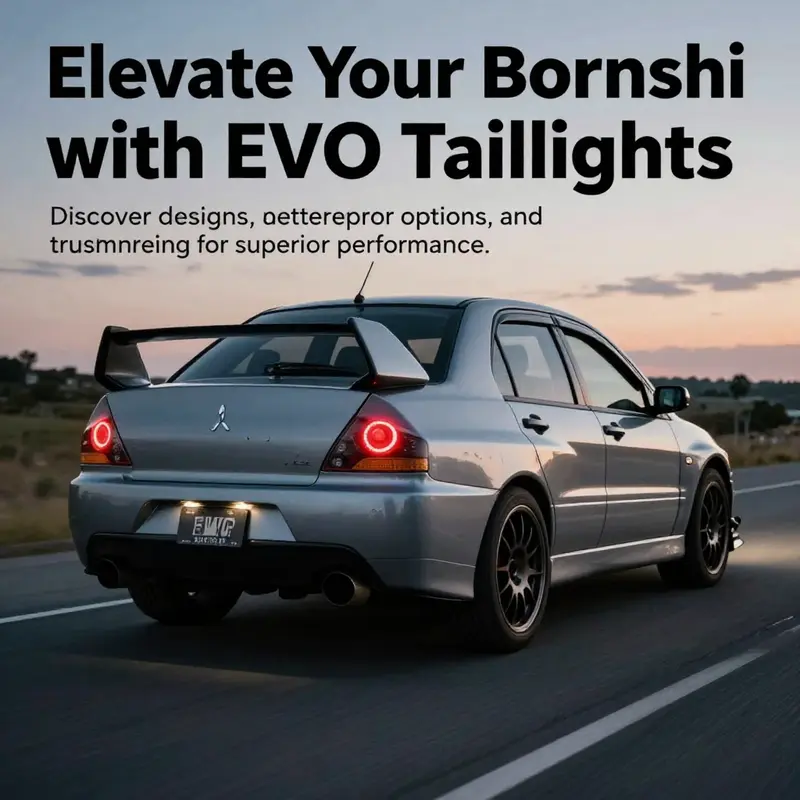

EVO taillights represent not just an aesthetic choice but a crucial component in enhancing the overall performance and safety of Mitsubishi vehicles. Business owners and automotive enthusiasts alike understand the importance of quality automotive parts, and taillights are no exception. This article delves into the various designs and features of EVO taillights, explores aftermarket options that can boost performance, and addresses common issues that may arise with these components. Each chapter aims to equip you with the knowledge to make informed decisions regarding EVO taillight choices and maintenance.

Radiant Signatures: The Design, Tech, and Personalization of EVO Taillights

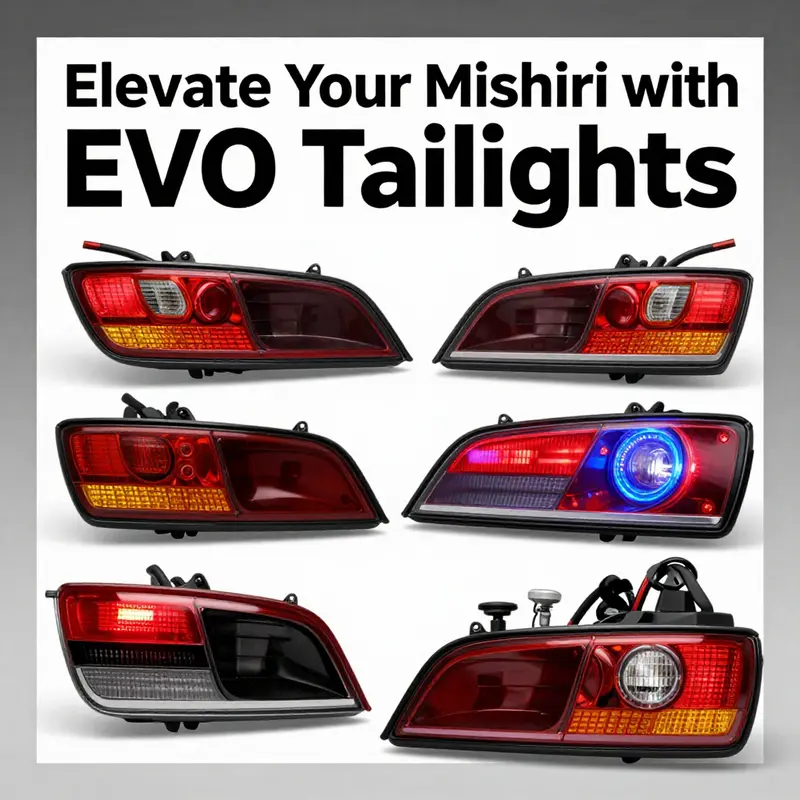

The rear lighting of a Mitsubishi Lancer Evolution carries more than visibility; it carries the car’s personality. In the Evolution X, a phase that spanned more than a decade from 2008 to 2020, taillights moved beyond mere safety signals to become a defining element of the car’s stance and identity. What began as a practical lighting solution grew into a visual signature that enthusiasts recognize from afar. The centerpiece of this signature is the distinctive LED pattern often described in terms that evoke speed and precision. The central, high-mounted brake light acts as a bright beacon, but it is the two horizontal clusters that flank it, each carrying its own array of LEDs, that bring the rear end into a compact, aggressive silhouette. This arrangement—bold, geometric, and symmetrical—reads as a modern homage to the traditional performance cues of rally-inspired design, while also signaling the car’s contemporary engineering. The effect is immediate: the rear looks wider, more planted, and distinctly purposeful whether the car is stationary in a showroom or ripping along a twisty back road. The simplicity of the lines contrasts with the complexity of the lighting technology, creating a visual language that is both legible to follow-on traffic and instantly recognizable to an audience that knows the EVO’s heritage. It is not an exaggeration to say that the taillight design contributes as much to the vehicle’s personality as the engine’s grunt or the chassis’ handling balance. The light pattern has thus become a visual shorthand for performance, a feature that owners learn to interpret with the same fluency they use to read a racetrack corner before it appears on the horizon. The straightforward geometry also makes the EVO taillights a ripe candidate for customization. Enthusiasts discover that the same core form can support a wide spectrum of modifications without sacrificing the recognizable identity that makes the EVO X stand out among other performance coupes. This is where the conversation about taillights extends beyond shape and into the realm of experiential design: color temperature, dynamic signaling, and even programmable effects become extensions of the driver’s personality and the car’s narrative. In this sense, taillights function like a stage lighting rig, shaping perception at a distance and shaping mood up close. The shift from incandescent to LED technology within these taillights brought improvements that mattered in practical terms as well. LEDs illuminate more quickly, emitting a sharp, focused glow that improves reaction time for following traffic. They also offer higher efficiency and greater longevity, which translates into fewer maintenance interruptions and more consistent performance across weather conditions. The Horse Race-like LED configuration, with its central high brake light and the two lower clusters, is not merely a pretty arrangement; it is a functional layout that supports rapid recognition under varying lighting conditions. The LEDs produce a brightness profile that is easy to parse for drivers behind, ensuring that braking intentions are communicated clearly even at higher speeds or in rain and fog. The pattern’s geometric clarity helps reduce misinterpretation, a crucial factor in high-speed contexts where split-second decisions can make a significant difference. During daylight or in well-lit streets, the taillight LEDs still contribute to the car’s legibility, outlining the rear with a crisp, modern glow that complements the EVO’s angular lines. The design also carries with it a sense of continuity; while new aftermarket options flood the market with different looks, the core motif remains anchored in that central brake element and the surrounding LED rows. This continuity is important for owners who want to preserve the EVO X’s distinctive identity while exploring enhancements that reflect contemporary tastes. Beyond the iconic pattern, aftermarket taillights expand the range of textures and finishes available to the owner. Some makers offer smoked or tinted lenses that soften the light’s outward appearance, lending the rear a more mysterious, street-ready aura. Others provide fully clear lenses with chromed or brushed inner finishes that emphasize a modern, precision-oriented aesthetic. These variations can subtly shift how the rear ends of the cars read in different lighting environments—from the glare of noon sun to the soft, twilight glow of a canyon road. The material choices in aftermarket kits also matter for durability. A robust taillight package typically uses polycarbonate lenses—a material prized for impact resistance and optical clarity over time—coupled with aluminum housings in some premium builds. Such construction helps manage heat generated by the LEDs and resists exposure to weathering, which is essential for owners who drive in diverse climates or encounter frequent road spray. The practical benefits extend to reliability in the long run. Under all weather conditions, from humid coastal air to chilly inland winds, the taillight system can perform consistently when well-sealed and engineered to resist moisture ingress. Moisture intrusion is a common pitfall, and it is a reminder that even the most exciting cosmetic upgrades must be paired with attention to sealing, gasket integrity, and proper mounting torque. In some discussions within the EVO community, moisture buildup or fog inside taillights has been cited as an issue in certain configurations. The takeaway is not to vilify aftermarket options but to acknowledge that sealing quality, electrical integrity, and proper installation determine whether a customization meets the rider’s expectations for reliability. For many, the pull of the EVO’s taillight identity is strong enough to justify investing in kits that tout improved waterproofing and stable light sources. These attributes translate into longer service life and more consistent performance across a spectrum of conditions, from heavy rain to dusty highways, and they help maintain the vehicle’s visual impact through the years. The allure of the taillights also lies in how well they harmonize with other design elements of the car. The rear lighting does not exist in isolation; it interacts with the bumper contour, the rear fascia, and the car’s aerodynamic lines. When the taillights glow, they accentuate the car’s width and weave a subtle bridge between the corners of the rear bumper and the glasshouse above. The interplay of light and shadow across the taillight faces contributes to a perception of depth, enhancing the car’s sculpted surfaces rather than simply illuminating the night. Enthusiasts often remark that the taillight treatment is most effective when balanced with other performance cues—rear diffusers, spoiler integration, or side-deck styling—that echo the same mechanical intent. In this sense, taillights become part of a larger choreography in which lighting communicates both function and form. For some, this choreography extends into advanced signaling features. Sequential turn signals, for example, have become a popular aftermarket enhancement because they deliver a dynamic motion cue that is easy for following drivers to read. A sequence of LEDs lighting in order from inside to outside can convey intent with a subtlety that mirrors the precision of a high-performance machine. RGB options, where available, open another avenue for personalization, allowing owners to tweak color temperatures and even create dramatic color shifts under certain conditions or events. While RGB lighting may be more common in other segments, when applied to an EVO taillight system it invites a personalized touch that still respects the original design language, because the underlying geometry remains recognizable even when the light output changes. In this way, personal expression and brand identity can coexist, giving owners a way to celebrate a passion for motion without losing the EVO’s historical silhouette. The broader ecosystem surrounding taillight upgrades also matters. Installation can be straightforward for plug-and-play options, reducing the barrier to adoption for enthusiasts who want a quick upgrade that preserves the vehicle’s factory wiring footprint. Yet not all plug-and-play solutions are equal. The best kits are designed with careful attention to weatherproofing, harness compatibility, and seal integrity, ensuring longevity in conjunction with an OEM-like fit. In some cases, builders tailor their approach to align with the vehicle’s other performance components, integrating cooling considerations or heat dissipation strategies around the LED assemblies to maintain brightness over long sessions on winding roads or track days. In other words, the EVO taillight story is as much about engineering discipline as it is about visual drama. Even as aftermarket options broaden the spectrum of appearances and features, there remains a strong respect for the original form. The taillight design has an iconic status that makes any change an act of careful negotiation between heritage and innovation. This balance keeps the EVO X faithful to its roots while inviting a new generation of owners to claim their own look. For readers who want to bridge the gap between OEM aesthetics and modern customization, there exists a range of options that preserve the original shape with elevated materials, sealing, and lighting technologies. The concept centers on letting light do more work—delivering quicker, clearer signals—while letting the exterior finish and the surrounding panels do the heavy lifting in terms of style. In practical terms, the decision to upgrade or preserve hinges on two factors: how often the car is driven in challenging weather and how much emphasis the owner wants to place on a distinctive rear silhouette. Those who drive regularly in rain or road spray may prioritize waterproofing and seal integrity, while those with a preference for bold visual cues may lean toward smoked lenses or sequential signals that accentuate the car’s motion. In both cases, the taillights remain a powerful storytelling device. They tell a tale of performance, precision, and customization all at once, joining a lineage that stretches back through the legacy of Japanese domestic market design and into the modern ecosystems of aftermarket engineering. For readers who are curious about the specific paths toward OEM authenticity and modernized aesthetics, there are routes that honor the original look while embracing new signaling capabilities. For those seeking a more historically faithful path, there are options that echo the JDM market’s styling cues in a way that respects the EVO X’s lineage. In contrast, for those who want a sharper, more contemporary stance, more aggressive lens finishes, higher-contrast reflectors, and lighter-weight components can deliver a more aggressive rear appearance that still plays nicely with the car’s overall balance. These choices reflect a broader trend in automotive customization: the pursuit of a signature look that remains legible to onlookers and safe for the road. The end result is not a single, monolithic upgrade but a spectrum of possibilities, each with its own flavor of personality and performance. The topic invites a conversation about how the rear end communicates with the road, how lighting technology has evolved, and how enthusiasts color their driving experience with a few strategic changes. An important note for readers who want to explore these options is the idea that some configurations keep the core geometry intact while offering a choice of finishes and signal dynamics. Keeping the original footprint guarantees compatibility with mounting points and wiring harnesses, reducing installation complexity and preserving return-to-stock options should the owner wish to revert to OEM styling. In other words, there is a practical path alongside the expressive one. If the journey toward customization is to be coherent, the owner should consider how taillight upgrades sit within the broader chassis and body-kit ecosystem. A complete package can be assembled that preserves the EVO X’s performance character while introducing a nuanced, high-visibility rear that can be tailored for subtlety or boldness. The taillight story, then, is not about a single feature but about a design philosophy. It is about recognizing how light and form interact with the car’s behavior, how a certain pattern can evoke speed even when the car is standing still, and how the right balance of materials, sealing, and electronics can extend the life of a visually dynamic element that is often the last thing a driver notices when stepping on the gas. For readers drawn to the OEM-inspired path, there exists a credible option that maintains a closer alignment with factory styling while offering authenticity in the signal and finish. This path emphasizes a faithful reproduction of the original pattern and lens geometry, ensuring that the light distribution remains familiar to observers who know the EVO’s rear at a glance. In contrast, those who want to push the envelope can lean into a more dramatic interpretation—smoked finishes, color-shifting accents, or motion-enabled signaling—while still honoring the familiar central brake beat and the two side clusters. The evolving dialogue around EVO taillights is a reminder that design and technology in performance cars are never static. They adapt to new production realities, new materials, and new driver expectations. The taillight, once a relatively backstage component, has become a frontier where aesthetics meet engineering. It is a place where the potential for personal expression can coexist with the shared identity of a beloved performance platform. As a final reflection, enthusiasts who examine the EVO X taillight design often encounter a practical truth: the right taillight choice improves safety, enhances comfort on long drives, and reinforces the emotional resonance of owning a car that was built to feel fast, even when parked. The interplay of light, form, and engineering tells a story that is as much about anticipation as it is about arrival. For readers who want to explore deeper, there is a curated path to authentic JDM styling variants that preserve the original cues while allowing modern power and brightness to accumulate over time, a route that respects history while inviting new interpretation. See this internal reference for a perspective on closer-to-OEM authenticity and its look-and-feel implications: authentic-jdm-evo-9-mr-taillights. External resources that illuminate the EVO X’s official lighting design and its visual language can be found at the official manufacturer’s site, which documents the taillight geometry and lighting philosophy in detail: Mitsubishi EVO X official lighting page.

null

null

Behind the Glow: Diagnosing and Fixing EVO Taillight Issues

The rear end of an Evolution is more than a slipstream silhouette and a row of bright lamps. It is a compact, living system that communicates intention to other drivers and, in many respects, to the vehicle’s own brain. EVO taillights are designed to blend form and function, weaving crisp LED geometry with the practical duties of signaling, visibility, and safety. Across generations, these rear lamps have become a signature detail—a visual cue that signals a car built for performance and precision. Yet the same complex integration that gives them their distinctive look also makes them susceptible to the kinds of faults that unsettle enthusiasts and daily drivers alike. When the glow fails or falters, it is rarely a single, solitary bulb that has given up the ghost. More often, it is a cascade of small issues that compound into an unreliable lighting system. Understanding this cascade is essential for anyone who intends to keep the rear lighting both dependable and expressive, preserving the vehicle’s aesthetic while safeguarding its functional role on the road.

The most frequent disruption is non-functioning or flickering tail lights. In practice, one or more lamps may cease to illuminate, or they flicker intermittently as the car is driven. The root causes can be as simple as a burnt-out bulb, or as intricate as a compromised electrical path. In basic terms, dual-function clusters—those that handle both tail and brake lighting—rely on robust filament integrity when using traditional bulbs. If the brake-light filament fails, the tail light might still glow, but the incomplete signaling can mislead following traffic and heighten the risk of a collision. The diagnostic path starts with the familiar, almost ritual check: inspect each bulb, replace any that are burnt, and look for corrosion or loose connections in the socket. A multimeter becomes a loyal guide here, testing continuity from the harness to the lamp. The tone of the issue can hint at deeper electrical faults, especially when multiple lamps show symptoms in concert. In such cases, the problem is rarely confined to the lamp itself but suggests a broader electrical or control-system fault that deserves careful tracing.

A second pattern centers on the brake light switch. Nestled near the brake pedal, this switch is the momentary bridge that activates the brake lamps whenever the pedal is pressed. Over time, wear, misalignment, or simply a ding from repeated use can cause the switch to stick or drift. The consequence is a brake signal that either lingers when the pedal is released or, conversely, fails to engage when needed. The practical test is straightforward: with the pedal held steady, measure the voltage response at the harness using a multimeter. If there is no change as the pedal depresses, the switch may need replacement. But the diagnosis should also consider mechanical clearance and alignment. A misaligned switch can produce the same symptom as a failed switch, and a simple readjustment can restore proper signaling without touching the wiring.

Grounding problems form the third common thread that threads through many EVO taillight failures. A weak or corroded ground can sow uncertainty into the circuit, producing dim lighting, uneven brightness, or intermittent operation that seems to wander from one lamp to another. The rear light cluster often grounds to a trunk or frame rail, sometimes through a hardware-fastened point that corrodes with exposure to humidity and road spray. The remedy is practical and tactile: locate the ground point, clean the metal surface to bare metal, and reattach the ground lead with a solid mechanical bite. Dielectric grease can help to seal the connection against future moisture intrusion while preserving electrical contact. This isn’t a glamorous fix, but it’s one of the most effective ways to stabilize the energy path that powers the taillights, especially in climates that subject cars to rain, spray, or frequent car washes.

Water ingress and lens fogging represent another facet of the same problem: moisture can slip into the housing through aging seals or microscopic cracks, and once inside, it can condense on lens surfaces, corrode connectors, or even create tiny short circuits. In practice, moisture is not always obvious from outside the lamp. A slightly foggy interior, a pearl-like sheen on the inner wall, or a subtle dampness around the sealing gasket can all be signs of trouble. The immediate steps are to inspect the rubber seals around the housing and to replace any that show cracking or hardening. If moisture has already penetrated, the taillight unit should be removed to dry the internal components thoroughly. After drying, the connectors should be treated with dielectric grease to guard against future moisture ingress. In the long term, ensuring that seals match the housing geometry and that gasket compounds are appropriate for automotive use reduces the likelihood of recurrence.

Electrical overloading is a more technical fault line that emerges when aftermarket lighting components or high-wattage bulbs draw more current than the EVO’s electrical system was designed to handle. The result can be blown fuses, damaged relays, or, in the worst case, harm to the instrument cluster or the body control module. The caution here is simple: aftermarket LEDs or brightened units can be alluring, but compatibility is not decorative—it is essential. The practical approach is to verify that any replacement lamps or assemblies are designed to work within the factory electrical envelope. When in doubt, choose lighting options that include built-in resistors or load equalizers to simulate the electrical load of the original lamps. If a fuse has blown, locate the relevant fuse in the fuse box—the label in the panel typically clarifies its function—and replace it after confirming that the installation won’t create a new overload elsewhere in the circuit.</n

Alongside these electrical considerations, a dashboard warning triangle often punctuates the issue with a yellow beacon of caution. This symbol can indicate a minor fault, such as a single bulb failure, but it more often points to a broader electrical fault or sensor/ECU communication problem. The prudent route in such cases is to pull the OBD2 scanner and read the fault codes tied to the lighting system. Codes like those associated with brake switch malfunctions, lighting system faults, or lost communication with the body control module provide a map of where to focus the investigation. The codes themselves do not fix the problem, but they translate a scattered set of symptoms into actionable steps. With this information in hand, an owner can decide whether the issue is best resolved through targeted bulb and socket replacement, a recalibrated switch, a reestablished ground, or a more systemic electrical repair that might involve the BCM or related controllers.

In exploring these fault modes, it is important to keep in view the generational nuances that shape EVO taillight design. Across generations, rear lighting clusters evolved from simpler, more bulb-based arrangements to more integrated assemblies that emphasize LED signaling, optics, and sealing technologies. The shift toward LEDs brought brightness, color control, and longer life but also introduced new failure modes, such as temperature-sensitive resistor behavior, connector friction, and seal integrity under varied thermal cycles. The reading of the cluster’s behavior—whether a lamp is dim, flickers, or fails entirely—benefits from a holistic diagnostic mindset. Rather than treating a single symptom in isolation, a methodical approach traces the symptom through the power supply, the control input, the ground reference, and the physical sealing. This approach not only increases the likelihood of a correct fix but also helps preserve the aesthetic integrity of the taillights. After all, the EVOTail design is meant to be as striking in the dark as it is precise in signaling, and a reliable electrical backbone is essential to maintaining that balance.

From a maintenance perspective, preventive care pays dividends. Regular inspection of the taillight assemblies during routine servicing—checking seals, ensuring clean contact surfaces, and confirming that fasteners remain snug—helps forestall many issues before they become evident to drivers. When installing any aftermarket lighting, care must be taken to manage electrical load and signal behavior. Even though the temptation to push brighter, more attention-grabbing options is strong, the vehicle’s electrical architecture demands respect. Specialist guidelines suggest using plug-and-play assemblies that are designed to interface with the vehicle’s wiring with minimal modification. They also recommend avoiding high-power configurations that circumvent built-in resistance and that could cause unintended consequences, such as dimming of other lamps or dashboard warnings.

For readers seeking a more authentic, factory-adjacent appearance while maintaining performance, there are dedicated variants that follow OEM styling cues. These options tend to emphasize alignment, seal integrity, and exact-lens matching, which helps reduce moisture ingress and misalignment that can contribute to signaling irregularities. However, even with OEM-styled or OEM-compatible options, the same fundamental principles apply: precise installation, verified electrical compatibility, and thorough testing after any replacement. The tail end of the process is a functional verification across all lighting modes—running, braking, and signaling—to confirm that the entire system behaves predictably under real-world driving conditions. In practice, the tail lights should illuminate promptly when the headlamps and running lights are active, brighten distinctly under braking, and execute a clean, unambiguous signaling sequence when the turn signals are engaged. This is the essence of reliable EVO taillight performance: a lamp system that communicates clearly, stays consistent through the car’s duty cycle, and endures the rigors of daily use.

Alongside the practicalities of diagnosis and repair, the literature and community discourse around EVO taillights underscore a broader theme: the balance between aesthetic ambition and electrical reliability. Enthusiasts are drawn to the way taillight assemblies frame the vehicle’s rear silhouette, the way LEDs render crisp, controllable signals, and the possibility of dynamic lighting features such as sequential turn signals or color-changing modes. The same features that make the lighting system so appealing also raise the stakes for reliability. When a lamp fails in a high-visibility, performance-oriented car, the impact is felt not only in safety but in the perception of the build’s quality. Therefore, a careful, informed approach to troubleshooting is not merely technical housekeeping; it is a craftsman’s discipline—one that preserves both the car’s performance identity and the trust that comes with reliable signaling.

It is worth noting how the aftermarket ecosystemhas built on this relationship between form and function. A wide range of replacements and upgrades exist for EVO taillights, from sealed LED assemblies to advanced optics that shape the light pattern for improved visibility. The availability of these options reflects a community of builders who value both the aesthetic punch of a bright rear end and the practical realities of wiring, sealing, and electronic compatibility. Yet, this diversity also introduces more decision points for the owner: choosing components that resist moisture intrusion, match the vehicle’s electrical characteristics, and integrate with the car’s signaling logic. The guiding principle remains straightforward: any modification should preserve or enhance safety and reliability while respecting the engineering constraints of the EVO’s lighting system. The result is a carefully curated balance—one that keeps the glow as a badge of performance and a dependable indicator of intent on every drive.

For readers who want to explore the subject further in a more hands-on way, there is a wealth of practical guidance on installation and electrical handling. While the broader landscape is full of variations, some universal tips cut across generations. Always begin with a clean slate: verify the power and ground connections, test the continuity of the wiring harness, and confirm that fuses and relays are appropriate for the load. When aftermarket components are introduced, validate compatibility with the car’s body control module and consider adding load resistors to ensure that the LED assemblies do not create electrical feed-through problems elsewhere in the system. This kind of systematic approach is the bedrock of reliable taillight performance, and it serves as a reliable companion to the more aesthetic side of EVO lighting that car enthusiasts chase.

A reader who looks to deepen their understanding can take a practical step into the world of OEM-adjacent solutions with a dedicated reference that discusses JDM styling and its integration with proper sealing and mounting. This resource, linked here for further reading, provides context on how authentic styling approaches converge with the realities of modern automotive electrical systems. authentic-jdm-evo-9-mr-taillights. It is not a substitute for the hands-on checks described above, but it helps frame the discussion around the importance of fit, finish, and reliability when pursuing a look that respects the car’s lineage while embracing contemporary lighting technology.

In closing, the journey through EVO taillight issues is really a study in how precision engineering meets practical maintenance. The taillight system is not just a cosmetic flourish; it is a critical safety and signaling network that operates in a harsh, real-world environment. When any element—bulbs, switches, grounds, seals, or control modules—drifts from spec, the entire system’s integrity can be compromised. The right troubleshooting mindset is about tracing symptoms to their sources with a combination of straightforward electrical checks and careful mechanical inspection. It is about recognizing how changes in one part of the system can ripple through the others. And it is about balancing the desire for an eye-catching rear end with the imperative of reliable signaling. For enthusiasts and owners alike, this balance is the key to keeping the EVO’s taillights both spectacular and dependable, ensuring that every night drive ends with a clear message from the car to the world behind it.

External resource for installation and maintenance guidance: https://www.manuals.plus/vland-led-headlights-installation-guide-for-mitsubishi-lancer-evo-x-2008-2020

Final thoughts

Investing in quality EVO taillights is essential for not only enhancing the aesthetics of Mitsubishi vehicles but also ensuring their safety and performance. With an array of designs and features available, including aftermarket options that offer enhanced functionalities, business owners can better serve the automotive needs of their clients. However, being aware of common issues and understanding troubleshooting techniques will help maintain the integrity and longevity of these components. By adopting these insights, you can ensure both the beauty and performance of the vehicles you manage.