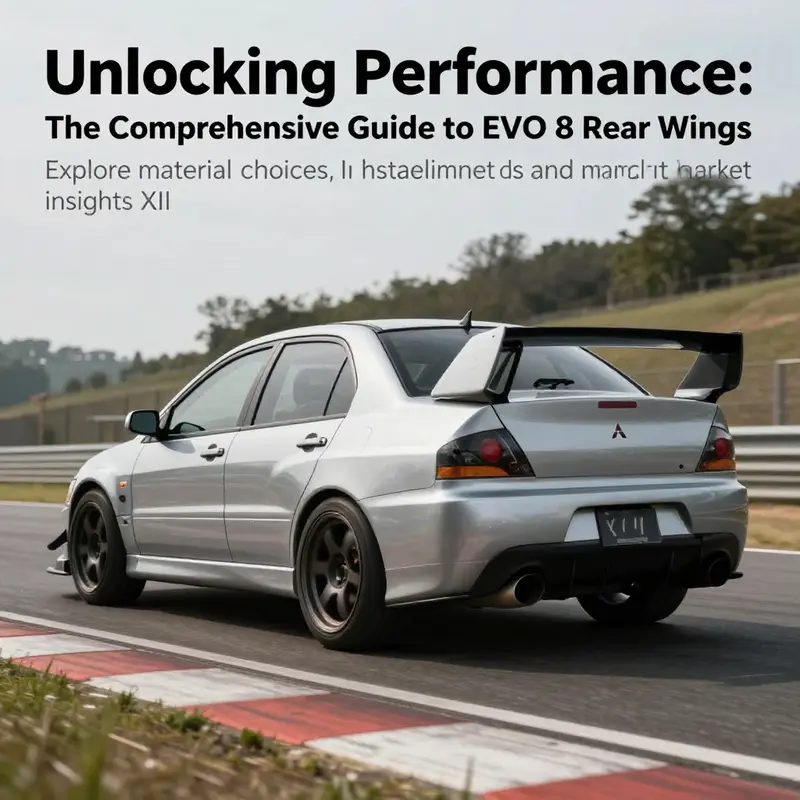

The Mitsubishi Lancer Evolution VIII (EVO 8) is a vehicle that embodies performance and enthusiasm in the automotive world. One crucial aspect that elevates the EVO 8’s performance capabilities is its rear wing, an essential modification for both aesthetics and aerodynamics. Understanding the various materials and types available, the installation methods, and the pricing in the current market are key for business owners looking to cater to this niche. This guide addresses these considerations, highlighting knowledge that can enhance customer offerings and ensure top-notch modifications for EVO 8 enthusiasts.

Choosing the Right Rear Wing for Your EVO 8: Fiberglass or Carbon Fiber and What It Means on Track and Street

Material Choices and What They Mean for Your EVO 8

Selecting a rear wing for the Mitsubishi Lancer Evolution VIII is more than a cosmetic choice. The wing you pick influences balance, stability, and confidence at speed. It also shapes the visual character of your car. For EVO 8 owners the two dominant material families are fiberglass (FRP) and carbon fiber. Each delivers distinct trade-offs in weight, strength, cost, and appearance. Understanding those trade-offs will help you choose a wing that matches your driving goals and budget.

Fiberglass wings are the most common aftermarket option for EVO 8 owners. They offer a cost-effective path to the high-wing silhouette that defines many Evolution models. Manufacturers mold FRP wings to match OEM proportions or to produce more aggressive profiles. The material is forgiving in tooling, so complex shapes and larger center sections are possible without the premium cost of carbon. For daily drivers seeking a tasteful upgrade, fiberglass wings provide stable performance and long-term durability. They resist road weathering and can be finished in body color or left in a standard black gelcoat. That makes them a practical choice for owners who want an OEM-style presence without spending a small fortune.

From a performance standpoint fiberglass adds weight compared to carbon fiber. The extra mass is rarely a problem for street use but can affect how quickly the rear responds to transient inputs on track. Fiberglass still generates meaningful downforce when sized and angled correctly. A properly designed FRP wing will improve stability in high-speed corners and reduce lift on long straights. For many owners the balance of cost, look, and effectiveness tips toward fiberglass for a car that splits its time between daily driving and occasional track days.

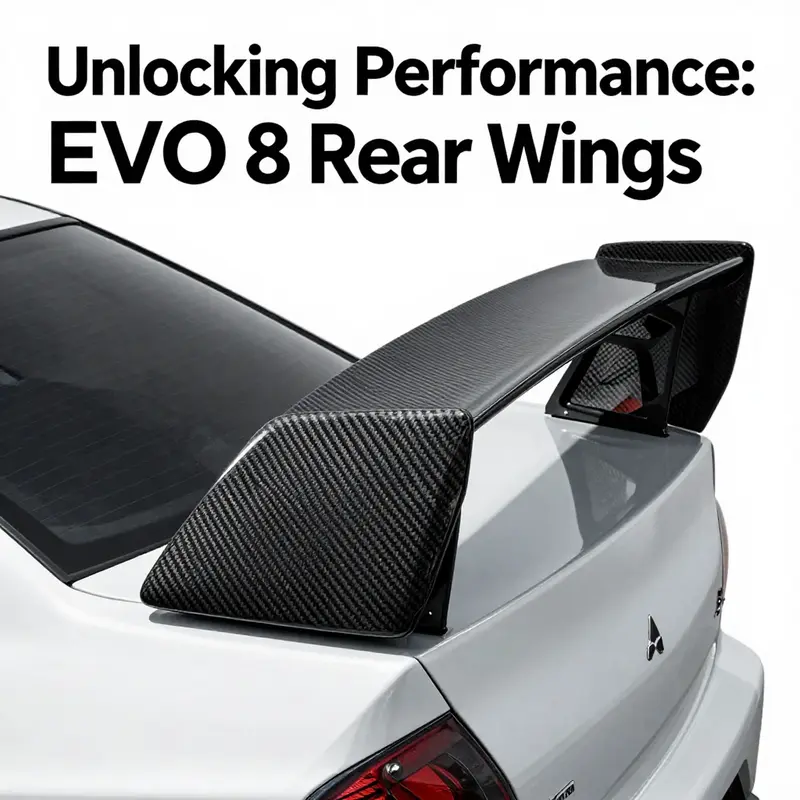

Carbon fiber wings occupy the high-performance end of the spectrum. They combine low mass with high stiffness. A carbon wing reduces unsprung and overall rotating mass at the rear, making the car feel sharper. When you are chasing lap times, carbon’s weight advantage and superior stiffness matter. The material also accepts precise aerodynamic shaping. Manufacturers tune mid-span sections, endplates, and flap profiles to produce targeted downforce with minimized drag. Many carbon wings offer adjustable elements, allowing fine-tuning of angle of attack to match track conditions or driver preference.

Beyond performance, carbon fiber makes an immediate visual statement. The weave and glossy finish convey race-bred intent. For many owners that impact is as important as any performance gain. But carbon comes with caveats. It is more expensive. Prices can climb substantially for hand-laid or prepreg constructions. A larger, high-quality carbon piece can require an investment that dwarfs an FRP alternative. You should also consider practical trade-offs. Carbon wings can obstruct rear visibility more than low-profile options. They may interfere with sunroof clearance on some cars. And wind noise may increase during highway cruising due to sharper airflow separation.

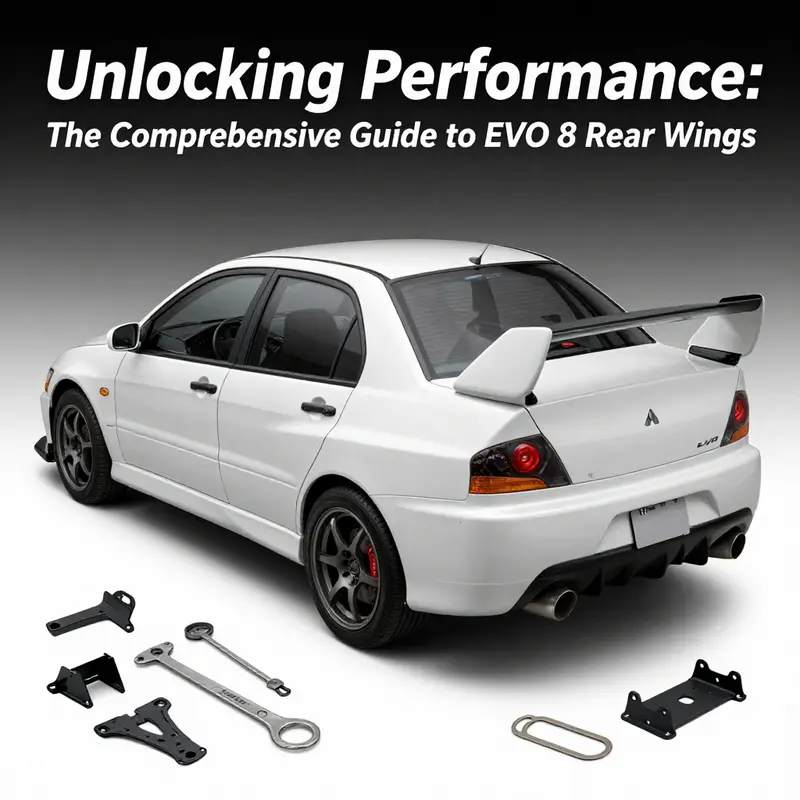

Fitment and installation place similar burdens on both materials. The majority of aftermarket wings designed for the EVO 7-9 series use bolt-on mounts. This makes attachment straightforward for a competent technician. Bolt-on systems use trunk-top points reinforced with backing plates. They avoid cutting structural members or welding, making the modification reversible. Proper install requires attention to trunk reinforcement and sealing. Holes drilled through the trunk must be treated against corrosion and fitted with rubber grommets or sealed fasteners. Many suppliers package wings with mounting kits that include bolts, reinforcement plates, and instructions. But careful pre-fit checks are still essential. If a wing isn’t centered or torqued correctly, it will introduce asymmetric loads at speed.

When selecting between a high-wing and a low-profile lip wing, think about your driving environment. A taller high-wing increases leverage and produces more rear downforce at a given angle. That helps balance a powerful, front-biased aero setup on track. High wings often pair well with additional aero hardware, such as front splitters and canards, because they contribute to a well-distributed downforce balance. Conversely, a low-profile lip wing keeps the car cleaner visually and reduces parasitic drag on the road. It delivers subtle improvement in rear end stability without the pronounced visual or aerodynamic penalties of a large wing. For street-driven EVO 8s that still see track days, mid-rise wings often deliver the best compromise.

Manufacturing methods alter both cost and performance within each material family. Fiberglass wings are commonly produced using wet layup or hand-layup processes. These methods reduce tooling costs and accelerate production. They also allow multiple color and finish options without significant cost increases. Carbon fiber production often uses prepreg laminates in molds cured under heat or in autoclaves. Higher-end carbon units may include carefully oriented ply stacks for strength and tuned stiffness. This precision yields a lighter, stiffer part but increases price and lead time. For some wings, manufacturers combine materials. A carbon center blade with FRP endplates gives a visual and weight compromise while keeping costs below a full carbon assembly.

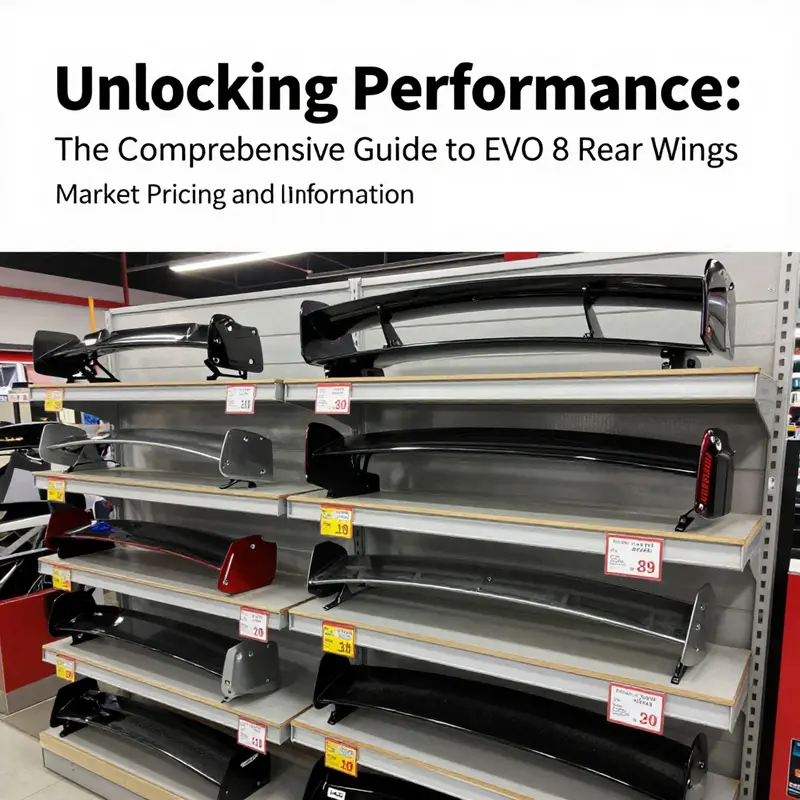

Cost ranges widely. Basic FRP wings may start in the low hundreds of local currency units. Higher-quality, fit-and-finish components push prices upward. Carbon wings command a premium, with accurately crafted pieces reaching multiples of FRP equivalents. A detailed example from suppliers shows a 1.4-meter carbon wing built for EVO 7-9 class cars offered at a mid-range premium price point. That price reflects material costs, labor intensity, and the performance-oriented design of the wing. When budgeting, also account for shipping, packaging, and potential customs fees if the parts come from overseas. Packaging itself varies from poly-bag internal protection to foam padding and external wooden crates for high-value pieces. These steps protect delicate finishes during transit and add to final cost.

Real-world durability differs between materials. Fiberglass resists dings and small impacts without catastrophic failure. It is straightforward to repair. A cracked FRP wing can be fiberglassed, sanded, and repainted at reasonable cost. Carbon fiber, while stronger under tension, can suffer discrete laminate failures if struck hard. Repair is possible but costlier and sometimes visually imperfect. UV protection is important for both materials. Most wings use gelcoat, clearcoat, or paint to guard against sun exposure. Over time, prolonged sun and salt exposure can dull finishes or, in the case of clear-coated carbon, develop micro-cracks if not properly protected.

Consider the operational trade-offs when choosing a wing for everyday use. A large carbon wing will provide more downforce at higher speeds, but it can increase wind noise and reduce rear visibility on the street. Fiberglass wings are typically quieter and more subdued. If you keep your car as a daily driver, the simpler FRP option often makes more sense. It adds personality and improves stability without significantly altering cabin comfort. For cars that live on track, a carbon wing’s lighter weight and adjustability can shave tenths off lap times. These gains compound with a broader aero program and suspension tuning.

Compatibility across EVO generations is another factor. Most wings designed for the EVO 7-9 platform will bolt onto the Evolution VIII without heavy modification. The trunk layout of these models is similar, and many suppliers engineer a universal fit across the three generations. However, compatibility with the EVO X is less certain. The tenth generation introduced altered trunk contours and lid structures. Some wings claim multi-model compatibility that includes EVO X. Always verify fitment with supplier templates or part-specific documentation before ordering.

Beyond the wing itself, the vehicle’s supporting systems matter. If you increase rear downforce relative to front, you may need more front grip or additional front aero to preserve handling balance. Suspension tuning should follow any meaningful aero change. Stiffer springs, revised damping, and alignment adjustments often translate wing-induced improvements into useful on-track gains. Tire selection also interacts with aerodynamic changes. Greater rear downforce can expose lateral grip limitations or understeer if the front tires lack matching performance.

Installation nuance goes beyond simple bolting. Many wings require trunk reinforcement plates to distribute loads. Without reinforcement, the wing puts concentrated stress on a small area of metal. Over time that can deform the trunk lid or cause metal fatigue. Use stainless fasteners and proper torque values to prevent corrosion and avoid loosening. If painting or wrapping the wing, mask all hardware or use removable mounting hardware to preserve finish quality.

Practical maintenance is straightforward. Clean the wing with gentle car shampoo and soft microfiber. Avoid high-pressure spray directly at seams and fastener interfaces. Inspect mounting bolts periodically for looseness and corrosion. If the wing is carbon fiber with a clearcoat finish, use a UV-protective sealant to preserve gloss and prevent oxidation. For exposed weave finishes, apply a ceramic-style coating or repeated polish cycles for long-term protection.

Aesthetic choices matter to many EVO 8 owners. Fiberglass allows for painted, matched appearances. You can replicate factory colors and keep the car’s profile factory-correct. Carbon emphasizes performance with visible weave patterns and contrasted hardware. Some owners choose to mix the two: a painted FRP mainplane with carbon endplates or a carbon center paired to fiberglass supports. This hybrid approach can control costs and achieve a distinctive look without full carbon expense.

Supply chain details are also practical considerations. Many aftermarket wings originate from regional hubs of manufacturing and distribution. Cities and provinces with established automotive component industries often supply a wide selection of wings and accessories. Lead times vary with demand and production methods. FRP options may ship within one to two weeks if in stock. Carbon pieces often carry longer lead times due to lower production throughput and more careful finishing. Packaging differs by value. Fragile, high-cost items ship in wooden crates with foam internal protection. Lower-cost FRP parts use reinforced cardboard and foam.

Finally, think about reversibility. Many EVO owners prefer modifications that are reversible for resale or inspection. Bolt-on wings are typically reversible given proper installation and careful hole sealing. If you remove a wing later, clean and refinish pierced surfaces and consider using a small amount of paint or sealant to preserve trunk metal. This preserves value and prevents water intrusion.

Making the decision ultimately comes down to use case and budget. Choose fiberglass for an economical, durable, and visually flexible upgrade that suits mixed street and track use. Choose carbon fiber if weight savings, precise aero shaping, and a race-focused aesthetic are your priorities. Evaluate mounting hardware, reinforcement, and installation quality as much as material. A well-engineered fiberglass wing can outperform a poorly designed carbon piece. Balance your purchase across material, design, and supplier reputation.

If you want to see how other EVO VIII components pair with rear wings, consult related replacement and styling options available for the platform. For example, aftermarket bumper and diffuser parts often complement a wing visually and aerodynamically. One resource that lists compatible bumper options and styling parts for EVO VIII and EVO IX models is available for reference: JDM rear bumper for EVO VIII/IX.

For a deeper technical primer on carbon fiber materials and how their properties translate into real-world performance, see this external resource on the composite polymer used in high-performance wings: https://en.wikipedia.org/wiki/Carbonfiberreinforced_polymer

null

null

Winged Truth: Navigating EVO 8 Rear Wing Options, Value, and the Aftermarket Landscape

The Mitsubishi Lancer Evolution VIII sits at a crossroads of performance aspiration and practical modification. When drivers talk about pushing the car’s dynamics toward the edge of grip, the rear wing is rarely a mere cosmetic flourish. It is a tool that can tune the car’s behavior, signaling intent to the wind and to the track. The EVO 8 rear wing, in particular, acts as a focal point for a broader conversation about how small, well-chosen aerodynamic upgrades can reshape handling, balance, and confidence behind the wheel. Across the market, the rear wing is offered in a spectrum of materials, profiles, and mounting philosophies, and this spectrum matters as much as the shape itself. To understand why choices differ, one must consider what the wing does, how it’s built, and what someone intends to do with the car on a road, a street, or a circuit.

At the core, a rear wing on an EVO 8 is about managing downforce and drag in a way that complements the car’s mid- to high-speed behavior. In a car like the EVO 8, which balances a purposeful chassis with a turbocharged engine and an all-wheel-drive system, the rear wing can help stabilize the vehicle when the car is loaded hard through a fast corner and then released into the throttle. A correctly chosen wing can contribute to rear-end stability, reducing lift at high speeds and allowing the driver to maintain rotational control without excessive steering input. Conversely, a wing that is too aggressive for the weight and aero package can introduce unwanted drag and hamper acceleration or corner entry. The art lies in recognizing that not every track day needs the same amount of rear-downforce, and not every street setup benefits from the same visual footprint.

The market presents two broad material paths for EVO 8 rear wings: fiberglass, commonly referred to as FRP, and carbon fiber. Each path has distinct trade-offs that align with different user stories. A fiberglass wing typically aims for a balance of cost and performance. It tends to deliver OEM-high-wing aesthetics with straightforward bolt-on installation, and it remains a practical choice for enthusiasts who want a track-capable silhouette without a heavy financial commitment. These wings are often designed to mirror the look of a factory high-wing while offering enough rigidity to handle daily driving and occasional track sessions. The price point for fiberglass variants is approachable enough to spark a wide range of builds, from mild streetable setups to more competitive configurations, all without forcing a heavy investment in the aero parts budget.

Carbon fiber wings, by comparison, emphasize weight savings and refined aerodynamic properties. While some carbon wings are fully constructed from carbon fiber, many in the mid-range tier use carbon-look styling with a primarily FRP core or a carbon-skin finish that improves aesthetics while maintaining a reasonable price. The allure here goes beyond weight: carbon fiber often carries a premium perception of stiffness and sophistication. For serious track enthusiasts, a true carbon-fiber wing, particularly one with a longer span or a more refined foil profile, can offer noticeable gains in stiffness and reduced inertia, enabling quicker wing reactions during fast transitions and more predictable behavior at speed. A typical full-carbon option for the EVO 8 family can command a premium, with higher-end designs reaching well into thousands of yuan or dollars, and sometimes appearing in configurations sized to around 1.4 meters in span for EVO 7–9 progeny. What matters is that the choice aligns with the driver’s priorities: maximum stiffness and a leaner mass budget for racing, or a more forgiving and cost-conscious approach for weekend track days and spirited street drives.

A practical point often emphasized by builders and buyers is the installation path. For EVO 8 rear wings, the common approach is a bolt-on mount. This means the wing can be attached using existing mounting points without invasive structural modification to the chassis. The bolt-on philosophy is attractive for those who want to test aero changes on a limited budget, or who prefer a reversible modification. It also reduces the risk of compromising the vehicle’s suspension geometry or sheet-metal integrity. The ease of installation translates into a wider window for experimentation, allowing owners to cycle through different wing sizes and materials as they refine their preferred balance of downforce and drag. Of course, as with any bolt-on upgrade, it’s wise to verify fitment against the exact model year and configuration; some products claim compatibility with EVO 7, 8, and 9 from 2003 to 2007, while others extend to EVO X with caveats. The landscape is varied, and a careful buyer will confirm fit to avoid gaps in performance or alignment. In this sense, the rear wing becomes a case study in the broader aftermarket ecosystem, where fitment data and community experience often guide the final choice more reliably than glossy marketing claims.

Pricing narratives in this space reflect the spectrum of material and build quality. At the economical end, fiberglass products targeting modification enthusiasts are notably economical. The market data indicates price ranges around the low tens of dollars—indeed, economic fiberglass offerings cluster roughly in the mid-$30s per unit when sourced from mid-market producers. The practical upshot is that a broad swath of EVO 8 owners can equip their car with a look and function that evokes the track without breaking the bank. These wings typically carry standard bolt-on mounting, and their finish may be straightforward, sometimes with paint-match options that keep the overall aesthetic coherent with the exterior. For a buyer on a tight budget, this tier can be a compelling first step into aero upgrades, especially for those who want a practical upgrade without a long accessory list to manage.

Stepping up from the most affordable options, mid-range carbon fiber-inspired wings present a mixture. They offer a more refined appearance and improved aerodynamic intention, often with a more convincing carbon-weave finish. These mid-range wings generally range from about two hundred to six hundred dollars at typical online retailers. They are commonly constructed with a carbon-fiber look or a partial carbon composition that blends aesthetics with functional materials, delivering a lightweight impression while not always achieving the stiffness or low weight of a full carbon structure. For street and occasional track use, this tier can deliver a meaningful enhancement in feel and look without the premium price tag associated with pure carbon fiber wings. In this space, the balance is delicate: many buyers prioritize visual authenticity and a modest performance gain over the pure weight savings a full CF wing might claim. The result is a product category that resonates with drivers who want a credible aero upgrade that looks the part on a weekend car show and performs respectably on the track.

At the high end sits the full carbon fiber wing, where weight savings, stiffness, and aerodynamic precision are the primary currencies. The market literature places these wings at substantial price points, sometimes exceeding a thousand dollars. A prominent example notes a 1,400-millimeter full carbon wing designed for EVO 8–9 variants that can command over a thousand dollars, reflecting the scale of investment that serious track enthusiasts are willing to make for performance and durability. Such wings are typically crafted for strength and low weight in a way that suits club racing and higher-speed aerodynamics. They may feature refined mounting hardware and laser-cut brackets that contribute to precise alignment and reduced flex. The visual impact is also meaningful; carbon fiber wings convey a purposeful stance that communicates a driver’s intent on the road and the track alike. Yet the practical calculus remains: the performance gains depend on more than raw weight. It requires harmonizing wing geometry with the car’s chassis, the suspension, the tire package, and the driver’s style. In other words, the most expensive wing can only deliver its best performance when the rest of the aero and mechanical package supports it.

A practical note about price and availability is the interplay between new production and the secondary market. The price scenes show that many buyers find themselves choosing between new, china-origin wings—where a robust supply chain in regions like Guangdong, Jiangsu, and Jiangxi feeds the aftermarket—and used or OEM wings found on international platforms. For example, a pre-owned OEM carbon fiber rear wing can surface on global marketplaces with a price tag around five hundred eighty dollars, sometimes with free shipping. This exemplifies how the market negotiates value: a lightly used, high-quality wing can offer near-OEM performance at a fraction of the new-part cost, while still requiring due diligence on condition and mounting integrity.

The supplier landscape for EVO 8 rear wings emphasizes a global-to-local dynamic. Although the main supply streams originate in China, the vendors range from large automotive parts manufacturers to smaller, regionally focused shops. In China, hubs in coastal and inland industrial clusters drive a broad spectrum of products—from economical FRP wings to high-end carbon options. A broad slice of the supply chain is located in metropolitan and manufacturing corridors, with several notable manufacturers offering a full range that covers the lower-cost FRP spectrum to premium carbon. This ecosystem creates both opportunity and risk: opportunity in the sense that buyers can tailor their purchases to specific goals and budgets, and risk in the sense that the variability in quality and fit can be substantial. The MOQ (minimum order quantity) barrier sometimes exists for bulk buyers, with certain suppliers seeking to incentivize discount pricing only when a batch of tens of units is ordered. This dynamic is typical of a market that serves both individual enthusiasts and small fleets of shops stocking multiple EVO models.

From a consumer’s perspective, the decision matrix for EVO 8 rear wings is driven by several soft factors beyond raw numbers. A visually bold wing can transform the perceived character of the car, making the car look more racetrack-ready even when driven on public roads. At the same time, the functional elements—such as downforce, balance, and chassis load distribution—must be considered. An overly aggressive wing for a given street setup can introduce instability at the rear, particularly in crosswinds or during rapid throttle transitions. Conversely, a wing tuned for a lighter drift-friendly handling profile might underperform in high-speed apex exits where rear stability becomes paramount. The nuance is that the EVO 8 rear wing is not a one-size-fits-all piece; it is a tuning tool, a signal of intent, and a part of a wider aero and chassis strategy.

To help readers place these options within a concrete decision framework, consider how a rear wing’s span relates to the car’s track width and weight distribution. A wing that spans roughly 1.4 meters tends to offer a strong visual presence and substantial downforce potential, especially when matched with a properly balanced wing foil and endplate design. However, the exact gains depend on the car’s overall aero package, including underbody flow, diffuser performance, and the height at which the wing sits relative to the car’s center of gravity. For EVO 8 enthusiasts, this is not merely a matter of chasing peak numbers; it is about achieving a coherent aero story that complements the engine’s power band, the transmission’s gearing, and the suspension’s ability to harness downforce without destabilizing the chassis.

In practical terms, many EVO 8 owners begin with a fiberglass option as a gateway upgrade, then evaluate a mid-range carbon-style wing for an incremental step in aesthetics and aerodynamics. Those who pursue competitive track performance may move toward a dedicated full-carbon solution, mindful of installation precision, mounting hardware, and the potential for increased wing loading to affect yaw stability during rapid steering inputs. The process often includes trials with different wing heights and angles of attack, along with tire and brake setups tuned to the car’s new aero profile. It is this iterative approach that makes the EVO 8 rear wing ecosystem feel dynamic rather than deterministic. Each choice creates a conversation with the car’s behavior, inviting the driver to respond with tire pressures, suspension tuning, and even weight distribution adjustments.

One practical path through this landscape is to consult community knowledge and verified fitment data. For example, a number of sources highlight compatibility with EVO 7, 8, and 9 through model years in the mid-2000s, with some designs advertised to accommodate later EVO X applications with caveats. In this context, the wing becomes a boundary object—something that helps unify the driver’s expectations of performance with the realities of a twenty-year-old chassis concept that has seen many evolutions through the aftermarket. The right wing, in this sense, helps the EVO 8 bridge the gap between its factory identity and a modern track-oriented character, preserving the car’s essential balance while allowing it to participate in more aggressive aero regimes when the driver is prepared to tune the rest of the vehicle accordingly.

To illustrate the market texture, consider the value proposition across the price tiers. The most economical fiberglass wings deliver a cost-effective way to achieve a high-wing aesthetic with reliable bolt-on installation, suitable for street use and occasional track sessions. They empower a change in the car’s silhouette with minimal financial exposure and a straightforward maintenance path. The mid-range carbon-fiber-inspired options offer improved aesthetics and sense of stiffness, often with a lighter feel and a more convincing carbon finish that can elevate the car’s presence on the streets and paddocks alike. The high-end, fully carbon wings stand as the performance apex in this sector; they promise not only reduced mass but a more direct aero signal to the air, translating into potentially sharper turn-in behavior and more stable transfer of downforce through the rear axle. Each tier does not simply represent a different price point; it carries a philosophy about how the EVO 8’s handling character should evolve as the car’s aero balance changes. In that sense, the rear wing becomes a narrative device, a tangible way to script how the car behaves as the owner learns to read the wind and the chassis’s reactions on a range of surfaces.

For readers who want to explore beyond the immediate product descriptions, the aftermarket ecosystem includes avenues like pre-owned or OEM variants that might surface on international marketplaces. These options remind us that the value of aero parts is not solely a function of newness; condition, compatibility, and installation state play equally crucial roles in the decision. A lightly used OEM carbon fiber rear wing can offer a balance of authenticity and performance at a compelling price, provided the buyer can verify its condition and ensure that the mounting hardware remains reliable. The presence of such options underscores a broader market truth: aero components are part of a larger conversation about vehicle personalization, where the lines between performance, appearance, and resale value intersect in practical ways.

Within this evolving ecosystem, a single, essential question persists for the EVO 8 owner seeking a rear wing: what is the day-to-day expectation from the car’s aero upgrade? If the aim is to improve mid- to high-speed stability for weekend track days, a well-chosen wing—carefully mounted and aligned—can improve rear grip and confidence on corner exits. If the goal is more about street presence and visual impact, then a fiberglass or carbon-style wing that emphasizes the silhouette and the tactile feel of a more aggressive stance may be perfect, provided it does not unduly compromise daily usability. The answer, of course, depends on the driver’s willingness to balance ambition with maintenance and tune, and on the willingness to engage with a market that rewards experimentation and learning as much as it rewards performance numbers.

To connect these threads back to the broader article topic, the EVO 8 rear wing is not a standalone upgrade; it is a catalyst that reveals how modern aftermarket ecosystems are organized around a classic platform. The material choices, the mounting philosophies, and the price stratification all reflect a vendor ecosystem that is attuned to both global manufacturing and local, hands-on customization. In this sense, the rear wing becomes a microcosm of automotive modification culture: a blend of engineering discipline, aesthetic intention, and community-driven knowledge transfer. It asks the driver to weigh what is gained in speed and control against what is given up in weight, drag, and complexity. And as the EVO 8 continues to attract enthusiasts who relish the process of learning and refining their car’s behavior, the rear wing stands as a tangible interface between dream and discipline—a piece of hardware that invites a conversation about balance, purpose, and the evolving craft of driving.

For readers who want a concrete touchpoint while traversing this aero landscape, consider how a small, bolt-on addition can unlock a broader set of experimental opportunities. The wing invites you to test, measure, and iterate. It becomes an instruction in car dynamics, a way to translate the physics of air into the immediacy of road feel. It also embodies a larger truth: that in the EVO 8’s ongoing story, the rear wing is more than a part. It is a statement about what you want the car to do, how you want to feel it, and how you are willing to invest in the learning curve that comes with the open-ended pursuit of performance.

As a closing thread, the market’s layered pricing and supplier capabilities suggest one practical takeaway: start with a clear objective. If you want a visually bold, cost-efficient upgrade that remains reversible, begin with an economical fiberglass option and test how it changes the car’s balance on your usual roads or track day route. If your ambition is to shave time on a circuit while keeping a manageable budget, a mid-range carbon-style wing may offer a better blend of aesthetics and performance without the commitment of a full CF wing. If your aim is to push the car toward a high-performance aero envelope, prepare to invest and pair the wing with a tuned suspension, a calculated tire setup, and a frame of mind that prioritizes precise alignment and repeatable testing. The EVO 8 rear wing, in this sense, is both a hardware piece and a learning tool—one that invites you to explore the wind’s language and, in doing so, to shape the car’s eventual alignment with your driving philosophy.

Internal link for further context on related aftermarket components can be seen here: evo-8-9-varis-front-bumper-with-carbon-lip. While this link points to a broader EVO part family, it helps situate the rear wing within a coherent, aero-focused modification path. For readers seeking a tangible catalog reference on carbon-fiber upgrades beyond wings, the broader aftermarket ecosystem offers a spectrum of options that can complement a wing’s presence and function without derailing the car’s balance. As always, the path to the best result is rooted in clear intent, careful measurement, and a willingness to iterate as conditions and ambitions evolve.

External resource: https://www.ebay.com/itm/274958676765

Final thoughts

The rear wing of the Mitsubishi Lancer Evolution VIII plays a significant role in enhancing both its performance and aesthetic appeal. By exploring various material types, understanding straightforward installation processes, and being aware of market pricing, business owners can effectively cater to the needs of customers seeking to upgrade their vehicles. Armed with this knowledge, your business can forge ahead in offering valuable modifications that resonate with EVO 8 enthusiasts, ultimately fostering customer loyalty and satisfaction.