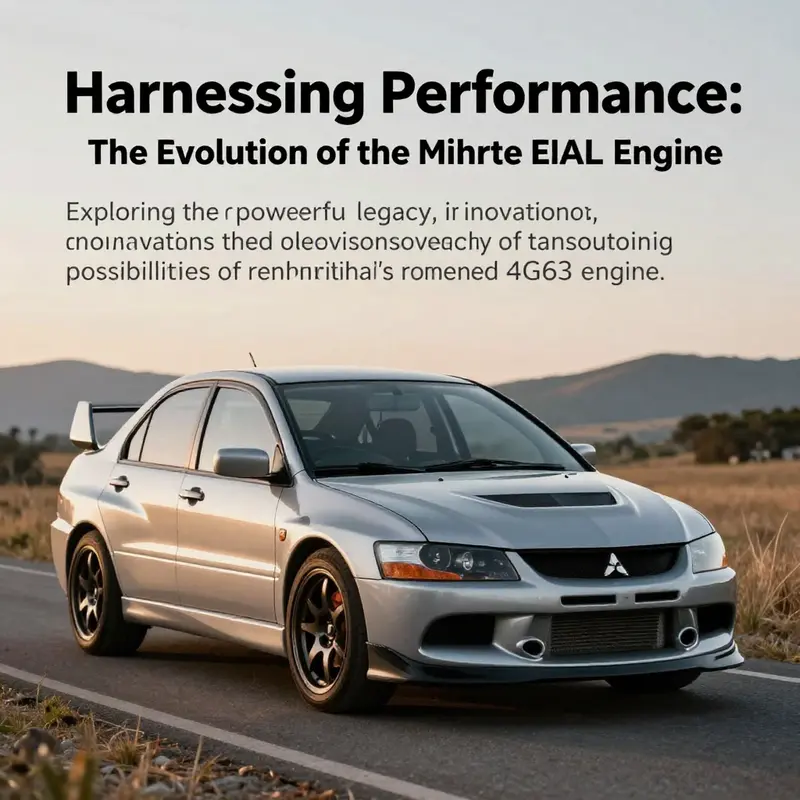

The Mitsubishi Lancer Evolution (EVO) series stands as a remarkable achievement in the automotive landscape, primarily driven by its iconic 2.0-liter inline-four turbocharged engine, the 4G63. This engine has not only defined the EVO’s considerable reputation in performance circles but has also revolutionized the industry standards for reliability and power. This article takes a comprehensive look at the legacy of the EVO Mitsubishi engine across five chapters. Each segment will delve into the evolution of the 4G63, its remarkable innovations and features, its robust performance specs through generations, its pivotal role in motorsports, and the extensive tuning potential that enthusiasts cherish. Together, these insights will provide business owners interested in automotive technology a well-rounded understanding of a cornerstone in performance engine design.

How the 4G63 Forged the Evo Identity: Design, Development, and Lasting Tuning Legacy

The 4G63 Forged the Evo Identity

When you trace the lineage of the Mitsubishi Lancer Evolution, you follow the arc of a single engine family that defined a car and a culture. The 4G63 inline-four turbocharged engine sits at the center of that story. Born from a mid-1980s platform, the 4G63 became the mechanical soul of the first nine generations of Evo. Its character comes from an intentional set of engineering choices: a long-stroke layout, a stout cast-iron block, and a head design that tolerated stress and heat. Those choices gave the engine strong, usable torque, and a resilience that made it ideal for rally stages and aggressive tuning alike.

The 4G63’s long-stroke configuration, where the stroke exceeds the bore, established its personality. The 88mm stroke paired with an 85mm bore emphasized midrange torque. That torque mattered in rallying, where traction and driveability often beat peak power. A long stroke generally yields better mechanical advantage at lower revs, and it reduces the need to scream to high RPMs for usable thrust. This mechanical foundation, combined with robust internals, meant the 4G63 could endure sustained high loads without catastrophic failure.

Durability was a priority from the start. Early Evo engines featured a cast-iron block that resisted deformation under high cylinder pressures. In competition, where detonation, heat, and repeated hard use are normal, an iron block provided a steady platform for aggressive tuning. The cylinder head evolved to lighter aluminum alloy to reduce weight and improve heat dissipation. Over time, the head and its cooling passages were refined to improve flow and temperature control, which helped the engine survive hard use and high boost. Enthusiasts often recall the red-painted head versions with affection, giving rise to the affectionate nickname that underscored the engine’s character.

Power and torque climbed gradually across generations. The first Evo delivered a solid base of performance. Incremental changes across each model—improvements to turbocharger sizing, intake and exhaust flow, intercooling, and internal mapping—raised output steadily. Engineers increased compression ratios slightly and swapped to larger turbine housings and compressor stages to expand the torque curve. By the later Evo models, peak figures were markedly higher than at the outset, reflecting a careful balance between reliability and outright power. Those gains did not come from radical redesigns but from iterative refinement.

Turbo technology played a pivotal role in the 4G63’s evolution. Early setups used single-scroll turbochargers that offered strong top-end performance. Later, twin-scroll designs and more advanced turbine geometries appeared, improving spool and reducing lag. Twin-scroll turbos make better use of exhaust pulses, improving low-end torque without sacrificing high-rpm flow. For rally drivers and spirited road users, that meant a sharper throttle response and more consistent power delivery across the rev range. Complementing the turbo advances, Mitsubishi fitted large top-mounted intercoolers for many Evo models, leveraging short, direct piping to quickly cool compressed intake air. Denser intake charge meant more efficient combustion and higher power potential without undue temperature rise.

Refinement inside the engine continued too. Changes to piston design, stronger connecting rods, and improved bearings extended the engine’s safe operating window. Engineers managed compression ratios judiciously, nudging them upward over the years as combustion control improved. Electronic control units became better at mapping fuel and ignition, which allowed safer operation under higher boost levels. Each small step made the package more potent and more reliable when pushed.

The 4G63’s motorsport pedigree amplified its reputation. The engine delivered repeatable performance in world-class rally environments, where parts that survived gravel, jumps, and high thermal loads gained real credibility. That track-bred toughness translated into aftermarket appeal. Tuners discovered the 4G63 responded well to common upgrades: larger turbochargers, higher-flow fuel systems, improved intercoolers, and aggressive engine management. With the right supporting modifications, many examples exceeded factory outputs by wide margins, with some builds comfortably surpassing 600 horsepower. The block and head tolerated those transformations in ways many contemporary engines did not, making the 4G63 a platform of choice for high-output swaps and endurance builds.

As regulations and market demands changed, Mitsubishi made a strategic shift. The tenth-generation Evo introduced a new engine family designed to meet tighter emissions rules and deliver better fuel economy. A modern aluminum-block engine with variable valve timing provided better refinement and lower mass. This newer engine offered advantages in efficiency and packaging but differed in character. The aluminum block was lighter, but also less amenable to extreme power increases without significant modification. Variable valve timing improved torque spread and emissions, yet some enthusiasts felt the visceral feel and straightforward tunability of the older cast-iron 4G63 had been lost.

That divergence did not mark the end of the 4G63’s story. A thriving aftermarket kept the engine alive. Builders combined the 4G63’s rugged architecture with modern technologies where possible, integrating refined valve timing systems and improved cooling. Used low-mileage units remained highly sought after by those seeking an authentic Evo heart. For builders, acquiring a genuine example of the 4G63 often starts a cascade of upgrades aimed at balancing durability and output. A common path includes stronger bottom-end components, modern engine management, and an upgraded cooling package to handle high boost and sustained runs. For reference and sourcing, enthusiasts sometimes turn to listings for genuine low-mileage 4G63T engines when starting a restoration or high-power project, such as a genuine JDM low-mileage 4G63T listing.

The 4G63 endures because of what it represents: a clear trade-off favoring mechanical strength and tunable potential over marginal gains in weight savings or factory refinement. Its long-stroke design rewarded torque and robustness. Its cast-iron block accepted extreme tuning. Its evolution across nine generations showed an engineering approach rooted in incremental improvement and real-world validation on stages and streets.

For readers who want a concise, authoritative timeline and technical summary of the Evo series and its engines, a detailed industry overview captures the 4G63’s development and the broader shifts leading to its replacement: https://www.motortrend.com/cars/mitsubishi/lancer-evolution/.

Breathing Fire: The 2.0-L Turbo Inline-Four at the Heart of Mitsubishi’s Evolution Engine Heritage

Across the rally-inspired lineage of the Evolution, the engine is more than a power source; it is the defining heartbeat that shapes every chase, every corner, and every street duel with performance. The core of this story is a 2.0-liter turbocharged inline-four that, through a century of incremental refinements, became one of the most recognizable powerplants in modern motorsport culture. From its debut in the early era of the series, the unit was designed to endure the punishing demands of competition while remaining responsive and tractable on public roads. Early versions proved that high output could be paired with reliability, a dual promise that would evolve as engineers learned to push the limits without losing the essence of driveability. The numbers tell a frame of reference: power climbed from the mid-260s horsepower in the early years to a peak in the vicinity of 400 horsepower in the most capable configurations, with torque well above 450 newton-meters. Those figures did not just reflect peak performance; they signaled a philosophy that balanced power with a broad, usable torque band. It is this balance that made the engine legendary among enthusiasts and accessible to amateurs who pursued the thrill of speed without sacrificing daily usability.

What makes the Evolution’s engine story so compelling is not a single invention but a disciplined sequence of improvements that respond to the requirements of rallying and the expectations of the street. The fundamental architecture is straightforward in concept: a compact, high-revving, four-cylinder layout fed by turbocharging, with meticulous attention paid to breathing, cooling, and fuel management. The turbocharger setup, for example, was designed to minimize lag and to deliver a broad, usable torque curve. A twin-scroll design helped separate exhaust pulses, improving turbine response and reducing滯 lag across the rev range. In practice, this meant quicker throttle reactions and stronger midrange punch, which translated to faster acceleration out of corners and more confident throttle control under demanding conditions. The result was a powertrain capable of delivering surge when needed and keeping the driver in command as the speed built across a sequence of bends.

The heart of the engine’s resilience lies in its block and cooling strategy. The early blocks were built from reinforced iron, a choice that gave the necessary rigidity to withstand high cylinder pressures and sustained racing temperatures. Over time, the drivetrain philosophy shifted toward reducing weight without compromising strength, with aluminum cylinder heads joining the equation to shed mass where it mattered most for responsiveness. This combination—rigid, high-torque blocks paired with lighter top-end components—helped preserve durability under the strenuous demands of rallying while enhancing the engine’s ability to rev quickly and cleanly. For readers curious about the exact structural evolution, an illustrative example in the aftermarket ecosystem highlights a billet-block approach that embodies the same principle: combining strength with an optimized mass distribution to improve the engine’s overall response. See 4B11T billet-block for a concrete reference to high-performance block architecture that echoes this engineering mindset.

Cooling remained a central pillar of performance as boost pressures increased and engine temperatures rose under load. The Evolution’s cooling strategy extended beyond the radiator and coolant flow; it included the intake air cooling path itself. The intercooling system was designed to deliver denser, cooler air to the combustion chamber, a critical factor when you are asking the intake charge to withstand higher pressures and temperatures without knocking. A distinctive feature in the design was a top-mounted intercooler that could efficiently shed heat and help maintain air density. This choice, combined with careful routing of air through the front end of the car—where the large openings in the bumper and hood served as deliberate ducts for cooling air—worked in concert with the engine’s boosted state. The result was not just more power, but more predictable, repeatable power across varying temperatures and altitude, a crucial advantage for rallied performance on diverse courses and climates.

Alongside airflow and cooling, fuel delivery and engine management played pivotal roles in shaping the engine’s character. The Evolution’s ECU was tuned to manage a high-load, high-output condition with a focus on precision. The aim was to extract every available horsepower without sacrificing reliability or detonation resistance. This meant precise control of ignition timing and fuel delivery to keep combustion stable under boost. The outcome was a unit capable of sustaining high power levels for extended periods—an essential trait for rally stages and track sessions alike. Enthusiasts have long recognized that the real culture around this engine is not merely about raw horsepower, but how the engine responds to small, deliberate changes. A clean map can lift throttle response, while a robust fueling strategy can preserve power output under sustained high-load conditions. This is where the Evolution’s engineering shines: it is a system that rewards thoughtful tuning as much as outright hardware upgrades.

The evolution of the engine across generations mirrors the broader evolution of Mitsubishi’s performance philosophy. Each new generation refined the core concepts while pushing the envelope in areas such as intake and exhaust efficiency, cooling effectiveness, and electronic control. The journey from the early, mighty yet temperamental bruiser to the later, more refined high-output variant illustrates a relentless pursuit of a single goal: to deliver grippy, reliable power that can be summoned with confidence in any environment. The tuning culture around the engine reflects this objective. Enthusiasts frequently upgrade two pillars—the intake and the exhaust—while simultaneously reworking the engine’s breathing and fuel maps. Large, efficient intercoolers are swapped in, turbochargers are tuned for quicker spool and greater midrange torque, and the ECU is remapped to sustain power through the gears. Some builders have demonstrated power outputs beyond six hundred horsepower in purpose-built configurations, illustrating the extraordinary tuning potential of a platform designed for both road and stage use. It is this potential, and the willingness to exploit it responsibly, that keeps the engine relevant and revered.

Looking at the broader arc, the engine’s heritage sits at the intersection of rally knowledge and street performance. It is not a single invention but a living, evolving system shaped by competition experience and road-going practicality. The engine’s architecture demanded a balance: strength for reliability, lightness for agility, and smart cooling for long-haul performance. It demanded an air path designed to keep intake temperatures down while preserving the density needed for power. It demanded a control system capable of translating aggressive boost launches into predictable, repeatable behavior. In this sense, the Evolution engine is a craft of harmony as much as a machine of speed. The last generation pushed the envelope further, attaining impressive power figures while preserving the immediacy and tractability that define the driving experience. The story of this engine, then, is a narrative of how engineering discipline, rally heritage, and a passion for driving pleasure converge in a compact, meticulously engineered package that continues to inspire and challenge engineers and drivers alike.

For readers who want to explore the mechanical ecosystem further, the engine’s lineage can be traced through components and design choices that remain relevant to modern high-performance four-cylinders. The core idea remains simple: optimize the path of air and fuel into a confined space, manage heat, and preserve the engine’s ability to translate the engineer’s intent into forward motion. The Evolution’s engine stands as a benchmark for how far a powerplant can be developed within a practical, road-legal framework when rally experience informs every stage of design. It is a testament to the idea that performance is a sum of parts working in unison—from the block and the heads to the turbo, the intercooler, and the control electronics. The result is not merely speed, but an elevated sense of driving pleasure and a clear sense of how a well-tuned engine can transform a car into a responsive, confidence-inspiring machine.

External resource: https://mitsubishiautopartsshop.com/evo-x-halfcut/

Evo Engine Evolution: Performance Through the Generations of Mitsubishi’s Rally-Bred Powerplant

The engine at the heart of Mitsubishi’s Lancer Evolution lineage is more than a power source; it is a chronicle of engineering ambition driven by rally grit and the practical demands of high-performance road cars. From the first turbocharged forcefully cast on the 2.0-liter inline-four to the lighter, more capable 4B11T that powered the final generations, the Evo’s powerplant tells a story of how a single concept—turbocharged torque, efficient breathing, and durable construction—could be reimagined generation after generation without losing the core essence that made the Evo a legend on stages and a benchmark for enthusiasts. Across generations, the engine’s evolution mirrors a broader pursuit: to extract more usable power across a broader band, to sharpen throttle response, and to do so with reliability that could endure the demands of rallying while delivering the kind of exhilaration only a properly tuned four with a twin-scroll turbo can provide.

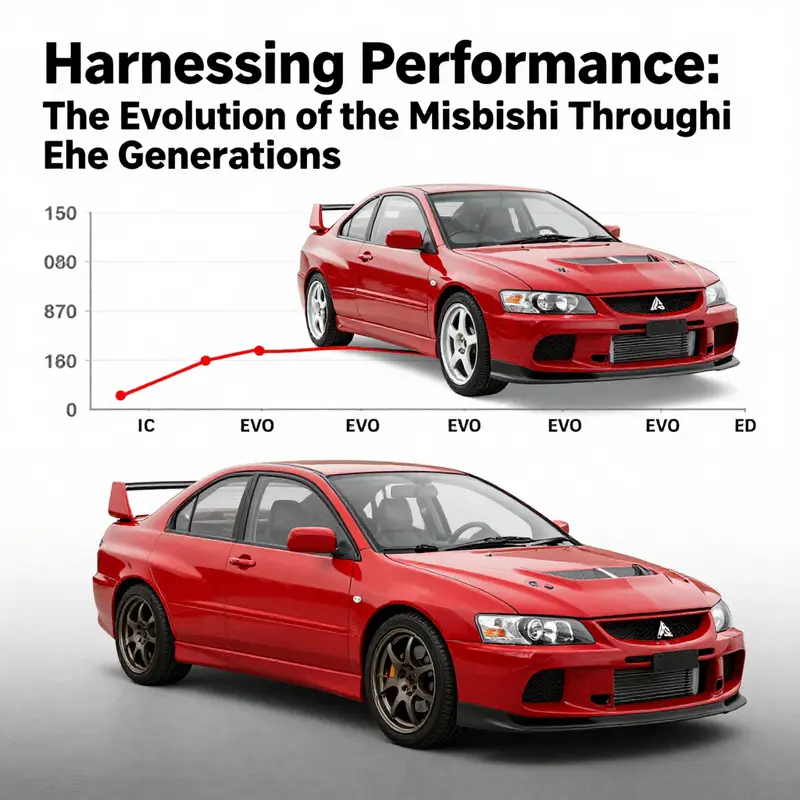

The journey begins with the 4G63T, the quintessential heart of the early Evo era. Introduced in the mid-1990s as the foundation for the Evo I through Evo IV, this 2.0-liter DOHC 16-valve turbocharged engine became the practical embodiment of Mitsubishi’s performance philosophy. In its early form, the 4G63T offered roughly 280 PS (about 276 hp) at around 6,500 rpm and torque in the vicinity of 330 N·m (243 lb-ft) at roughly 3,500 rpm. The configuration—an inline-four with twin overhead cams, a robust turbocharger, and a large intercooling path—was designed not merely to yield peak numbers but to deliver strong, controllable power when the driver needed it most on a rally stage or on a winding mountain road. Over the Evo I through IV, refinements focused on reliability and consistency. The intercooler and cooling systems were tuned to handle the heat of repeated boost, while the turbo itself was calibrated to broaden the usable torque curve. This period established a dynamic baseline: a midrange punch that could be relied upon in demanding conditions, paired with chassis that could convert that power into precision handling.

As the Evolution line matured into the mid-2000s, Mitsubishi pushed the 4G63T toward greater refinement with the Evo V and Evo VI. The numbers for these generations remained in the same ballpark—roughly 280 PS (276 hp / 206 kW) and about 330 N·m of torque—but the engineering focus shifted toward better delivery and more forgiving behavior. Aerodynamics, suspension geometry, and drivetrain tuning were aligned with the aim of turning a potent engine into a balanced, all-weather weapon. The 4G63T found improved intercooling, refined ECU calibration, and revisited intake and exhaust strategies that smoothed throttle response and reduced turbo lag, translating raw horsepower into a more controllable and repeatable driving experience. The result was not simply more horsepower, but a more confident platform; the driver felt the same engine, but more of its power at more of the rev range, with a chassis that communicated better through the seat and wheel.

The late Evo VII, Evo VIII, and Evo IX represent a convergence of performance and electronics that transformed the vehicle into a more sophisticated race car for the street. These generations retained the 2.0-liter turbocharged core, yet the engine management strategies matured considerably. The power output stayed near the 280 PS mark, while torque remained around 330 N·m, but the bigger gains came from how the engine breathed and how the car managed what the engine produced. The ECU—more capable and more finely tuned—cracked open the door to more efficient fuel delivery, more precise ignition timing, and improved intercooling behavior. The turbo response sharpened, the intercooler layout was optimized for quicker cooling and denser charge air, and the overall package—suspension, tires, and AWD control—allowed the engine’s power to be harnessed with greater fidelity. This era underscored a central truth: it is not only about raw numbers but about how those numbers are delivered to the pavement and how the chassis translates it into controlled, repeatable performance.

Then came Evo X, a turning point in how Mitsubishi conceived the powerplant for the modern era. The 4G63T era gave way to the 4B11T, a move that signaled lighter weight, improved efficiency, and a fresh approach to engine management. The 4B11T is an aluminum inline-four designed to meet contemporary emissions and efficiency demands while still delivering the immediacy expected from an Evo. The shift to an aluminum block and head helped reduce rotating mass, contributing to quicker throttle response and a more agile character at lower speeds, with the twin-scroll turbocharger continuing to play a pivotal role in reducing lag and delivering robust mid-range torque. Mitsubishi integrated MIVEC, or a variant of valve timing control, to optimize power across the rev range. The result was a powerplant that could maintain the Evo’s rally-heritage aggression while offering more usable power on the street and better fuel economy for everyday driving.

Factory figures for the Evo X reflect the consolidation of the new generation’s design goals. The standard GSR configuration produced around 280 PS (roughly 276 hp / 206 kW) with torque near 330 N·m at 3,500 rpm. In higher-output forms, factory configurations could push toward about 300 PS (roughly 296 hp / 221 kW) and correspondingly higher torque in the mid-range, a testament to the 4B11T’s capacity when tuned within Mitsubishi’s performance envelope. Yet it is crucial to recognize the nuance in these numbers. The Evo X era also opened the door to distinctly tuned and modified configurations that far exceeded stock ratings. Enthusiasts-report power outputs well beyond 600 horsepower through a combination of larger turbochargers, upgraded intercoolers, optimized intake and exhaust, and advanced ECU tuning. In some documentation, peak power is cited well into the four-figure horsepower territory when extreme tuning is paired with high-boost hardware. The practical takeaway is that the 4B11T era, with its aluminum architecture and modern control systems, was designed to support serious performance upgrades while offering a more efficient, reachable platform for advanced tuning.

The evolution of these engines is not a tale of a single milestone but a sustained effort to refine, adapt, and broaden the powerband. The early 4G63T gave the Evo its rally DNA—a torque-rich, responsive character that could be exploited with a responsive chassis and a well-balanced drivetrain. The subsequent generations did not simply chase higher peak numbers; they improved breathing, heat management, and control so the engine’s potential could be exploited more effectively. The twin-scroll turbo configuration, a hallmark of the era, played a central role in reducing turbo lag and delivering torque where it mattered most. The top-end ambitions of the early turbo era, refined through ECU sophistication and mechanical enhancements, culminated in a 4B11T that embraced the modern expectations of efficiency, emissions compliance, and tunability. The engine’s lifecycle—from iron-block durability and heavy, robust heads to a lighter, freer-flowing aluminum architecture—reflects a broader engineering philosophy: performance without compromise is built on improved fundamentals as much as on new hardware.

For enthusiasts, the evolution is visible not only in numbers but in how the engine communicates with the driver. The early 4G63T models rewarded bold throttle inputs with predictable, linear torque. By the time the 4B11T arrived, the engine could still deliver the same electrifying midrange push, but with improved acceleration feel and better response at the apex—precisely the kind of behavior that invites more aggressive cornering and more confident overtaking. The AWD system, refined chassis geometry, and electronic aids such as adaptive torque distribution and active differentials further translated the engine’s capability into a coherent, track-ready experience. In this sense, the Evo engine’s progression is a case study in how a well-conceived powerplant can remain fundamentally recognizable while evolving to meet new performance paradigms.

The practical reality for owners and tuners is that the Evo’s core reliability—rooted in its turbocharged design and reinforced blocks in the earliest iterations—was preserved while the engine’s architecture was adapted for modern demands. The 4G63T’s durability under aggressive use built a foundation that permitted ambitious upgrades, and the 4B11T era reinforced that philosophy with lighter components, better gas-mileage credentials, and a platform ripe for high-horsepower experimentation. The result is a powertrain that respects its origins—an inline-four, a turbo, a robust block, and a synchronized intake/exhaust ballet—while embracing a modern toolkit that includes aluminum block construction, variable valve timing, and sophisticated engine management. Enthusiasts continue to push the envelope, swapping larger turbos, upgrading intercoolers, and tuning the ECU to measure and exceed performance boundaries. In that sense, the Evo engine remains a living story—one that mirrors the persistent, adaptive nature of performance engineering itself.

Internal link for enthusiasts exploring internal upgrades: 4b11t-billet-block.

External reference for broader context on the Evo X’s engineering: https://www.motortrend.com/cars/mitsubishi-lancer-evolution-x/.

Breathing Turbocharged Resilience: The Evo Engine’s Rallying Legacy and Motorsport DNA

The realm of rallying and high level motorsport is a theatre where a compact powerplant must do more than produce numbers. It must deliver torque when it matters, endure heat and stress, and respond with immediacy as the surface through which it travels changes in an instant. The engine at the center of the Evo lineage embodies this philosophy. A 2.0 liter turbocharged inline-four lies at its core, a small displacement that relies on boosted air, well-timed valve events, and a robust heartbeat to stay poised under pressure. What makes this engine enduring is not a single feature but a symphony of choices: a robust block, a light, efficient head, a turbo system that wastes no pulse energy, and an intercooling architecture that preserves air density as boost climbs. The result is a powerplant capable of delivering a broad, usable pull across revs, with torque that refuses to vanish as loads shift and grip ebbs and flows on uncertain surfaces. This foundation underwrites a racing ethos that prizes confidence and consistency as much as peak power, a combination that translates into wins on stages where every meter of grip is earned and every second counts.

From the earliest iterations to the latest developments, the engineering team pursued a sequence of upgrades that reinforced the core concept without breaking the chassis harmony. Early designs favored a cast iron block for unyielding strength and heat tolerance, paired with a dual overhead cam arrangement to optimize valve timing under boost. As the program matured, aluminum alloy cylinder heads reduced rotating mass, a refinement that sharpened throttle response and reduced inertia when the driver flicked the throttle mid corner. A top-mounted intercooler grew in importance, cooling the compressed air so it could rush into the cylinders with density intact. The twin-scroll turbocharger emerged as a key enhancer, separating exhaust pulses to minimize lag and maximize midrange torque. The engineering logic was straightforward but demanding: keep average torque high, maintain reliability under repeated boosts, and ensure intake air remained dense enough to translate boost into real power through the combustion process. The practical outcome was a power curve that felt broad and usable rather than a narrow spike that vanished as soon as the revs climbed away from the ideal range.

Rallying and high-speed circuit running demand more than raw power; they demand a partnership between powertrain, drivetrain, and the surface underfoot. The engine did not operate in isolation but in concert with an all-wheel-drive system and an advanced torque-splitting strategy that could translate wheel torque into controlled acceleration rather than sudden wheelspin. That synergy became especially important on gravel, snow, or mud, where traction is a moving target and steering input must be precise enough to keep momentum without provoking understeer or oversteer. Over generations, power output climbed while the control algorithms matured, allowing drivers to press on with a level of confidence that might once have seemed magical. The shift from early high-boost, lower-turge configurations to higher-efficiency, higher-boost arrangements meant more consistent power delivery through corners and over crests, which, in turn, enabled competitors to maintain speed through sections that would have taxed weaker designs. A deeper technical overview of one critical archival example can be found here: genuine-jdm-low-mileage-1995-1999-jdm-mitsubishi-4g63t-2-0l-dohc-turbo-engine-evo-7-bolt-eclipse-talon-awd-automatic-transmission-and-ecu-attached.

As the decades rolled on, the engine family reflected a disciplined approach to performance. The mid-generation iterations refined boost management and intake paths while preserving the durability that rally and endurance racing demand. The move toward lighter components, including optimized cylinder heads and refined block geometry, reduced mass without compromising stiffness. The turbocharged core stayed a central feature, but the boost it could sustain while the engine endured a long stage became more controllable, easing the load on the cooling system and the lubricating film that keeps moving parts from galling under heat stress. These refinements mattered precisely when the surface turned unpredictable and the throttle was pressed while the air was thinned by altitude or composition changes on a dusty road. The engine did not merely survive such moments; it learned to deliver predictable, repeatable performance, a quality that translates to driver confidence and team trust in the box of telemetry and data that judges every run.

The rally and motorsport environment rewards more than a single performance figure. It rewards timing—the moment the boost arrives, the point at which air meets fuel, and the fraction of a second the engine takes to respond to the driver inputs. In the later stages of the engine lineage, a higher level of integration between air handling, boosting strategy, and exhaust scavenging helped stabilize torque across a wider rpm band. This meant the car could accelerate out of turns with a cleaner hook, reducing the need for dramatic throttle correction as the tires found traction. The outcome was not merely power; it was confidence that the vehicle would behave as the driver expected in fast, demanding sections. Across years and upgrades, that philosophy endured: maintain strength in the block, keep weight down where possible, manage boost with precision, and ensure air cooling remains robust enough to prevent heat soak after long, aggressive runs.

The culture around these engines extended beyond factory work and into the hands of enthusiasts who pursued the ultimate tuning challenge. With the right combinations of turbocharger, intercooler, intake, exhaust, and control software, the platform could move from factory output into a realm of serious, track-focused performance. The tuning culture proved that a well designed powerplant could accept substantial horsepower increases without giving up driveability or reliability, provided the modifications honored the fundamental synergy of air, fuel, and timing. In practice, this meant that careful upgrades and proper calibration could yield power levels well into the six-figure horsepower range when paired with a robust drivetrain and a well-prepared chassis. The broader implication is clear: a strong engineering foundation, disciplined in maintenance and tuning, can support ambitious performance goals while maintaining a degree of everyday drivability that makes track work sustainable for enthusiasts.

Even after the official line shifted away from the production rally scene, the engine lineage left a living legacy. Teams and privateers carried the philosophy forward, applying the same core ideas—strength in the block, lightness in moving parts, and a disciplined approach to boost and cooling—to newer, more efficient packages. This continuity extended into grassroots programs, where the same fundamentals continue to guide decisions about air flow, boost management, and the tuning strategies that balance power with reliability on a weekend sprint or a training day. The engine’s influence persists because it teaches a clear lesson: performance is not a single snapshot of power but a relationship among a set of tightly interwoven systems that must perform under pressure, again and again. The possibility of a future evolution, including hybrid concepts that preserve the core DNA of throttle response and torque while embracing electrified propulsion, underscores the ongoing appetite for innovation that defines motorsport culture. A broader perspective on these developments can be explored in the official hybrid evolution concept announced by the manufacturer: https://www.mitsubishi-motors.com/en/news/2026/0204-hybrid-evo-launch.html

Unlocking the 4G63T: Real-World Tuning Paths and Aftermarket Strategies for Evo Engines

The Evo’s reputation as a tuner’s car grows from a single engineering fact: the 4G63T engine was built to respond. Its cast-iron block, efficient head design, and turbocharged breathing make it forgiving when pushed. That responsiveness shapes how enthusiasts plan upgrades, from conservative bolt-ons to full internal builds that chase four-figure horsepower numbers. A clear, practical strategy begins by deciding the goal, then matching parts and calibration to support it.

Start with the fundamentals: cooling, airflow, and fueling. When boost rises, intake air heats quickly and combustion efficiency drops. That makes a high-flow intercooler and sensible piping the first, most impactful upgrade. A larger top-mounted intercooler reduces intake temperatures and sustains power under repeated hard runs. Complement it with a less restrictive intake path and a smoother intercooler plumbing layout to reduce pressure drop. Taken together, these changes commonly yield 20–50 extra horsepower on sustained runs, because the engine can safely ingest denser air.

Fuel delivery must follow airflow. Stock fuel pumps and injectors work for moderate tuning, but higher boost demands larger injectors and a high-flow pump. Without reliable fueling, detonation risk increases and the ECU cannot maintain safe air-fuel ratios. The simplest route pairs upgraded injectors with a fuel pump sized for the planned power, then lets the engine management system control mixture precisely.

Forced induction upgrades come next. Turbos define the engine’s character: spool, peak power, and midrange torque. Small, fast-spooling turbos favor daily driveability and sharp throttle response. Larger turbos deliver high-end power but increase lag. Twin-scroll designs, or modern hybrid turbos, extract more energy from exhaust pulses. For many builders, a moderately larger turbo plus matching supporting parts gives the best compromise between drivability and peak output.

Exhaust flow is equally crucial. A free-flowing downpipe and exhaust reduce back pressure and heat retention. When combined with intake and turbo upgrades, exhaust changes open breathing through the whole rev range. But gains depend on tuning. A custom tune ties intake, turbo, and exhaust changes into a coherent map that controls boost, timing, and fueling.

Engine management is the glue. ECU remapping, or a standalone controller, allows precise control of ignition timing, boost targets, and fuel trims. Proper calibration reduces knock risk and extracts safe power. Good tuning accounts for fuel octane, intake temps, and component variances. Dyno-based tuning and datalogging during road sessions reveal issues early and ensure reliability.

When bolt-ons reach their limits, internal upgrades are required. The 4G63T responds well to forged pistons and stronger connecting rods, which handle higher cylinder pressures. A strengthened crankshaft and balanced rotating assembly improve rev stability. These changes let builders push past 500 horsepower while maintaining durability. Cylinder head work — porting, flow matching, and valve upgrades — increases volumetric efficiency and complements forced induction gains.

But internals are not the whole story. The drivetrain must cope with added torque. Clutch, flywheel, and transmission upgrades prevent slippage and breakage. Differential and driveshaft reinforcements improve power delivery, especially under high-wheel-torque conditions typical in rally-inspired setups. For sustained high-power builds, cooling for the gearbox and differential also matters.

Chassis and handling upgrades should accompany engine gains. More power amplifies suspension and brake demands. Upgraded dampers, springs, and anti-roll bars help control weight transfer. Larger brakes reduce fade on repeated hard stops. Tire choice and wheel fitment influence traction dramatically, so do not overlook contact patches and alignment settings when tuning for straight-line or track performance.

A practical build plan divides into stages. Stage 1 focuses on reliability and modest power: improved intake, intercooling, a high-flow exhaust, and an ECU tune. Stage 2 adds fueling upgrades, a larger turbo, and stronger clutches for significant gains. Stage 3 turns to forged internals, head work, and fully reworked engine management for maximum, reliable power. Each stage builds on the previous, minimizing surprises and aligning costs with goals.

Maintenance and durability strategies keep tuned engines alive. Regular oil changes using high-quality lubricants, frequent coolant checks, and conservative ignition timing under high intake temperatures extend engine life. Compression and leak-down testing help detect early wear on high-mileage cores. For those sourcing replacement engines, a low-mileage turbocharged core remains valuable and cost-effective. Consider sourcing a verified low-mileage core when starting a major build to reduce unknown variables; there are reputable listings for low-mileage cores that can save time during a rebuild.

Tuning pitfalls are avoidable. Running air-fuel ratios too lean, or timing too aggressive, causes knock and catastrophic failure. Ignoring supporting systems — fuel pressure, cooling, and drivetrain strength — produces bottlenecks that stress components. Likewise, mixing parts without proper calibration often yields marginal gains and reduced reliability. The correct sequence is consistent: support systems first, then power components, and finally, calibrate on a dyno.

The aftermarket ecosystem around these engines is unusually deep. That depth means parts compatibility across model years, countless performance options, and many tuning houses offering expertise. This makes swaps, retrofits, and custom solutions possible. When sourcing parts, prefer components with documented performance and clear specifications. Community-shared dyno charts and build logs help predict outcomes before committing funds.

For many enthusiasts, the most rewarding aspect is the customizability. A modestly tuned car can be a lively daily driver. A fully built motor becomes a weekend track weapon or a competitive rally car. Each path demands different compromises, but the engine’s architecture supports both. Thoughtful planning, proper fueling, thermal management, and tuned engine management deliver the balance between power and longevity.

If you plan a build, start by defining the vehicle’s purpose and a realistic power target. Map upgrades into stages. Prioritize cooling, fueling, and strong driveline components. Finally, invest in professional tuning and regular maintenance to protect the engine and get the most satisfying results. For a useful technical perspective on tuning specifics and typical upgrade outcomes, consult this comprehensive technical guide on Evo engine tuning: https://www.motor1.com/tech/2026/01/26/mitsubishi-evo-9-engine-tuning/.

For those seeking a replacement core or donor engine to start a rebuild, consider verified low-mileage turbo cores to reduce unknowns early in the build process. One good source to review is a listing for genuine JDM 4G63T low-mileage cores, which can be a smart foundation for a long-term performance project: https://mitsubishiautopartsshop.com/genuine-jdm-low-mileage-1995-1999-jdm-mitsubishi-4g63t-2-0l-dohc-turbo-engine-evo-7-bolt-eclipse-talon-awd-automatic-transmission-and-ecu-attached/

Carefully planned upgrades, consistent tuning, and diligent maintenance unlock both the practical and extreme potential of the Evo engine. The platform rewards patience and smart choices with a blend of usable power, engaging drivability, and a proven track record that keeps builders coming back.

Final thoughts

The Mitsubishi EVO, driven by the powerful legacy of the 4G63 engine, embodies a triumph of automotive performance engineering. Each iteration is a testament to the relentless pursuit of innovation, catering to enthusiasts and professionals alike. As we have explored through its evolution, technological innovations, performance benchmarks, motorsport excellence, and tuning potential, the EVO’s engine remains a symbol of power and adaptability. For business owners and automotive enthusiasts, understanding the intricacies of this engine can unlock new opportunities in performance tuning, aftermarket modifications, and rally sport engagements. The journey of the 4G63 is far from over; it continues to inspire and pave the way for future innovations in the automotive world.