the car to maintain traction without generating excessive parasitic resistance. The rear diffuser is a critical piece of the puzzle. It channels air from beneath the car toward the trailing edge, where it interacts with the wake created by the body. A well-designed diffuser lowers pressure under the car, enhancing downforce and smoothing out the turbulent wake that tends to destabilize the car at the exit of the corner. The result is a vehicle that remains planted not only when it is leaning into a turn but also as it powers out, where a few degrees of attitude can make the difference between throttle application and tire scrabbling chatter. The overall geometry is complemented by a tail section that looks forward as much as it looks back. The integrated rear deck and the curvature of the trunk lid are sculpted to maintain smooth airflow across the curvature of the tail. A set of eye-catching details—a large fixed wing for downforce, a low-profile spoiler line that helps clarify the vehicle’s aerodynamic intent, and an underbody air management system that reduces parasitic drag—interlock to maintain a stable rearward flow. The effect is a car that feels more predictable at the limit, with a telling sense that the chassis is sharing the air’s burdens rather than fighting it.

Beyond the silhouette, the materials chosen for this kit reveal the same engineer’s obsession with balance. The construction alternates between carbon fiber and high-strength composite materials. The carbon fiber components—hood, some panels, and the rear wing elements—deliver not just strength but a compelling weight advantage. Reducing mass where it matters helps the car accelerate more aggressively, brake later into corners, and rotate with less effort when the throttle is coaxed to mid-traffic speeds. Where carbon fiber is not used, high-strength fibers and layered composites provide the rigidity required for accurate aero performance and long-term durability on track surfaces that demand both resilience and lightness. The structural integration is careful. Mounting points align with the car’s original chassis nodes, minimising the need for invasive alterations. The integration extends to the underside, where aero skirting and a continuous undertray align with the car’s existing under-floor channels. The goal is not to simply cover the car but to unify every air-management surface into a single, predictable system. This approach matters when the car is driven at speed through complex wind conditions, where a single misaligned panel can introduce flutter, chatter, or even a lift-inducing wake. The practical consequence of this design is a vehicle that can carry more tire width, more downforce, and more aggressive calibration of suspension geometry without compromising reliability or daily usability.

In this context, the variety of available components matters far less than the philosophy behind their integration. The front end can be upgraded by replacing the standard bumper with a performance-oriented version that is ventilated to maximize cooling while preserving air passage to the radiator and intercooler. The side skirts sculpt the flow around the belly of the car, guiding air away from the rear wheels and reducing wind-induced yaw moments. A rear diffuser works in concert with the undertray to pull air through the rear, smoothing the transitions at the trailing edge. The tail assembly, with its adjustable wing and the clean, continuous line along the deck, completes the aero story, making the vehicle’s rear wake a calculated element rather than an unpredictable consequence of speed. The effect of all these choices is not just a sharper look. The aero package changes how the car behaves in mid- and high-speed corners. It lowers the car’s center of pressure, reduces lift generation at the corners, and increases the tire’s contact patch with the road under load. At track speeds, this translates into improved turn-in response, more confident mid-corner stability, and a more linear, progressive breakaway when the tires approach their limit. The tire’s grip is no longer the sole gatekeeper of performance; the air’s behavior around the body becomes an active partner in keeping the car planted.

For enthusiasts who want to explore the upgrade path more intimately, there is a modular path that offers further refinement without abandoning the broader package. This approach enables a smoother integration of the front end, allowing for a more compact, efficient development that keeps the vehicle within a manageable footprint for road use. It is here that an accessory set, designed to work with the surrounding aero surfaces, becomes more than a convenience; it becomes a strategic upgrade to the car’s dynamic balance. The idea is simple: tailor the kit to the driver’s intent, whether that means aggressive track days, spirited weekend runs, or a blend of both. A careful selection of wheels and suspension, tuned to the aero’s demands, can unlock a level of grip and precision that would be difficult to achieve with the stock configuration.

The practical implications extend beyond outright performance. The kit’s emphasis on material choice and construction supports longevity and repeatability. Carbon fiber elements are not just about saving weight; they are about maintaining structural integrity under repeated load cycles typical of track sessions. The FRP portions, while heavier than carbon, are engineered to resist impact and resist the salt, moisture, and heat encountered on long events. The combination yields a chassis that remains true after a weekend of competition and can still be driven to the nearby airfield or racetrack without a heavy maintenance footprint. In short, the package does not merely dress the vehicle in a dramatic guise. It reshapes the way the car breathes, moves air around its body, and responds to the driver’s inputs, particularly under high-speed, high-load conditions.

The cultural resonance of such a transformation is hard to miss. It speaks to a lineage of performance tuning that values a precise, purposeful aesthetic over a mere flourish. The broad stance, the visible engineering, and the measured complexity of air channels present a narrative of discipline and craft. It is a language that speaks to the racer and the enthusiast in equal measure, offering a signal that speed is not only a matter of power, but of controlled, intelligent airflow and well-considered weight management.

For installers and readers who want a glimpse into a more integrated front-end development, the evo-x-halfcut path provides a modular alternative that can facilitate a more compact, efficient installation while preserving the aero intent. evo-x-halfcut offers a reference point for those seeking a nuanced balance between front-end performance and overall packaging.

As the pursuit of performance continues to drive these developments, one truth remains clear: a full-body aero kit is more than an adornment. It is a disciplined design choice that, when executed with care, transforms air into an ally rather than a foe. The drive to achieve lower drag, greater downforce, and improved cooling does not end at the tail. It travels forward, folding into the engine bay and around the tires, ensuring the car remains predictable, stable, and exciting through every turn and straightaway. In this sense, the kit is a unifyer of form and function, a manifestation of engineering intent that makes the Evo X not only a faster car but a more confident partner for the driver who dares to push it to its limits.

External resource for deeper reading: https://www.varis.co.jp/technical/airflow.html

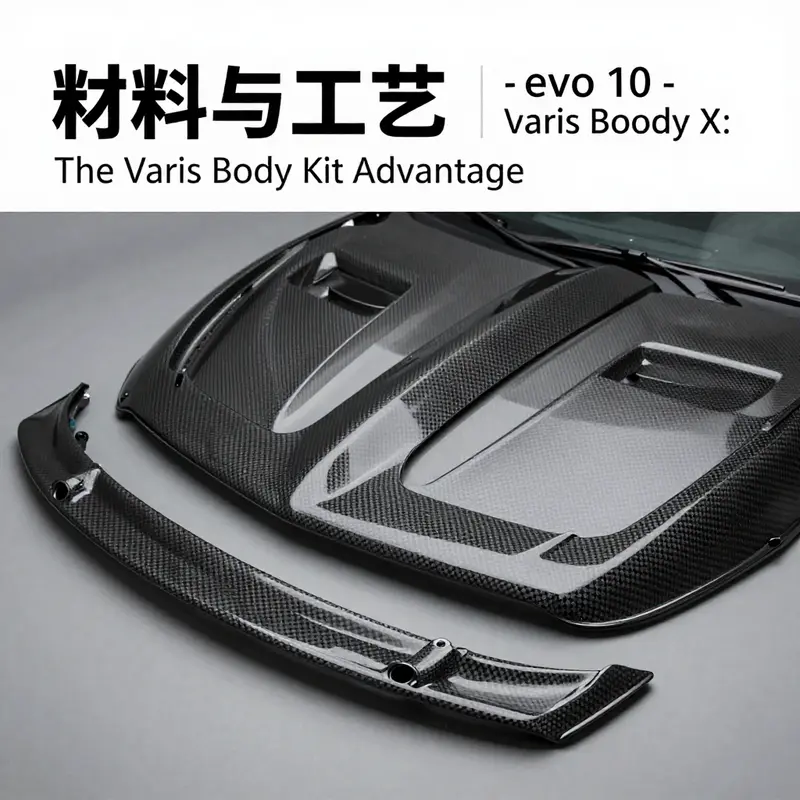

Materials and Craftsmanship Behind the EVO X Varis Widebody Kit

The EVO X Varis widebody kit sits at the intersection of aesthetics, aero engineering, and practical fabrication choices. At its core, the front lip, side skirts, rear diffuser, and the distinctive rear wing are not mere cosmetic add-ons; they are integrated components designed to manipulate airflow, manage lift, and balance the car through corners and straightaways. The Detailed research notes that the EVO X Varis front lip kit is manufactured from high-quality ABS plastic, a material choice that informs a range of design and performance decisions. ABS provides robust impact resistance and long-term durability, traits that are crucial when a kit is intended for aggressive track sessions as well as for street use. This material choice also aligns with the aim of delivering precise fit and durable performance at a cost that is accessible to a broader group of enthusiasts who want to push their EVO X beyond stock limits without incurring the premium costs associated with carbon fiber.

What ABS brings to the table, and how it ties into the kit’s aero goals, deserves a careful look. ABS is inherently stiff enough to hold the crisp lines that define Varis’s aggressive silhouette, yet it remains forgiving enough to withstand daily driving stresses, minor impacts, and the repeated heat cycles that come with high-speed runs and open-air track days. The result is a front lip and body panels that can be driven hard without the immediate penalties of rigidity loss that sometimes accompany more brittle composites. From a manufacturing perspective, ABS is well suited to standard automotive body-part production processes. The EVO X Varis front lip can be produced with reliable injection-molding workflows, followed by finishing steps that preserve edge definition and the smooth, aero-efficient surfaces that keep airflow attached at high speeds. The stated approach emphasizes precise installation fit, predictable mounting behavior, and lasting performance, all of which are critical as drivers push deeper into cornering limits and braking performance on the track.

Beyond the front lip, the rest of the kit follows the same design philosophy of combining strength, fit, and value. The full body kit, as described in the overview, brings together widened fenders, side skirts, a rear diffuser, and a large rear wing. Each component is shaped to work with the EVO X’s chassis geometry while accommodating the stresses of high-lateral-load driving. The ABS foundation is particularly well suited to this multi-piece approach, because it allows for consistent color matching and finishing across components that must align visually as a single aerodynamic plan. While other Varis lineups—such as those for different models—sometimes explore carbon fiber or fiberglass as lighter or stiffer alternatives, the EVO X variant prioritizes a balance of rigidity, cost, and repairability through ABS. This choice does not diminish the kit’s aero effectiveness; instead, it reinforces a practical, track-ready package that remains accessible to a broader audience of EVO X builders who value repeatable fit and reliable performance in real-world environments.

The manufacturing method and material choice also influence how the kit integrates with other performance-oriented upgrades. For example, the EVO X community often reports owners pairing the Varis front lip and side skirts with adjustable suspension systems and performance wheels to maximize handling precision. In practice, this means that the kit is designed to be mounted with standard hardware and mounting points, which reduces the complexity of installation. The alignment of the front lip with the bumper line and the seamless transition into the widened fenders are not incidental; they are the fruit of engineering that respects both the car’s original geometry and the altered aerodynamics introduced by the wider stance. The approach to fit is complemented by an emphasis on airflow management: the broader fender openings, the curved contours of the side skirts, and the rear diffuser’s ducting paths are all crafted to direct air in ways that reduce drag and help balance the vehicle’s lift profile at speed. In short, the ABS-based kit is designed to be a predictable, repeatable platform from which enthusiasts can tune aero balance with other upgrades like tires, brakes, and suspension stiffness.

The variance within Varis’s broader product family also signals a broader philosophy about material choice and application. Although some models employ carbon fiber or fiberglass for select parts to shave weight or increase stiffness, the EVO X kit’s core materials emphasize durability, repairability, and a favorable cost-to-performance ratio. This is not a denial of carbon fiber’s advantages but a pragmatic acknowledgment that, for many EVO X owners who track their cars or enjoy time-attacking events, a robust ABS base provides the best combination of resilience and accessibility. The front lip’s integration with the stock or upgraded bumper, including the potential for a Japan-market high-spec front bumper option described in optional configurations, demonstrates how Varis designs to maintain cooling efficiency and aggressive visuals without compromising fit. The result is a cohesive, performance-focused kit that turns the EVO X into a more stable, planted machine through tighter aero control and a broader, more confident stance on the road and the track.

Aesthetic and aerodynamic performance go hand in hand with the practicalities of installation and maintenance. ABS, as used in this EVO X kit, enables the finish to be painted or wrapped with predictable results, an important factor for builders who want a consistent look that matches body panels and interior accents. The finish not only provides a visual cohesion but also contributes to UV resistance and the longevity of the color over time, which matters for outdoor track days and weekend drives where sun exposure is unavoidable. The manufacturing process’s emphasis on precise fit also means that the kit can be installed with standard automotive fasteners, preserving the vehicle’s factory mounting philosophy while enhancing the car’s aero silhouette. It is this blend of precise fit, durability, and cost-effectiveness that makes the EVO X Varis ABS kit a practical choice for enthusiasts who value both form and function without compromising daily usability or long-term ownership costs.

In the broader context of Varis’s work, the EVO X kit represents a philosophy of engineering that treats each component as part of a larger aerodynamic system rather than as a purely decorative layer. The rear diffuser and large wing, for example, are not merely styling cues; they are intended to work in concert with the front lip and side skirts to shape the wake behind the vehicle, reduce lift, and enable more stable high-speed travel. The decision to standardize on ABS across the main elements supports a predictable performance envelope, which is important for drivers who are tuning their cars for Time Attack or track days rather than building a showroom display. For those who want the most aggressive front-end appearance while retaining manageable maintenance and replacement costs, the EVO X Varis kit offers a balanced path that respects both the car’s original design language and the enhanced aerodynamic logic that Varis aims to deliver.

Internal reference for Varis’s front-bumper lineage can be seen in related discussions of earlier generations, where the front bumper design and materials evolved from the EVO 8/9 era to later models. For readers curious about how Varis has varied the bumper approach across generations, a representative variant can be explored here: evo-8-9 varis front bumper with carbon lip 2. This glance back provides a sense of the consistent pursuit of aero efficiency, fit precision, and aggressive aesthetics that defines Varis’s broader family of kits, even as the EVO X kit makes its own distinctive material and process choices to suit its specific performance goals.

As a final note, the material choice and manufacturing approach for the EVO X Varis front lip and the wider kit carry broader implications for care, repair, and longevity. ABS is relatively easy to repair and refinish, which can be advantageous after track days or urban commutes that test a panel’s resilience. It also means that owners can expect a cost structure that supports a broader community of enthusiasts who want to push the EVO X toward higher levels of performance without facing prohibitive replacement costs. For curious readers seeking a deeper technical grounding on the material itself, a general external reference on ABS plastic offers foundational context: https://en.wikipedia.org/wiki/ABS_(plastic). This external source provides a broader look at how ABS behaves under heat, impact, and environmental exposure—factors that, in the end, influence how the EVO X Varis kit performs over time in real-world conditions.

Evo 10 Varis宽体套件:精准适配、气动极致与赛道日的综合追求

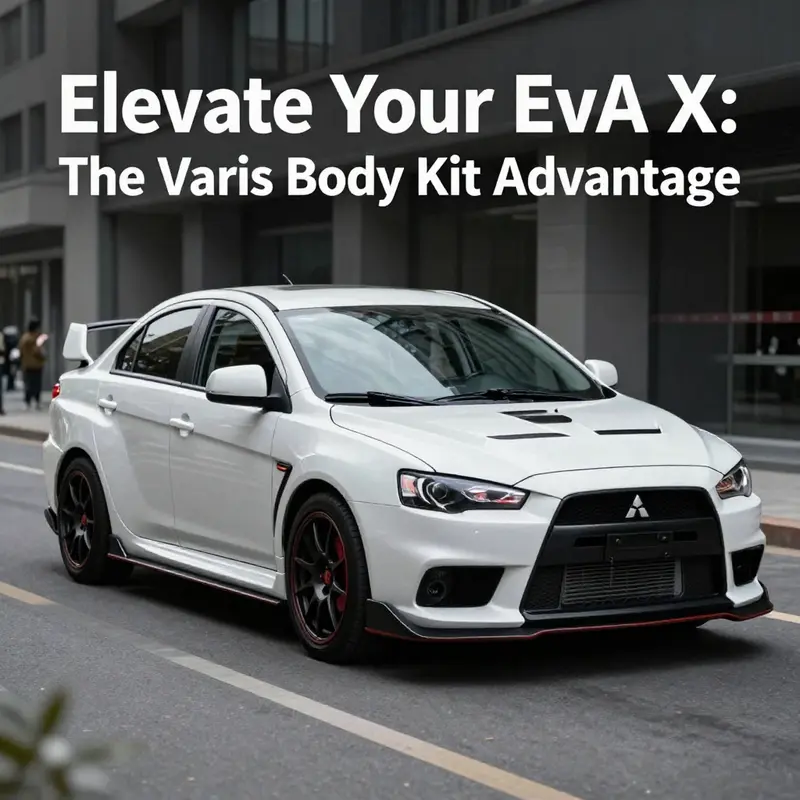

The Evo X Varis widebody kit represents a synthesis of bold aesthetics and engineering precision, a package that does not merely alter the silhouette of a car but recalibrates how air, weight, and chassis respond to speed. In the realm of high-performance street machines and track-ready builds, Varis has positioned itself as a benchmark for a full-body approach that seamlessly blends form and function. The kit for the Evo X typically comprises a front lip, side skirts, a rear diffuser, and a prominent rear wing, with carbon fiber and reinforced FRP options that trade some mass for rigidity and heat management. What makes this configuration especially compelling is not just its aggressive look, but the deliberate channeling of air to extract a tangible performance dividend: reduced lift at the front, controlled rear wake, and a more coherent flow along the car’s flanks that translates into higher cornering confidence at speed. In practice, the effect is a car that feels more planted in fast transitions and more compliant in mid-c to high-speed stability tests. The result is a vehicle that can hold a line through a demanding sequence of corners with a cadence and precision that challenge some stock platforms at the same time it commands attention with its visual heft.

The discussion of fitment begins with an almost unromantic but essential truth: precision matters. Varis frames its V3 widebody kit for the Evo X with the kind of OEM+ mindset that seeks to respect factory geometry while expanding capability. An important point of reference comes from real-world fitment demonstrations that circulated in 2024, where a TikTok-based test conferred a practical stamp of approval on the kit’s compatibility. The takeaway was clear: after installation, the car did not exhibit rubbing, misalignment, or unanticipated interference with suspension components or the wheel arches. That level of alignment is not something to be assumed with a broader fender extension; it is the core prerequisite for any meaningful performance gain. The modular nature of the kit—front lip, side skirts, rear diffuser, and a sizable wing—enables staged installation, which is a practical advantage for builders who plan a progressive approach to aero and suspension upgrades. In this regard, the kit behaves like a carefully choreographed system rather than a collection of individual parts slapped onto the body. Each module speaks to a common design philosophy: work with the Evo X’s original geometry, not against it, and let the added width and aero add to the car’s stability rather than create new handling quirks.

Material choice is a practical discipline, and Varis has long balanced rigor with performance at the scale of a racecar. The primary materials—a combination of high-strength glass-reinforced plastic (FRP) and carbon fiber—reflect a pragmatic approach to weight and stiffness. Carbon fiber front lips and rear wings bring measurable gains in mass reduction and thermal resistance while maintaining the crisp geometries required for effective airflow. FRP variants, while heavier than full carbon, still deliver a robust, cost-effective route to the same overall aero profile, with the resilience needed in track conditions where stone impaction and curb contact are realities. A 2026 technical overview of Varis components highlights the recurring theme of “high-precision manufacturing” and “fitment conformance,” reinforcing the claim that the kit’s strength lies not merely in its external lines but in the fidelity of its construction. The craftsmanship matters when the car is pushed beyond everyday speeds; it is the difference between a cosmetic upgrade and a genuine performance layer that remains durable during repeated heat cycles on a track.

The packaging and modularity of the kit also reflect a deliberate attention to serviceability. In practical terms, the front lip and side skirts are designed to align with a range of suspension configurations, which is important for Evo X owners who may opt for adjustability in ride height and damping settings. When you pair the wide fenders with an adjustable coilover system and a wheel package that favors wider rubbers, you unlock a more balanced aero footprint. The kit’s rear diffuser is not just an aesthetic flourish; it is engineered to manage the wake that travels under the car, accelerating air out of the underbody while stabilizing the rear flow that meets the wing. The rear wing itself is often an adjustable carbon structure, allowing drivers to tune the balance between downforce and drag as road and track demands evolve. The end result is a system that accommodates a broader tire footprint without sacrificing stability; the wider stance, if properly aligned, does not invite turbulent corner exit behavior but rather steadies the vehicle through high-speed sweepers.

From the standpoint of aerodynamics, the Evo X Varis kit addresses the three primary aerodynamic zones: the front, the sides, and the rear. At the front, the widened chin and aerodynamic blades guide air toward the brakes and between the wheels, reducing front-end lift while delivering cooler intake air to the brake ducts and engine bay. The sides benefit from integrated fender flares and riveted wheel arch extensions that work to arrest flow separation and to contain the wake within the wheel wells. The consequence is a smoother crosswind profile and more predictable high-speed steering; the car’s response through quick direction changes is less perturbed by the slipstream that often grows around a stock-outline. The rear, anchored by a well-integrated diffuser and a form-following rear wing, channels air under the car and off the trailing edge with an emphasis on sustained downforce rather than a momentary sprint of drag. In this architecture, downforce is not a blunt instrument; it is a calibrated outcome designed to promote consistent high-speed stability through a sequence of corners rather than simply to press the nose into the ground.

Driveability and chassis behavior are inseparable from this aerodynamic package. A wider track, achieved by the revamped fenders and arches, increases lateral stiffness when the car is loaded in a bend. The Evo X’s all-wheel-drive architecture, particularly in its advanced variants of the time, benefits from such stiffness gains because the power delivery can be translated more directly into tire grip without excessive chassis twist. In practice, drivers notice more precise turn-in feel and less tiresome understeer as speeds climb through midrange corners. The kit does not eliminate understeer entirely, but it shifts the balance in a direction that rewards precise steering inputs and measured throttle modulation. This is a subtle but meaningful difference for track days and Time Attack events, where every incremental improvement in cornering consistency translates into more reliable lap times and more repeatable performance.

The practical considerations of street use are not ignored. The aggressive stance and lower ride height inherent to a widebody configuration can collide with ordinary urban infrastructure—speed bumps, steep driveways, and uneven surfaces become real concerns. The literature and field reports emphasize the same point: while the Varis kit excels on smooth tarmac and on the racetrack, day-to-day driving in regions with challenging pavement requires careful attention to clearance and ramp angles. In other words, the kit elevates the vehicle’s ambitions and invites owners to plan for a mission profile that includes dedicated track sessions and performance weekends, rather than a daily commuting routine. This is the fundamental trade-off that defines the kit’s place in a high-performance repertoire: amplification of track-ready characteristics at the cost of everyday practicality.

Installation and fitment discussions reveal a pragmatic pathway to achieving the expected performance gains. The OEM+ philosophy is not merely about tacking on wider fenders; it is about preserving the factory’s control points, aligning with the car’s original chassis geometry, and ensuring the aero components cooperate with the suspension’s geometry. Several owners choose to replace the original front bumper with a high-spec Japanese-market version to maximize airflow and cooling efficiency. It is a strategic choice that requires careful calibration of the cooling circuit and radiator flow paths. The modular nature of the kit makes staged integration feasible, enabling a builder to install the front lip and side skirts first as a foundation, test clearance and handling, then complete the rear diffuser and wing once the baseline dynamics are validated. This is a process that benefits from professional installation, which can ensure precise fitment across seams, minimal gaps, and proper alignment of shut lines with the body panels. When done correctly, the kit not only looks the part but behaves as a coherent aero system that improves high-speed stability and cornering confidence.

In terms of audience and application, the Varis Evo X package sits comfortably at the intersection of aesthetic indulgence and track-ready engineering. It is especially appealing to enthusiasts who participate in Time Attack events, track days, or high-end personalized builds where the objective is to maximize performance without compromising the car’s character. The kit does not pretend to be a universal fix; rather, it offers a refined, engineering-informed pathway to a wider stance and a more disciplined aerodynamic profile. For those who want to see how such a kit translates into real-world dimensions and alignment practices, the side-skirt module serves as an instructive example. The side-skirt implementation, along with exposed wheel-arch treatment and riveted fender extensions, demonstrates how a relatively simple aero element can contribute to a cleaner separation of tire and body air, reducing the formation of ducted vortices that incubate drag and lift. For further context on such components, the Evo X side-skirt page provides a clear reference to how the lower body work integrates with the rest of the kit. lancer-evo-x-side-skirt.

All told, the Evo 10 Varis widebody kit embodies a philosophy that emphasizes coherence across aesthetics, weight, and aerodynamics. It demonstrates how a carefully engineered body kit can translate a dramatic visual statement into measurable performance advantages on the right stage. It invites drivers to think of aero not as a cosmetic layer but as an active control system—one that interacts with suspension settings, tire choices, and driving style. It also reminds us that the most successful aero programs are those that respect the vehicle’s core platform and work within its inherent constraints rather than against them. The result is not a mere transformation of the car’s silhouette but a cohesive performance package—one that enables a driver to exploit the Evo X’s potential in ways that feel both exhilarating and controllable, a balance that is essential when you push a machine toward its limits on a club race day or a time-attack session.

External resources for deeper exploration at the end of the chapter can help readers appreciate how the concept translates to real-world practice. For those who want to visualize a live fitment progression or study the step-by-step installation in a controlled scenario, a recent demonstration video provides a practical complement to the theoretical discussion. External resource: https://www.tiktok.com/@tkmautosportparts/video/7354987654321098765

null

null

Final thoughts

The Varis body kit represents the pinnacle of performance and aesthetics for the Mitsubishi EVO X. Its superior aerodynamic design and high-quality materials not only enhance the vehicle’s overall look but also significantly improve handling and efficiency. For business owners and automotive enthusiasts alike, investing in this body kit is not merely an aesthetic choice; it symbolizes a commitment to performance and engineering excellence. With the right setup, the EVO X can excel on both the racetrack and city roads. Elevate your driving experience now.