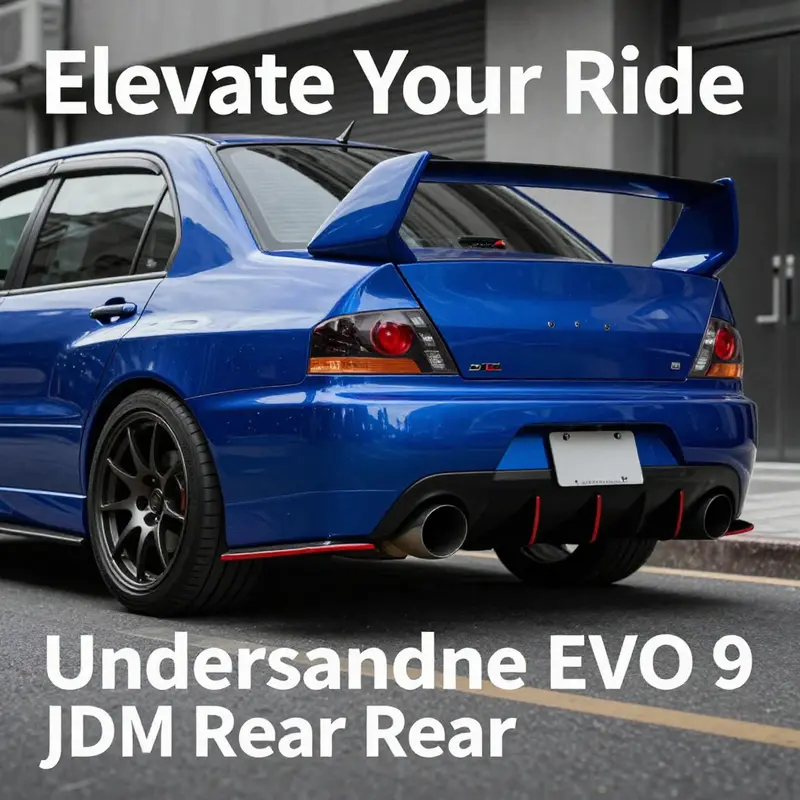

The Mitsubishi Lancer Evolution IX (Evo 9) is known for its spirited performance and iconic styling, and among its standout features is the rear bumper, which plays a pivotal role not just in aesthetics but also in functionality. As businesses engage with the growing market for aftermarket parts, understanding the nuances of these JDM components is essential. This article meticulously details the materials and construction of the Evo 9 JDM rear bumper, explores its impact on vehicle performance, compares OEM and aftermarket options, conducts a cost analysis, and highlights consumer feedback and market trends. Each chapter will provide business owners with critical insights to navigate this niche automotive sector effectively.

Exploring the EVO 9 JDM Rear Bumper: Materials, Construction, and the Quiet Science of Fit and Flow

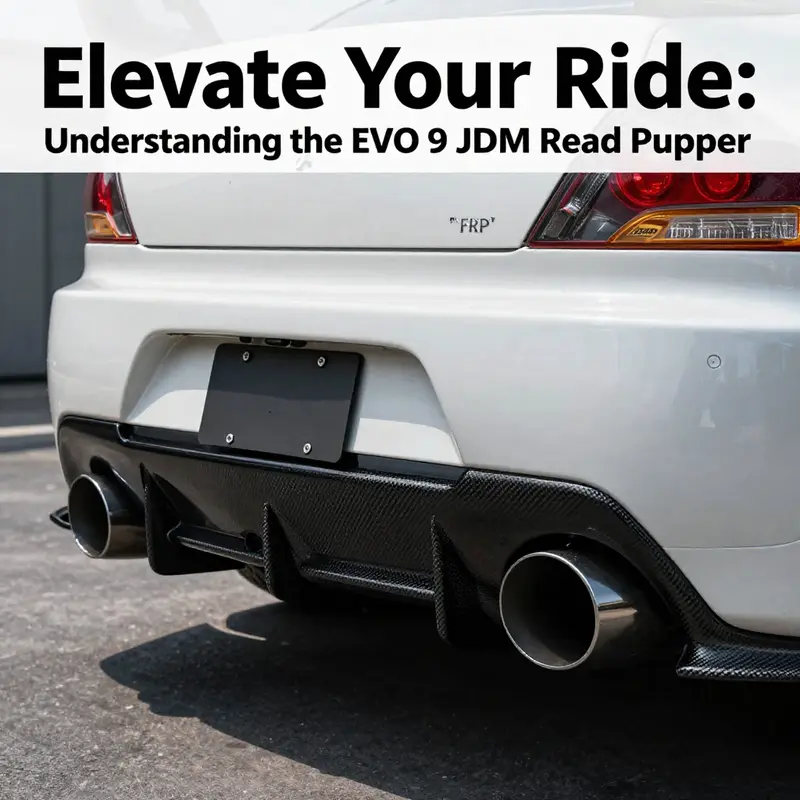

The rear bumper of a high‑performance sedan like the EVO 9 is more than a closed panel; it is a carefully engineered interface between the car’s architecture, its aerodynamics, and the driver’s sense of how the machine speaks to the road. In the Japanese Domestic Market (JDM) scene, bumpers for the EVO 9 push beyond simple aesthetics. They embody a balance of weight, strength, and form that supports agile handling, cooling efficiency, and the factory cadence of line and contour that defines the car’s visual language. The materials chosen for these parts—primarily fiberglass reinforced plastic, better known as FRP, and carbon fiber—are selected for practical reasons as much as for their performance attributes. FRP offers a favorable cost‑to‑strength ratio, a rigidity that resists deformations under stress, and an amenable base for customization. It holds a sharp edge on the performance tree: a well‑made FRP bumper contributes to a measurable improvement in weight management compared to heavier alternatives, a win for handling and fuel efficiency, especially when paired with other weight‑saving strategies. On the other hand, carbon fiber bumpers sit at the higher end of the spectrum in terms of strength‑to‑weight efficiency. A 3K twill carbon weave, often finished with a high‑gloss coat, is a recognizable signature of this class of parts. The layup and cure process matters here: carbon fiber components are frequently manufactured using vacuum infusion, a technique that ensures resin is drawn evenly through the fabric. This reduces voids and material defects, producing a part that behaves consistently under load and over time. The result is a bumper that not only looks the part but resists the kind of micro‑cracking that can undermine performance on a twisty road or a track session. In the JDM context, these materials are chosen with an eye toward not just raw lightness but reliable durability, a consideration that becomes especially important when the bumper nests behind a diffuser or an air intake that must not distort under pressure. The construction philosophy mirrors the car’s broader engineering ethos: parts must align with the vehicle’s original geometry while offering a platform for enhancement. This is where the concept of OEM fitment enters the conversation. JDM bumpers are frequently designed to align with precise mounting points and body lines, maintaining the factory aesthetic even as the component introduces enhancements—diffusers, vents, or other aerodynamic features. The aim is a seamless integration where the rear silhouette remains true to the EVO’s design cues, and any added functional hardware, such as diffusers integrated into the bumper, works in concert with the car’s air management requirements. Even the finishing stage matters in the perception of quality. A bumper finished in black primer is common in the aftermarket sphere because it invites custom color work, but an exposed carbon surface or a polished carbon lip can also be part of a deliberate styling choice. This approach respects the owner’s autonomy to tailor the vehicle’s surface to a particular hue or texture, while still preserving the underlying geometry that makes the part fit as if it had rolled straight from a factory assembly line. The procurement and selection process for these bumpers often hinges on the quality of the listing and the accompanying details. In a market where fitment and authenticity are crucial, shoppers will compare measurements, mounting points, and any stated compatibility with body kits or other OEM components. The best indicators of a bumper’s value are explicit specifications, solid build notes, and a track record of satisfied buyers. A practical path for buyers seeking confidence is to review listings carefully for compatibility statements, finish options, and documented mounting procedures. It is also prudent to consider seller feedback and any installation notes that reveal how closely the part mirrors the OEM geometry. For those who want to glimpse how such parts translate into real‑world fitment, the OEM‑style rear bumper for EVO 8‑9 pages provide a useful benchmark—these pages emphasize the importance of preserving factory alignment while allowing for aftermarket refinement. See the OEM‑style Evo 8‑9 rear bumper page for a concrete sense of how precise fitment is maintained across generations, with an emphasis on mounting points and body line continuity. OEM-style Evo 8-9 rear bumper. Beyond the raw materials, the engineering philosophy centers on how the bumper integrates with the rest of the vehicle’s performance envelope. Integrated diffusers, air vents, and channels that guide airflow to the brakes and powertrain play a crucial role in managing pressure distribution and cooling. In high‑strung driving conditions, where sustained throttle application and cornering demand disciplined heat management, every vent or diffuser becomes a tiny, efficient contributor to the car’s reliability. The combination of lightness and structural integrity supports sharper responses during corner entry and mid‑corner adjustments, while the diffuser geometry helps keep wake turbulence in check, reducing drag without compromising downforce. The result is a rear end that feels connected to the front’s aero intent, preserving a cohesive silhouette that communicates purpose rather than mere style. It is this fusion of aesthetic fidelity and engineering practicality that marks JDM rear bumpers as more than cosmetic upgrades. They are, by design, components that contribute to the car’s overall dynamic balance. The choice between FRP and carbon fiber, between a plain finish and a carbon‑accented look, becomes a matter of priorities: weight savings, cost, and the degree to which a given owner wants to emphasize structural stiffness versus show‑through surface texture. Yet even with a strong emphasis on performance, fitment remains a non‑negotiable criterion. The EVO 9’s bodywork is a single, tightly integrated system, and a bumper that does not align with the body lines or mounting points undermines the entire build. This is why authentic fitment information—whether it is explicitly stated by a seller or confirmed through user reviews and specified dimensions—carries as much weight as the material choice itself. The maintenance of authenticity also speaks to the perceived value of these parts in the broader community. Owners who invest in JDM rear bumpers expect a long‑term relationship with their selections, counting on consistent performance across seasons and miles. The durability of FRP is a function of resin systems, surface finishing, and careful resin to fiber ratios, all of which influence how the bumper holds paint and resists cracking after impacts. Carbon fiber parts, while lighter, demand attention to resin encapsulation and UV protection to preserve gloss and prevent surface degradation. In daily use, these considerations manifest as a smoother repainting experience, a cleaner edge where the bumper meets neighboring panels, and a more confident return to the road after a minor contact. The practical realities of ownership—stock levels, price pressures, and the ever‑present trade‑off between cost and performance—also shape the decision landscape. While carbon fiber variants deliver weight savings and a premium feel, a well‑constructed FRP bumper can deliver excellent stiffness and durability at a more approachable price point. For enthusiasts who regard the rear of the EVO 9 as a key stylistic and functional feature, the choice often reflects not only a budget framework but a philosophy about modification—whether to pursue a clean, OEM‑leaning look or to embrace a more aggressive aero stance with carbon details and an integrated diffuser. In sum, the EVO 9 JDM rear bumper exemplifies a disciplined approach to component design where materials, manufacturing, fitment, and aerodynamics converge. The narrative is not about a singular material or a single aesthetic, but about how weight management, structural integrity, and the long‑term relationship with the car’s geometry inform every pick a builder makes. The rear panel becomes a microcosm of the car’s broader performance story: a careful blend of form and function, sensitive to the car’s original engineering, yet prepared to evolve as riders seek greater connection with the road. To appreciate the depth of this evolution, it helps to recognize that the very choices behind FRP versus carbon fiber, or a plain painted surface versus a carbon lip, are guided by a philosophy of balance—between speed and handling, between a factory look and a personalized edge, and between durable daily use and the demands of spirited driving. For those who want a practical reference toward authentic fitment and factory‑style alignment, the OEM Evo 8‑9 rear bumper page offers a useful blueprint for how these parts are designed to integrate with the vehicle’s architecture without compromising its lines or its mounting geometry. External resource: Official specifications and safety considerations can be found on the manufacturer’s external site at https://www.mitsubishimotors.co.jp/.

Shaped for Speed: The Evo IX JDM Rear Bumper as a Subtle Vector for Aerodynamics, Balance, and Handling

The Evolution IX has always lived in a space where form meets function, where every panel contributes to a total balance that drivers feel more than they can articulate. The rear bumper, often overlooked in favor of more conspicuous upgrades, plays a quiet but meaningful role in shaping how the car behaves at the edge of adhesion. In the JDM market, rear bumpers crafted for the Evo 9 are not merely cosmetic; they are engineered with an eye toward airflow, weight distribution, and the way the car communicates with the road through its rear end. The materials—typically lightweight composites such as fiber-reinforced plastics—allow for a design language that is both faithful to factory lines and flexible enough to host performance-minded features, like integrated diffusers or pockets for air management. When a rear bumper includes a carbon diffuser or a profile that seals more effectively around the exhaust and underbody, it becomes a small but purposeful piece of an integrated performance puzzle. This is why many enthusiasts see the Evo 9 JDM rear bumper not as a standalone upgrade but as a component that harmonizes with suspension tuning, aero refinements, and even alignment choices to deliver a more coherent driving experience at speed.

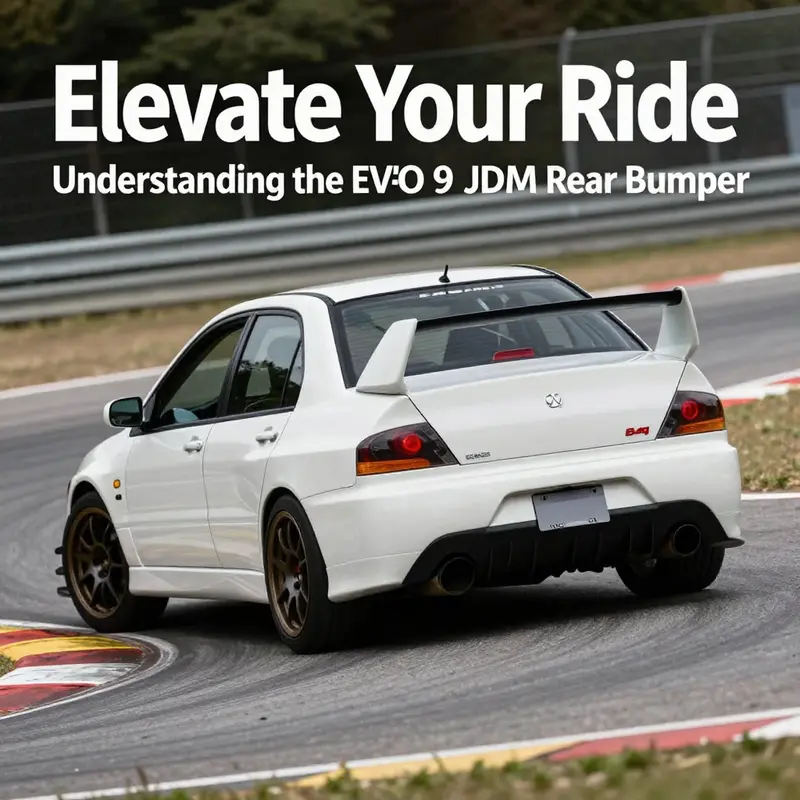

Design and aerodynamics rarely earn a headline on the factory spec sheet, yet the Evo 9 JDM rear bumper is distinctly tuned to manage the wake generated behind the car. Compared to the mass-market US versions, the JDM variant tends to present a more aggressive silhouette that visually communicates a tighter integration with the rear diffuser and valence. This integration matters because the shape of the trailing edge influences how air detaches from the body at high velocity. A cleaner separation path reduces rear turbulence, which in turn can help the car feel more stable as speeds climb and tires lose grip at the rear in cornering or during heavy braking. Even subtle changes—a slightly deeper trailing edge, a reshaped bumper cheek, or a recessed diffuser pocket—can redirect the boundary layer in ways that yield more consistent yaw response and a calmer rear axle under load. The driver experiences that calm through the steering and seat of the pants: a sense that the car is more planted, more predictable, and more communicative when pushed into a turn.

Materials choices amplify these effects without imposing unnecessary weight. In the Evo 9’s JDM ecosystem, bumpers are frequently fabricated from FRP composites, chosen for their strength-to-weight ratio, impact resistance, and the ease with which curvature and air channels can be formed. The weight savings matter not only for the front-to-rear balance but also for how the chassis responds to braking and cornering. A bumper that is lighter than a metal or heavier composite counterpart shifts the car’s inertia slightly toward the nose, but in practical terms the net result is often a more nimble rear during quick transitions and a more linear load transfer under braking. Repairability remains a real consideration here as well; FRP can be repaired with skill and appropriate materials, which is critical because the Evo’s tuning culture tends to push cars toward more aggressive setups that invite scrapes and scrapes invite repairs. The durability of the bumper under track rub and daily driving becomes a practical metric of its value, even if its direct horsepower impact remains elusive on the dyno. In a broader sense, the bumper’s material choice contributes to the car’s overall feel—the cadence of its balance when loaded into a corner, the way the tail returns to center after a lane change, and the quiet confidence that comes from knowing the rear skin is doing its fair share of aero chores without adding excessive weight.

From a dynamics perspective, the bumper is best understood as part of a wider performance ecosystem. The Evo 9 gains its strongest benefits not from any single upgrade but from the way components interact. When the bumper is paired with a refined suspension setup—improved dampers, carefully tuned springs, and bushings chosen for predictable compliance—the rear’s aerodynamic cues are translated into usable handling characteristics. A properly matched bumper can support a more efficient rear diffuser, guiding air into channels that reduce underbody turbulence and minimize drag-induced lift at speed. In this sense, the bumper is a passive but essential contributor to high-speed stability. In conjunction with a front-end aero kit or a rear undertray, the overall effect can be a more coherent aero envelope: less buffeting, a more linear response at the limit, and a chassis that communicates grip through the seat and steering wheel rather than through guesswork.

Within enthusiast circles, authenticity enhances value as much as performance. The drive toward original or OEM-style components—particularly in the Evo MR-XBB and similar build chronicles—reflects a tuning philosophy that respects heritage while advancing handling. Owners seek JDM parts to preserve the car’s intended balance and to avoid hybridized geometry that can sometimes undermine a carefully tuned chassis. In this context, a genuine JDM rear bumper becomes more than a cosmetic piece; it is a deliberate step in keeping the car’s dynamic character authentic while still enabling the integration of modern aero cues and updated materials. It’s a practical reminder that performance culture often thrives on thoughtful restraint: choosing a bumper that fits the lines, weight distribution, and load paths the car already believes in, while still opening doors to aerodynamic refinements that improve the driving experience as a whole.

Yet there is no singular metric by which the bumper’s impact can be declared in isolation. Official data rarely attributes measurable gains in lap times or acceleration to a rear bumper alone. What engineers and serious hobbyists alike emphasize is a holistic view: the bumper’s contribution becomes meaningful when you view the Evo 9 as a system—engine, drivetrain, suspension, tires, and aero working in concert. In this light, the rear bumper is a tuning lever, not a magic wand. It helps shape the car’s operating window—its peak grip zone, its preferred steering feel, and its habits at the limit—so that the entire performance package can operate with fewer compromises. As with any component chosen for performance, the bumper’s value emerges most clearly when installed as part of a coherent plan—suspension upgrades that exploit the improved rear balance, tires that match the aero envelope, and an alignment strategy that respects the intended distribution of downforce and drag.

When sourcing these parts, many owners weigh fitment and finish as heavily as they weigh aerodynamic gains. The Evo 9’s market for JDM rear bumpers is filled with listings that emphasize factory-level fitment, precise mounting points, and compatibility with other Evo 8–9-era components. The most informative way to gauge quality is to examine the listing directly—user reviews, fitment notes, and photos that reveal how well the bumper aligns with the bumper’s mounting tabs, rear clips, and the surrounding bodywork. A well-executed JDM rear bumper often arrives with care taken to preserve the car’s original geometry, ensuring that gaps remain uniform and that paint lines do not require radical adjustments. In practice, this means less time spent on trimming, more time enjoying the balance and feel that a properly integrated bumper provides. The dream scenario is a seamless blend of aesthetics and performance: a rear bumper that looks right, fits right, and contributes to a chassis that behaves in a linear, communicative way when pushed through a corner at speed.

For readers who want to see a concrete example of how these parts are positioned within a broader upgrade pathway, a practical reference point is the OEM-style JDM rear bumper designed for Evo 8–9 platforms. The link below points to a source that specializes in these compatible components, highlighting the importance of fitment alongside performance intent. OEM JDM rear bumper for Evo 8-9

In sum, the Evo IX JDM rear bumper operates as a finely tuned instrument within a larger orchestra of modifications. Its value rests not in dramatic horsepower gains but in its capacity to support more stable high-speed behavior, more predictable cornering, and a chassis that communicates more clearly with the driver. It embodies a tuning philosophy that respects the car’s original dynamics while enabling a cohesive upgrade path—one where aero, suspension, and alignment cooperate rather than compete. This is the subtle art of Evo 9 performance: the rear bumper as a vector that channels air, balances weight, and supports handling finesse, all while preserving the authenticity that fans of the model prize.

External reading that expands on the broader theory of bodykit dynamics can provide a useful theoretical backdrop to this practical exploration. For a detailed overview of how bodykit characteristics, standards, and performance interact in the Evo 9 context, see The Fundamentals of Bodykit Evo 9: Characteristics, Standards, and Performance.

External link: https://www.ercar.co.uk/evolution-9-bodykit-guide/

From Factory Fit to Custom Flair: Navigating OEM and Aftermarket Rear Bumpers on the Evo IX JDM Scene

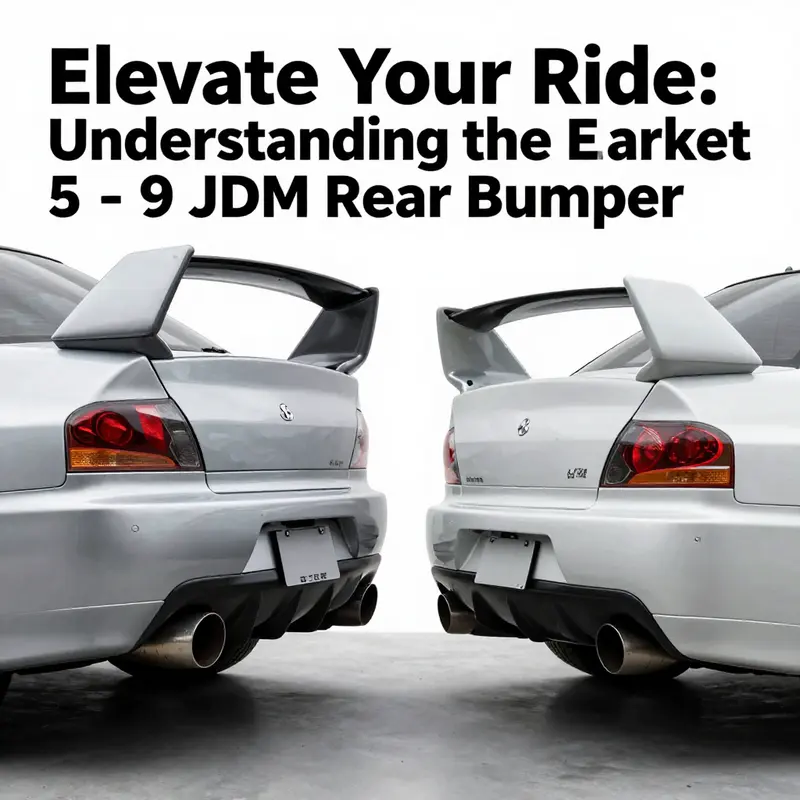

The rear end of a performance-focused hatchback can tell you a lot about how a car is meant to behave. For the generation in question, the rear bumper isn’t just a cosmetic shell; it is a carefully crafted interface between aerodynamics, balance, and the visual stance that defines the car’s character on the street and the track. In the Japanese Domestic Market, two broad paths vie for attention among enthusiasts: the authenticity of an OEM piece that preserves the car’s original symmetry and airflow, and the bold customization of aftermarket options that promise lighter weight, bolder lines, and new aerodynamic ideas. The Evo IX, with its distinctive rear treatment and a heritage steeped in rally-inspired design, sits at the center of this choice. The decision, while personal, rests on a few tangible criteria—fitment accuracy, material performance, and how much the bumper’s look and function align with the owner’s goals for daily drive, weekend fun, or competition use.

OEM rear bumpers for this generation are produced to mirror factory geometry with meticulous attention to mounting points and airflow channels. The materials are chosen to maintain rigidity while resisting impact and wear, typically a high-density thermoplastic blend designed to absorb minor scrapes without permanent deformation. The result is a seamless integration with the car’s rear fascia, preserving the line where the bumper meets the quarter panels and ensuring that the diffuser, if present, works with the underbody geometry the original designers intended. Paint finishes on OEM pieces are intended to match the body color with factory-level control, so the visual transition from bumper to body reads as a single, continuous surface. On the street, that consistency matters not only for aesthetics but for long-term durability; a bumper that mirrors factory tolerances reduces gaps that could invite debris or water intrusion and keeps alignment predictable through hot summers and cold winters alike.

Those who lean toward OEM replacements often emphasize reliability and resale value. An OEM bumper is not merely a direct swap; it preserves the car’s original aerodynamic profile and helps maintain the car’s built-in balance, ensuring that rear airflow continues to function as it did from the showroom. This has tangible implications for performance, especially at higher speeds where the diffuser and the surrounding geometry contribute to rear-end stability. In practice, the installation is straightforward for a technician familiar with the chassis: the bumper uses factory mounting points, and the process is typically clean enough to complete without extensive modification. The trade-off, however, is cost. OEM parts command premium pricing, and in markets outside the home country, availability can be sporadic, requiring patience or a longer shipping route. Yet, the value proposition remains clear for purists who prize originality, factory integrity, and the assurance that every line and curve retains its intended effect.

On the other side of the spectrum lies the aftermarket route. This path opens the door to a spectrum of materials and designs, from light FRP to carbon fiber composites. The primary lure is customization: a bumper can shed weight, alter the silhouette, or include integrated features that were not offered by the factory. A common feature in aftermarket rear bumpers is an integrated diffuser or diffuser-inspired geometry—an element that can sharpen the rear stance and influence airflow across the trailing edge. When carbon fiber or carbon-infused accents are used, the weight savings can be meaningful for performance-minded builds, and the aesthetic can lean aggressively toward the JDM-leaning style that many owners seek. Even if the bumper is marketed as a direct fit, the practical reality is that some aftermarket pieces require a bit of adjustment during installation. Panels may need careful alignment to close gaps evenly, and the finish must be carefully matched to the rest of the body if a color-matched appearance is desired. In addition, paint quality on aftermarket units can vary, particularly with lighter-weight materials that may absorb paint differently or show different sheen levels after curing. Still, the right combination of materials and finish can deliver a striking, cohesive look that elevates the car’s presence without compromising key performance cues.

Another factor driving aftermarket adoption is the breadth of design language available. Unlike OEM, which adheres to factory aesthetics, aftermarket options allow enthusiasts to experiment with a more aggressive contour, a more subtle interpretation, or a silhouette that echoes the lineage of decades of tuning. The choice can extend to subtle details like the contour of the rear lip, the shape and size of cutouts, or the integration of venting features that influence rear-end cooling and downforce. For some, the appeal is purely visual—a bumper that instantly signals a car is in a more aggressive, performance-focused mood. For others, the emphasis is functional: a lighter, more aerodynamically optimized rear end that can contribute to sharper handling and improved stability at higher speeds. All these possibilities underscore a broader point: the rear bumper becomes a practical engineering choice as much as a stylistic one.

With these considerations in mind, buyers weigh several practical questions. How important is factory authenticity to the car’s character and value? Do I plan to use the car primarily as a daily driver, or will I push it on weekends or at track events where wind tunnel-tested aero and chassis balance matter more? How critical is weight savings, and how carefully will the finish be matched to the rest of the body? The answers will shape the decision toward the option that best aligns with intent. Even in the best cases, the journey to select a bumper—whether OEM or aftermarket—benefits from a careful vetting process. Prospective buyers should examine fitment diagrams, study any available alignment testimonies, and, when possible, review install notes or photos from owners who share their experience with similar bodywork. The end result should be a bumper that not only looks right but behaves as the car was designed to behave, especially at speed.

In the context of the broader evo scene, the discussion often converges on a practical approach: balance authenticity with personal expression. A well-chosen OEM bumper guarantees that the car remains faithful to its original purpose and performance intent, preserving the reputation of the model as a well-calibrated machine built for reliability and precision. By contrast, a thoughtfully selected aftermarket bumper can complement a build aimed at lighter weight, unique styling, or enhanced rear-end aerodynamics, turning the car into a personal statement while maintaining road legality and daily usability. The key, as with any bold modification, is to plan with an eye toward fitment, finish, and function. The conversation around rear bumpers, at its core, asks not only what the car will look like, but how it will feel when driven—how the rear end keeps pace with the front, how air flows beneath and around, and how the entire silhouette communicates intent to onlookers and judges alike.

For readers seeking a grounded reference that speaks to empirical fit and performance, a respected automotive publication offers a measured comparison of OEM versus aftermarket approaches. This resource provides a framework for evaluating fitment, materials, and aerodynamic impact, helping to translate the choice into a more confident purchase decision. When exploring the practicalities of a rear bumper swap, it is worth consulting that analysis as a baseline while weighing the specific needs of your own build. For a direct example of how the OEM path can be described in a real-world listing and its implications for fit and finish, you can explore a dedicated OEM rear bumper page that targets the Evo 8-9 generation with a factory-mitted geometry and color compatibility. This page is organized to help buyers verify compatibility and to illustrate what a factory-grade installation entails, from mounting points to paint matching.

Internal reference for OEM fitment and easy access to a factory-style option can be found here: OEM Evo 8-9 JDM rear bumper OEM page.

For a broader perspective on the OEM versus aftermarket dynamic and how it translates to real-world performance and aesthetics, consult an external expert resource that synthesizes fit, weight, and aerodynamics across generations. The linked article offers a concise framework for evaluating these choices, grounded in tested practice and shared experiences from the community. External reference: https://www.motortrend.com/cars/mitsubishi/lancer-evo-9/2005-2007-oem-vs-aftermarket-bumpers/

Price and Practicalities: An In-Depth Look at EVO 9 JDM Rear Bumper Options

The rear end of a Mitsubishi Lancer Evolution IX has always been a focal point for enthusiasts chasing the balance between factory feel and aftermarket flair. When people talk about the EVO 9 JDM rear bumper, they are really discussing a spectrum of choices that hinge on budget, weight, fitment, and the visual statement the car will make on the street or strip. The decision is rarely about a single feature; it is about how a bumper integrates with real-world use, how it alters airflow, and how it aligns with the car’s overall stance. In the aftermarket scene, JDM rear bumpers for the Evo 9 span a wide range of materials and manufacturing philosophies, with FRP (fiber reinforced plastic) continually proving itself as a sweet spot between rigidity, weight, and cost. This material class offers enough stiffness to resist deformation under moderate impact or tire spray, while staying light enough to avoid the abrupt handling shifts that heavier options might provoke. That is especially relevant for owners who track weekends or aggressively street-drive the car, where the bumper’s weight and its aerodynamics can influence cooling, underbody flow, and the perceived weight balance of the vehicle. The Evo 9 context adds another layer: the car’s rear end has a defined silhouette that many JDM bumper manufacturers aim to reproduce, sometimes with a carbon diffuser or integrated lip to emphasize downforce and aggressive lines without straining the budget of everyday use. In practice, buyers encounter a continuum of options, starting with budget direct-fit replacements and climbing toward performance-oriented, reinforced designs that lean into more aggressive aesthetics and slightly higher price points. The key is understanding what each tier brings in terms of fit, finish, and long-term value, rather than chasing the lowest sticker price alone.

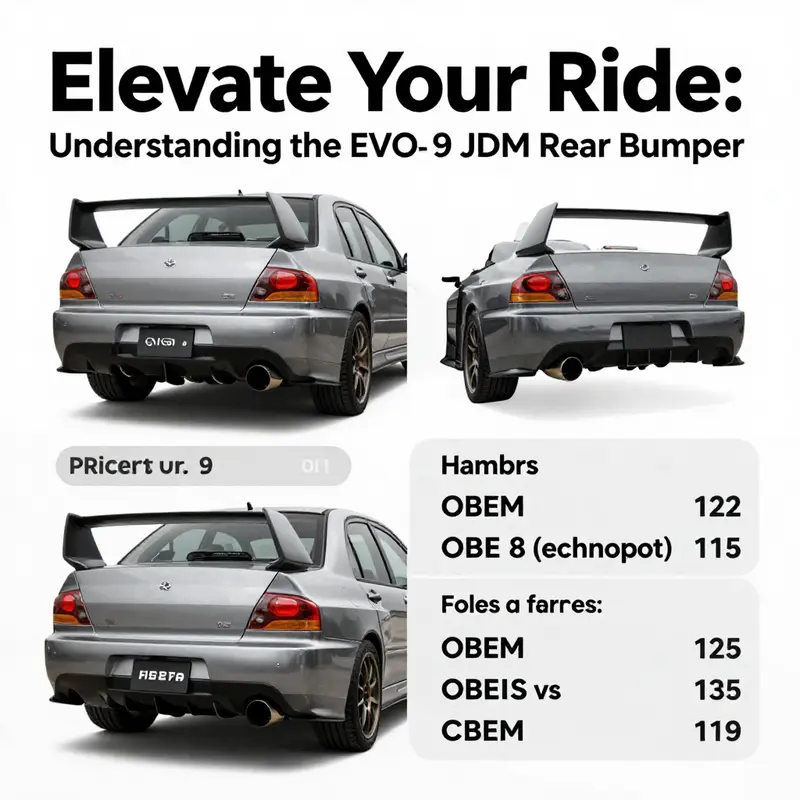

Budget options form the backbone of the market for those who want a straightforward return to OEM-like fit without a premium price tag. On platforms known for budget parts, prices typically range from roughly $200 to $400 for a rear bumper designed to serving as a direct OEM replacement. The materials in this tier frequently include steel or polypropylene, chosen for cost-effectiveness and basic durability. The objective here is simple: restore or maintain the factory look and compatibility with the Evo 9’s mounting points, while avoiding the premium costs associated with factory fresh or highly engineered aftermarket pieces. These budget bumpers are often cast or molded to approximate the original contours and cutouts, including the openings for the exhaust, reflectors, and the subtle curvature that helps the bumper align with the bumper beam and bumper reinforcement. The trade-off, however, is not only raw price but also long-term resilience and the subtle nuances of fitment. In many cases, paint matching and minor adjustments become necessary to achieve a seamless appearance, especially if the original bumper hardware has seen its share of heat cycles and impact. For the mechanically minded, the value proposition rests on the ease of swap and the ability to maintain a stock-like aesthetic without a financial commitment that would rule out future upgrades. In this space, the goal is solid, predictable replacement, not necessarily a radical reengineering of the rear profile.

Moving up the ladder, performance-focused bumpers entice drivers who prioritize aerodynamic intent, cooling efficiency, or a more aggressive stance. These bumpers commonly employ reinforced plastics or even aluminum sections to reduce weight while preserving rigidity. The price band for these parts generally sits between $400 and $800, reflecting a move from “just replace” to “enhance function and form.” Direct-fit variants in this category aim to snap onto the Evo 9’s mounting points with minimal modification, but they often feature design cues that support more aggressive airflow management. Features may include deeper cutouts for brake cooling ducts, larger air intakes, or channels engineered to guide air toward the intercooler or the radiator using the bumper’s geometry. The addition of a carbon diffuser is a popular upgrade in this tier, offering a visually striking contrast to the body color while contributing to a cleaner wake behind the car. For many Evo 9 enthusiasts, a carbon diffuser also signals a performance-minded intent, pairing well with a set of aftermarket exhausts and a tuned suspension. The practical payoff is dual: improved downforce and a more balanced rear-end silhouette that remains controllable at higher speeds. While the price is higher, the perceived value comes from a combination of function, weight savings, and the impression of a more purposeful machine when viewed from behind.

The market also features premium, high-visibility entries, including JDM-style bumpers that are marketed as authentic styling—sometimes with elements that echo factory cues found on later Evo models or MR variants. These pieces can command prices nearer the upper end of the spectrum, with some listings approaching or exceeding $579.88, depending on whether they include features such as a carbon diffuser, integrated lip, or match to the Evo 8/9 MR design language. The premium is often tied to brand-specific design, the perceived authenticity of the styling cues, and the level of finish achieved in paint-ready surfaces. Buyers should weigh whether the aesthetic payoff aligns with their broader goals for the car and how much time they anticipate dedicating to fitment and refinishing. The genuine allure of this tier lies in its ability to deliver a factory-inspired look without compromising compatibility with the Evo 9’s geometry, all while offering a visually cohesive upgrade that can be painted to mirror or contrast the vehicle’s existing palette.

In reality, the total cost of upgrading the EVO 9 rear bumper is not just the sticker price of the bumper itself. The complete financial picture includes paintwork, hardware, and any necessary preparation. A direct OEM-inspired bumper may require minor trimming or drilling, which adds time and labor costs. If the bumper arrives unpainted, color-matching and clear-coat application become essential steps to prevent fading or mismatches over time. Even when the bumper is described as a direct-fit replacement, some micro-adjustments are often necessary to ensure perfect alignment with the rear bumper cover, tailgate seam, and the quarter panels. For many owners, these steps are well worth the effort, especially when a consistent finish is achieved and the overall look is cohesive with the rest of the car’s exterior. The total cost thus emerges from a combination of the bumper’s base price, the day-rate of labor if a shop is involved, the paint and clear-coat materials, and the quality of the hardware that can support the bumper’s weight and aerodynamic function over time. The result is a car that not only looks more aggressive but also behaves more predictably in high-speed conditions, where rear aerodynamics can influence stability and the car’s perceived balance at the limit.

To anchor these considerations in a concrete image, consider a scenario where a buyer is eyeing a JDM-style rear bumper cover designed for the Evo 8/9 MR lineage and featuring a carbon diffuser. The list price on a high-visibility listing could be around $579.88, which reflects the premium that authentic styling and brand-specific design commands in the market. That price, while notable, still sits within the broader range of options that buyers weigh against their budgets and expectations for performance. It also underscores the market’s willingness to pay for the visual authenticity of a JDM part that preserves an OEM silhouette while delivering a modernized, race-inspired vibe. The takeaway for buyers is clear: if the goal is to preserve the Evo 9’s original lines while injecting a serious, sports-car ethos, this premium option aligns with the aesthetics and the targeted fitment, but it demands careful consideration of installation, paint, and long-term ownership costs. It is essential to gauge whether the premium aligns with one’s intended use, overall project scope, and willingness to invest in the associated ancillary services.

For anyone navigating this space, a practical strategy is to query live listings, compare the detailed specifications, and read user reviews that speak directly to fitment, color match, and paint durability. The most effective way to gauge a bumper’s true quality is to examine the listing itself: the described dimensions, the exact material composition, the included mounting hardware, and any notes about fitment with the Evo IX’s bumper reinforcement structure. High-quality listings also reveal whether the bumper is a direct OEM replacement or a modified aftermarket design, which can have substantial implications for alignment, stability, and the likelihood of rubbing against the exhaust or rear wheels during suspension articulation. In this sense, price becomes a function of not just the bumper’s advertised features, but also the confidence a seller has in the product’s ability to meet real-world assumptions about drive style, climate, and the car’s other modifications. This is where the narrative around cost becomes a story about value rather than a simple ledger entry.

Within the broader ecosystem of Evo 9 customization, the choice of bumper must be weighed against other visible and functional upgrades. A bumper is not an island; it is part of a wider aero and stance strategy. Integrating a JDM rear bumper with a carbon diffuser, for instance, often sits alongside choices for wheels, a front bumper or lip, and underbody components that accentuate the car’s aerodynamic profile. It is common for builders to coordinate color, texture, and finish across these elements so that the car presents a unified silhouette rather than a patchwork of mismatched textures. The chapter’s focus on cost becomes a lens through which to view the entire project scope, encouraging buyers to map out a realistic budget that includes not only the bumper itself but also the ancillary work needed to bring the vision to life. In this way, the EVO 9 JDM rear bumper decision is both a financial and a design calculation, a moment where performance ambition meets the pragmatic realities of maintenance, repair, and ongoing ownership. When approached with a clear plan, the bumper becomes a durable, aesthetically compelling component that complements the car’s mechanical setup and the owner’s personal expression.

For readers seeking a more direct dive into OEM-fit options that align with factory-like geometry while preserving the Evo 8-9 JDM identity, a dedicated resource outlines the OEM guidance for these late-model cars. The page offers a concise overview of the key fitment checks and reflects the desire for a clean, factory-aligned installation that still embodies the JDM aesthetic. It serves as a helpful companion to the broader price discussion by ensuring that the chosen bumper meets the necessary fitment benchmarks before committing to paint or labor. See the OEM-focused guide here: 03-06 Mitsubishi Evolution 8-9 JDM rear bumper OEM.

In sum, the EVO 9 rear bumper market presents a spectrum of options that reward careful budgeting, fitment diligence, and a clear sense of purpose about what the car should communicate on the road. From budget OEM replacements to performance-oriented, carbon-enhanced designs, each choice carries implications for weight, aerodynamics, and the car’s overall stance. The car owner’s challenge is to align the bumper’s characteristics with the EVO 9’s personality, ensuring that the investment translates into a coherent, durable, and visually striking result. As with any visible upgrade, the true value lies not merely in price but in the harmony achieved between form and function, ensuring that the EVO 9 remains a capable, exciting machine long after the hobbyist’s initial excitement has settled.

External resource: https://www.ebay.com/itm/165297917457

null

null

Final thoughts

In summary, the EVO 9 JDM rear bumper is more than just a stylish addition; it embodies critical aspects of vehicle performance and personalization. For business owners in the automotive aftermarket, understanding its materials, performance impacts, cost structures, and consumer preferences can lead to strategic advantages. As the demand for JDM parts continues to rise, tapping into this knowledge will not only enhance product offerings but also engage a passionate community of automotive enthusiasts who seek quality and performance in their vehicles.