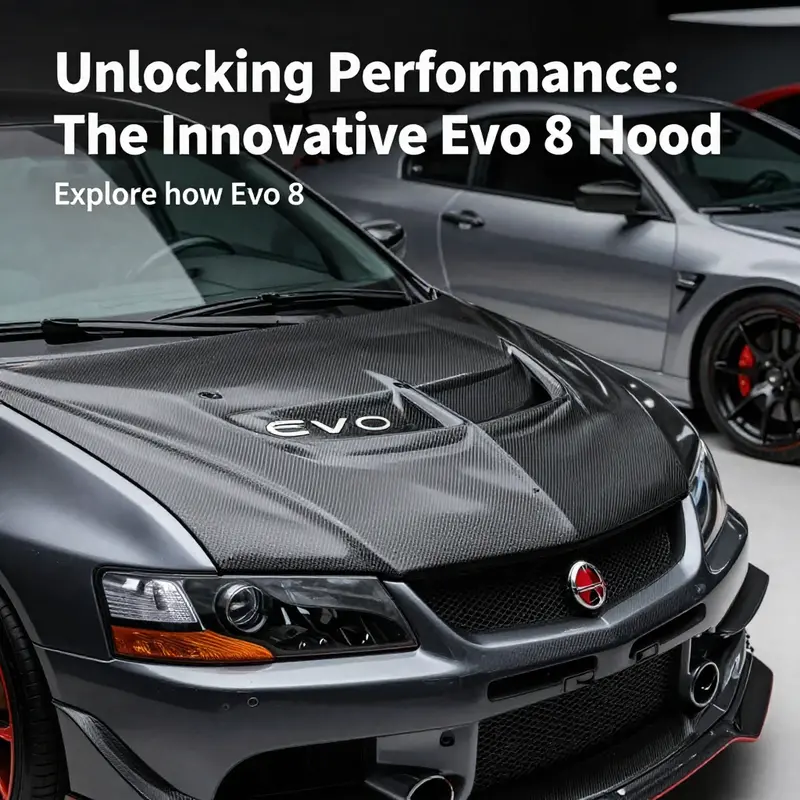

The Evo 8 hood is a cutting-edge component designed for Mitsubishi Lancer Evolution VIII, revolutionizing automotive performance enhancements and customization options. This article delves into the materials and performance features that make the Evo 8 hood stand out, the opportunities for customization and compatibility, its reliability certifications, market pricing, and the performance enhancements it offers. Each chapter uncovers essential knowledge, helping business owners capitalize on offering or investing in these premium automotive parts to enhance vehicle functionality and appeal.

null

null

null

null

EVO 8 Hood: Certification, Durability, and Real-World Reliability

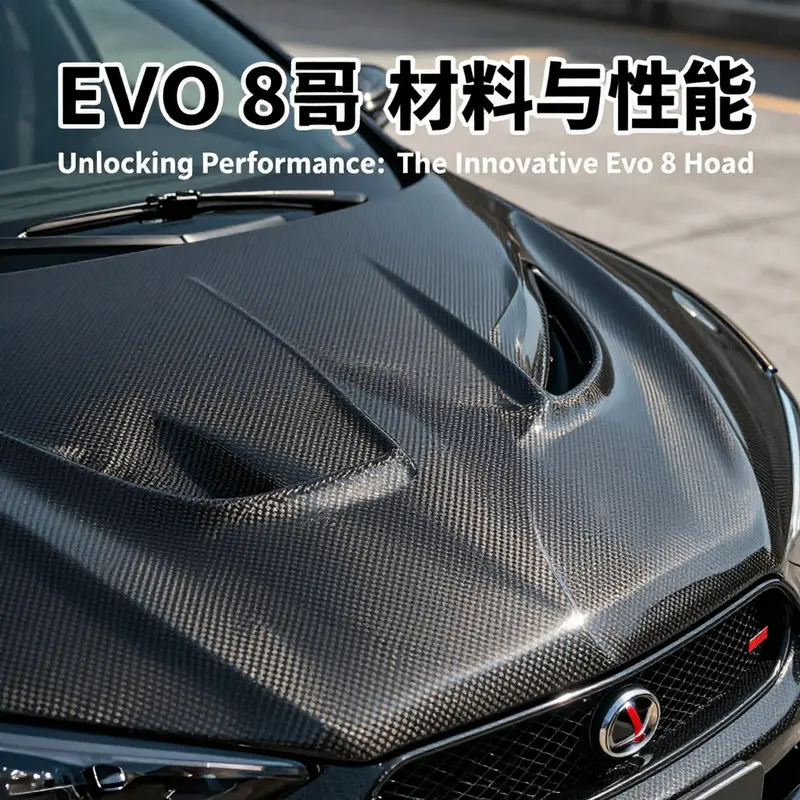

The EVO 8 hood is more than a cosmetic upgrade. It is a structural component that affects weight, aerodynamics, and engine cooling. When made from carbon fiber, the hood promises significant weight savings and improved stiffness. But buyers should look beyond glossy photos and bold claims. Certification, tested durability, and verified fitment determine whether a hood delivers on promises. This chapter examines what credible certification looks like. It also explains how reliability is proven in the workshop and on the road.

Certification begins with materials. Carbon fiber hoods rely on fiber orientation and resin systems. Prepreg carbon with controlled fiber percent and high-grade epoxy yields predictable strength. Wet-lay composites can vary more in consistency. A certified hood will list material specifications. Look for details about fiber type, resin class, and core materials. Those numbers matter because they set expectations for stiffness, impact resistance, and thermal behavior.

Structural certification usually includes standardized tests. Tensile and flexural tests measure stiffness and strength. Impact and fatigue tests reveal how the hood reacts to repeated loading. High-quality suppliers document these tests with clear reports. The reports show test methods, sample sizes, and pass/fail criteria. That transparency is essential. It separates reputable components from aesthetic replicas.

Fitment and dimensional accuracy are part of certification too. A hood that does not mount accurately can stress hinges and latches. Precise tooling, quality molds, and consistent manufacturing processes ensure repeatable dimensions. Good suppliers provide measurement sheets and template drawings. These documents show hole locations, hinge bosses, and latch cutouts. Buyers should compare these sheets to their car before purchase.

Environmental durability is another certification facet. UV exposure, temperature extremes, and chemical resistance are relevant. Hoods undergo accelerated aging tests to show how clearcoats and resins hold up. Thermal cycling tests simulate hours of engine heat followed by cold conditions. A hood that survives these cycles without delamination or surface crazing is more likely to remain serviceable long term.

Aerodynamic and thermal performance is often advertised, but certification makes claims believable. Wind-tunnel or CFD results quantify drag reduction and airflow improvements. Thermal testing measures hot-air extraction and engine-bay temperatures. A certified hood will provide numbers and test conditions. Independent testing adds credibility. Numbers without context are marketing.

Beyond laboratory tests, practical reliability depends on manufacturing controls. Consistent layup schedules, controlled curing, and inspection checkpoints reduce variability. Many reliable suppliers use autoclave curing when possible. Autoclave processes compress plies and remove voids. The result is a stronger, lighter part with fewer defects. Quality control includes nondestructive inspection, such as ultrasonic scans, to detect internal flaws.

Corrosion and galvanic compatibility are often overlooked. A carbon fiber hood meets an aluminum or steel body at fasteners and hinges. Where dissimilar materials meet, designers must insulate contact points to prevent electrochemical corrosion. Certified hoods address this with appropriate bushings, coatings, or isolating washers. Without these measures, long-term fitment and latch integrity may suffer.

Safety is a core concern. In a crash, a hood should deform in a predictable way. Too brittle a finish can shatter, while too soft a structure may not protect the windshield. Certification evaluates how the hood behaves under impact. It also assesses hood retention systems so the hood does not detach at speed. Reliable products include reinforced mounting areas and validated latch compatibility.

Track use places added stress on a hood. Vents and cutouts change load paths. Certification for vented hoods incorporates localized reinforcement around openings. Engineers model stress concentrations and add bonded or molded reinforcements accordingly. The result is a hood that looks aggressive while retaining the required structural integrity.

Installation quality affects perceived reliability. Even the best hood will fail to perform if installed poorly. Certified parts usually ship with installation guides and torque specifications. They note hinge adjustment procedures and recommended fasteners. When modifications are needed, documentation warns about potential issues, like welding on thin sections or altering hinge geometry. Good guides also recommend periodic checks after the first few hundred miles.

Warranty and traceability matter. A credible product comes with a clear warranty and a quality control trace number. The trace number ties a hood to its production batch and test records. If defects appear, traceability helps identify causes. Warranties show the manufacturer’s confidence in materials and workmanship. They also provide recourse for buyers, which indicates long-term commitment.

Not all aftermarket hoods are equal. Some mimic the appearance with composite blends and lower costs. These parts can serve as budget options, but they often lack the same test documentation and material consistency. When buying, compare weight data, fiber content, and test reports. A small price difference may reflect significant quality gaps.

Regulatory factors can influence suitability for road use. Different regions have varied rules about replacement body panels and crashworthiness. Certified hoods often meet or exceed the applicable guidelines. Seek hoods that reference relevant standards. Local compliance ensures the part can be used legally and safely on public roads.

A practical buying checklist helps cut through marketing. Request material specifications. Ask for test reports and measurement drawings. Confirm manufacturing methods and finish options. Verify warranty terms and traceability. Insist on clear installation instructions. If possible, review third-party test data or independent user reports. A well-documented hood gives you the evidence needed to trust it.

Fitment for specific models is another key consideration. Hoods designed for exact model years reduce modification needs. Properly engineered parts use OEM mounting points and maintain hood-line continuity. They preserve aerodynamic balance and ensure the hood works with existing vents, scoops, and under-hood components. When a hood is described as compatible with several model years, verify the specific fit for your vehicle before ordering.

Finally, evaluate the supplier’s aftercare. Reliable vendors provide support for fitment issues and clarity on repair procedures. They can advise on paint preparation, clearcoat application, and sealing methods. Good customer support often reflects sound manufacturing practices behind the scenes.

For further reference on carbon fiber bonnet options for related Lancer models, see this product listing with specifications and photos: brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x.

Detailed product listings and international supplier pages sometimes include test claims. One example of a supplier listing with data and purchase information is available here: https://www.alibaba.com/product-detail/Mitsubishi-EVO-8-Carbon-Fiber-Hood-full_1600741714221.html

Reading certification and reliability information carefully reduces risk. The right hood will improve weight, cooling, and style. The wrong hood can create fitment headaches and safety concerns. Trust evidence, not just imagery. Choose parts with measurable test data, traceability, and clear installation guidance.

Weight, Wind, and Wallet: Navigating the Evo 8 Hood Market Across Global Gateways

Acquiring a carbon fiber hood for the Mitsubishi Lancer Evolution VIII is more than a simple purchase; it is a statement about balance between performance, durability, and value. The hood, engineered to shed weight significantly, can improve acceleration and fuel efficiency while stabilizing the car’s front end. The weight reduction translates into crisper throttle response and more predictable handling, especially when paired with the car’s existing aero underpinnings and tuned suspension geometry. On the wind, the hood’s streamlined profile helps manage air flow around the engine bay, reducing drag and aiding cooling at high speeds. Market realities reflect these performance goals in price, with carbon fiber hoods typically occupying a mid-range band that mirrors the labor-intensive production and the precision of fit. The result is a part that influences both straight-line performance and corner balance, not merely how the car looks. Heat management is also a factor; with lighter front-end mass, heat soak in the engine bay can be better managed, helping nearby components perform consistently under demanding driving conditions.

Customization remains a core driver of Evo VIII hood choices. The same engineering process that shapes the airflow also enables a range of surface finishes, colors, and vent geometries. Whether a racer wants a matte weave for a stealth appearance or a glossy clear coat to showcase the carbon’s texture, there are options that preserve fit while aligning with personal aesthetics. The hood contour is engineered to harmonize with the 2001–2007 Evo VII and Evo VIII architecture, delivering an installation that feels factory rather than aftermarket. This precision matters when the car is pushed on track days or when street use demands predictable hood line and consistent hood-to-cowl alignment during high-speed runs. The choice is not merely cosmetic; it underpins heat management, durability under spirited driving, and even noise characteristics inside the cabin during aggressive driving sessions. Some buyers also consider whether vent openings align with factory engine components to avoid interference and to maintain consistent airflow to the intercooler and radiator.

Pricing sits in a spectrum that mirrors build quality and sourcing strategy. On wholesale channels connecting factories with buyers, carbon fiber variants typically trade within roughly 470 to 598 USD. The spread reflects factors such as weave pattern, resin system, finish, edge reinforcement, and whether the part includes reinforced mounting edges. More budget-minded options or look-alike pieces, which imitate the hood’s appearance but rely on different materials, can be priced near similar ranges depending on branding and packaging. For enthusiasts seeking the most premium feel or bespoke configurations, costs can climb beyond the mid-five hundreds and into higher brackets when custom vent shapes, reinforced perimeter rims, or unique mounting features are requested. Lead times, shipping costs, and regional duties can further widen the price gap, making careful comparison essential even before choosing a supplier. Buyers should also consider whether the finish is UV-stable and how resilient the clear coat is to road grime and washing.

Searching for the right source blends practicality with confidence. Because these parts are performance-oriented, buyers should evaluate supplier credibility, testing credentials, and traceability of materials. Reputable sellers typically present clear documentation about automotive-grade safety standards and airflow testing results, ensuring the component can withstand the vibrations, heat, and stresses of spirited driving. The procurement path often begins on broad wholesale networks and ends with a direct purchase from a manufacturer or an authorized distributor. For individuals needing a single piece rather than a bulk order, consumer marketplaces become viable channels, sometimes offering lower entry prices but with trade-offs in warranty coverage and consistent quality control. When evaluating options, pay close attention to the stated material composition—full carbon fiber versus a composite look—as this distinction affects both objective weight savings and long-term durability under heat cycles. Counterfeit finishes and misrepresented weights are risks; verify weave density and resin consistency as part of due diligence, and request photos of the finished product in different lighting to confirm authenticity.

To ground this discussion in a practical scenario, consider how a carbon-fiber hood is presented to buyers who expect a precise, factory-like fit. A credible route for exploring concrete options is to view professional-grade carbon-fiber hoods designed with geometry that aligns with the factory hood line, including mating points for hinges, latch hardware, and ventilation ducts. For a real-world reference that echoes this topic, see this carbon-fiber bonnet hood for Mitsubishi Lancer Evo-X, which demonstrates how surface finish, edge treatment, and packaging are described in a product listing. See link: carbon-fiber bonnet hood for Mitsubishi Lancer Evo-X.

The decision on an Evo VIII hood also engages practical considerations such as weight saving versus cost, and how thoroughly one intends to drive the car. The weight saved by using carbon fiber flows into improved weight distribution and potentially faster cadence in gear changes on a track. At speed, the lower inertia of the front section helps the steering feel to remain predictable, while the higher stiffness ensures the front end remains responsive under braking. Aerodynamic performance improves when the hood’s venting is matched to the engine’s cooling needs; properly designed vents can reduce intake temperatures, helping the turbo or high-pressure engines maintain performance. In daily driving, the incremental gain could translate into marginal fuel efficiency improvements and a more composed ride, especially when the rest of the car’s aero package is tuned accordingly. The market recognizes this value by offering a spectrum of options and by presenting channels that scale from a single purchase to bulk procurement, depending on the scope of the project and the budget. For buyers weighing aesthetics against function, the decision often hinges on the perceived return on investment—whether the upgrade justifies the effort and cost for their specific use case.

Finally, for readers who crave deeper technical grounding on carbon fiber in automotive parts, there are external resources that explain the material’s stiffness-to-weight benefits and the manufacturing demands behind premium composites. These sources describe why a lighter front end can improve steering response without sacrificing rigidity, a principle behind many modern performance upgrades. The economics reflect the realities of carbon fiber production, where labor-intensive layups and strict quality assurance contribute to price. Although the Evo VIII hood sits in a specialized corner of the aftermarket, the price and procurement path illustrate how performance technology travels from engineered know-how to street-ready configurations, with the right supplier and the right fitment making all the difference. External resource: https://www.compositesworld.com/articles/why-carbon-fiber-automotive-parts

Lightweight Power and Cooler Running: How a Full Carbon Evo 8 Hood Transforms Driving Dynamics

Lightweight, aerodynamic and thermally efficient — a full carbon hood is more than a visual upgrade. For an Evo 8, swapping the stock steel hood for a full carbon fiber piece reshapes vehicle behavior across acceleration, handling, and engine reliability. The change starts with mass. Carbon fiber hoods commonly shed up to forty percent of the original weight. That reduction sits high on the chassis, directly lowering the car’s rotational inertia. Reduced mass over the front axle translates to sharper turn-in and quicker weight transfer control. Drivers feel it as a more responsive car through corners, and a lighter front end under braking.

Beyond handling, lighter weight improves straight-line performance. Every kilogram removed reduces the energy required to accelerate. For turbocharged four-cylinder platforms, the cumulative effect is measurable in better launch response and marginally improved lap times. Fuel efficiency benefits too, because the drivetrain carries less inertial load. Those gains compound when the hood becomes part of a coordinated weight-saving strategy across other components.

A well-designed carbon hood also changes how the car manages airflow. Modern pieces combine sculpted contours with engineered vents. These vents are not mere styling cues. They channel high-pressure air away from the engine bay and out through controlled exits. The result is twofold: reduced aerodynamic drag and improved under-hood ventilation. Lower drag improves stability at speed and can reduce overall aerodynamic lift. Properly placed outlets help extract heat from the turbo, intercooler plumbing, and radiator. Heat extraction keeps boost control components and intake air temperatures closer to optimal levels during sustained high-load driving.

Thermal management matters most on track or during spirited runs. Turbos and exhaust manifolds quickly heat the engine bay. If trapped, that heat raises intake temperatures and increases the risk of detonation under boost. A carbon hood with vents dumps that heat directly into the airstream. Cooler intake air yields denser charge, which improves combustion and helps maintain consistent power delivery. Drivers notice steadier performance on successive laps and fewer temperature-related torque drops.

Structural behavior is another crucial advantage. High-quality carbon hoods are engineered with layered fiber orientations. Those layers deliver strength while keeping weight low. The result is improved stiffness compared to thin stamped steel panels. A stiffer front end resists flex under aerodynamic load. That stability matters when pairing the hood with other aerodynamic modifications. When integrated properly, the carbon hood helps maintain consistent airflow over wings and splitters, preserving downforce and predictable balance.

Fitment and compatibility cannot be an afterthought. Hoods designed specifically for the Evo 8 ensure correct latch alignment and hood-to-fender gaps. Precision in design minimizes installation work. It also reduces the risk of improper mounting, which could create vibration, wind noise, or stress concentrations. For enthusiasts who track their cars, this precise fit matters because it preserves the chassis’ original crash energy pathways and avoids unforeseen structural issues.

Customization options amplify both function and form. Carbon hoods come in a range of finishes, from raw clear-coated fabric to painted and prepped surfaces. Buyers can choose vent layouts and shapes tailored for either maximum cooling or a cleaner aesthetic. These choices let owners balance visual identity with performance goals. For show cars, a gloss weave finish becomes a signature element. For track machines, vents and weight savings are prioritized.

Safety and testing are not optional. Quality carbon hoods undergo rigorous testing for impact resistance, weather durability, and long-term structural integrity. Manufacturers evaluate peel strength, UV stability, and the hood’s behavior under repeated loading. These tests ensure the hood remains safe in normal use and maintains predictable failure modes in extreme events. Choosing a hood that meets industry standards reduces liability and enhances the owner’s confidence during high-speed driving.

Integration with other upgrades yields the most significant performance leap. A lightweight hood pairs well with stiffer suspension components and upgraded brakes. When the front mass is reduced, suspension rates can be retuned for improved responsiveness. Brake systems feel less prone to nosedive under heavy stops when overall mass drops. Aerodynamic pieces also interact: vents that release engine bay pressure complement front splitters by reducing underbody lift. When the hood is part of a holistic build, each change multiplies the performance benefits.

Maintenance and durability deserve careful attention. Carbon is not immune to damage. Small chips and rock strikes can compromise clear coats or expose fibers. Regular inspection prevents small issues from becoming structural ones. Cleaning with pH-neutral detergents and avoiding abrasive tools preserves the finish. For painted hoods, proper prep and paint procedures extend life and reduce the chance of peeling. If repairs are needed, skilled composite technicians can restore strength and appearance.

Cost and value must be weighed realistically. A full carbon hood commands a premium over composite alternatives. That premium buys true weight savings and superior aesthetics. The investment is justified if the buyer prioritizes track performance, weight reduction, or high-quality appearance. For casual drivers, lower-cost composite options may offer acceptable looks with less expense. Understanding budget and goals clarifies the right choice.

When choosing a hood, examine the manufacturing process. High-pressure molds and multi-axis fiber layups produce more consistent parts. Check for full carbon construction versus bonded skins over foam cores. Full carbon delivers predictable mechanical properties and often lasts longer. Also seek hoods engineered to accept factory hardware and latches without modification. That reduces installation time and preserves safety systems.

Practical use cases illuminate the hood’s true value. For a track-focused Evo 8, a carbon hood reduces lap times and keeps intake temperatures stable. For a street-driven car that sees occasional canyon runs, it offers sharper handling and a more aggressive look. For a show car, the weave pattern and finish create a visual focal point that signals purpose-built intent. In every case, thoughtful selection and professional installation unlock the best outcomes.

For owners looking to compare similar bonnet designs and finishes on a related chassis, see this reference for an original carbon fiber bonnet for a later-generation Lancer: original carbon fiber bonnet for Lancer Evo X.

For technical specifications, sourcing, and a detailed listing of a full carbon hood compatible with Evo platforms, consult the external product listing linked below.

https://www.alibaba.com/product-detail/Mitsubishi-EVO-8-Carbon-Fiber-Hood-full1600769188215.html?spm=a2700.galleryofferlist.pimage.5.6f1a6b65ZcNwRi&albq=63d9895535324461a61b59e31e5d3083

Final thoughts

The Evo 8 hood represents a significant advancement in automotive performance and customization. It stands as an essential component for business owners looking to upgrade their offerings in the aftermarket parts market. By understanding the materials, reliability, customization options, and pricing, businesses can position themselves to better serve customers seeking high-performance solutions for their vehicles. The Evo 8 hood is not just an upgrade; it’s an investment in quality, performance, and a unique driving experience.