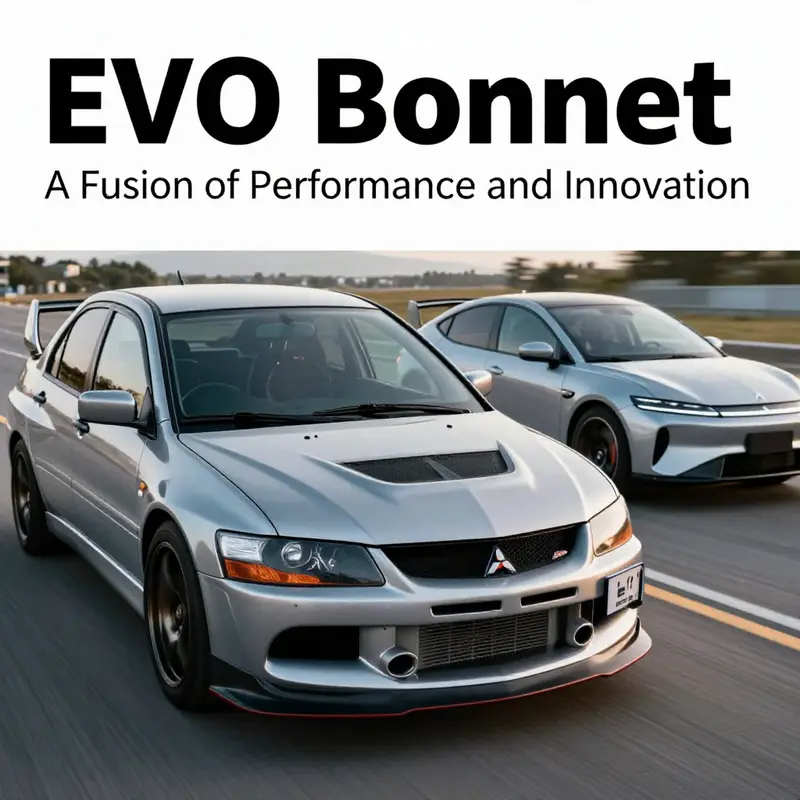

The evolution of automotive components often marks the difference between standard vehicles and those bearing the hallmark of performance. Among these, the EVO bonnet stands out as both an original and aftermarket part, primarily designed for the Mitsubishi Lancer EVO series. Not only has it influenced design aesthetics, but it has also become associated with innovation in the electric vehicle market, evident in the naming trends seen in models like the BYD ATTO 3 EVO. With advancements in materials, manufacturing techniques, and economic trends affecting its production and sales, the EVO bonnet reflects broader themes within car culture. This article takes an expansive look into the multifaceted significance of the EVO bonnet, exploring its design aspects, economic implications, and its profound impact on the automotive community at large.

EVO Bonnet: From Factory Fit to Featherweight Performance in a Performance-Driven Lineage

The bonnet of a high-performance car is more than a lid for the engine bay. In the lineage of the EVO, it acts as a signal and a tool. It signals a philosophy of balance between weight, cooling, and rigidity, and it serves as a practical interface with the road. For those tracing the EVO’s history, the bonnet embodies a recurring tension: preserve the precision of factory engineering while exploring the gains that lighter, more efficient materials can unlock. This tension is not unique to Mitsubishi; the badge-like use of EVO in the broader automotive language has grown into a shorthand for performance, suggesting that the bonnet is where the car’s ambition first meets the air. In that sense, the bonnet becomes a point of entry into a larger conversation about how performance is built, measured, and perceived.

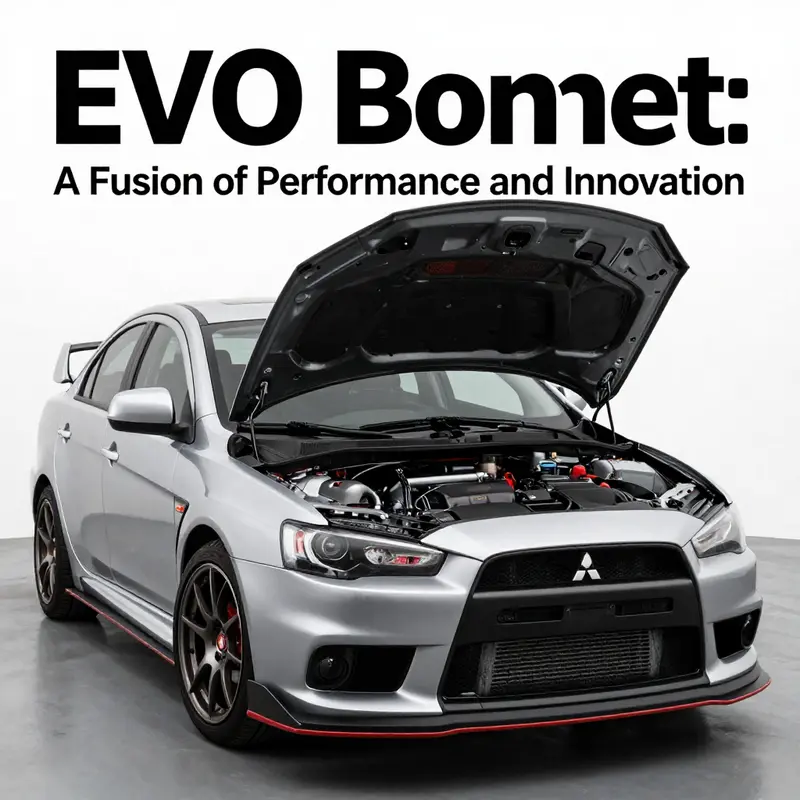

Original equipment bonnets for the EVO series are the turnkey choice for purists and restore‑project enthusiasts. They are designed to match the car’s exact specifications, ensuring precise fitment and seamless alignment with the rest of the bodywork. The value of an OEM bonnet lies not only in its geometry but in the confidence it affords during restoration or when preserving stock integrity. For someone seeking a restoration that remains faithful to the factory intent, an OEM bonnet provides a baseline of rigidity, paint prep, and surface finish that supports a correct silhouette. In practice, owners often encounter used OEM bonnets described as being in “great used condition,” which underscores how the car’s identity can be preserved without paying the premium for a brand-new panel. The decision to pursue a genuine part frequently comes down to whether the project aims to retain originality or to restore a car to its factory feel with modern reliability.

The aftermarket space, by contrast, opens a broader spectrum of choices that speak directly to performance gains and cosmetic customization. Lightweight carbon fiber bonnets have become a staple in performance builds because they reduce front-end mass, an effect that translates into sharper steering response, quicker weight transfer, and improved acceleration characteristics. The front-end lightening is not simply about shaving kilograms; it also reshapes the car’s dynamic balance under hard driving. Vented designs, scooped heat management, and carefully tuned openings enable more effective engine bay cooling. On a track or a back‑road sprint, these features help keep the engine within its optimal thermal window, supporting sustained performance during repeated runs. While the aesthetic impact is undeniable—the exposed weave or dry‑shaped finish can transform the car’s visage—the functional gains are the core driver for many enthusiasts who choose aftermarket carbon fiber or composite bonnets.

The choice between OEM and aftermarket is rarely binary. It hinges on the car’s purpose, the owner’s budget, and the level of fit and finish that matters most. A genuine bonnet promises exacting tolerances and pristine alignment with the hood gaps, fenders, and leading edges. An aftermarket carbon fiber piece promises weight savings and striking presence, but it also commands careful preparation and hardware selection during installation. The hood panel is not a standalone piece; it interacts with hinges, latch assemblies, weatherstripping, and the hood’s support structure. In practice, a well-executed installation requires attention to paint protection at the edges, even coat thickness, and sometimes a slight adjustment to ensure the bonnet sits flush across the entire perimeter. These considerations remind us that a bonnet is a living part of the front end—one that must harmonize with the car’s overall rigidity, aerodynamics, and aesthetics.

Underlying these practical choices is a shift in how the EVO branding is perceived within the broader automotive world. The term EVO has grown beyond a single model line to symbolize a mindset: relentless refinement, an emphasis on performance envelopes, and the willingness to test limits. This mindset explains why the same suffix now surfaces in other brands’ performance narratives, signaling a lineage of high-performance engineering rather than a single chassis or model. In this light, the bonnet becomes a tactile mirror of that philosophy. It is a place where design intent—weight, airflow, and structural stiffness—interacts with material science and manufacturing precision. The result is a front end that can communicate a car’s personality with the honesty of its construction. The bonnet, in this sense, becomes a compact laboratory: measuring how a lighter panel behaves under load, how air is managed across the heat exchangers, and how the front end responds to gusts and road irregularities at speed.

For the builder who wants to blend heritage with modern performance, there is value in exploring a range of materials and configurations. Carbon fiber, for instance, pairs a dramatic weight reduction with a distinctive aesthetic that signals intent from the curb. Yet this choice invites scrutiny of durability under durability under real-world conditions. The front edge is a high-stress region; impact resistance, repairability, and paint adhesion all factor into the long-term viability of such a panel. Conversely, aluminum or composite alternatives offer a compromise between stiffness, cost, and weight, with benefits in corrosion resistance and ease of repair. The bonnet’s architecture—whether it features integrated vents, a vented dual‑pane style, or a clean, uninterrupted surface—also influences the car’s charging, cooling, and driving dynamics under demanding use. It is a reminder that performance components are not isolated upgrades; they reshape how the vehicle breathes, carries load, and responds to the driver’s input.

The dialogue between OEM fidelity and aftermarket experimentation is not simply a debate about price or prestige. It reflects a broader narrative about how enthusiasts curate a car’s character. Some owners crave the assurance that a factory‑matched panel provides, feeling more at ease when the seam lines align with factory geometry and when the finish has a new‑car gloss that lasts. Others want the drama of a visible carbon weave, the sensation of reduced mass when the car sits on its wheels, and the raw feedback of a front end that’s more reactive to throttle and steering input. Either path is legitimate; what matters is the continuity of the car’s purpose. A well‑chosen bonnet, whether OEM or aftermarket, should support the vehicle’s intended use, reinforce its handling balance, and contribute to the owner’s satisfaction with the driving experience.

For readers seeking concrete options within this spectrum, a practical stepping stone is to explore specific carbon fiber offerings that emphasize lightweight construction and functional airflow. One accessible route is to inspect dedicated catalogs that highlight customized, lightweight carbon fiber bonnets designed for performance EVO‑line chassis. The idea is to examine how vent layouts, weave patterns, and edge detailing influence both performance and fit. It is also worth noting how these parts are marketed and supported by practitioners who care about alignment with the rest of the front end’s geometry, from the hinge points to the latch mechanism and the hood’s edge profile.

If you are curious about a particular carbon fiber option that emphasizes a factory‑level finish and direct compatibility with the EVO’s bonnet region, you can explore a product page described as a brand-new original carbon fiber bonnet hood for the relevant EVO model. This resource can provide a tangible sense of what a genuine‑feeling aftermarket piece looks like, how it sits in relation to adjacent panels, and what kind of hardware or prep work is typically involved in the swap. For readers who want to weigh this path against other aftermarket choices or against a renewed OEM panel, such a page offers a practical snapshot of a living, off‑the‑shelf option.

As you navigate these choices, it helps to keep an eye on the broader engineering ethos at play. The EVO bonnet is not just a sheet of material; it is a statement about how much front-end mass a car can shed without sacrificing engine bay integrity, how efficiently air can be moved through the radiator and intercoolers, and how the front end communicates the driver’s intent at the limit. This is where the bonnet’s design intersects with the car’s overall aerodynamics, weight distribution, and mechanical reliability. The result is a front end that is as much about the car’s voice as its silhouette. For the curious reader who wants a tangible link to the modern carbon fiber option discussed above, a practical example is available through a dedicated product page that showcases a brand-new original carbon fiber bonnet hood for Mitsubishi Lancer Evolution X, offering a concrete glimpse into how such parts are presented and positioned in the market. brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x.

Finally, the broader landscape reminds us that the EVO nomenclature still carries a gravitational pull for enthusiasts who seek performance. While the EVO bonnet story began with a factory‑issued panel, it continues to unfold as owners experiment with materials, airflow, and weight at the front of the car. The journey from stock to lighter, more aggressive front ends reflects a persistent theme in modern performance culture: every component, when chosen with intention, contributes to a cohesive driving experience that blends heritage with modern engineering. For readers who want to deepen their exploration, a practical path is to consult supplier catalogs and technical notes, which offer a window into how these panels are framed, reinforced, and finished for real-world use. In the end, the bonnet remains a decisive element of how an EVO‑proof car speaks to its driver—clear, responsive, and ready to meet the road with a carefully balanced edge.

External resource reference: https://www.alibaba.com/product-detail/Customized-Lightweight-Carbon-Fiber-Bonnet_1600493788211.html

Evolution on the Front: EVO Bonnet and the Language of Electric Performance

The EVO bonnet is more than a panel. It sits at the crossroads where a storied tradition of performance engineering meets a future defined by electric power and efficiency. The term carries a double weight: on one hand, it recalls a lineage of rally bred chassis and heat management; on the other, it signals a modern vocabulary where performance is not only about fuel but about energy use, discipline, and aerodynamic finesse. In this light, the bonnet becomes a small stage where history and innovation perform a quiet duet.

The bonnet is a functional component that channels air, aids cooling, houses sensors, and contributes to structural integrity. When the same word appears on an electric platform, the focus shifts to thermal strategies for batteries and power electronics and to how packaging supports range and charging speed. EVO connotes evolution: a continual refinement of front end behavior, balance, and efficiency that honors heritage while embracing new energy realities.

In the practical realm, the EVO front end shapes decisions about materials, weight, stiffness, and aerodynamics. Lightweight panels, carbon fiber where appropriate, and precision latches all contribute to a front end that remains rigid under load while resisting drag and thermal loss. The bonnet is thus not a cosmetic prefix but a controllable piece of the chassis that participates in delivering a coherent driving experience, be it track performance or daily efficiency.

As BEV architectures mature, the EVO branding expands its meaning. It marks improved cooling for batteries, smarter thermal routing, and a packaging strategy that makes room for larger packs without compromising handling. The front end becomes a window into a brand’s engineering discipline, signaling maturity, capability, and a forward looking approach to performance that is powered by electricity rather than combustion.

In short, EVO on the bonnet is a synthesis: heritage respect, material innovation, and energy system engineering coming together to define how a car greets the air and the road in an electric era.

Weight, Wind, and Wonder: The Technological Evolution of the EVO Bonnet

The EVO bonnet is more than a simple cover for an engine bay. It is a doorway into how modern performance design fuses weight, airflow, aesthetics, and manufacturing precision into a single, purposeful component. What began as a functional lid evolved into a sophisticated system that shapes a car’s dynamic character at its core. The journey is not just about lighter materials; it is about a holistic approach to how a hood can actively contribute to performance and reliability while also signaling a brand’s engineering philosophy to the world.

Material choices mark the most visible leap in the EVO bonnet story. Traditional steel, while robust, imposes a weight penalty at the front of the vehicle that translates into slower acceleration, less nimble handling, and a higher energy cost during braking and cornering. The shift toward advanced composites, with carbon fiber at the forefront, redefines what a bonnet can do. Carbon fiber hoods, in particular, offer substantial weight reductions—often a third to nearly half lighter than their steel counterparts. This is not just about shedding pounds; it directly translates to crisper steering, improved throttle response, and more stable front-end behavior at high speeds. Lighter front weight also means better engine cooling because the overall chassis can shed heat more efficiently while the radiator and intercooler operate with greater margin. In performance-focused design, every gram saved at the nose helps the vehicle cut through air more cleanly, reducing front-end lift and allowing the suspension to work more effectively.

But the material story is only the starting point. The EVO bonnet concept embraces functional integration as a core virtue. Modern hoods no longer resemble inert lids; they act as engineered channels that actively influence how air travels around the engine compartment. Integrated air ducts begin life in the mold, forming pathways that direct cooler air to critical components such as the intercooler and charge air system. The idea is straightforward in principle—better cooling and more consistent intake air temperatures improve reliability under stress and preserve performance when the engine is pushed toward the limit. Yet realizing this in practice demands extraordinary precision. The ducts must maintain optimal cross-section and smooth transitions to minimize turbulence, all while preserving the bonnet’s structural stiffness. Advanced mold technology and tight tolerances make this possible, turning what could be a fragile, airflow-focused add-on into a robust, integrated solution that behaves predictably under extreme conditions.

The manufacturing story behind EVO bonnets is a testament to modern industrial metrology. The use of extensive mold libraries—often described as thousands of aluminum molds configured for complex geometries—enables consistent reproduction of a part that demands both lightness and rigidity. The sheer variety of shapes and thickness distributions achievable with this approach means engineers can tailor stiffness, weight, and aero behavior to specific vehicle architectures without sacrificing surface quality. In practice, this translates to a bonnet that not only clears the engine bay with space to spare but also carries a refined, even tactile, finish that hints at its performance pedigree. The craftsmanship embedded in these components goes beyond a glossy surface; it is embedded in the minute details—the precise radii of air duct entries, the smoothness of transitions, the alignment of symmetry, and how every panel edge communicates intent to the technician assembling the car. This is where engineering meets artistry, a quiet alliance that elevates the hood from a protective shell to a deliberate performance element.

Aesthetics also play a decisive role in how the EVO bonnet is perceived and valued. The best examples fuse bold visual language with practical functionality. The glossy undertones of carbon fiber, the subtle weave visible under light, and the crisp lines that echo the chassis’ geometry all contribute to a look that speaks of precision and purpose. In many cases, the hood’s surface can be finished to match OEM aesthetics, providing a seamless visual integration with factory panels, or it can be tuned for a more aggressive, track-ready stance. The marriage of performance and style in these hoods captures a broader consumer desire: owners want a component that signals capability at a glance while also delivering tangible, measurable gains on the road or the race track.

Beyond the technical specifics, the EVO bonnet embodies a broader industry trend. The term EVO has evolved from a model lineage to a versatile badge associated with high-performance engineering across multiple brands. It signals a commitment to pushing the envelope—lighter weight, smarter air management, and more disciplined manufacturing processes. This broader badge language reinforces the bonnet’s role as a key performance enabler, not merely a cosmetic upgrade. As electric and hybrid formats continue to mature, the bonnet still serves as a site where air management, mass distribution, and thermal strategy intersect. Even as powertrains evolve, the bonnet remains a crucial interface between the car’s breathing apparatus and its aerodynamics. The design philosophy—remove weight where it hurts, channel airflow where it helps, and present a finish that invites scrutiny—remains remarkably consistent across generations and platforms.

The practical implications of these advancements extend to reliability and everyday usability. A lighter bonnet reduces the lumpiness of front-end dynamics during rapid direction changes, enabling more precise handling inputs from the driver. It can also improve brake fade characteristics by lowering the initial energy demanded from the suspension and steering systems during high-speed deceleration. The integrated ducts, while optimized for performance, do not compromise accessibility for routine maintenance; in fact, the cooler, more stable engine environment can reduce thermal stress on components that endure repeated cycles. The aesthetic signal of a carbon fiber or similarly engineered hood can positively influence resale value, reinforcing a perception of quality and technological sophistication. In a market where visibility and perceived value often count as much as raw performance, such a hood becomes a meaningful differentiator.

The chapter’s thread returns to a simple, but essential, idea: the bonnet is a microcosm of how modern engineering operates when performance, reliability, and style converge. It demonstrates that materials science, fluid dynamics, and precision manufacturing are not isolated disciplines but complementary facets of a holistic design philosophy. The hood’s evolution mirrors the broader trajectory of performance vehicles—where every component is conceived as an integrated system, where weight is trimmed with surgical precision, where airflow is choreographed with intention, and where aesthetics are inseparable from function. For enthusiasts, engineers, and designers alike, the EVO bonnet represents a compact but powerful example of how modern mobility continues to redefine the meaning of speed. The hood’s evolving role invites a deeper appreciation for the unseen labor that makes a car feel responsive, confident, and expressive every time its engine wakes up beneath a crafted carbon surface.

For readers who want to visualize the practical instantiation of these ideas, a look at the carbon-fiber bonnet page provides a concrete reference to how such components are presented and marketed in contemporary automotive ecosystems. The page illustrates how the balance of weight, stiffness, airflow, and finish can be harmonized in a single part, echoing the themes described above. Interested readers can explore the concept further through that dedicated resource, which offers a tangible example of how the engineering priorities discussed here translate into a purchasable product. carbon-fiber bonnet hood page.

Externally, the bonnet’s development resonates with a broader engineering ethos observed across performance-focused brands. It highlights how teams increasingly rely on digital design tools, high-fidelity simulations, and rapid prototyping to validate aero and thermal strategies before committing to mass production. The result is a hood that not only reduces weight and drag but also reinforces the vehicle’s stance and identity. In this sense, the EVO bonnet illustrates a key principle of modern automotive engineering: the best components are those that earn their keep through measurable gains in speed, efficiency, and durability while delivering a visual and tactile cue of advanced craftsmanship. This convergence of performance and presence helps explain why the EVO bonnet continues to captivate builders, drivers, and collectors who value precision as much as prestige. A hood that can deliver both measurable performance benefits and an unmistakable design language embodies the essence of thoughtful engineering, where even a small component has a story to tell about how speed is achieved and preserved.

External resource for further reading on the broader concept of performance bonnet design can be found here: https://www.made-in-china.com/products/2029768440-1143795297/Mitsubishi-Evo-Bonnet.html

EVO Bonnet as Economic Engine: The Interplay of Weight, Safety, and a Growing Market for High-Performance Hoods

The EVO bonnet—in its most immediate sense a hood designed to fit the Mitsubishi Lancer Evolution lineage—has become more than a simple automotive panel. It sits at the intersection of engineering ambition, safety regulation, and a broader market dynamic that rewards lightweight, aerodynamically informed, and safety-enhanced components. The automotive bonnet market, which reached around 11.54 billion USD in 2025, is projected to expand at a robust pace, with a compounded growth rate of just over 10 percent from 2026 to 2033. This trajectory is not merely about cosmetic upgrades or brand symbolism; it reflects a systemic shift toward values that matter to both manufacturers and consumers: lighter weight, smarter safety features, and smarter airflow management that together tune performance, efficiency, and cost of ownership. A parallel stream of growth focuses on active bonnet systems, an area aimed at reducing pedestrian injuries in collisions. This segment is expected to grow even faster in relative terms, signaling how safety technology is increasingly woven into the hood’s function rather than treated as a separate add-on. In practical terms, this means an increase in research and development investment, a more complex value chain, and a willingness among automakers and aftermarket suppliers to accept higher production costs in exchange for higher perceived value and the prospect of premium pricing.

The pull toward premium materials and advanced technology is clear. Carbon fiber hoods, for instance, have gained traction in high-performance applications where every gram of weight saved translates into measurable gains in acceleration, handling, and cooling efficiency. The lighter mass reduces tire load and suspension stress while enabling more aggressive aero packaging, particularly around air scoops and ducting that feed the intake and intercooler. In racing-inspired or torque-rich architectures, such hood designs also contribute to cooler engine breathing, allowing the turbocharged and high-boost setups to operate with more consistent charge temperatures. The economic logic is straightforward: if the hood can contribute even modestly to horsepower and throttle response, and if it also improves reliability under repeated heat cycling, buyers are willing to pay a premium for the combination of performance and durability. This is the essence of value-driven pricing in the premium hood segment, where manufacturing costs rise with the adoption of prepreg materials, automated layup processes, and precision bonding, but margins widen as consumers equate these features with long-term performance gains and enhanced protection for critical engine components.

Alongside material choice, the industry’s embrace of smart safety and performance-focused design has implications for the entire supply chain. Active hood concepts, sensors, impact-absorbent structures, and fail-safe latching mechanisms introduce a layer of complexity that requires tighter integration with bumper, grille, sensor arrays, and pedestrian-detection systems. In markets like Europe and North America, regulators increasingly favor such integrated safety approaches, driving automakers to accelerate development timelines and adopt standardized testing protocols. This regulatory pressure translates into higher capital expenditure for tooling, test rigs, and quality assurance, but it also opens opportunities for suppliers who can deliver turnkey safety modules or modular hood assemblies that meet evolving standards without sacrificing performance. The cost structure shifts as well: upfront tooling and material investments rise, but the potential for premium pricing and higher-margin aftersales opportunities helps offset these costs over the product’s lifecycle. The market’s trajectory, then, is less about a single part and more about a system-level approach where the hood acts as a critical node in performance, cooling, and safety.

Directly relevant to enthusiasts and professional tuners alike is how the EVO bonnet lineage translates into real-world offerings. The engineering challenge is to balance strength and stiffness with weight reduction, while ensuring compatibility with a growing set of fasteners, seals, and reinforcement structures. OEM and high-end aftermarket producers often pursue material choices that promise improved engine breathing and heat management, alongside aesthetic appeal. In this space, one can observe a shift toward specialized, lightweight hood designs that incorporate air intakes or scoops designed to channel cooling air into the intake system, thereby supporting higher horsepower targets and more efficient combustion. While the broader market embraces these trends, the EVO-specific applications underscore a practical point: the bonnet’s role extends beyond mere enclosure to active participation in engine performance and reliability.

For those looking to explore the premium side of the EVO bonnet ecosystem, the emphasis on carbon fiber and other lightweight composites is telling. The premium segment does not merely chase a slimmer silhouette; it invests in coatings and surface treatments that protect the underlying composite from environmental exposure and heat-related degradation, thereby improving longevity and maintaining a showroom finish. Technology adoption here is not purely cosmetic; protective coatings and surface engineering contribute to the durability of a hood that endures the thermal cycles of forced induction engines and track-minded use. And as consumer willingness to pay for high-quality materials and longevity grows, manufacturers and aftermarket suppliers find opportunities to capture higher margins by delivering integrated solutions that combine weight savings, airflow optimization, and protective longevity.

The EVO bonnet narrative thus embodies a broader market truth: badge-driven performance signals are increasingly supported by tangible engineering, safety, and material science. The EVO naming convention has migrated beyond a single automaker’s model line into a broader high-performance lexicon that signals advanced engineering—while still anchoring itself in the practical realities of fitment, warranty, and real-world durability. For those who want to see a concrete example of how premium carbon-fiber hoods are positioned in the market, consider the carbon-fiber bonnet pages dedicated to performance applications. These pages illustrate how the premium segment translates engineering into tangible performance gains and durability, linking form and function in a way that resonates with drivers who demand more from their vehicles. See the carbon-fiber bonnet page for Mitsubishi Lancer Evolution X for a representative case of how premium hood design translates into real-world performance gains.

In turn, the EVO bonnet story ties back to a larger ecosystem of parts and services that shape the automotive aftermarket. The premium hood is not a standalone product; it interacts with latches, reinforcement panels, sealants, coatings, and the body’s structural geometry. As buyers increasingly seek not only a lighter hood but one that breathes better and protects the engine under aggressive driving regimes, suppliers are incentivized to invest in integrated design approaches. The result is a market that rewards those who can deliver reliable performance without compromising on safety, durability, or fitment. The growing emphasis on value-added features—improved airflow, safer hood mechanisms, and longer-lasting finishes—helps explain why the premium segment continues to command pricing that reflects both performance and protection.

For researchers and practitioners seeking a broader market perspective, a global market analysis offers a comprehensive view of regional dynamics, competitive landscapes, and segment forecasts through 2033. This external resource provides a structured synthesis of where weight-conscious performance components and safety-focused hood technologies are headed across major markets. https://www.grandviewresearch.com/industry-analysis/automotive-bonnet-market-size,-share-and-trends-analysis-report-by-material-by-application-by-region-and-segment-forecasts-2026-2033

The Hood of Evolution: How the Bonnet Became a Symbol of Performance, Craft, and Car-Culture Identity

The hood is often the quiet theater where a car’s story unfolds. It shields the engine, it provides a silhouette that tells you something about the machine beneath, and, in the hands of enthusiasts, it becomes a canvas for evolving identity. In this chapter, we explore the evo bonnet not as a single component but as a nexus where engineering ambition, aesthetic taste, and social practice meet. The evo bonnet—a term that evokes speed, refinement, and advancement—reads like a shorthand for a broader culture that values lightweight performance, heat management, and the shared language of modification. It is a topic that sits at the confluence of mechanical detail and communal storytelling, offering a lens on how people relate to machines that are more than their parts.

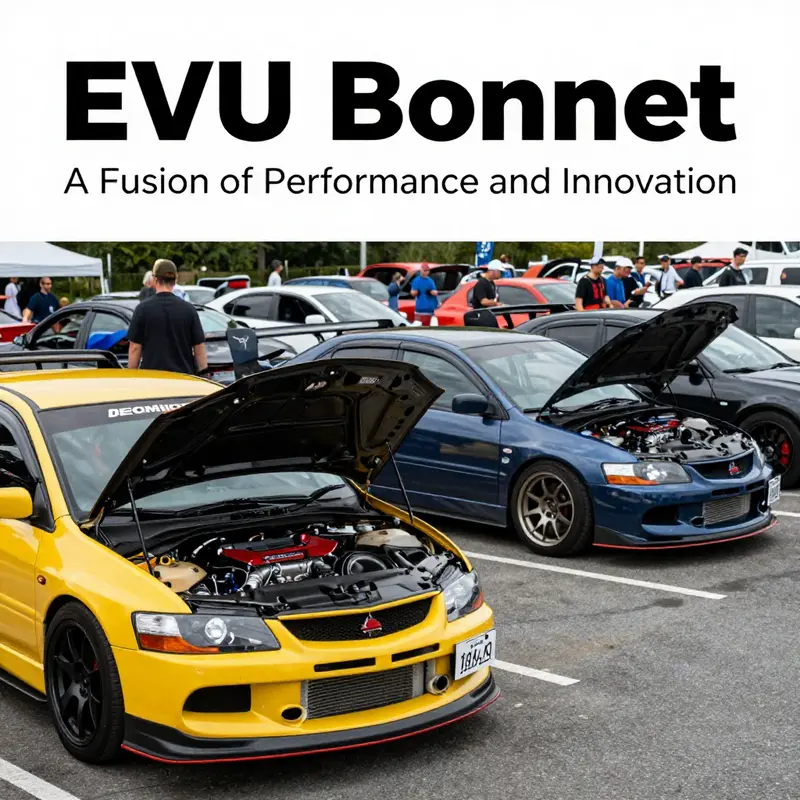

At its core, the bonnet is a crucial interface between powertrain and environment. Its design influences heat dissipation, aerodynamics, and weight, but it also signals intent. A hood with vents or a sculpted surface communicates a readiness to push an engine toward its limits. Carbon-fiber hoods, for example, are not merely fashion statements; they embody a philosophy of efficiency. The light, stiff weave of carbon fiber reduces mass—an advantage in acceleration, handling, and braking dynamics—while also resisting the fatigue that comes with repeated heat cycling under track or road use. Yet the material choice also carries social meaning. It is a visible commitment to a high-performance ethos, a way to mark a vehicle as belonging to a community that cares about weight, strength, and the craft of fabrication.

In many tuning cultures, the hood becomes a stage for experimentation, a place where form and function meet in practical decisions. A hood might incorporate vents that channel hot air away from the engine bay, or it could feature a recessed profile to clear tall turbochargers or intercoolers. Either way, the bonnet tells the observer that the car is not merely about making power; it is about managing power responsibly. The latching mechanism—a seemingly humble detail in the grand scheme of performance hardware—plays a critical role here too. A robust latch ensures reliability under hard use, while a lighter, quicker-action latch can shave milliseconds off a vehicle’s response time at the drag strip or on a circuit. These choices ripple outward into how a community shares information. When enthusiasts discuss these components, they talk not only about measurements and fitment but about the feel of engagement—the tactile satisfaction of a hood that closes with a confident snap, the crispness of a carbon surface under bright lights, and the visual cue that a car was built with intention.

The evo bonnet also sits within a broader dialogue about modernization and identity. The term evo, or evolution, carries a promise: a continual process of improvement, refinement, and adaptation. In the modern car landscape, that promise often spills beyond mechanical upgrades into branding and naming conventions. A suffix or label that signals evolution can lend a sense of premium or advanced status, whether on combustion-engine models or on new electric platforms that redefine what performance means in the twenty-first century. In that sense, the bonnet is more than a physical cover; it is part of a narrative about how engineers and drivers imagine the future of mobility. It suggests a community that values not only the thrill of speed but the craft of tuning, the discipline of maintenance, and the social rituals that accompany sharing knowledge about how to coax more from a machine.

This cultural texture is reinforced in the everyday lives of enthusiasts. Car meets, social media posts, and DIY tutorials transform the bonnet from a practical piece of hardware into a symbol of skill and belonging. When a driver presents a modified hood, they are planting a flag in a network of peers who understand the language of heat management, material science, and the nuances of fitment. The hood becomes a passport to conversation—from questions about finite tolerances and paint protection to debates about the trade-offs between stiffness and weight. In communities built around performance cars, the bonnet is a recurring motif—one that carries stories of late-night adjustments, road-test sessions, and the quiet pride of turning a plan into a measurable improvement.

The social meaning of the evo bonnet grows more complex when one considers how naming conventions shape expectations. In an era when suffixes imply performance or cutting-edge design, the bonnet becomes part of a larger vocabulary that enthusiasts use to describe their objects of affection. A hood that hints at lightweight construction, efficient cooling, and a deliberate, engineered look speaks to a shared ideal: that performance is both a technical and a social achievement. At the same time, the bonnet sits within markets that valorize customization and accessibility. The aftermarket ecosystem offers a spectrum of options—from basic protective skins to full, engineered panels—each with its own cost, weight, and installation profile. This ecosystem invites newcomers and veterans alike to participate—to learn, trade, and contribute to a living body of knowledge about how to balance speed, reliability, and personal expression.

A thread worth tracing is how the evo bonnet relates to the current moment in the broader automotive landscape. As electric platforms become more prevalent, the idea of evolution takes on new meaning. The connotations of speed, control, and refinement persist, but the engineered pathways shift. In some contemporary electric models, a naming choice that incorporates evo-like language signals a brand’s attempt to align new propulsion technology with a heritage of performance discipline. The bonnet, even when it no longer houses a traditional internal combustion engine, remains a crucial interface for thermal management and a visual cue of technical intent. The cultural resonance endures: the bonnet remains a space where people observe, adjust, and celebrate the ongoing transformation of what performance looks like in the age of electrification. Acknowledging this continuity helps explain why people invest in high-quality panels, vents, and latching systems, even when the underlying powertrain is changing shape.

For readers curious about contemporary carbon-fiber bonnet options, see the carbon-fiber bonnet page. This internal resource reflects how the community talks about fit, weight, and finish in practical terms, while also illustrating how optics—how the surface catches light and how a seam line reads from a distance—conveys a story of care and competence. This is not mere cosmetics; it is a conversation about the relationship between a car’s body and its performance behavior. In the same spirit, the bonnet acts as a shared classroom where people compare techniques for prepping surfaces, protecting coatings, and ensuring that aftermarket components integrate cleanly with factory hardware and alignment tolerances. The social dimension is inseparable from the technical one: a hood is always a statement about who you are as a driver, a builder, and a member of a community that venerates the careful balance between speed and stewardship.

As the chapter closes on this examination, the evo bonnet emerges not simply as a piece of metal or a sheet of carbon fiber but as a living artifact of performance culture. It embodies practical decisions about heat, weight, and airflow while also radiating the social energy of communities built around shared curiosity and craft. The hood becomes a microcosm of automotive identity—the place where engineering ambition, personal aesthetics, and collective storytelling converge. This is why, even as technology evolves and powertrains shift, the bonnet remains a potent symbol of evolution in every sense: a testament to how people imagine, shape, and celebrate the ongoing journey of performance.

External reference: https://en.wikipedia.org/wiki/Hood_(car)

Final thoughts

The EVO bonnet serves as much more than just a functional automotive component; it is a symbol of performance, innovation, and community. From its establishment as a premium feature for the Mitsubishi Lancer EVO series to its representation in modern electric vehicles like the BYD ATTO 3 EVO, the evolution of the EVO bonnet mirrors shifts in automotive trends and consumer preferences. The interplay of technology and design is shaping the future of these components, while economic dynamics influence the market landscape. Meanwhile, the cultural significance of EVO bonnets in automotive enthusiasts’ circles fosters a sense of identity and pride. As the automotive industry continues to evolve, the legacy of the EVO bonnet will undoubtedly persist, driving innovation and passion for years to come.