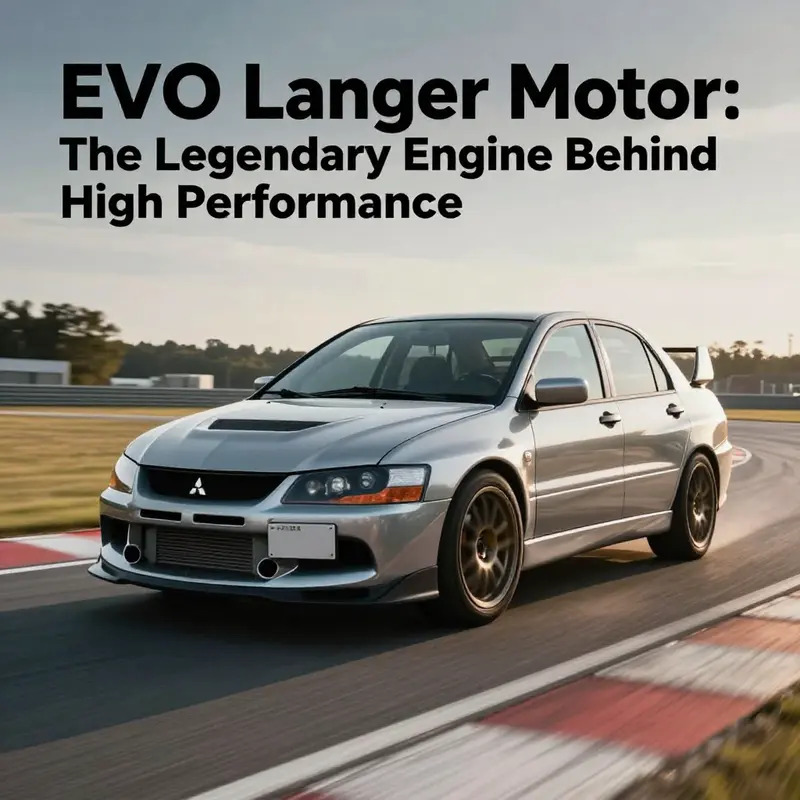

The EVO Lancer Motor, integral to the renowned Lancer Evolution series, has been at the forefront of automotive performance since its inception in the 1990s. This high-performance engine has not only evolved through different generations, but it has also established itself as a benchmark in the racing community for its durability, tuning potential, and technological advancements. This article delves into the core engine models that drive the Lancer Evolution, explores the advanced technical specifications that define their capabilities, and offers insights into their remarkable performance metrics across generations. Additionally, we will highlight the cultural significance of the EVO engines, including their modification potential, before concluding with the historical impact and engineering legacy they have left behind in the automotive world.

Heart of the Rally: Core Engine Legacies in the EVO Lancer Motor

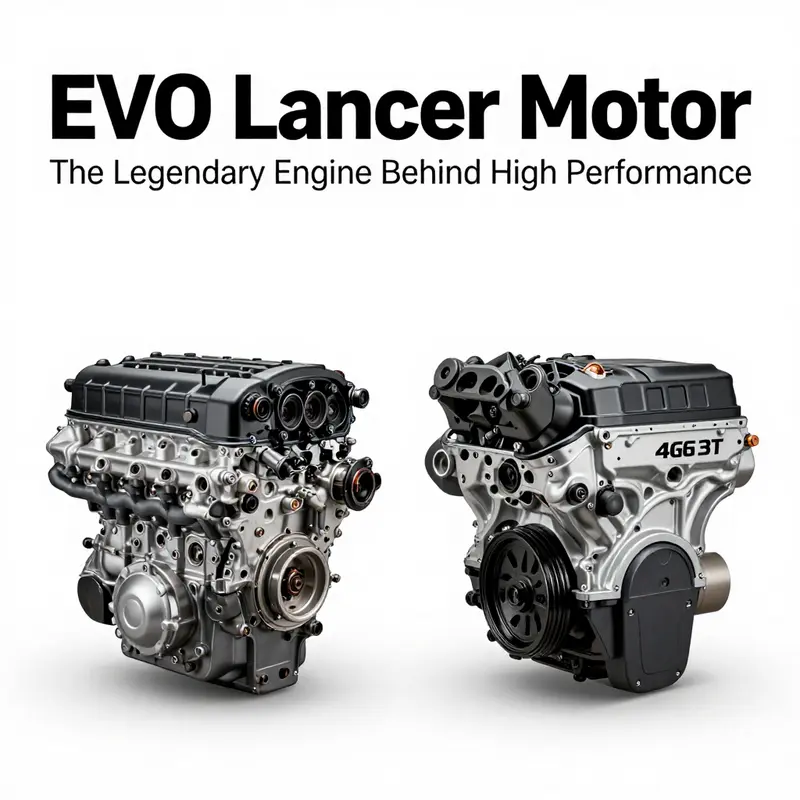

The engine is more than a powerplant in the EVO Lancer line; it is the beating heart that stitches together rally urgency with road-day reliability. Across generations, Mitsubishi’s EVO family kept evolving its core engines while preserving a stubborn sense of identity—a blend of race-bred intent and practical engineering that turned the Lancer Evolution into a benchmark for what a production car could be when pushed to the edge. At the center of that story are two standout powerplants that define the chapter: the 4G63T that powered the earlier generations and the 4B11T that closed the corridor with a new technological vocabulary. Understanding these engines means tracing how materials, forced induction, and electronic control rewired the relationship between speed, response, and durability on both the track and the street.

The 4G63T began life in the EVO line as the core propulsion for Evo I through Evo VI. It is a turbocharged inline-four that married a compact displacement with a robust bottom end and a capable turbocharger to produce a competitive blend of power and responsiveness. In its heyday, this motor became the symbol of Mitsubishi’s rally engineering on the road: a compact, torquey unit that could be tuned to push well beyond stock figures, proving its mettle in factory rallying and in the hands of countless enthusiasts who pursued more drive for less weight. The engine’s durability soon became part of its legend. Even as owners pushed boost, upgraded intercoolers, and recalibrated ECUs, the 4G63T displayed a resilience that encouraged aggressive modification without surrendering reliability. It wasn’t just about raw numbers; it was about how those numbers translated into a linear, predictable surge that could be harnessed through the car’s sophisticated all-wheel-drive system.

From Evo I through Evo IV, the 4G63T cemented a reputation for strength. The design incorporated reinforced internals and a tuning-friendly architecture that could handle the higher cylinder pressures associated with turbocharging. As generations advanced—particularly around Evo IV’s refinements—the engine showed visible gains in response and mid-range torque. A common memory among enthusiasts is the way the 4G63T delivered a surge of torque that arrived with a willingness to stay strong as boost rose. In the era when power outputs were often framed by regulation rather than marketing slogans, this engine proved capable of delivering roughly 250 horsepower in stock form, with torque around 300 Nm. The figurebook often reflected a “gentleman’s agreement” mindset that capped outputs publicly, yet the engine’s real-world capabilities lived in a zone where drivers felt the car’s performance as a coherent, controllable force rather than a sudden spike. The chassis and the drivetrain were tuned to exploit that surge, enabling corner-exit acceleration that could threaten rivals with a well-managed balance between traction and inflation of speed.

The Evo VIII era introduced a significant evolution in breathing and response with the advent of a variable geometry turbo (VGT). This was more than a technical trick; it addressed a fundamental driver complaint: turbo lag. With VGT, the turbine could alter its geometry to optimize flow at lower engine speeds, reducing lag and delivering quicker throttle response as boost built up. The effect was a more usable midrange and a broader, more predictable power curve. For many, the Evo VIII and IX represented the point at which Mitsubishi’s approach to the 4G63T felt complete: a robust base engine, boosted by intelligent aerodynamics and electronics, with a liveable torque band that could be exploited in a variety of driving styles. The result was not just higher numbers on a spec sheet, but a more confident, race-inspired drive that rewarded smooth transitions, precise gear selection, and a willingness to push the car into a corner with fuel and steering in sync.

The performance story of the 4G63T is also a narrative of evolution in architecture and durability. Across the Evo I–VI, the engine’s block, crankshaft, and pistons were reinforced to withstand dramatic increase in boost pressures. The bottom end’s resilience accompanied a gearbox and drivetrain that could transfer that energy to the wheels with a sense of predictability that made the car approachable for ambitious drivers. It was common to see these engines tuned—not simply to chase peak horsepower but to expand the usable power band and to maintain linearity as boost rose. In practice, many Evo drivers learned to harness the engine’s strength through an integrated play of turbo management and ECU calibration, turning what could be a sharp power spike into a controllable, race-inspired acceleration profile.

Yet even as the 4G63T defined the early EVO ethos, Mitsubishi prepared the next leap in engine technology as emissions and efficiency constraints intensified. By the time the Evo X arrived, the company had designed a new 2.0-liter powerplant to fulfill markedly different goals. The 4B11T that powered Evo X offered a clean sheet approach inside a compact, all-aluminum block. It was a case study in modern engineering: lighter weight without sacrificing rigidity, a design intent that enhanced handling and responded more quickly to throttle input. The 4B11T also featured Mitsubishi’s MIVEC variable valve timing technology, a control strategy that optimized valve lift and timing for both efficiency and performance. The introduction of MIVEC helped optimize air flow across a broad range of engine speeds, enabling better fuel economy in daily driving while preserving the punch of a turbocharged response when the accelerator was pressed firmly.

The numbers tell a part of the story. The 4B11T’s factory output landed in the high 290s to low 300 horsepower range in various trims, with torque figures stretching from the mid-300s to the low 400 Newton-meters depending on model year and specification. This represented not merely a step up in official figures but a transformation in how the engine could be paired with the EVO’s drivetrain—especially in terms of throttle mapping, turbo response, and the car’s overall weight distribution. The shift to an aluminum block did more than reduce weight; it freed the engine to rev with a more immediate sense of urgency and responded more cleanly to the electronic control system that managed boost, fuel, and ignition. In this sense, the 4B11T was not only a different engine; it was a different driving experience—more immediate, more responsive, and better calibrated for the kind of high-demand driving that the EVO lineage has always chased.

An additional attribute that shaped the 4B11T’s character was its combination of MPI and TPI fuel delivery strategies. The multi-point injection of fuel paired with a secondary injection approach provided a more precise, flexible fuel delivery under boost and at lower engine speeds. In a sports car meant to sprint from a corner exit to the next apex, such fuel control translates into improved throttle feel and more linear torque delivery. This is part of what allowed Evo X to feel both tractable in daily use and brutally quick on a closed circuit. The engine’s electronic orchestration did not stand alone. It was part of a broader system—MIVEC timing, variable intake runners, and an advanced ECU mapping that harmonized with Mitsubishi’s all-wheel-drive architecture to deliver confidence through corners. The upshot was a powerplant that could sustain spirited driving with a measured efficiency, rather than a pure peak-number machine that demanded sacrifice in daily use.

Within this lineage, the maintenance and durability narrative also shifted. The 4G63T’s reputation for ruggedness translated into a community of builders who pushed the envelope with larger turbochargers, intercoolers, and sophisticated engine management. The 4B11T, by contrast, required new considerations around aluminum block heat management and the endurance of newer internal components under higher boost and higher rpm. Reinforced cylinders and crank assemblies remained a theme, but the equation now included electronic reliability and cooling efficiency as well. Engine builders often look to the billet-block upgrades for the 4B11T as a way to extend the platform’s life in high-boost configurations. A notable upgrade path is the 4B11T billet block, which many builders see as enabling higher boost and long-term reliability in tuned applications. It is a reminder that the EVO’s core motors are not merely power sources; they are platforms that invite engineering creativity while demanding disciplined engineering discipline.

The cultural footprint of these engines is inseparable from their technical footprint. The 4G63T became a benchmark engine in the world of production-based rallying and tuning culture. Descriptions from mainstream outlets over the years have called it one of the most iconic production racing engines, a label earned through years of reliability under pressure and through countless stories of clubs building ambitious, street-legal machines that could still survive a rally-like assault on a windy back road. The 4B11T, meanwhile, closed the chapter with a modernized approach—lighter, electronically sophisticated, and capable of delivering substantial power with a more refined torque curve. This progression is more than a list of specifications; it is a narrative about how engineers, drivers, and fans reimagined what a high-performance production engine could deliver while still maintaining a sense of daily usability.

In the broader arc of the EVO story, these engines illustrate an essential truth: performance in this family was not built around a single device but around a philosophy of engineering integration. The engine did not stand alone. It spoke to the car’s driveline architecture, its weight balance, its chassis stiffness, and its traction control logic. The All-Wheel Drive system worked in concert with the engine’s torque curve to deliver a controlled, predictable surge that could be coaxed into a race-like rhythm. That harmony is why generations of enthusiasts still study these engines with reverence and why the EVO line remains a touchstone for conversations about performance tuning, reliable power, and the art of delivering speed through engineered symmetry. The legacy continues to illuminate how a powerplant can be both a technical achievement and a cultural touchstone, shaping not only how a car performs but how a community imagines the very idea of driving enthusiasm.

For readers who want to dig deeper into the technical breadth of these engines, Autocar’s engine-specs overview provides further context on how the 4B11T compared with contemporaries in the era. External resource: https://www.autocar.co.uk/article/mitsubishi-lancer-evolution-x-engine-specs

The Heart of Performance: Tracing the EVO Lancer Engine from 4G63T to 4B11T and the Drive That Shapes Mastery

The engine at the heart of the EVO Lancer’s legend is more than a powerplant. It is the physical manifestation of a sprinting discipline—an intricate dialogue between combustion, forced induction, and drivetrain choreography that has evolved through generations as Mitsubishi chased ever tighter control, harder acceleration, and more precise handling. Across the lineage, the core ethos remains clear: a compact, turbocharged four with a willingness to yield extraordinary performance when paired with a sophisticated all‑wheel-drive system. The story begins with a 2.0‑liter turbocharged inline‑four that set the template for the era, and it continues with a modern, lighter, more electronically integrated powertrain that redefined what a production sedan could deliver on demand. To understand the EVO’s engine is to understand the car’s charisma—its ability to respond to throttle input with immediacy, to deliver high‑rpm vitality in a straight line, and to maintain traction through corners that might trip a less disciplined performance car. It is not an exaggeration to say the engine and the chassis are locked in a mutual, ever‑advancing conversation, each generation pushing the other toward faster, more controlled metering of power in real world conditions. The journey through the EVO’s powerplants is a tour through a shifting balance of torque, boost, and precision fuel delivery, all tethered to an all‑wheel-drive platform that translates that engineering into a coherent, operable experience for the driver.

In the early days, the EVO’s propulsion was defined by a robust 2.0‑liter turbocharged four with a reputation for durability and a hunger for upgrades. This was the era of the 4G63T, a powerplant that could surprise with its willingness to play to the tuner’s hand. The engine’s architecture—an inline four with generous displacement for its class, a robust bottom end, and a turbocharger that could respond decisively—made it a prime candidate for performance experimentation. The resulting combinations of turbo sizing, intercooling efficiency, and exhaust flow created a momentum that owners and builders could feel as soon as the accelerator opened. The power output, modest by later standards but resonant with immediate response and controllable delivery, invited a culture of enhancement. It is telling that the 4G63T earned a nearly mythic status in the tuning scene; the so‑called “holy grail” engine for those who wanted to push a street car toward the track without chasing an entirely bespoke powerplant. The engine’s strengths lay not only in peak numbers but in the predictability of its character: a linear ramp of boost, a willing top end, and a torque curve that rewarded confident throttle application rather than frantic revving alone.

With each successive generation, Mitsubishi tightened the engine’s integration with the EVO’s all‑wheel drive system, recognizing that traction is a function of both power delivery and grip. The earlier EVOs leaned into the synergy between turbo boost and four‑wheel torque management, where the engine’s torque helped—or occasionally challenged—the differential architecture that governs how power is apportioned to the front and rear axles. The result was a dynamic that rewarded precise throttle control, steering inputs, and a chassis that could exploit the engine’s torque to rotate the car through corners rather than simply push straight ahead. As the lineup progressed into the mid‑2000s, the 4G63T family continued to evolve in response to performance benchmarks and regulatory expectations. The revisions across Evo V, Evo VI, and Evo VII refined air handling, cooling strategies, and internal components to withstand higher boost pressures and sustained high‑rpm operation. This was not mere incremental tuning; it was a recalibration of how the engine could live at the edge without a brittle boundary between performance and reliability.

A turning point arrived with the emergence of variable geometry technology within the turbocharger lineup. Beginning with the Evo VIII, the installation of variable geometry turbochargers sharpened the engine’s low‑ to mid‑range response. Where the earlier setups could exhibit a hint of turbo lag, the VGT arrangement allowed the turbo to spool more quickly and smoothly, delivering usable torque earlier in the rev range while preserving top‑end breath for higher speeds. The effect on handling and driving experience was palpable: the engine felt more eager to respond to light footwork and more predictable as boost rose through the midrange. That subtle but meaningful refinement sits at the heart of EVO’s identity—an acknowledgment that real performance isn’t just about peak horsepower but about the confidence a driver feels when requesting power across the full spectrum of road conditions.

The jump to the Evo X era marks a significant architectural shift that mirrors a broader industry move toward tighter integration of chassis, turbocharging, and fuel delivery. The core engine in this period became a new 2.0‑litre unit—an all‑new design that stepped away from the venerable 4G63T in favor of a modern, aluminum block configuration and a more sophisticated fuel system. The 4B11T engine retained the compact, high‑revving nature that EVO owners expect, but it leaped forward in terms of weight saving and electronic control sophistication. Aluminum construction reduced mass, contributing to sharper throttle response and less inertia in the rotating assembly. The engine’s fueling strategy moved from traditional port injection to a more advanced system that incorporated direct injection in addition to conventional methods, upgrading combustion efficiency and enabling more aggressive timing and boost while preserving fuel economy. This dual‑injection approach speaks to Mitsubishi’s recognition that modern performance engines must combine precision fueling with the ability to scale output across a broad operating window.

If the 4G63T represented a raw, reliable pathway to power, the 4B11T embodied a refined, electronically aware approach to delivering that power. The engine’s bore centers and piston geometry were revisited to handle elevated pressures and temperatures generated by the turbocharging and the modern injection strategy. The cooling system, too, was redesigned to meet the heat management demands of higher boost and tighter ignition control. An integrated intercooler and a sophisticated cooling circuit were engineered to keep intake temperatures consistent, ensuring that air density remained favorable even under sustained load. All of this contributed to responding more linearly to throttle input, offering a smoother torque curve and more precise power delivery at the moment of demand. In practice, drivers could press the accelerator and feel immediate, steady response rather than a delayed surge, which translated into more predictable cornering, steadier exit from turns, and a greater sense of control over the car’s dynamic balance.

Embedded in this evolution is a broader story about how performance culture evolves alongside technology. The EVO’s engine has always thrived because it didn’t exist in isolation; it grew up with an all‑wheel drive system that could exploit its capabilities. The drivetrain was more than a mechanism for delivering power; it functioned as an intelligent partner that modulated torque to the wheels in real time, using active differentials and sophisticated stability control to maintain traction and steering feel. The result is a dynamic where the engine’s output, turbo response, and fuel strategy are not simply about peak horsepower but about how those factors combine to translate intent into motion on the road. This is why the EVO is remembered as a benchmark: it demonstrated how a performance engine can coexist with an AWD architecture in a way that makes the car both exhilarating and controllable in real world driving.

From a performance and tuning perspective, the story of the EVO engine is also about accessibility. The 4G63T era established a cultural baseline in which a broad community of enthusiasts could experiment—turbo upgrades, intercooler improvements, exhaust tuning, and ECU recalibration—without sacrificing reliability. The later transition to the 4B11T did not erase that spirit; it elevated it. With a lighter block, modern injection systems, and advanced electronic control, the foundation remained approachable for skilled tuners yet offered a wider envelope for factory‑prescribed performance tuning. The result is a powertrain that invites modification not just for more peak horsepower but for more usable torque delivery across a broader band, which is exactly the kind of characteristic that feeds a car’s driving character.

In addition to the mechanical and electronic innovations, the EVO engine’s development tells a deeper narrative about engineering philosophy. Mitsubishi’s approach blended raceproof engineering with a driver‑centric acoustics and feel. The sound of the turbo spooling, the crispness of the intercooler’s air intake, and the way the engine breathes as it climbs through the revs—these elements create an aural map of performance that connects the driver to the car’s physics. It is a feedback loop that teaches restraint and precision: you learn to time your shifts to keep the engine in its sweet spot, to adjust your line through corners to maximize traction, and to utilize the AWD system as part of a larger choreography between throttle, steering, and brake modulation.

Ultimately, the EVO engine is a chronicle of technological evolution tempered by a singular driving philosophy. Its early years celebrated robust torque and immediate boost; its middle years refined response with variable turbine geometry; its latest chapter embraced lighter materials, advanced fuel delivery, and a high‑tech control ecosystem. Across that arc, one constant remains: the engine isn’t merely about moving a mass of metal and air. It’s about translating driver intention into controlled motion. It’s about the way boost maps onto a chassis that can feed that energy into the road, the way electronic safeguards keep that energy from becoming unpredictable, and the way the whole package feels when you twist the key and acknowledge that you are about to play a long game with a machine that has learned to think and react with you. The EVO’s powertrain is not a static set of numbers; it’s a living, evolving relationship between engineering, regulation, and human ambition. That is the engine’s true legacy: a lineage that pressed forward with each new generation, always asking, in both calm and chaos, how to deliver speed with such composure that the road itself seems to yield to the driver’s intent.

For readers who want to dive deeper into the engineering mosaic that underpins this lineage, a focused look at the newer powerplant’s internal components—such as a billet block designed for higher rigidity and reliability—offers a tangible glimpse into how contemporary performance engines are built to breathe more freely under pressure. 4B11T billet block captures the spirit of this ongoing refinement, illustrating how modern successors maintain core strengths while embracing lighter construction and more exacting tolerances. The end result is a powertrain that still speaks in the same language of drive and control, yet does so with a vocabulary that speaks to today’s electronics, materials science, and energy efficiency.

External resources can broaden the technical picture beyond the EVO’s own pages. For a comprehensive overview of how these engines translate their specifications into real‑world performance, a detailed, industry‑oriented technical guide provides context on tuning potential, kit compatibility, and how such powertrains respond to upgrades across different generations. This broader perspective helps situate the EVO engine within the wider landscape of performance engineering and race‑inspired production cars. You can explore a broader technical guide here: https://www.motortrend.com/cars/mitsubishi/lancer-evolution/technical-guide/

From Rally-Bred Rhythm to Hybrid Horizon: The Evo Lancer Motor Through Generations

The heart of Mitsubishi’s Lancer Evolution lineage has always been more than a single component; it is a living tapestry where engineering discipline meets rally-writ DNA. Across generations, the Evo’s motor has narrated a story of relentless refinement, not through a single leap, but through a sequence of calibrated improvements that kept pace with evolving race track demands and increasingly stringent efficiency targets. In the earliest years, the 2.0-liter turbocharged flat-four, known within the enthusiast world as the 4G63T, became the winning tempo for a car that lived at the edge of grip and precision. This engine was more than power on paper; it embodied a compact philosophy: maximize combustion efficiency, optimize exhaust energy, and pair that with a chassis that could translate every psi of boost into controlled movement. The result was a compact sedan that could punch above its weight in rally-bred handling and on-track exhilaration, a promise that defined the Evo from its 1990s origins through the mid-2000s. In those early days, power figures hovered around the mid-two-hundred-ps range, but the real achievement lay in how that energy was managed—how the turbocharged surge aligned with Mitsubishi’s sophisticated all-wheel-drive system to deliver traction where most cars simply could not sustain it. The engine’s architecture—its compact bore, its forged internals, and its robust cooling—was tuned to survive not just street duty but the punishing cycles of rally-style acceleration and cornering. And because the engine lived in a package prepared for high-stress operation, it carried an aftermarket legend into the street and strip: the 4G63T became a platform for modification that could reliably push beyond 400 horsepower with the right turbo, intercooler, and ECU work. In those days, the synergy between engine and chassis was deliberate, with the all-wheel-drive arrangement acting as the hand that coaxed the car into corners with extraordinary confidence. The Evo’s early generations were a study in how to extract performance through intelligent breathing: a turbo that spooled quickly, an intercooler that kept charge temperatures in check, and a compression profile that allowed 7,000 rpm-like vitality without sacrificing reliability. By the time the mid-to-late 1990s rolled in with Evolution III and beyond, the engine family had honed not just the peak figure but the delivery: a linear, controllable rush that could be trotted out on a public road or a racing circuit with equal poise. The Evolution III, famous among enthusiasts for its rally heritage, pushed the 4G63T to about 270 PS (266 hp) and roughly 308 Nm of torque. It was not merely raw numbers that defined the era; it was the way the car felt at the edge—an adjustable diaphragm of power and grip that rewarded precise throttle modulation and disciplined steering inputs. This was the cradle of a tuning culture that would outlive the model line, where enthusiasts treated the engine as a modular performance platform rather than a finite power source. As the generations progressed into Evolution IV through VII, the engine lineage continued to sharpen. Horsepower crept upward, torque grew, and Mitsubishi refined the turbocharging and cooling loop to reduce heat soak during sustained high-speed runs. Evolution VI and VII refined traction and balance, with improvements in the Active Yaw Control (AYC) system that helped the chassis make the most of the engine’s torque vectoring. In this era, the engine still wore its 4G63T badge proudly, but the car’s handling architecture—its suspension geometry, its chassis stiffness, and its electronic management—began to outpace the numbers on a spec sheet. The 0–100 times dipped toward the mid-fives, and the top speeds edged into the 250 km/h neighborhood for the stronger variants. The aural and tactile cues—the flutter of the turbo, the crisp intake sound, the moment of wheelspin controlled by the torque-delivery of the drivetrain—were as much a part of the Evo’s identity as the numbers on a brochure. Even as the 4G63T delivered a steady cadence of performance improvements, Mitsubishi’s engineering mind kept looking for ways to respond to a broader set of driving conditions. The Evolution VIII introduced a notable refinement—a variable geometry turbo (VGT) that began to address the infamous lag between mid-range throttle input and turbo boost. The VGT allowed the engine to deliver quicker spool characteristics at low and mid-range revs, a critical improvement for real-world driving and circuit work where the wrong torque timing can make or break a lap. The VIII era, followed by IX, maintained the reliance on the 2.0-liter turbo vertical of the Lancer Evolution tradition, yet the chassis and electronics matured in tandem with the engine’s capabilities. The 0–100 km/h sprint hovered around five seconds for the best variants, and top speeds crept upward in the upper 250s. This period underscored a broader engineering principle: performance is a maxim that straddles two continents—on one hand, the raw engine response, and on the other, the precision of electronic control. The Evolution X, for its part, marks a turning point in the engine’s story. Mitsubishi introduced the 4B11T, a purpose-developed, lighter, and more modular 2.0-liter engine that continued the turbocharged flat-four tradition but did so with a fresh block and a more sophisticated fuel-and-injection philosophy. The 4B11T’s aluminum block and the synergy of multipoint and direct injection (MPI+TPI) technologies helped improve both fuel efficiency and throttle response. The shift wasn’t just about power numbers; it was about a more integrated control strategy that allowed better torque delivery across the rev band and more reliable high-speed behavior under load. A deeper structural upgrade—along with a reinforced crank, forged internals, and improved cooling passages—helped the Evo X sustain higher boost pressures while maintaining durability. For the aftermarket community, the 4G63T era became a sacred ground for engine swaps, turbo kits, and ECU mappings, a cultural touchstone that left an enduring imprint on tuner culture around the world. The engine’s reputation for robustness—the so-called “God engine” legacy—granted it a certain mystique. Enthusiasts learned that to coax maximum performance, a comprehensive approach was essential: turbo efficiency, intercooler capacity, fuel delivery precision, exhaust geometry, and the way the engine’s breath fed the partner systems, including the drivetrain’s torque distribution and the chassis’s dynamic response. The Evo’s motor, from its rally-bred roots to its road-going maturity, was more than a set of numbers. It was a philosophy that every generation could interpret with its own engineering priorities: earlier generations emphasized raw response and durability; later ones pursued refined, linear power and better low-end torque, aided by VGT and improved electronics. The Evolution X’s 4B11T, even as it preserved the character of the previous engines, introduced a material and control strategy aimed at reducing parasitic losses and enabling more aggressive performance at higher speeds. As we move toward the Hybrid Horizon with Evolution XI, the motor’s lineage takes on a new dimension. The latest chapter combines a 2.0-liter MIVEC turbocharged petrol engine with electric propulsion, creating a combined system that delivers around 300 PS (296 hp) and up to 441 Nm of torque. The instantaneous torque delivery from the electric motor reshapes the car’s initial urge, producing a rapid, linear response that complements the petrol engine’s mid-to-top-end surge. The claimed 0–100 km/h time of about 4.6 seconds signals a performance approach that blends traditional internal combustion ethos with modern electrification, a synthesis that preserves the Evo’s driver-focused ethos while stretching into a cleaner, more efficient operating envelope. Handling remains central to horsepower in this hybrid, and the advanced S-AWC system continues to integrate the shutdown, refining torque distribution with nearly instantaneous calculation—a response time measured in tenths of a second. The result is not simply higher numbers but a more assured and confident grip, especially in wet or uneven conditions where the car’s electronic brain can nudge power to the wheel that needs it most. The Evo XI’s electrified edge comes with a practical footprint: the hybrid setup extends overall range and reduces energy consumption without sacrificing the core thrill of powering through a corner with a surge of torque. Official figures cite a hybrid efficiency that could approach the low single-digit liters per 100 kilometers under certain conditions, along with an electric-only range that broadens the car’s usability beyond the track. In this light, the chapter on the Evo Lancer motor is also a chapter about how a raw performance core can adapt to changing energy landscapes without losing its identity. The 4G63T’s reputation as a compact, sturdy, and highly tunable engine anchored a generation that could be both a road car and a rally car in essence. The 4B11T carried the baton forward with lighter weight and an engine-management philosophy that emphasized efficiency alongside vigor. The introduction of a hybrid powertrain in Evolution XI represents the hardest part of the Evo story: maintaining driver engagement while embracing electrification. It is a careful balance, one where the engine’s breathing becomes more refined than before, and the drivetrain’s torque steer is managed with a level of control that only an integrated control system can provide. In this sense, the Evo engine family is a chronicle of engineering pragmatism and bold experimentation—a narrative of how to preserve a car’s fundamental identity while expanding its potential. For readers who want to dive deeper into the technical evolution behind the 4B11T and the specific block design that enables higher boost and better heat management, there is a practical detail worth exploring: the 4B11T billet block 4B11T billet block. This component, while often overlooked in casual glossaries of horsepower, illustrates how modern performance engines push beyond traditional cast blocks toward materials and manufacturing processes that can withstand the stresses of advanced turbocharging and high-boost operation. The shift from a fully forged, cast-aluminum approach to more dimensionally stable and thermally robust blocks mirrors the broader trend in performance engineering: better materials, tighter tolerances, and smarter cooling, all aimed at delivering consistent power delivery across a wide range of conditions. Turning toward the future, the Evo’s motor story does more than celebrate horsepower peaks. It tells how a brand’s engineering culture evolves with the times—from rally heritage and mechanical ingenuity to electrified performance and intelligent control. The Evolution XI’s blended powertrain is, in a sense, the culmination of a long conversation started decades ago: how to marshal a compact, responsive engine inside a chassis that can exploit its strengths with surgical precision. The data points from the recent era—300 PS combined output, 441 Nm torque, sub-five-second 0–100 times, and a credible electric range—concur with a broader industry trajectory where performance, efficiency, and deliverability converge. This is not merely a tale of numbers but a reflection of how the Evo’s engine has become a platform for ongoing experimentation. It remains a driver’s car at heart, where the powertrain’s personality—its ability to deliver a rewarding midrange surge, its willingness to rev out cleanly, and its seamless integration with a sophisticated AWD system—continues to define its allure. The engine, in every generation, teaches a persistent lesson: peak horsepower matters, but the true allure lies in how quickly that power can be harnessed, how reliably it can be sustained, and how transparently the car communicates its intent to the driver through throttle, steering, and chassis feedback. External reference: Evolution XI Launch—Mitsubishi Motors official press release provides insights into the hybrid strategy and performance targets that shape this next era of the Evo motor. https://www.mitsubishi-motors.com/en/news/2026/02/lancer-evolution-xi-launch

From Rally Pedigree to Garage Icon: The EVO Lancer Motor’s Cultural Grip and Tuning Canvas

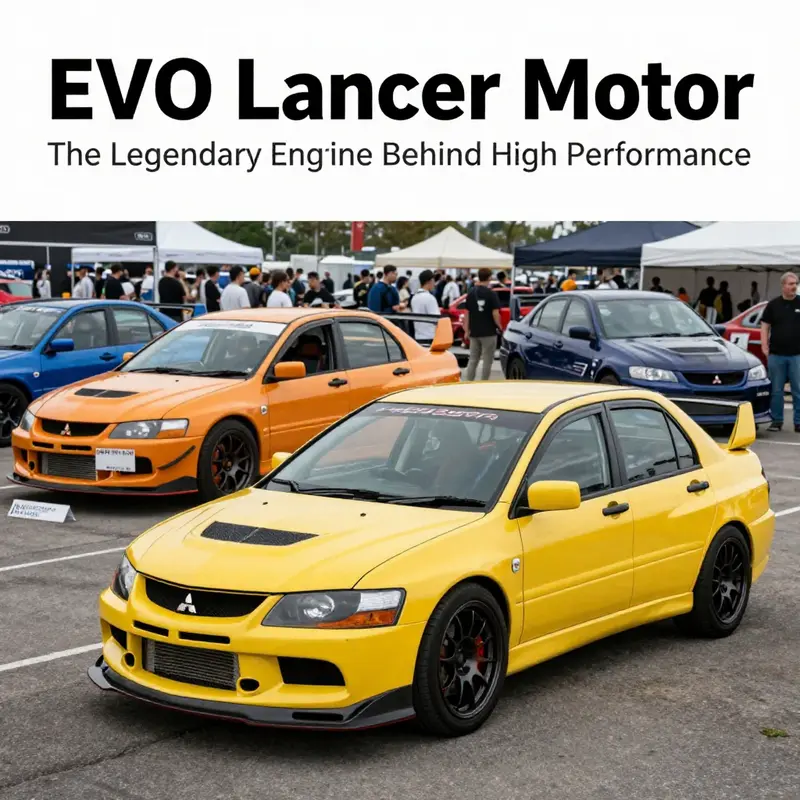

A living engine, a cultural symbol, and a blank canvas for builders — the motor at the heart of the EVO Lancer is more than metal and engineering. It is the reason the car became myth, the excuse countless enthusiasts use to gather in garages, and the mechanical foundation that allowed ordinary owners to chase extraordinary performance. Born from rallying, refined on asphalt and gravel, and celebrated on screens and streets, the EVO’s engine shaped a global subculture that still thrives.

The EVO’s story begins with a relentless pursuit: translate competition-winning technology into a road-legal package. That lineage gave the engine instant legitimacy. It was not merely designed for performance; it carried the demands of motorsport into everyday use. This pedigree forged a distinct identity. For owners it was proof that their car shared DNA with championship machines. For fans it provided a tangible link between pro racing and amateur enthusiasm. That link helped the motor transcend its physical role and become a symbol of authenticity.

Cultural resonance grew as much from narrative as from numbers. Appearances in popular media crystallized the image of the EVO as a driver-focused weapon. Stories and scenes featuring the car did more than showcase speed; they framed the EVO as the archetype of precise, committed driving. In many regions, this portrayal spawned intense loyalty. Rivalries with contemporary performance cars added drama, turning comparisons into cultural rituals. Enthusiasts debated handling characteristics, torque delivery, and which generation captured the spirit best. Those debates reinforced the engine’s mythos and kept its legend alive long after production changes altered the lineup.

Emotional attachment also found roots in accessibility. The motor’s mechanical resilience made ambitious projects realistic for private builders. Where many high-performance engines demanded exotic parts and specialized shops, the EVO’s powerplant tolerated experimentation. Its strength invited modifications; its quirks became part of the craft. A community formed around shared solutions and incremental progress. Knowledge was traded freely: which turbos spooled fastest, how to avoid heat soak during repeated runs, and the best ways to tune fuel delivery for larger injectors. That community shaped the EVO’s cultural identity as much as any race result.

This cultural importance dovetails naturally with the motor’s extraordinary modification potential. At the core was an engine block built to handle stress. This strength created a foundation for dramatic upgrades without catastrophic failure. Tuners exploited that robustness first with bolt-on changes: larger turbochargers, high-flow intercoolers, upgraded fuel pumps, and remapped engine control units. Each step brought tangible gains and taught builders about limits that were often set more by supporting systems than by the block itself.

As ambitions grew, so did the scope of changes. Strengthened internals, forged pistons, and upgraded crankshafts let owners push power into figures that would have once seemed extreme for a compact sedan. Equally important were supporting modifications. A powerful engine requires a drivetrain that can transfer torque without slipping, suspension that preserves traction, and brakes that shed energy predictably. The EVO’s sophisticated all-wheel-drive system gave tuners a head start. Its capacity to manage torque distribution meant more of the motor’s output could be used on launch and corner exit. Later iterations introduced advanced torque vectoring, improving cornering confidence when power grew.

Yet modification is not only about raw numbers. The motor’s tuneability made it a pedagogical tool. Builders learned tuning fundamentals through iterative upgrades. A turbo swap would reveal new fueling needs; a more efficient intercooler would show where heat had previously masked potential. Enthusiasts learned to balance boost pressure with reliability, and to invest in cooling and fueling before chasing the next horsepower milestone. These lessons spread through forums, meetups, and local garages, weaving a culture of shared expertise.

That culture also produced distinct styling and function trends. Owners paired engine builds with aerodynamic work and weight reduction, seeking harmony between power and control. Carbon fiber bonnets, lightweight seats, and aggressive splitters were common visible signs of an investment focused on performance. Brake upgrades and suspension geometry changes were frequent companions to engine work. The result was often a car that performed far beyond its original remit, capable of surprising established sports cars on tracks and in drag strips.

Practical realities tempered the romance. Higher power demands adequate maintenance and careful planning. Neglecting cooling upgrades or ignoring drivetrain limits invites rapid wear. Sensible builders stage modifications, reinforcing weak points before increasing output. Sourcing quality parts matters; a used core engine may save money but can hide costly wear. For those who want authenticity or a reliable starting point, marketplace listings for original motors and components remain important. For example, enthusiasts often seek genuine low-mileage donor engines to begin projects, using them as dependable foundations for ambitious builds. genuine JDM low-mileage 4G63T engine listing reflects the kind of resource builders consult when sourcing a starting point.

The EVO’s later evolution illustrates another facet of its legacy. A change in engine architecture did not erase the culture built around the original motor. Instead, it diversified the community. Some purists continued to worship the earlier design for its character and modability. Others embraced newer engines for their efficiency and modern electronics. The conversation shifted to integration: how to blend classic strengths with contemporary tech. That dialogue broadened the EVO’s cultural footprint, ensuring its engine remained a topic of debate and inspiration across generations.

Ultimately, the EVO Lancer motor is a study in how engineering can seed culture. Robustness invited creativity. Racing roots conferred legitimacy. Media and community amplified identity. The engine became shorthand for a larger ethos: performance that rewards skill, mechanical work that educates, and a social fabric built on shared obsession. For anyone who loves building, driving, or simply understanding how form and function converge, the EVO motor remains a compelling subject. It has delivered not just horsepower, but a language enthusiasts use to talk about commitment, craft, and the thrill of making more from less.

For authoritative historical context and technical specifications, see Mitsubishi Motors: https://www.mitsubishi-motors.com

EVO Lancer Motor: Rally-Bred Engineering and the Engine That Became a Legend

The motor at the heart of the EVO Lancer defines more than horsepower. It embodies a philosophy where rally demands shaped road car engineering. From the earliest homologation specials to the final bespoke models, the EVO’s powerplant proved resilient, adaptable, and endlessly tunable. Its story ties together competition rules, mechanical ingenuity, and an aftermarket culture that turned a factory engine into a global icon.

The EVO’s competitive origins forced engineers to harvest maximum performance from a 2.0-liter displacement class. Regulations and rally stages favored cars that balanced torque, response, and durability. The result was an engine family built around a robust block, efficient forced induction, and a willingness to accept high stress. The most celebrated version became famous for its cast-iron strength and modular upgrade path. Enthusiasts praised its ability to deliver strong midrange torque and linear, controllable power. This made the car predictable at the limit and forgiving when drivers pushed beyond normal bounds.

Beyond raw output, the motor’s character came from its integration with drivetrain and chassis systems. Powerful turbos alone do not make a rally car competitive. The EVO married its engine to an advanced all-wheel-drive system that constantly evolved. Early transfers distributed torque front to rear. Later systems introduced active torque vectoring to the rear axle. That innovation reduced understeer, improved rotation through corners, and let drivers place the car with confidence. Suspension geometry evolved in step with the powertrain, so the motor’s output could be used without upsetting balance. Aerodynamic aids, though subtle, further allowed the engine to work at its best by keeping the chassis stable at speed.

One of the motor’s defining engineering triumphs was its adaptability. Although purpose-built for competition, the design translated well to road use and modification. Internals were strengthened to endure repeated high-boost runs. Cooling paths and oil circuits were optimized for sustained heat. The result was an engine that could, with sensible upgrades, survive and thrive beyond factory ratings. Builders routinely replaced turbos, boosted fuel and ignition management, and upgraded internals. On preserved blocks and reconditioned heads enthusiasts found platforms that, when paired with modern supporting mods, could produce figures that once seemed impossible.

That tunability fostered a worldwide aftermarket. A healthy ecosystem grew around replacements and performance parts. Specialists offered forged pistons, strengthened rods, and high-capacity intercoolers. Electronic control units could be remapped to suit individual hardware changes. For those seeking a ready foundation, there remain listings for low-mileage, genuine JDM 4G63T engines that preserve original quality while giving tuners a sound starting point. Such supply channels kept the engine relevant, even after newer factory units arrived.

As rules and market demands shifted, later production moved to an all-new block and architecture. The newer motor kept the 2.0-liter turbo layout, but adopted aluminum construction and dual-injection strategies. It improved fuel economy and throttle response while retaining broad torque bands. This transition illustrated a core truth: the EVO’s identity was not a single engine alone. It was a system-level achievement that balanced power, weight, and driveability. Newer units honored that identity while embracing modern manufacturing and emissions technology.

Rallying taught engineers invaluable lessons about transient response. Turbochargers historically introduced lag as the turbine spooled up. To counter this, the EVO program experimented with and then implemented variable geometry turbo technology in later iterations. This innovation tightened throttle response at low engine speeds and preserved high-end flow. The result was a more immediate throttle feel and greater tractability on tight stages. Paired with precision fuel delivery, ignition mapping, and strengthened exhaust paths, the motor delivered both grunt and finesse.

The interplay between engine and electronic control was another critical advance. As engine management systems matured, so did torque control strategies. Boost pressure, fuel trims, and ignition timing became adaptive. Control logic learned to prioritize traction, adjusting output to available grip. This synergy was especially valuable on loose surfaces, where a sharp power spike could saddle the car in understeer or cause wheelspin. The careful calibration of these systems allowed drivers to exploit power while maintaining momentum.

Durability under extreme conditions defined the motor’s reputation. Rally stages punish components with repeated high-RPM bursts, rapid throttle changes, and temperature swings. Engineers addressed these stresses through thicker cylinder walls, robust crankshafts, and improved lubrication channels. Heads were ported and flowed with careful attention to detonation resistance. These measures gave the engine a rare combination of service life and upgrade headroom. Constructors and privateers learned they could extract significantly more power than factory specifications without catastrophic failure, provided the supporting systems were upgraded.

The motor’s cultural legacy is inseparable from its engineering. Its image migrated from service pits and time sheets to posters, games, and film. Enthusiast communities formed around tuning guides, maintenance techniques, and race histories. That knowledge sharing accelerated development of bolt-on solutions and bespoke modifications. Clubs organized events and builds that tested the motor’s limits and celebrated its strengths. The engine became shorthand for a particular driving ideal: mechanical honesty, tunability, and a focus on driver engagement.

Even as production ceased, the motor’s lessons remained relevant. Modern performance cars still borrow its dual priorities: accessible power and comprehensive chassis control. Turbo response, torque vectoring, and durable internal design are now common expectations in performance engineering. The EVO program demonstrated how a focused competition requirement can produce technological spillovers into road cars. Its engines taught designers that durability enables performance, and that integrated systems yield better results than isolated upgrades.

For technicians and enthusiasts, the motor represents a living laboratory. It rewards careful maintenance and thoughtful upgrades. Replacing wear items, improving cooling efficiency, and ensuring proper engine management calibration extend usable life and improve performance. When upgraded holistically, the engine continues to offer a compelling balance of reliability and tunability. That balance made it a favorite platform for both amateur racers and professional tuners.

The motor’s influence extends beyond mechanics. It shifted perceptions about what a compact performance car could be. By insisting on an engine that could win on gravel and still be enjoyed on the street, the program created a template that many manufacturers later followed. Its legacy lives on in garages, race stages, and the collective memory of drivers who learned to value an engine that was both a tool and a companion.

For a concise recap of the model history and technical milestones, the official manufacturer history provides an authoritative account of the platform’s evolution and motorsport achievements: https://www.mitsubishi-motors.com/en/vehicles/lancer-evolution/history/

Final thoughts

The EVO Lancer Motor stands as a testament to Mitsubishi’s engineering prowess and the passion of automotive enthusiasts around the globe. From its core engine models that defined a generation of performance vehicles to groundbreaking technological innovations and modifications that keep enthusiasts engaged, the Lancer Evolution series has significantly impacted both motorsport and car culture. Its legacy, rooted in both racing and rich tuning possibilities, ensures that the EVO will remain a revered name in automotive history for years to come.