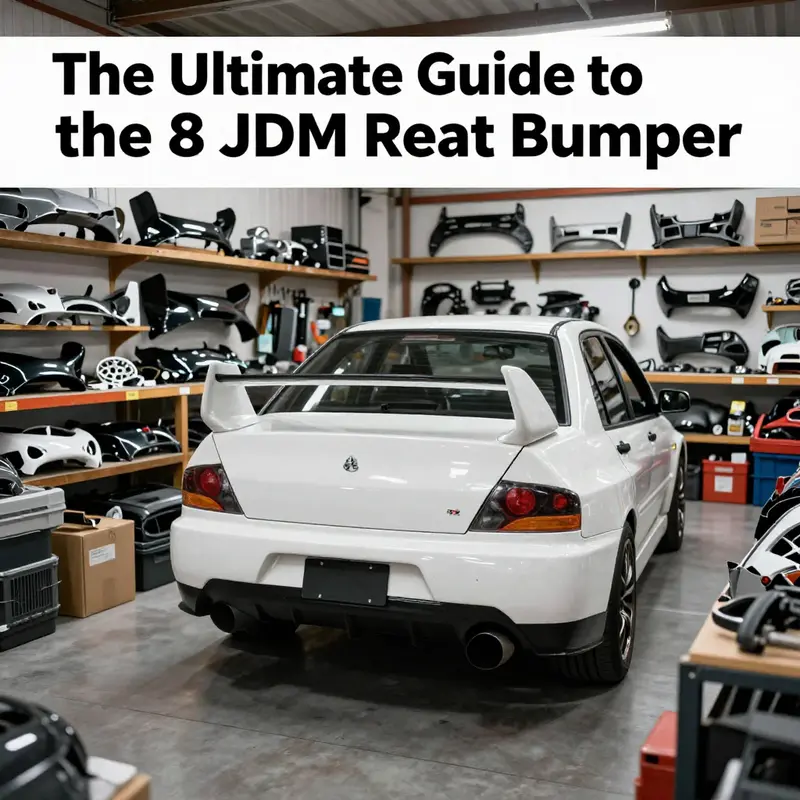

For business owners in the automotive aftermarket industry, understanding the nuances of components like the Mitsubishi Lancer Evolution VIII (Evo 8) JDM rear bumper is critical. This article delves into the evolution of the Evo 8 bumper, highlighting its design improvements over the years and the impact of materials used in its construction. Additionally, we will analyze how this bumper enhances vehicle performance, focusing on the balance of style and function. We will also explore current market trends and availability, enabling business owners to make informed procurement decisions. Each chapter builds on this theme, equipping you with the knowledge to effectively meet the needs of performance vehicle enthusiasts.

null

null

Weaving Weight and Wind: The Carbon-Fiber Reality of the Evo 8 JDM Rear Bumper

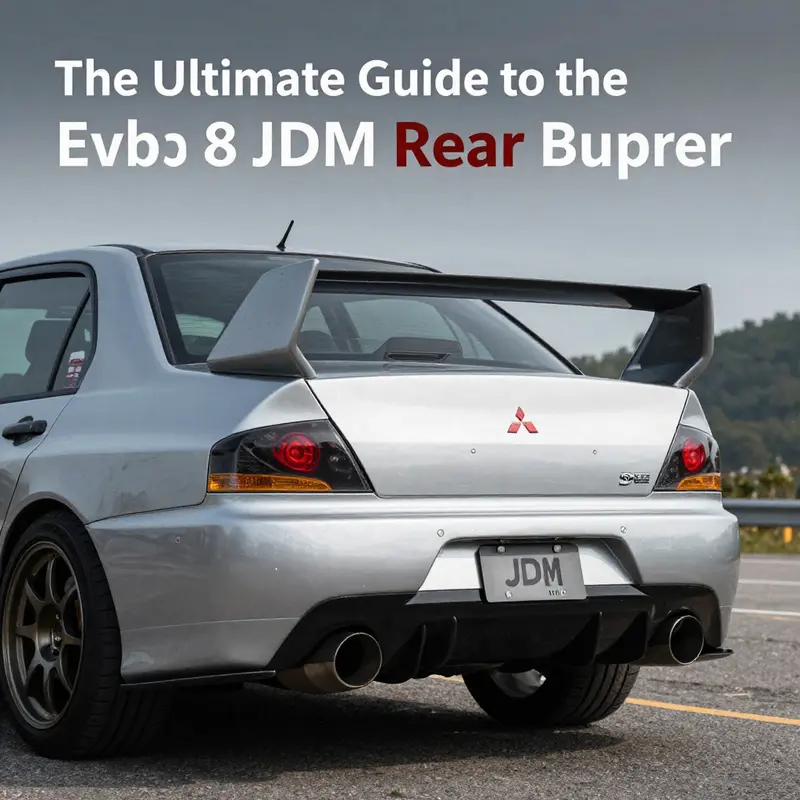

The Evo 8 rear bumper is more than a simple shell. It forms a critical line in a car that balances brutal street presence with track-ready performance. For enthusiasts chasing authentic JDM aesthetics, the bumper is a focal point where design intent, material science, and manufacturing discipline converge. The search for a replacement or upgrade is not merely about appearance. It is about preserving the aggressive silhouette while achieving predictable behavior under load. The choice of material and the way it is made determine whether the rear of the car remains compliant with the original intent or becomes a liability on twisty roads and high-speed straights. In that sense, the rear bumper becomes a barometer for how faithfully a modern interpretation can echo a legendary era of tuning without sacrificing reliability.

In the realm of high-performance automotive engineering, carbon fiber occupies a singular position. The research results on the Evo 8 JDM rear bumper extensions place carbon fiber at the forefront. This is not accidental. Carbon fiber offers an exceptional strength-to-weight ratio, a key factor for any component that has to endure road debris, speed-induced stress, and the aerodynamic demands of a compact, high-power platform. The material’s stiffness translates into better structural integrity for the bumper’s mounting points and its adjoining extensions. The result is a component that resists deformation under load, maintaining precise alignment with the car’s body lines and providing consistent aero performance across the speed range. This reliability matters when the bumper is paired with a diffuser, a subtle but tangible device that helps manage wake and drag.

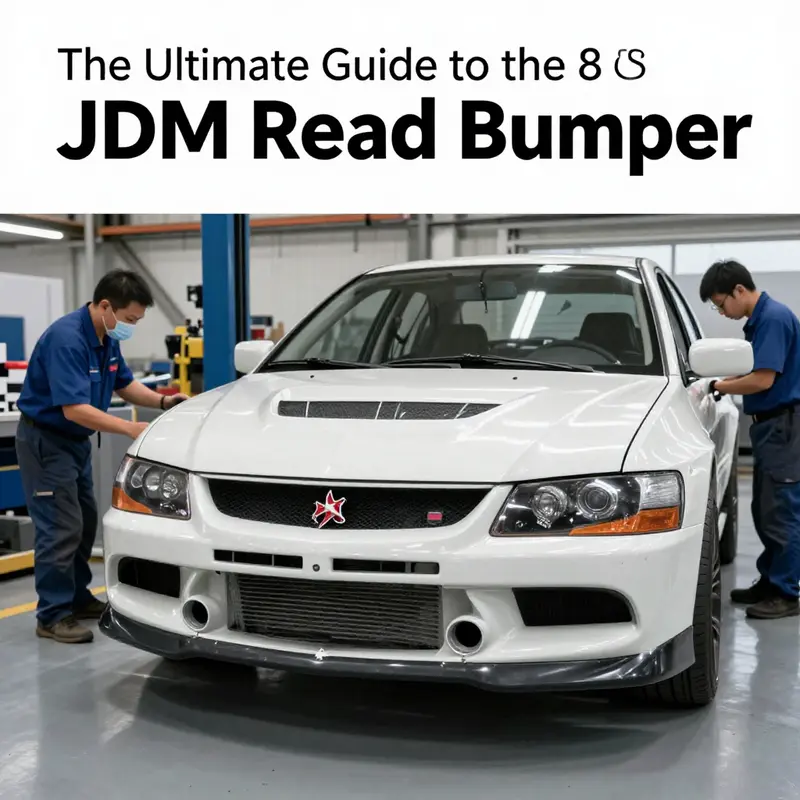

Manufacturing carbon fiber bumper extensions relies on advanced techniques that ensure both dimensional stability and aesthetic perfection. Resin transfer molding, or RTM, is one such method. In RTM, a precisely engineered mould is filled with resin-infused fibers, producing a uniform resin distribution and eliminating air pockets. The outcome is a rigid, lightweight section that integrates smoothly with the bumper shell. Vacuum bagging is another technique used to achieve consistent results. In this process, the composite layup is enclosed in a vacuum-sealed environment, with resin distribution driven by the pressure difference. Both RTM and vacuum bagging require careful process control, because even small inconsistencies in resin content or fibre alignment can lead to voids or waviness in the surface—imperfections that are unacceptable when a clean, flush finish is demanded by the Evo’s lines.

The manufacturing sequence typically begins with hand-laying carbon fiber onto a precisely engineered mold. This hands-on step allows technicians to tailor the fibre orientation to the bumper’s stress paths. For a rear extension that must align with the vehicle’s rear fascia and diffuser, consistent fiber angles are essential. After the layup, curing occurs under controlled heat and pressure. This phase locks in the resin, solidifies the laminate, and imparts the necessary stiffness. It also helps control shrinkage, a common concern when working with carbon fiber composites. The finished shell is then trimmed and finished to a flawless surface, ready for paint or a clear protective coat that preserves the carbon’s signature weave.

Weight is the most immediate dividend of carbon fiber. In a car like the Evo 8, every gram saved from the rear bodywork translates into better mass distribution and a more favorable polar moment of inertia. A lighter rear end can contribute to quicker turn-in and more predictable handling, especially when the powertrain delivers strong back-end torque. Yet carbon fiber is not only about weight. Its thermal resistance is also superior to traditional plastics. The rear bumper, exposed to heat from exhaust proximity and sun exposure, benefits from a material that remains stable and resilient. For performance applications, this stability reduces the risk of warping or surface degradation over time, preserving both function and form.

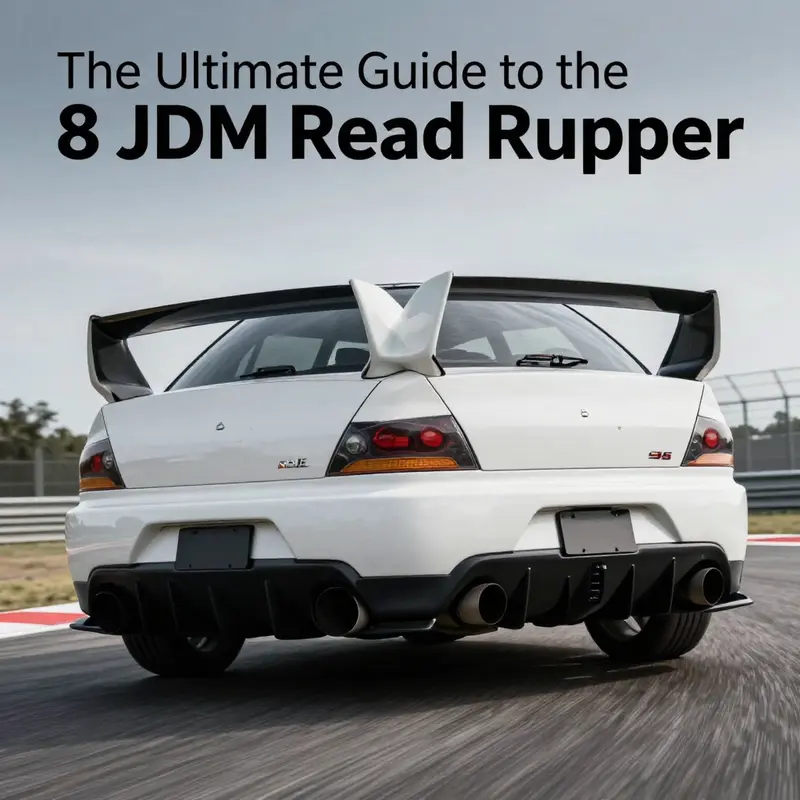

The decision to employ carbon fiber in rear bumper extensions is deeply tied to the Evo’s design language. The car’s rear end carries a bold stance, with proportional lines that convey mass and speed even when stationary. A carbon fiber extension, precisely shaped to match the OEM geometry, preserves those lines while enabling a refined silhouette that looks almost sculpted from a single piece. The emphasis on precision is not simply aesthetic. It ensures seamless integration with the underlying bumper cover, the rear diffuser, and any trailing aero devices that influence downforce and stability. When the fit is exact, there is no need for cosmetic seams to bridge gaps, no misalignment that disrupts airflow, and no visual break in the car’s clean rear profile. The result is a coherent visual statement: a car that looks fast even when parked, with a rear end that communicates purpose and engineering discipline.

From a practical standpoint, carbon fiber bumper extensions are designed to interact with the car’s existing geometry. They slot into place with minimal modification, provided the mounting points and fastening patterns are correctly matched to the Evo’s rear structure. This compatibility is crucial for owners who value reliability and retainability of factory tight tolerances. It also means that installation can be accomplished with conventional tools and procedures, without the need for exotic hardware. Yet the process demands care. Carbon fiber surfaces can be sensitive to impact if not finished with proper protective coatings, and the weave needs attentive finishing to avoid micro-cracks that could propagate under load. The best practices involve meticulous inspection of the laminate, a proper surface preparation, and a finish that protects the weave while preserving the deep, glossy appearance that carbon fiber enthusiasts prize.

The modern Evo’s rear end is often configured to interact with a diffuser and, in some trim lines, a subtly integrated spoiler or lip. The carbon fiber rear extension is designed to complement that configuration rather than compete with it. The diffuser’s flow paths unify with the bumper’s contours, guiding turbulent wake away from the trailing edge. Because carbon fiber has stiffness advantages, the extended rear end can support a more aggressive diffuser without extra support brackets that could add drag or weight. In addition, the tight tolerances of the layup reduce the risk that the extension will sag or warp under heat or mechanical stress. This is particularly important for those who push their cars on track days, where aero components endure repeated thermal cycles and high-speed vibrations.

The broader discussion of materials for the Evo 8 rear bumper invites a practical contrast. Polyurethane, fiberglass, and ABS plastic remain common choices for aftermarket bumper covers and extensions. Each material has a lineage in the Evo’s tuning culture. Polyurethane offers a balance of toughness and ease of repair, a factor that makes it appealing for road-going cars that see occasional curb contact and parking lot incidents. ABS plastic brings colorability and resilience, with predictable impact behavior that can keep the bumper looking intact after minor collisions. Fiberglass, while lighter than some full plastic builds, can require more careful finishing and is less forgiving of impact without cracking. In the specific context of JDM rear bumper extensions, carbon fiber is chosen where the goal is peak stiffness with minimal weight, a combination that aligns with track-oriented or high-performance street builds. This choice harmonizes with the Evo’s character—an uncompromising machine whose rear bodywork is both a visual signature and a functional aero element.

For builders and collectors who want to explore authentic JDM aesthetics, there is value in understanding the options beyond simple cosmetic upgrades. The genuine JDM rear bumper extensions, when properly matched to the chassis and trim, deliver a sense of continuity with the original engineering philosophy. They are intended to maintain, rather than compromise, the car’s aerodynamic integrity. The exact fitment preserves the lines that the factory designers etched into the vehicle, while the material’s properties deliver measurable performance gains. The process of verifying compatibility, of course, starts well before installation. It involves checking the bumper’s mounting points, diffuser integration, and the overall geometry against the vehicle’s year and trim. In this context, a reputable source for OEM-compatible options can be a practical path to ensure that the project does not derail due to misalignment or misfit.

For readers who want to explore specific options that align with OEM geometry while embracing modern carbon fiber fabrication, an informative resource is available that catalogs Evo 8/9 rear bumper options. The page highlights how an OEM-style rear bumper can be sourced in a way that respects the car’s original design cues while incorporating contemporary materials. To delve into that path, visit the OEM Evo 8/9 rear bumper page. It provides a descriptive overview of fitment considerations, finish options, and the balance between authenticity and performance. OEM Evo 8/9 rear bumper page.

Beyond the aesthetic and performance implications, the manufacturing narrative of the Evo 8 JDM rear bumper extensions speaks to a broader philosophy in modern hot-rodding. The process emphasizes precision, controlled environments, and deliberate material choices. The aim is not to chase weight savings alone but to harmonize them with stiffness, durability, and an integrated look. Carbon fiber, with its distinctive weave and high-end reputation, becomes a visible marker of that philosophy. Yet the conversation remains grounded in practical realities: the need for proper curing, accurate moulds, and careful finishing to protect the weave’s integrity and achieve a surface that can be painted or clear-coated to match the car’s overall finish. In that sense, the bumper extension is a small-scale example of how advanced composites have migrated from race paddocks to street cars, a trend that continues to shape the Evo’s ongoing legacy.

As buyers and builders weigh the trade-offs, the material choice often boils down to priorities. If track performance and weight reduction are paramount, carbon fiber appears as the natural choice. It marries lightness with stiffness, enabling the rear end to respond more predictably under aggressive handling. If, however, ease of maintenance and lower upfront cost take precedence, a more conventional bumper extension might be appealing, with polyurethane or ABS providing resilience and repairability under everyday use. The Evo’s appeal rests on an ability to tailor the rear end to a driver’s goals, whether they chase a museum-perfect street machine or a garage-kept track car. The rear bumper’s material story, therefore, is not just about a cladding or a cover; it is about how the vehicle’s kinetic story is told from the tail end forward.

External reference: The Evolution VIII product cycle and its official documentation offer a capsule of the design intent that informs contemporary reissues and replicas. For those seeking a primary source on the vehicle’s design philosophy and specifications, see the official pages maintained by the manufacturer. https://www.mitsubishi-motors.com/jp/evolution/evolution-8.html

Rearward Velocity: Redefining Aero, Weight, and Street Authority With the Evo 8 JDM Rear Bumper

Every car carries its silhouette forward, but in the Evo 8 the rear end is more than a visual cue. It is a carefully tuned element that interacts with air, weight, and chassis balance at speed. When a driver considers a rear bumper designed for the JDM variant, they are opting into a philosophy that treats the rear of the car as an active participant in performance, not merely a cosmetic panel. The Evo 8’s reputation for aggression and precision is anchored in its lines, but the rear fascia is where that aggression translates into real-world handling. A well-chosen bumper does more than fill the void behind the hatch; it guides air into a controlled wake, supports downforce where it matters, and preserves the car’s iconic stance while reducing the drag that can sap momentum on the highway and the track.

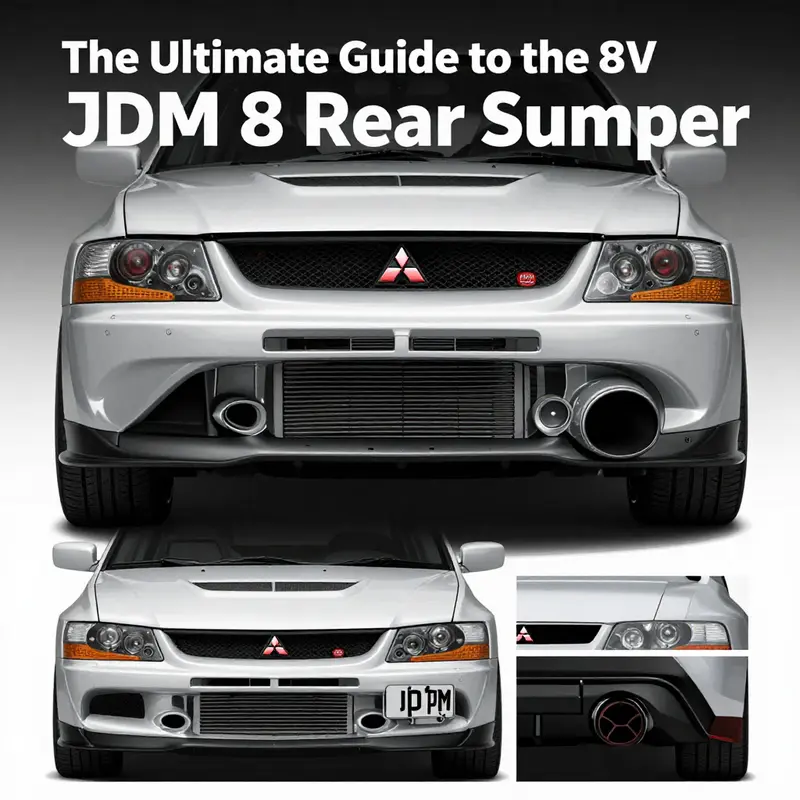

Aerodynamics at the rear of a compact performance hatch are deceptively complex. The bumper works in tandem with a diffuser and lower contours to shape the tail’s airflow, lowering turbulent wake and smoothing the transition from body to open air. A purpose-built rear fascia can shave drag and help the car settle into a steadier trim line at high speeds. The result is not just a marginal gain in top speed; it is improved high-speed stability, better traction, and more predictable handling as the road bends away from the rear wheels. This stability is particularly prized by drivers who push the Evo 8 toward the edge of grip, where even small improvements to downforce can translate into meaningful gains in cornering confidence and composure.

The material makeup of a rear bumper matters as much as the shape it wears. Many performance-minded options use high-grade polyurethane for its blend of toughness and flexibility. Polyurethane cushions impacts from road debris and curbs, resisting cracking in ways standard plastics often cannot. For enthusiasts chasing maximum efficiency and weight savings, lighter composites such as vacuum-infused fiberglass-reinforced polymer (FRP) or carbon fiber blends appear as viable alternatives. These materials retain stiffness and durability while trimming weight, a benefit that echoes through the chassis dynamics: less mass at the rear reduces inertial load during braking, aids acceleration response, and sharpens steering feel by keeping the rear axle from fighting against excessive unsprung weight.

Weight reduction is not a crusade for its own sake; it is a tangible lever in how the car translates power to speed and how it brakes into corners. A rear bumper that minimizes weight without compromising durability allows the Evo 8 to respond more quickly to driver inputs. In real-road terms, this can translate to crisper turn-in, cleaner mid-corner transitions, and more balanced behavior when the throttle is reapplied after apexes. A well-executed bumper swap preserves the car’s original silhouette while trimming kilograms where they matter, which is precisely the balance many fast street cars seek. The best implementations maintain the aerodynamic cues that give the Evo its edge, rather than erasing them in pursuit of a minimal weight alone.

The MR variant of the Evo 8, a designation that speaks to a higher-performance lineage, tends to emphasize aero cues that support increased downforce and more aggressive rear detailing. A properly chosen JDM rear bumper for this trim often mirrors those design intents: a more pronounced diffuser outline, integrated aero contours, and subtle lines that align with the car’s rear deck and spoiler geometry. The result is an appearance that looks purposeful at parking-lot speed yet becomes a working part of the car’s aero package when the pace climbs. For enthusiasts, this harmony between style and function is a central reason the rear bumper remains a popular upgrade: it offers functional benefits while preserving or enhancing the Evo’s aggressive visual language.

Fitment and preservation of the original lines are essential considerations. A rear bumper fashioned to the exacting tolerances of the Evo 8’s chassis geometry minimizes gaps, preserves panel alignment, and sustains the vehicle’s clean, uninterrupted rear silhouette. Precision fitment matters as much as the design itself because poorly matched panels can create drag, wind noise, or even misalignment with the undertray and diffuser elements. When the rear fascia slots into place with confidence, it reinforces a sense of purpose and steadiness at speed, which is exactly what a performance-oriented build aims to deliver. Enthusiasts often value this as highly as the bumper’s aesthetic impact, because it translates to consistent behavior across a broad range of speeds and driving styles.

From a daily-driving perspective, the aerodynamic and weight-related advantages carry into practical, routine use. On long highway stints, the rear fascia’s shaping can contribute to lower overall drag, modestly improving fuel efficiency during cruise. The constant pursuit of efficiency in a performance-oriented car is about balancing the thrill of speed with sensible energy use, and even small drag reductions at the rear accumulate over miles of open road. This is not about chasing a single percent; it is about creating a coherent system where the bumper, diffuser, and underbody work in concert to optimize flow with minimal compromise to ride quality or noise, vibration, and harshness.

Enthusiasts are drawn to the Evo 8 JDM rear bumper for both function and aesthetics. The aesthetic appeal comes from a stance that looks planted, aggressive, and ready for track days, while the functional benefits emerge in the form of improved stability and a lighter touch on the throttle through sweeping sections or open straights. The combination of aero efficiency, weight savings, and a visually assertive rear end has made this upgrade a common waypoint for builders who want a car that feels both grounded and razor-sharp when pushing through fast corners.

For those exploring OEM-equivalent options that honor the car’s original geometry, there is a catalog entry that focuses on the 03-06 Evo 8/9 JDM rear bumper in OEM specification. This path is rooted in preserving the factory geometry while incorporating the refined materials and tolerances that modern replacements offer. If you are curious about the exact fit and compatibility of this OEM-aligned option, you can review the item page that presents the rear bumper in a way that honors the car’s established lines and hardware locations, ensuring a smooth installation and a seamless visual integration with the existing aerodynamics and styling cues. 03-06 Mitsubishi Evolution 8/9 JDM rear bumper OEM.

When considering the broader ecosystem of rear-end enhancements, some builders experiment with carbon fiber or fiberglass composites to extract every possible ounce of performance. Vacuum-infused FRP versions, for example, can deliver a blend of stiffness and lightness that supports a more responsive chassis feel without sacrificing durability under road debris. The choices available reflect a simple truth: you do not have to trade one kind of performance for another. A thoughtfully designed rear bumper can contribute to aerodynamics, weight management, and the car’s aggressive identity all at once. This integrated approach—shape, material, and fitment—defines the modern path to a more capable Evo 8.

As with any modification that changes the car’s external structure, installation considerations matter. The rear bumper exists within a system of panels, undercarriage components, and mounting points that must align with the unit’s precise tolerances. A well-executed swap respects these connections, seals properly against the elements, and leaves the aerodynamic balance intact. The result is not merely a new cover but a harmonized package that maintains the Evo 8’s aggressive stance while offering improved performance characteristics. In practice, that means taking care with mounting points, ensuring proper sealing along the edge where the bumper meets the trunk and side panels, and confirming that the diffuser elements align with the undertray and exhaust layout. The payoff is a rear end that behaves predictably, with a visual and dynamic cohesion that mirrors the car’s overall engineering ethos.

Looking ahead, the conversation around the Evo 8 JDM rear bumper naturally leads toward broader discussions of how light-weight, aerodynamically aware fascia choices interact with other performance mods. A bumper that emphasizes airflow management can complement suspension tuning, tire selection, and brake upgrades, creating a holistic package where each change reinforces the others. The result is a vehicle that does not merely look fast in a showroom or on social media; it feels fast in every bend and straightaway, with a sense of continuity between design intent and on-road performance. This is the ethos behind the Evo 8’s enduring appeal: a chassis that invites precise, confident driving, with a rear end that speaks the same language of control and purpose as the rest of the car.

For readers who want to explore OEM-aligned options while keeping a close eye on compatibility and fit, the related catalog entry provides a reliable reference point without straying from the car’s original profile. It is a reminder that performance upgrades do not require abandoning the values that defined the Evo 8 in the first place. Instead, they invite a refined approach—one that respects the car’s heritage while embracing modern materials and engineering that unlock greater control and a more engaging driving experience. And as the rear bumper communicates through the car’s lines just as much as it does through its aerodynamic behavior, every choice made in this area contributes to a holistic, satisfying performance narrative.

External resources can expand the perspective beyond the OEM-aligned offerings and practical considerations. For a broader view of available rear bumper variants and their real-world applications, see an industry overview that documents several viable options and their performance implications: https://www.alibaba.com/product-detail/Evo-8-JDM-Rear-Bumper_1600432759476.html

Authenticity, Scarcity, and the Evo 8 JDM Rear Bumper Market: Navigating Trends and Availability in 2026

The rear end of a Mitsubishi Evolution VIII carries more than just fragile metal and plastic; it carries the car’s entire identity in a compact, highly visible form. For enthusiasts who want to preserve the Evo 8’s aggressive stance while upgrading or replacing a damaged bumper, the market has evolved into a careful balance of authenticity, condition, and rarity. In 2026, the market for the Lancer Evolution VIII’s JDM rear bumper—especially in FRP OEM form with a carbon diffuser—remains among the most sought-after segments of the broader Evosphere. The appeal is rooted in the origins: a part that came from the Japanese Domestic Market, built to exacting standards, and designed to harmonize with the car’s original lines. This emphasis on origin and fidelity is a core driver of value. The FRP OEM variant paired with a carbon diffuser offers not just the look but practical benefits. The high-grade composite provides a workable balance of rigidity and resilience, while the carbon diffuser delivers aerodynamic efficiency and a premium aesthetic that many owners find integral to the car’s character. In practice, this combination translates into a bumper cover that survives daily debris and minor impacts with far less cracking than less flexible plastics, and it looks right at home on both street or track vehicles. The material choice reflects a broader truth in the Evo 8 community: performance-minded owners prize durability that supports aggressive driving without compromising the distinctive silhouette that makes the car instantly recognizable on a showroom floor or a wind-blurred stretch of highway. The 3K twill carbon weave, when finished in a glossy coat, adds a premium depth that elevates the rear’s presence under the right lighting. It is not merely decoration; the weave signals a continuity of quality that enthusiasts believe should accompany a platform that was engineered for high-speed performance and precise handling. The visual impact, however, is inseparable from the functional one. A carbon diffuser, integrated into the OEM FRP shell, helps manage airflow and reduces rear-end lift at higher speeds. The combination—FRP backbone with carbon accents—offers an authentic look while keeping weight within reasonable bounds for a vehicle that still seeks a balance between daily usability and moderate track capability. When buyers scan the market, they often encounter listings that emphasize the part’s JDM provenance and its compatibility with the Evo 8’s more performance-focused variants. The idea of a “MR” trim, for example, is a shorthand way of signaling a higher-performance lineage, with subtle cues such as a more pronounced diffuser and sometimes a more integrated spoiler. Even without naming specific trim lines, the market consistently values those attributes because they align with the Evo 8’s original intent: a compact sedan engineered to deliver a compelling blend of grip, acceleration, and aerodynamic efficiency. The net effect is a subset of the market that concentrates on genuine OEM components rather than aftermarket replicas. As a result, buyers increasingly seek out original factory specifications and provenance to justify the premium that these parts command. This trend is reinforced by the reality that genuine OEM items—especially ones that include a carbon diffuser—have a limited supply. The Evo 8 ceased production in 2007, which means that most available units today come from used vehicles, salvage yards, or specialized online marketplaces that cater to JDM performance parts. Early 2026 data shows demand consistently outstripping supply, pushing prices higher for complete, undamaged bumpers with the matching carbon diffuser. The premium is not simply for the look; it is for the confidence that the part will align with the car’s mounting geometry and its aerodynamic characteristics as designed. In practical terms, this means buyers are more likely to pay a higher price for an intact complete unit than for a compromised or partial piece. The market’s pricing dynamics reflect a broader pattern seen in classic performance parts: scarcity compounds value, and the best returns occur when the part retains its original hardware, mounting points, and associated diffuser pieces. A complete bumper with the carbon diffuser is more likely to deliver a seamless installation and an authentic appearance, both of which matter when the vehicle is showcased or when it participates in track events where form and function must harmonize. Yet for all the allure of authenticity, buyers must navigate a landscape that is increasingly riddled with misrepresentation. The same marketplace that preserves the romance of a genuine JDM component also poses a risk: listings may mislabel parts as OEM or JDM when they are aftermarket imitations or misrepresented remnants from a salvage source. This is not just a matter of aesthetics; it is a potential compatibility issue. A bumper labeled OEM might look correct at first glance, but subtle differences in mounting points, interior housings, or diffuser fitment can create a mismatch that forces buyers into expensive refinishing or, worse, a problematic installation. The onus falls on buyers to demand clear documentation, detailed photos of both sides and the backside, and provenance that traces the bumper to a specific vehicle. Verified listings on reputable platforms—complete with photos showing mounting points and a clear description of condition, year, and VIN when available—are crucial in this environment. The balance between supply and demand also shapes how buyers approach the search process. Given the limited production run and the age of most parts, buyers often turn to salvage yards or dedicated online marketplaces that specialize in JDM performance parts. They look not only for the bumper itself but for the carbon diffuser, the diffuser’s attachment hardware, and any associated fasteners that ensure the rear end aligns with the car’s original geometry. The presence of the carbon diffuser elevates the part’s value but also its fragility. A carbon diffuser that has endured impact or exposure to harsh weather without any visible cracks remains highly prized. In many cases, sellers who can document the part’s provenance—where it came from, the condition of the diffuser, and whether any refinishing was performed—add another layer of confidence for a buyer who is preparing a restoration or a show-ready build. For those who want to see a real-world example of what a genuine OEM part looks like in the current market, a verified listing on a major resale platform offers a clear snapshot of condition, photos, and seller history. The emphasis on authenticity is not merely a matter of pride; it’s a practical discipline that safeguards investment and ensures compatibility with the Evo 8’s chassis and body panels. When examining any listing, buyers should check for high-resolution images that reveal the bumper’s mounting points, the inner surfaces, and the inner edge around the diffuser. The existence of matching numbers or documented VINs can significantly mitigate risk. To help guide the search, consider an example resource that focuses on a verified OEM rear bumper for the Evo 8-9 era; it provides detailed documentation and provenance, including the condition narrative and photos that help confirm authenticity. For a verified OEM listing, see 03-06 Mitsubishi Evolution 8-9 JDM rear bumper OEM. This kind of reference helps anchor buyers in a market that can otherwise feel like a maze of partially matching components and glossy facades. The link serves as a practical reminder that the best purchases come from sources that not only present the part but also validate its origin and fitment with precise compatibility notes. Even with careful verification, the marketplace remains dynamic, shaped by the ebb and flow of supply from aging vehicles, the prevalence of salvage entries, and the growing interest from collectors who view these bumpers as functional art rather than mere replacements. For the modern buyer, the strategy combines patience with diligence. It means setting expectations for premium pricing, especially when the part includes the carbon diffuser in excellent condition, and recognizing that the most valuable units are those that clearly document their origin and maintain matching factory specifications. This approach reduces the risk of receiving an item that looks the part but does not align with the Evo 8’s mounting geometry or aerodynamic profile. As a final note, for those who want to orient their search around trusted sources, the broader ecosystem of JDM performance parts offers a spectrum of options—from salvage-based finds to curated, verified listings. The best outcomes come from platforms that provide comprehensive photos, clear compatibility checks, and, when possible, VIN verification. These elements create a reliable baseline for assessing value in a market that remains intensely aspirational and technically exacting. An example of the kind of vetted experience available in the current landscape can be found on widely used resale channels, where a complete OEM unit with a carbon diffuser can be acquired with documented provenance and seller feedback. For those who want to review a real-world listing, an external resource is available here: Verified OEM listing on eBay. This reference demonstrates how documentation and provenance contribute to a smooth, confident transaction even when the overall market remains tight and the prices reflect the high premium placed on authenticity. The trajectory of this market segment suggests continued resilience for genuine OEM parts with authentic JDM lineage, particularly when those parts come with carbon accessories that reinforce the vehicle’s original performance and aesthetic narrative. Buyers who accept the premium and commit to due diligence will likely maintain access to genuine rear bumpers that preserve both form and function, ensuring the Evo 8’s distinctive silhouette endures as a benchmark for performance and style in the modern collector’s market. For enthusiasts and restorers alike, navigating this landscape with care becomes part of the project’s discipline, a reminder that the traditional values of rarity, authenticity, and careful stewardship still define the most meaningful investments in the Evo 8 era.

Final thoughts

In conclusion, the Mitsubishi Lancer Evolution VIII JDM rear bumper embodies not just aesthetic value but also significant performance enhancements. An understanding of its materials, manufacturing processes, and associated market trends is vital for automotive business owners seeking to cater to performance enthusiasts. By prioritizing quality and compatibility, businesses can effectively meet the demands of a niche market fueled by passion for classic JDM vehicles. The Evo 8 bumper not only represents an authentic aspect of automotive culture but essentially contributes to the functional enhancements of the vehicle. Ensuring that you have well-informed strategies to source genuine parts can significantly enhance your product offerings.