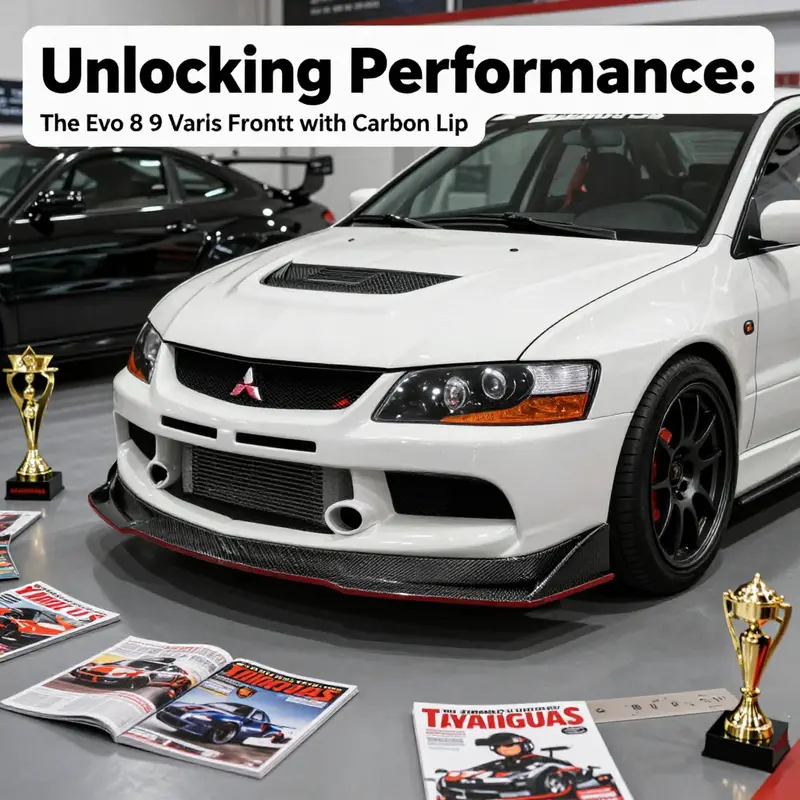

The Mitsubishi Lancer Evolution 8 and 9 are iconic in the automotive world, revered for their performance and styling. A key upgrade for enthusiasts is the Evo 8 9 Varis front bumper with carbon lip, designed to enhance both aesthetics and function. In the following chapters, we will explore how this component provides significant performance enhancements, the aesthetic upgrades it brings to the vehicle, the intricate material science that contributes to its effectiveness, and market insights to help business owners navigate availability and consumer interest in this aftermarket part.

Refining Grip and Stance: Aerodynamic Mastery with the Evo 8/9 Varis Front Bumper and Carbon Lip

The evolution of a performance sedan often hinges on the delicate balance between horsepower, weight, and the way air behaves around a low, aggressive silhouette. For the classic Evo 8 and its successor, a thoughtfully chosen front-end upgrade can transform not just the look, but the way the car breathes at speed. A modern approach to this transformation blends a purpose-built front bumper with a carbon fiber lip, aiming to tame the air flowing toward the radiator and under the chassis while adding a touch of aggression to the vehicle’s presence. The result is more than just a sharper nose; it is a calculated shift in aerodynamic posture that translates into measurable gains in stability, response, and handling on both winding roads and the occasional high-speed track day. When you stand back and survey the resulting stance, the interplay between the extended lower lip, the sculpted lateral intakes, and the overall profile makes it clear that form and function can cohere in a way that suits a driver who treats the road as a dynamic, living test bed.

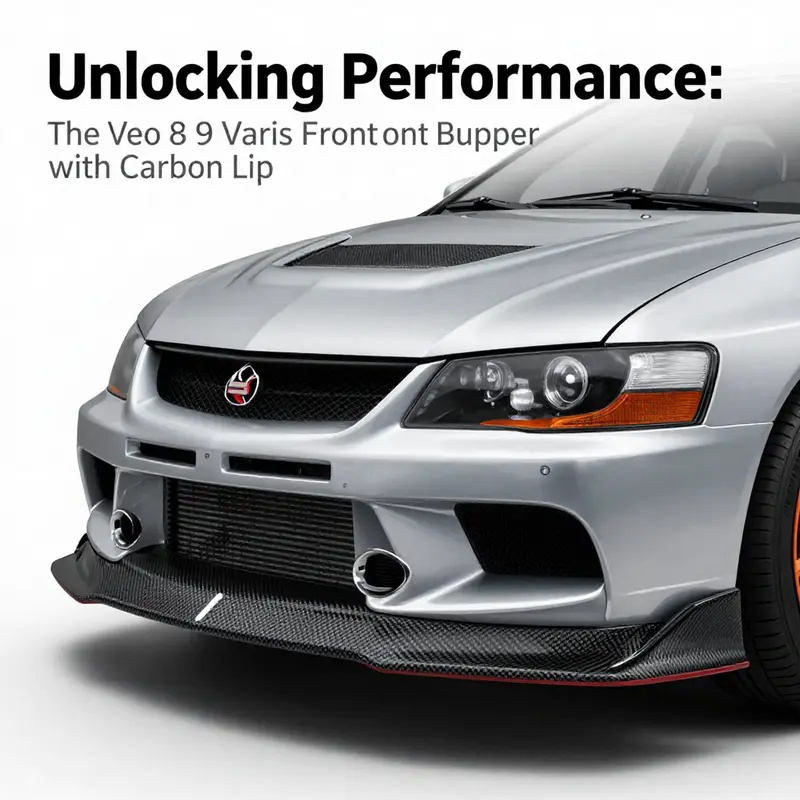

To understand the value of a front-end upgrade in this context, it helps to picture how air interacts with a relatively compact front fascia that has evolved over two decades of performance-focused design. The bumper is not just a shield for the radiator; it is a carefully contoured body panel that orchestrates air paths, peeling airflow away from the vulnerable central region and steering it along the sides. The extended lip and integrated canards—small aerodynamic devices that project forward and downward—work together to generate downforce at the critical nose area. In practical terms, this means the front tires gain more grip during hard braking and aggressive cornering, and the car’s front end stays planted rather than pitching upward as speed climbs. The carbon lip, in particular, performs two harmonizing roles. First, it reduces weight, which contributes to a lower overall mass and improved acceleration and braking efficiency. Second, it sharpens the front-end airflow by smoothing the boundary layer and guiding air more predictably over and under the bumper, which helps to minimize front-end lift at higher velocities.

The appeal of a carbon fiber lip goes beyond weight savings. Carbon is renowned for its stiffness-to-weight ratio, a trait that becomes especially relevant when a low-mounted edge acts as a focal point for fast-moving air. A stiff lip resists deflection under braking and at the edge of the front bumper where air is turbulent, maintaining a steady aerodynamic profile even when the axle weights shift during cornering. This stability is part of a broader aerodynamic concept that designers and enthusiasts alike value: a balanced front that pairs with a well-integrated rear diffuser and side elements to manage the car’s overall drag and downforce characteristics. In many setups, the carbon lip complements the bumper’s forward sweep by directing air into the wheel wells and around the sides, which can help reduce drag and improve cooling efficiency. The cumulative effect—air that remains more organized around the front of the car—translates into a tactile sense of steadiness when you drive at speed, and a more predictable steering feel as you approach the edge of lateral grip.

Choosing a front-end upgrade for the 8/9-generation chassis is not merely about aesthetics. Enthusiasts who pursue this path often do so with a broader plan: widening the car’s stance through a compatible widebody approach, improving aero balance from nose to tail, and ensuring that each piece plays a role in how the vehicle behaves in corners, over elevation changes, and on long, sweeping straights. A front bumper engineered to work with a wider front track can help channel air toward larger, aerodynamically efficient fender flares and side skirts. The extended lip works in concert with a midline splitter or diffuser elements to guide air to where it can do the most good—reducing unwanted lift and accelerating air along the car’s lower boundary. The synergy between these components matters because air does not behave in isolation; it is part of a continuous system that begins at the front bumper and continues under the car toward the rear diffuser. The objective is not simply to drag the car down; it is to manage the pressure gradient so that grip is enhanced where it matters most during aggressive driving.

From a materials perspective, the choice between a fiberglass-based bumper and a carbon fiber assembly is more than a weight consideration. Fiberglass can offer strong rigidity and a cost-conscious path to a close fit, but carbon fiber lip brings a distinct benefit in mass reduction and vibrational characteristics under load. The lighter weight provided by carbon fiber translates into a more favorable front-end feel during braking and corner entry, especially when the car is carrying momentum through a series of turns. Nevertheless, the overall balance depends on how the bumper integrates with the rest of the chassis. A well-designed unit respects the factory mounting points, aligns with the radiator core support, and maintains correct clearance to the hood, headlights, and fenders. The installation should preserve the intended geometry so that the dynamic values—camber changes under compression, toe shifts under load, and suspension bump behavior—stay within predictable, safe ranges. This is why the installation requires experienced hands and a measured approach. It is not simply a bolt-on change; it is a system upgrade that has to harmonize with the car’s suspension settings and weight distribution.

The performance narrative around such a front-end upgrade also hinges on the broader aerodynamic package that accompanies the car. When a widebody kit is adopted, the front bumper is often part of a coordinated scheme that includes widened fenders, side skirts, and a rear diffuser. Each component plays a specific role in managing airflow: the widened fenders create space for wider tires, which improves mechanical grip and braking stability; the side skirts and integrated diffusers sculpt channeling along the sides and underneath to minimize drag and to promote a smooth transition of air toward the rear. The front end, in this equation, becomes a doorway through which air enters and exits with less chaotic turbulence. In practical terms, this means the car can corner with more confidence, rotate with a more linear response, and feel more planted when straight-line speed tests are performed. The sum of these effects can equate to a tangible reduction in lap times or, at the very least, a more forgiving and communicative chassis as the driver tests limits during sessions on the road or track.

Of course, the path to such gains depends on a careful calibration of installation and alignment. Even the best front-end component can underperform if it is mounted without regard to the vehicle’s geometry. Changing the front-end geometry can, if not managed correctly, alter suspension camber, toe, and the alignment of the steering rack relative to the centerline. For a performance-minded build, alignment checks and adjustments are essential after any significant panel work or the addition of a widebody kit. These steps help preserve tire contact with the road through a broader range of steering inputs and loads, support even tire wear, and maintain stable behavior when the car encounters bumps or surface irregularities at speed. Professional installation ensures that the bumper not only fits well but also integrates with the car’s cooling needs, preventing any inadvertent obstruction of airflow to the radiator or intercooler. In modern applications, the aim is to marry the mechanical fit with the aerodynamic function, so that the bumper’s design does not sacrifice cooling efficiency for grip or vice versa. The result is a coherent package that feels more responsive and confident when the road becomes a little less forgiving.

The conversation around cost is part of the broader decision-making process. As with many performance-oriented parts, the price can vary widely depending on the material, the manufacturing process, and the source. Carbon fiber lip components tend to carry a premium due to material costs and the labor-intensive layup process. Yet the improvement in weight and stiffness can justify the extra investment for drivers who plan to push their cars at higher speeds or on track days, where every kilogram saved translates into more instantaneous acceleration and quicker deceleration when maneuvering through corners. For some, the financial calculus also includes the benefit of a more distinctive aesthetic that complements the car’s broader design language, reinforcing the sense that the vehicle is built to perform and to endure the rigors of spirited driving. All of this points to a broader driver value proposition: the upgrade is not a mere cosmetic dequeue; it is a performance-oriented modification that aims to deliver a balanced aero profile, reduced lift, improved front-end stability, and a chassis that communicates more clearly through the steering wheel during high-demand situations.

In this light, the front bumper with a carbon lip becomes part of a larger philosophical approach to modifying a car that favors deliberate, technically grounded choices over purely visual enhancements. The driver who adopts such a combination often does so with intention: to create a vehicle that remains agile at the limit, that carries more consistent front-end grip through the baseline of aero balance, and that maintains predictable behavior as grip conditions evolve with tire choice, weather, and track layout. The psychology of the upgrade matters as well. There is a sense of confidence that comes from knowing the vehicle’s nose is designed to manage air, to bite into the road with a front end that stays composed, and to deliver the kind of feedback that makes the act of driving a pleasure rather than a series of compensations for uncertain aerodynamics.

For readers seeking a tangible point of reference that speaks to the era and the ethos of the chassis, a related portfolio of components from the same era and platform offers a complementary perspective. For instance, you can explore authentic JDM taillights designed for the Evo 9 to understand how OEM-styled upgrades from the same vendor ecosystem can harmonize with the broader aero-focused program. This kind of look, while not directly part of the front-end package, can complete the car’s refreshed visage and contribute to a cohesive, period-correct appearance that still supports modern performance goals. See Authentic Evo 9 MR taillights for an example of an era-appropriate complement to the aero-centric transformation of the front end.

As the chapter closes on the practicalities and the performance implications of a modern front-end upgrade, it becomes clear that the value of a carbon lip and a purpose-built bumper lies less in sheer drama and more in the discipline of aerodynamics with a chassis that is ready to respond. The car’s behavior—its steering feel, its cornering balance, and its stability at speed—reflects a philosophy that places air management at the center of handling. It is a reminder that automotive performance is a system, not a single part. The nose of the car is the first act in a longer performance script, and when paired with the other elements of a well-executed aero program, it sets the tone for everything that follows on track or on the road. For those who value a measured, engineering-informed upgrade that respects both the car’s original intent and the demands of modern performance, the Evo 8/9 front-end enhancement with a carbon lip offers a compelling path forward.

Internal link reference: Authentic Evo 9 MR taillights

External resource: https://www.alibaba.com/product-detail/Varis-Front-Bumper-Carbon-Fiber-815_62709345282.html

Front-Row Performance and Style: The Evo 8/9 Front Bumper with a Carbon Lip, Aesthetic Power Coupled to Aerodynamic Precision

Designing a front end for a high-performance compact car is a study in balance. The Evo 8 and Evo 9 present a silhouette that invites bold upgrades, and a race-inspired front bumper paired with a carbon lip can redefine how the car breathes and looks. This is more than a cosmetic upgrade. The front bumper acts as the first line of defense against drag and lift, shaping how air meets the radiator, intercooler, and the undercarriage. The carbon lip drapes along the bottom edge like a slender, high-performance fin, adding not just flair but a functional edge. The result is a front end that reads as both street-ready and track-curious, a visual signal that the owner intends to push the machine toward its limits while still navigating daily roads. In the space where style, weight, and aero come together, the bumper and lip form a cohesive statement about the kind of driving experience the owner is chasing: precise, responsive, and unapologetically forward-looking.

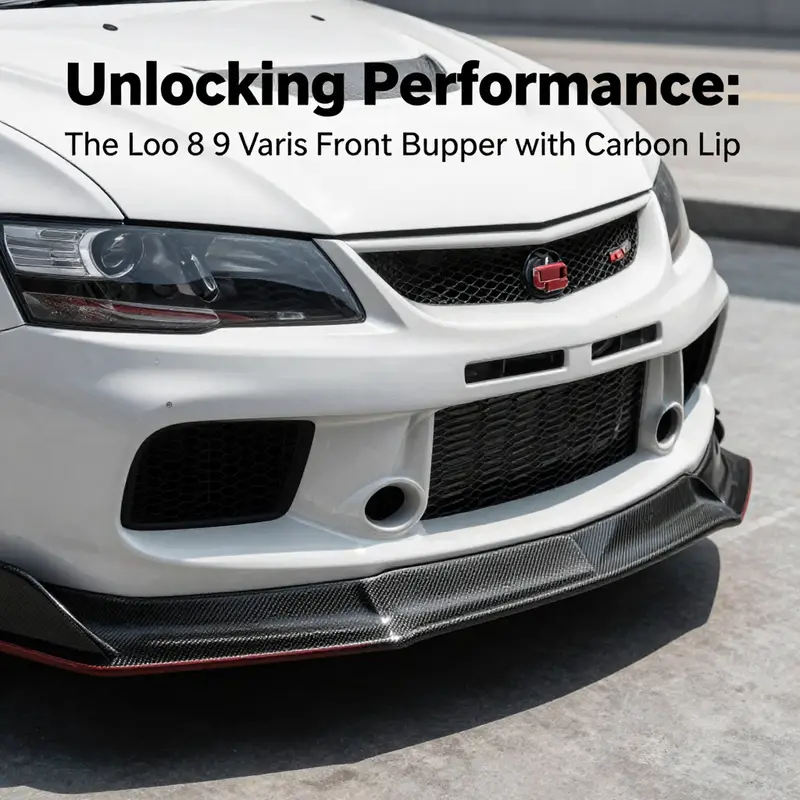

Move closer to the details, and the ensemble reveals a purposeful architecture. The bumper’s design emphasizes a more aggressive profile through enlarged air openings, sharper lines, and a defined lower splitter. These elements work in concert with a carbon lip to establish a clean, continuous interpretation of airflow along the front of the car. The air exits the lower channels in a controlled fashion, while air drawn into the larger intakes keeps the engine bay cooler under demanding use. Finishes range from exposed carbon fiber to resin-coated appearances, with options that suit both showroom polish and track-ready restraint. The kit is engineered to align with the Evo’s lines rather than clash with them, so mounting points, edge radii, and fascia gaps are meticulously matched to minimize need for aggressive trimming for proper fitment. The visual payoff is immediate: a face that looks purposeful even when the car is idle.

Material choice defines both feel and durability. High-grade fiberglass provides a balance of stiffness and cost efficiency, and it is a staple in many aftermarket front-end kits. Carbon fiber variants, however, deliver a weight advantage that is meaningful when every gram matters on the track. The lip itself is typically carbon fiber, chosen not only for its aesthetic clarity but for its stiffness along the most exposed edge of the front end. This stiffness translates into a more predictable boundary layer interaction with air as speed rises. The resin systems used in these builds—whether a clear-coated weave or a more rugged, UV-protected finish—determine how well the surface withstands sun exposure and road debris over time. The interface with the chassis is reinforced with upgraded mounting tabs and sometimes extra brackets designed to resist flex under high-speed airflow. The combination of a confident form and resilient materials makes the kit more than a one-and-done cosmetic modification; it becomes a long-term component that behaves as an integrated part of the car’s aero ecosystem.

Installation is a critical factor in realizing the kit’s promise. A front bumper designed for the Evo family aims to be a straightforward upgrade, with pre-cut openings for headlights and radiator access that align with factory geometry. The real-world experience often hinges on how well a kit mirrors the OEM mounting plan. A clean install minimizes rattles, gaps, and air leaks that can degrade aero performance. For those pursuing a flawless finish, a professional installation ensures that fasteners are torqued correctly and that the alignment is precise across all edges. It is common to encounter small adjustments—minor trimming or shimming—on non-OEM or non-factory-compatible assemblies. Informed installation practices include using the right sealants, correct hardware, and a steady hand during mock-up and final tightening. The best outcomes leave the customer with a front fascia that looks integrated, not aftermarket, and a setup that maintains consistent aero performance across a range of speeds and road surfaces.

From a performance standpoint, the bumper with a carbon lip does more than sharpen the car’s appearance. The aerodynamic intent is to shape the airflow into a more controlled path as the car speeds up. The splitter, a defining feature of the kit, helps sustain a front-end downforce that improves grip on entry and mid-corner. Larger air intakes serve cooling needs, an essential function when the engine or intercooler is working at high duty cycles. The canards, when present, introduce micro-vortices that energize the boundary layer near the bumper’s edges. These vortices reduce flow separation and direct air toward the sides, lowering the propensity for front-end lift at the wheels. The carbon lip, keeping close to the ground, minimizes the disruptive lift that can occur under high-speed travel and during aggressive braking. In combination, these features yield a more stable front end, a more confident steering feel, and a more predictable response under braking and cornering. The track-ready look and the measurable aero gains reinforce a single truth: aesthetic upgrades can be engineered to perform when the accelerator is pressed.

The visual transformation extends beyond mere speed cues. Street presence is amplified by a front end that hints at reserve power and a history of performance work. For many owners, the look alone changes how the car is perceived by others, turning heads toward the lowered stance, the crisp corner lines, and the reflective weave of carbon under varied light. On the street, this is as much about personal expression as it is about function. On the track, it becomes a statement about intent and discipline. The lip’s sheen catches the eye as the car approaches, while the bumper’s sculpted recesses offer a sense of depth that invites a second look. The result is a cohesive aesthetic that communicates speed without saying a word, a visual narrative of a car that has been tuned not only for better speed but for a more complete sense of purpose behind the wheel.

Careful maintenance supports the aesthetic as well as the performance. Carbon fiber requires more nuanced care than painted fiberglass, particularly in climates with intense sun or abrasive roads. A clear protective layer helps prevent micro-scratches and color fading, and periodic inspection of the weave can catch micro-cracks or delamination early. Cleaning should rely on mild soaps and soft tools to avoid scratching the surface, with attention given to any edge joins where the resin may be exposed. Fiberglass components benefit from regular inspection for gel coat wear, with attention to edge seams and mounting points. For both materials, avoiding harsh solvents and solvents-based detergents helps maintain finish integrity. Protective films or coatings can extend life in areas most prone to impacts and scrapes—such as the lower lip and splitter—without diminishing the aesthetic effect.

Economic considerations shape how enthusiasts pursue this upgrade. Pricing is a function of material choice, finishing quality, and the seller’s region and warranty terms. Carbon fiber assemblies command a premium for their weight reduction and stiffness, while fiberglass units offer a more accessible path to transformation. Availability fluctuates by geography, with some regions enjoying shorter lead times through domestic channels, and others benefiting from broader selection via international suppliers. Shopping across borders introduces variables such as shipping costs, customs duties, and potential delays, as well as the need to verify authenticity and fitment claims. The buyer weighs the sticker price against the expected lifespan, the reliability of mounting points, and the kit’s overall integration with the Evo’s broader aero plan. In the end, the value proposition rests on a durable front-end package that keeps its form and performance across miles of road and hours of track time, not just a momentary visual impact.

To avoid common missteps, buyers should seek vendors who provide detailed fitment documentation and installation guidance. A reputable kit will include precise diagrams that map the bumper’s alignment with the hood, fenders, and radiator—points used as a baseline to ensure consistent fitment across model years. The most reliable products come with reinforced mounting areas and explicit instructions for torques and fastener types, reducing the chance of flex under load. It is wise to consult with a professional installer about anticipated flex in high-speed scenarios and to verify that the chosen kit won’t interfere with critical systems such as brake ducts or intercooler plumbing. The Evo’s front-end geometry is a finely tuned ecosystem; changing one piece can ripple through the entire aero profile. Rather than viewing the bumper as a singular cosmetic item, consider it an integrated element of a broader tuning strategy that includes hood geometry, fender lines, undertray design, and wheel/package choices. A thoughtful approach to selection and installation yields a front end that performs as confidently as it looks, reinforcing a coherent performance narrative from the grille to the splitter.

For broader context on how this kind of upgrade fits within the Evo community, it helps to consult resources that map the geometry of common bumper configurations and their implications for fitment. A representative reference outlining Evo front and rear bumper options across model years can be found here: 2006-2012 Mitsubishi Evolution Front and Rear Bumpers.

External resource: for further detail on the production and material options available in the market, you can review an external listing that documents a carbon lip and front bumper setup. External resource: Alibaba listing for the Evo 8/9 bumper with carbon lip: https://www.alibaba.com/product-detail/Evo-8-Varis-Front-Bumper-Carbon_1600435297875.html

Material Alchemy: The Science Behind the Evo 8/9 Front Bumper with Carbon Lip

The front end of a high-performance Mitsubishi Lancer Evolution is more than a visual statement; it is a carefully engineered interface where materials, form, and function meet. When a front bumper is paired with a carbon fiber lip, the chassis is suddenly governed not only by aesthetics but by the way a composite continues to behave under pressure, at speed, and in the kinds of environments that demand repeatable performance. The Evo 8 and Evo 9 platforms were designed to be driven hard, yet the aftermarket front bumper with a carbon lip refines that dynamic by altering weight distribution, stiffness, and airflow in ways that matter to handling, stability, and even tire wear over time. Understanding the material science behind this combination—GFRP as the bumper’s backbone and CFRP as the lip’s high-tech edge—helps illuminate why this kit remains a coveted upgrade for enthusiasts who value both form and function in equal measure.

At the heart of the bumper’s structural performance sits glass fiber reinforced polymer, or GFRP. This material is chosen for its balanced blend of strength, impact resistance, and cost efficiency. In a high-speed scenario, the bumper must absorb minor knocks and deflect energy without fracturing while also resisting corrosion from road salts and moisture. GFRP achieves this through a matrix of glass fibers embedded in a resin, creating a lattice that carries load efficiently while remaining relatively lightweight. In practice, engineers optimize the layup schedule so the bulk of the material bears the brunt of frontal impact, preserving the integrity of the crash structure and protecting more sensitive components behind the bumper. The result is a robust shell that doesn’t bend or fatigue easily under the repetitive strains of spirited driving, track sessions, or occasional off-race terrain without turning the front end into a heavyweight burden that unsettles steering feel.

Yet the impression of a high-performance front end is incomplete without acknowledging the role of the carbon fiber lip. Carbon fiber, in its reinforced polymer form, is prized for a different set of properties: exceptional stiffness, high specific strength, and a remarkably favorable strength-to-weight ratio. The lip module is typically CFRP, a material choice that lets engineers extract downforce and aerodynamic efficiency with minimal mass penalty. The lip’s geometry is crafted to generate a subtle but meaningful pressure gradient as air accelerates over the bumper and redirects flow toward the underbody and splitter, helping to tame front-end lift at elevated speeds. The visual hallmark of CFRP—the distinctive woven pattern—adds a premium look that many builders equate with performance credibility. The combination of an GFRP bumper core and a CFRP lip represents a practical marriage of materials: the bumper provides a durable, economical base, while the lip supplies the aero punch without overloading the front end with weight.

Manufacturing these composite assemblies involves a careful orchestration of processes that ensure consistency, shape retention, and crashworthiness. Vacuum bagging is a staple in achieving strong, void-free laminates. By drawing excess resin and air from the composite layup, the technique promotes a tight, uniform bond between layers. This is essential for a component that must hold its geometry under the demanding conditions of cornering, braking, and acceleration. For segments like the CFRP lip, autoclave curing takes the volume of control a notch higher. The autoclave applies heat and pressure uniformly, refining the resin’s cross-linking and enhancing stiffness and dimensional stability. The resulting CFRP lip becomes not only a light but a precise aerodynamic element, capable of resisting delamination and sustaining its shape through repeated high-speed passes and the occasional contact with curbs or debris. While the core bumper often leans on a well-engineered GFRP matrix, the lip leverages the CFRP’s amplified stiffness to push the overall system into a more capable aerodynamic regime.

Material choices also reflect safety, compatibility, and durability. The front bumper is engineered to align with OEM fitment standards, ensuring a tight, predictable installation and preserving the vehicle’s crash performance envelope. The compatibility extends beyond mere bolt-on fitment; it includes radar, bumper sensors, and crash energy absorption zones that interact with the bumper cover. When a carbon lip is added, it is designed to cooperate with the bumper’s geometry rather than disrupt it. The lip’s landing geometry, thickness, and curvature work in concert with the shaping of the bumper to create a cohesive front end. Those elements matter when the car experiences high-speed gusts, rough pavement, or road imperfections. In such cases, the CFRP lip’s stiffness helps maintain a consistent separation and reduces flutter, contributing to a steady steering response and a more predictable front axle alignment. The final package is not simply about making the car look more aggressive; it’s about delivering tangible gains in downforce and front-end precision while maintaining a level of safety that keeps the car compliant with typical driving-conditions stress tests.

The balance between weight and stiffness is one of the most compelling aspects of this front-end composition. A typical bumper made from GFRP remains impressively light for its class, which helps to preserve the vehicle’s overall weight and, by extension, its tire load distribution and suspension dynamics. Every gram shaved from the front increases the chance of keeping the car’s inertial response more favorable during quick direction changes and hard braking. The CFRP lip then adds its advantage with minimal mass. The result is an aerodynamic element that elevates cornering stability at speed by contributing a downward force without proportionally increasing load transfer to the front. This is particularly valuable in the Evo 8/9 context, where precision steering and throttle modulation play central roles in lap times and road manners alike. In practice, the lip’s downforce is most effective when the rest of the aero package remains balanced, underscoring the importance of cohesive design and careful feedback from wind-tunnel or computational analyses, even when the workshop bench is filled with epoxy and carbon fiber scraps rather than a full-scale test rig.

The interior and exterior finishings of these composites also warrant attention. GFRP bumpers often receive gel coats or finishing coats that protect the optical clarity of the surface while deflecting micro-abrasions from road grit. The post-curing process, sanding, and clear-coating steps contribute to a surface that resists UV degradation and maintains color stability after repeated exposure to sun, heat, and rain. A CFRP lip, viewed from the outside, typically shows the natural weave pattern, which is part of its appeal. Some builds opt for a protective clear coat to preserve the weave’s visual integrity and to shield the resin-infused layers from moisture ingress. These cosmetic details matter to owners who intend to display or track their vehicles; the finish is not merely a matter of aesthetics, but a practical shield against environmental challenges that can degrade a composite’s surface and, over time, compromise its performance if micro-cracks propagate in resin-rich zones.

From a performance standpoint, the combination of GFRP and CFRP emphasizes the importance of a controlled workflow. The materials’ properties are highly sensitive to resin systems, cure schedules, and ingress of air during layup. If the resin is too viscous, or if air pockets remain, the resulting laminate can exhibit weak points that undermine impact resistance or stiffness. Conversely, if the resin pours too quickly or the curing cycle is too aggressive, the laminate might distort or warp, shifting the bumper’s alignment and its aero performance. Practitioners mitigate these risks through precise control of temperature profiles, pressure application, and curing times, which all contribute to a reliable product with predictable behavior on the road or on the track. The reliability of such systems is essential because any mismatch between bumper and car must not translate into unexpected performance changes or safety compromises during high-speed maneuvers or sudden braking events.

The broader value proposition for enthusiasts lies in how these materials translate into a coherent upgrade package. The automotive market often presents a spectrum of choices, with GFRP-based bumpers offering a cost-effective way to achieve a sharp, modern look and improved aero behavior. CFRP lips, while more expensive, deliver meaningful gains in downforce relative to weight and add a premium tactile impression that many owners associate with serious performance. The inclusion of a CFRP lip can also influence the front-end geometry, subtly altering the car’s overall balance. This may lead to adjustments in suspension tuning and alignment settings to optimize grip and steering response. In practical terms, drivers who install such a combination should expect a slightly more planted feel at high speeds and a more responsive turn-in when the front tires carry more of the load. What makes the Evo 8/9 package particularly appealing is that these improvements can be achieved without demanding extensive fabrication or intrusive changes to the core chassis. Installations are designed to be straightforward for technicians familiar with aftermarket composite parts, and the fitment is typically on par with OEM standards, preserving both function and form without forcing a compromise on daily usability.

A useful lens through which to view these developments is the idea that performance materials are about enabling confidence. The clamp of reliability around the front end—through a robust GFRP bumper and a stiff CFRP lip—translates into better high-speed stability, sharper steering feedback, and more predictable aerodynamics even when road surfaces are imperfect. This is not a fantasy of pure speed; it is a real-world synthesis of material science, manufacturing discipline, and design intent. The final product allows a driver to focus on line, throttle, and rhythm rather than compensating for a front-end that understeers, porpoises, or loses traction because the aero balance has shifted under load. In that light, the carbon lip becomes more than a cosmetic flourish; it is a performance device that leverages the advanced properties of carbon fiber to yield measurable gains in control at speed. The synergy between the GFRP bumper’s resilience and the lip’s aerodynamic refinement forms a practical, durable upgrade path that aligns with the expectations of enthusiasts who value repeatable performance alongside striking appearance.

For readers who want to explore more about the practicalities of aftermarket front-end components and their fitment on the Evo 8/9, there is value in examining how these parts relate to broader trends in the market. A representative example of the kind of aftermarket page that deals with front and rear bumper options on similar chassis can provide useful context without getting lost in brand-specific narratives. 2016 Mitsubishi Lancer front and rear bumpers can offer a reference point for compatibility, mounting principles, and the kinds of tolerances involved when integrating a new bumper with a carbon lip into an existing vehicle platform. This kind of resource helps bridge the gap between theory and practice, illustrating how the right combination of materials and manufacturing discipline translates into a successful installation that remains functional under daily use and spirited driving alike. For readers who want to examine this broader compatibility in a concrete form, the following page can serve as a practical touchstone: 2016 Mitsubishi Lancer front and rear bumpers. 2016 Mitsubishi Lancer front and rear bumpers page.

As the discussion circles back to material science, it is worth noting that the choice between GFRP and CFRP is often a matter of budget, purpose, and expected service life. GFRP is well-suited for front bumpers that require robust impact resistance and cost efficiency, making it a resilient backbone for a design that can see heavy use on public roads and occasional track sessions. CFRP, with its superior stiffness and low weight, simply elevates the lip’s aerodynamic influence while keeping mass to a minimum. The combination is a balanced approach that respects the constraints of a street-driven performance car while still chasing track-like behavior when the driver pushes hard. Finishes and coatings complete the package, ensuring that both the bumper and lip resist the elements and retain their aesthetic appeal for as long as possible. In the end, the material science behind this Evo 8/9 front bumper with a carbon lip tells a story about how modern composites can harmonize with traditional automotive engineering to deliver a product that looks as purposeful as it performs. Enthusiasts who recognize this harmony build cars that are not only faster but also more predictable, safer to push to the limit, and more satisfying to own on the road or the racetrack.

External resource: for a broader technical overview of composite materials in high-performance automotive components, see an official documentation source from the maker of carbon-lip body kits. https://www.varis.co.jp/

Aerodynamics in Focus: Market Realities and Availability of the Evo 8/9 Front Bumper with Carbon Lip

For enthusiasts who chase balance between performance and personality, the Evo 8 and Evo 9 front bumper with a carbon lip represents more than a simple replacement part. It sits at the intersection of aerodynamics, weight management, and visual impact. The market for these components is a narrow one—crafted for a specific generation of Mitsubishi Lancer Evolution and tailored by a niche of manufacturers and retailers who specialize in high-performance bodywork. Yet that narrowness belies a robust, enduring demand. Across continents, garages and showrooms alike, buyers seek a kit that can deliver both improved front-end stability at speed and an unmistakable race-leaning aesthetic. The result is a steady cadence of listings, restocks, and updated finishes that keep the option alive for track-focused and street-driven Evos. The story is less about mass-market ubiquity and more about a steady, quality-driven supply chain that meets a distinct need in a community that prizes both form and function.

A key driver of the market’s persistence is the promise of a carbon lip paired with an aggressively styled bumper. The carbon lip, in particular, serves a dual purpose. On the one hand, it contributes to a lighter overall front-end assembly when carbon fiber is used rather than heavier resins or fiberglass. On the other hand, it yields a sharp, visually striking line that complements the Evo’s angular silhouette. The effect is twofold: a reduction in rotating mass at the very front of the car and a psychological cue of performance. Owners look for a lip that not only withstands the punishments of high-speed driving and curbs but also mirrors the car’s mechanical tendencies—precise, purposeful, and ready to bite into air. This is the kind of product that appeals to drivers who treat their car as both a tool and a statement.

Market availability hinges on a network of global platforms and direct-from-manufacturer channels that collectively keep these bumpers in circulation. The listings that surface on major online marketplaces are typically posted by aftermarket specialists who understand the Evo’s geometry and mounting philosophy. They offer a range of options, from full bumper assemblies to components that key into the factory mounting points with minimal modification. This latter feature is a crucial selling point. Evo 8 and Evo 9 owners often prefer upgrades that do not demand extensive fiberglass reshaping or chassis alterations. A bumper designed to fit the Evo silhouette with a straightforward install is particularly appealing. In practice, this translates to a product line that emphasizes precise fitment, robust mounting hardware, and pre-fitted attachment points. The ability to bolt in a front bumper—perhaps with a carbon lip already integrated or supplied as an upgrade—reduces downtime in the garage and preserves alignment with the car’s existing sensor or lighting housings where applicable.

The material conversation also matters. High-grade fiberglass and carbon fiber are common in this segment, each with its own set of trade-offs. Fiberglass can offer cost advantages and easier repair in some cases, while carbon fiber lip components provide stiffness and weight savings that can be meaningful on a track day. The perception of quality often centers on the finish. A bumper arriving with a smooth gel coat, crisp lines, and clean surface prep is more likely to justify the perceived premium. Carbon finishes, specifically, must wear well under UV exposure and stone impact from highway debris, so buyers typically expect durable clear coats that resist yellowing and micro-cracking. Buyers who understand the value proposition tend to look beyond the sticker price and toward long-term durability, ease of maintenance, and the potential impact on handling characteristics as speed increases. In this sense, the market rewards thoughtful construction and meticulous finishing as much as immediate visual appeal.

From a performance standpoint, the aerodynamic package associated with a carbon lip and a front splitter is designed to lower front-end lift and provide more consistent downforce at elevated speeds. The result is improved front-wheel traction, better steering feedback, and more predictable behavior as the car approaches the upper limits of its speed envelope. For Evo models that were originally tuned for a narrow window of performance, any upgrade that adds stability without dramatically increasing drag is welcomed by drivers who track their cars. It is this careful balance—between downforce generation and air resistance—that sustains demand for these components. Enthusiasts who pursue circuit time often place a premium on the payoff: a front end that behaves like it’s plowing through air rather than fighting the wind tunnel. The mental image alone—of a car that feels glued to the pavement during high-speed cornering—adds to the allure of the packaging and pricing strategies that accompany it.

In shaping the pricing narrative, suppliers weigh several variables that reflect both global and local conditions. Material choice, whether carbon fiber or fiberglass-reinforced composites, informs the base cost. The production origin matters as well. Parts manufactured domestically in certain markets may command a premium for faster shipping and easier warranty coverage, while international sourcing can bring lower sticker prices but longer lead times and higher import duties. The variability in shipping costs can be significant, particularly for carbon fiber lip components that are both fragile and lightweight and thus expensive to insure and transport. Import duties and taxes introduce another layer of complexity for buyers outside the country of manufacture. As a result, price is rarely a simple function of materials alone. It is also a reflection of the broader supply chain, the reliability of the seller, and the level of customer support available post-purchase. In practice, buyers often weigh the trade-off between upfront cost and the certainty of a smooth installation experience when selecting a bumper kit or lip option.

The customer base for Evo 8/9 front bumpers with carbon lips tends to fall into several overlapping segments. There are enthusiasts who treat their vehicles as daily drivers but who also relish weekend track days. For them, the bumper’s aerodynamic advantages matter as long as installation remains practical and warranty considerations stay manageable. Another segment comprises track-minded owners who see the kit as an investment in performance. They are willing to engage in minor fabrication or additional bodywork if the payoff in downforce and front-end stability is clear. A third segment includes builders who want a bold aesthetic—carbon weave visible from a distance—and are prepared to invest time in paint matching and finish refinishing to integrate the bumper with the rest of the car’s presentation. This triad of motivations helps explain why the market persists even as models evolve and OEM pricing shifts.

With this market in view, availability is not simply a function of stock numbers. It is a matter of receiving consistent product updates about fitment, new finishes, and compatibility with modern sensors and lights. A bumper meant for the Evo 8/9 chassis must maintain alignment with the car’s grill opening, bumper support structure, and mounting points for the splash guard, radiators, and energy-absorbing foam behind the panel. It must also accommodate the car’s bumper-to-body seam tolerances so that paint lines meet cleanly and gaps remain uniform around the edges. Because these are not mass-market parts, sometimes the most reliable way to secure a kit is through direct communication with a trusted seller who can confirm the latest revisions, the expected lead times, and the exact hardware included in the package. The dialogue between buyer and seller becomes a meaningful facet of the purchasing process. A successful transaction often depends on a seller’s clarity about whether the lip is integrated or needs to be added post-purchase, whether the bumper includes pre-scored mounting points for a direct fit, and whether additional components like side skirts or corner pieces are recommended to achieve a cohesive appearance and function.

Even as the market demonstrates a consistent appetite, buyers should exercise diligence in evaluating options. A critical step is to confirm fitment with the specific Evo model year and trim level, as small variations in bumper geometry and mounting geometry can affect installation. The best sources provide documentation, measurements, and, ideally, a fitment guarantee. They also describe the finish options in detail, from raw carbon fiber with a protective coat to fully painted surfaces that match a car’s color code. Customers should request clear photos that reveal weave orientation and surface uniformity, inspect warranty terms for structural integrity and finish protection, and verify whether installation requires professional alignment or simply a straightforward bolt-on process. Given the nature of aftermarket parts, the risk of mismatch or cosmetic defects exists, so a cautious buyer will insist on a return policy and a way to confirm the part’s authenticity before it ships.

For those who want a snapshot of the broader ecosystem, a general overview of bumper variants and compatibility can be found here, offering a sense of how the Evo’s design language translates across generations. 2016 Mitsubishi Lancer front and rear bumpers This link provides a reference point for understanding how different bumper configurations align with the Evo chassis and how a carbon lip can be integrated or added as an upgrade. It is a reminder that the market’s vitality rests on continuity and compatibility as automotive design evolves. The availability landscape may shift with new generations or revised emissions and safety guidelines, but the core appeal—reduced weight, sharper aesthetics, and improved front-end behavior—continues to attract buyers who value performance with a street-credible stance. The community’s conversations about fit, finish, and long-term durability reinforce the idea that this is less about a single purchase and more about a continuing upgrade pathway that owners revisit as they chase new performance milestones.

From a consumer behavior perspective, the frequent appearance of these bumpers on large marketplaces signals that the segment remains active, even as price points shift with supply chain dynamics and the volatility of carbon fiber material costs. The attractiveness of a carbon lip lies not only in potential weight savings but also in the confidence it gives to drivers who want a front end that behaves predictably at speed. The aesthetic payoff—dark weave, glossy finish, and a fractionally lower silhouette—speaks to a culture that values both precision engineering and the ability to stand out. It’s a reflection of how a single component can influence a broader build philosophy: the choice to tune a car for better aero performance, combined with a desire for a bold, race-inspired look. In this sense, the Evo 8/9 front bumper with a carbon lip becomes more than a product; it becomes a symbol of a philosophy of driving that values control, balance, and identity on the road and track alike.

For buyers and sellers alike, the availability story is inseparable from the broader discourse on aftermarket performance parts. The ecosystem thrives on transparent communication, reliable shipping, and a shared understanding of the car’s geometry. It rewards sellers who provide precise fitment confirmations, clear installation instructions, and robust post-purchase support. It rewards buyers who bring patience to their purchase, asking pointed questions about compatibility and finish, and who prepare for a potentially longer lead time when sourcing internationally. In sum, the Evo 8/9 front bumper with carbon lip sits at a crossroads of performance engineering and expressive fashion. The market’s resilience rests on the community’s willingness to invest in components that compound benefits over time: a lighter front end, improved stability at speed, and a visual language that communicates the owner’s commitment to the craft of driving.

External resources and broader industry conversations reinforce this narrative. For readers seeking a more general perspective on automotive aerodynamics and the role of lightweight front-end components in performance tuning, a reputable automotive publication offers insights into how aerodynamic elements interact with vehicle dynamics and handling under race conditions. This broader context helps illuminate why the Evo 8/9 kit remains relevant even as new technologies emerge. To explore more about the principles behind these aero choices, visit the external resource: https://www.caranddriver.com. Integrating this perspective with the practical realities of sourcing and installation provides a well-rounded view of what to expect when venturing into the market for a carbon lip-equipped front bumper and its associated aero improvements.

In closing, the availability of the Evo 8/9 front bumper with a carbon lip reflects a durable and purposeful corner of the aftermarket scene. It serves a focused audience seeking an upgrade that balances downforce and weight with aggressive styling. The channel mix—global marketplaces, specialist retailers, and direct-from-manufacturer offerings—ensures that dedicated buyers can find a setup that aligns with their goals, whether they are chasing track performance, street presence, or a compelling combination of both. The path to acquisition is rarely linear, but with careful research, clear fitment expectations, and a tolerance for occasional lead times, EVO owners can secure a kit that respects the car’s heritage while pushing its capabilities forward. The ongoing conversation about fitment, finish, and long-term durability remains central to the market’s vitality, reminding us that in the world of high-performance automobiles, form and function are forever linked on the front bumper’s line as the car slices through air with purpose.

Final thoughts

The Evo 8 9 Varis front bumper with carbon lip is more than just a cosmetic upgrade; it is a synthesis of style, performance, and material innovation. For business owners in the aftermarket parts industry, understanding these factors is vital for capturing consumer interest and meeting market demands effectively. By leveraging these insights, you can align your offerings with what enthusiasts seek, ensuring success in this competitive landscape.