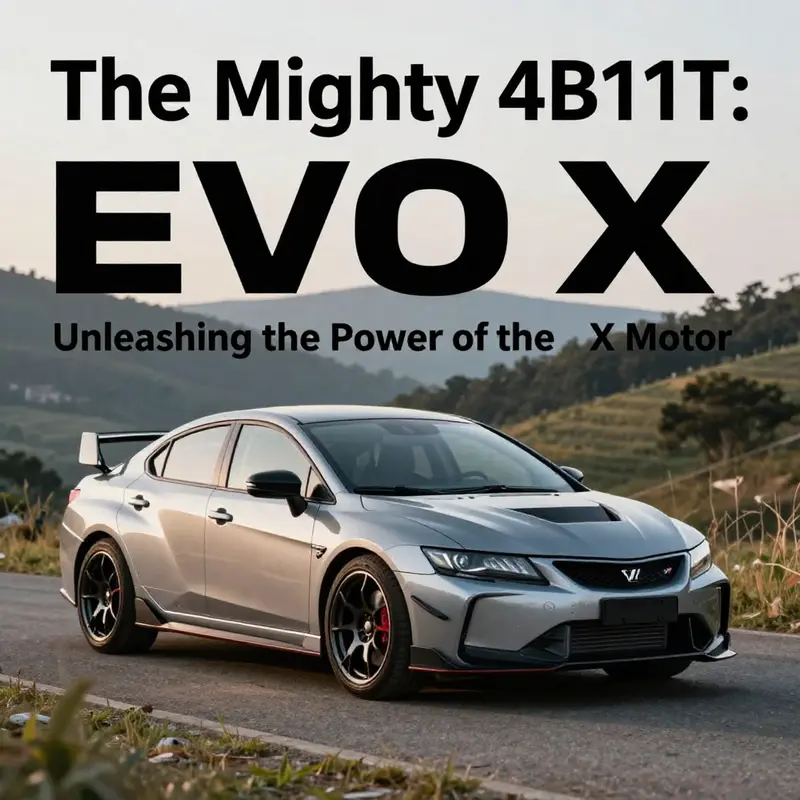

The EVO X, a hallmark of performance and engineering excellence, is powered by the 4B11T engine, a turbocharged marvel that has captivated enthusiasts and businesses alike. With specifications boasting up to 303 horsepower and 422 Nm of torque, this motor not only redefines speed but also represents a significant leap in performance engineering. In this exploration, we delve into the rigorous specifications and performance capabilities of the EVO X motor, the innovative technologies that pushed its boundaries, the economic ramifications it has had in the motorsport sector, and its profound cultural significance within automotive enthusiast communities. Each chapter will weave together these elements to portray the complete narrative of the EVO X motor’s legacy.

Power, Precision, and AWD Mastery: Inside the Evo X’s 4B11T Powertrain and Performance

The Mitsubishi Lancer Evolution X sits at a crossroads of racing-influenced engineering and everyday practicality, a compact sedan that roars with a purpose. At its core lies a 2.0-liter turbocharged inline-four, a compact engine that wears the code 4B11T with quiet pride. This drivetrain is a study in balance: a high-boost, responsive motor paired with a sophisticated all-wheel-drive system and a set of calibrations that translate raw cylinder pressure into predictable, track-ready handling. The engine’s heart is a DOHC, 16-valve layout that breathes via Mitsubishi’s MIVEC technology, a variable valve timing system that shifts the engine’s character from off-the-line pull to mid- and top-end response. With a compression ratio of 9.5:1, the 4B11T is tuned to squeeze significant power from every drop of air and fuel, while still maintaining enough tolerance for everyday running. The intake and fuel delivery are arranged to keep throttle response brisk and linear, an important trait when you are chasing lap times rather than merely cruising down the boulevard. The cooling system is engineered to match that ambition, featuring a front-mounted intercooler that keeps charge air temperatures in check, a critical factor when boost pressure climbs and the engine is pushed toward its upper limits on a hot summer day or a long, demanding session on a closed course. The engine’s torque curve is a direct witness to its design philosophy: strong response across a broad rev range rather than a narrow burst of peak numbers. In practical terms, that means acceleration remains confident and predictable as you climb through the gears, and torque is available where you need it most—on corner exits and mid-speed straights alike. The induction path and the turbocharger choice—the IHI VF37 in the early production stages, with later versions offering larger variants for higher-performance builds—was chosen to balance midrange force with top-end potential. The result is a powerplant that feels eager, not shouty, but where the sound and the surge make clear that there is more to offer if you’re willing to pursue it. The engine’s vigor is wired into the car’s broader performance architecture, and it is complemented by a robust cooling regime and reinforced engine mounts that minimize unwanted movement under high boost and aggressive cornering. The integration of the 4B11T with Mitsubishi’s Sequential Fuel Injection system ensures precise metering of air and fuel, maintaining efficiency and stability across the operating envelope. In short, the Evo X’s engine is not only capable of delivering substantial horsepower; it is designed to deliver it with a kind of everyday reliability and a feel that makes you want to keep turning the key, again and again, chasing the next corner or the next straight. The numbers tell a disciplined tale. In most markets, the Evo X GSR and MR models were tuned to deliver 291 horsepower at 6,500 rpm. This baseline performance in the early and mid-life variants reflects a torque figure in the neighborhood of 366 newton-meters, a value that aligns with the car’s all-wheel-drive intent and its capacity to put power to the tarmac without drama. The Final Edition, released in 2015 to commemorate the end of the line, pushed the output to 303 horsepower, a clear signal that the engineers aimed to squeeze every last drop from the platform while preserving the character that enthusiasts had come to value. Torque figures followed suit, extending from a practical 366 Nm to a robust 422 Nm (311 lb-ft), a peak achieved at a relatively accessible 4,000 rpm for the Final Edition. That torque profile—strong off-idle, then maintained into the midrange—plays into the Evo X’s ability to launch with authority from a standing start and to respond decisively in mid-range torque hunts on the road or track. The engine’s performance is not a solitary light in a room of darkness; it is a core component of a total system designed to deliver traction where it matters most. The transmissions paired with this heart are equally telling. The standard GSR version is equipped with a five-speed manual, a setup that aligns with enthusiasts’ desires for direct, mechanic-first involvement. For those seeking sharper on-road performance or track credibility, the MR designation adds a six-speed Twin Clutch Sport Shift Transmission (TC-SST). This dual-clutch arrangement seeks to bridge the gap between pure manual engagement and the smooth, rapid shifts that modern performance credentials increasingly demand. Yet the Evo X is more than a powerplant and a gearbox; it is a holistic drivetrain symphony engineered to exploit every bit of torque and every degree of grip that the all-wheel-drive system can muster. Mitsubishi’s Super All-Wheel Control, or S-AWC, is the umbrella that keeps power and control in a disciplined balance. It layers an active center differential with an active rear limited-slip differential, all tied together with an active stability control system that can intervene with surgical precision. This is not simply a drive mode; it is a dynamic hardware-software marriage that communicates with the engine control unit (ECU) in milliseconds, deciding which wheels receive bite, how much yaw stability to deploy, and how to transfer torque across the axle complex as the car navigates a corner or a straight. In practice, S-AWC yields traction not merely by distributing power, but by predicting and preventing loss of traction before it occurs, a capability that can be felt most clearly when the Evo X is pushed on a road course where chassis inertia is high and grip varies with apex speed and surface condition. The chassis engineers did not rely on electronics alone. They provided a cooling architecture robust enough to sustain performance under heat soak and extended track usage. The intercooler front-mounted but shielded from airflow obstructions, reinforced engine mounts, and a cooling loop designed to minimize temperatures during high-boost acceleration all converge to maintain consistent performance. This is the kind of orchestration that allows a 4B11T to deliver consistent lap times rather than a single, hot-blown burst of power on a cold morning. When we examine the engine by itself, we see a well-balanced combination of hardware and software that makes the Evo X more than a straight-line burner. The engine’s block in most high-performance configurations remains fundamentally sturdy, and with the right upgrades it has demonstrated the capacity to sustain enhanced horsepower levels well into the three-figure range, with examples circulating in enthusiast circles showing forged internals, upgraded turbochargers, and high-capacity fuel systems aimed at running on alternative fuels such as ethanol blends. In these high-end builds, components such as forged pistons, rods, and crankshafts, paired with larger turbochargers—some in the realm of significantly increased compressor flow—are used to extract power well beyond the factory numbers. Fuel delivery systems are similarly upgraded, often with higher-flow injectors and fuel pumps to maintain stable pressure under boost. It is not unusual for builders to push the 4B11T toward the 600 horsepower neighborhood in controlled environments, with reliability contingent on meticulous tuning and an appropriate fuel strategy. Even so, the baseline Evo X remains a potent machine with ample headroom for spirited driving and track use at stock or lightly upgraded configurations. What differentiates the Evo X from many of its contemporaries is not simply the raw horsepower; it is the depth of engineering behind the powertrain and the way it is integrated with the vehicle’s chassis and control systems. This is a car that rewards disciplined driving and precise input. It rewards the user who understands that torque is a tool to be wielded with finesse, not a ticket to reckless speed. It rewards the driver who respects the limits and uses wind, grip, and aero as allies rather than enemies. The Evo X’s powertrain is a living example of how a turbocharged engine, a well-motted torque path, and an advanced AWD system can work together to create a coherent and thrilling driving experience. The base power figures—291 horsepower and 366 Nm of torque—are not mere numbers; they are a snapshot of a broader design philosophy that emphasizes controllable power, stable midrange response, and predictable behavior under load. The Final Edition’s 303 horsepower and 422 Nm torque represent the culmination of engineering work that sought to extract every ounce of performance from a well-tuned platform without compromising the car’s overall balance and everyday usability. It is this balance—the engine’s ability to deliver strong, usable torque with a chassis that can translate that torque into grip and speed—that makes the Evo X a standout in the modern, turbocharged performance landscape. For those who prefer a more hands-on experience, the GSR’s five-speed manual remains a compelling option, offering direct mechanical engagement that fosters a tactile connection to the car’s dynamics. But even with a manual, the MR’s six-speed twin-clutch option is not merely about faster shifts; it is about maintaining the car’s composure and traction in high-load situations where a conventional manual might exhibit shift-induced torque disruption. The synergy between the 4B11T powerplant and the S-AWC system is what turns power into confidence on a winding road or a tight racetrack. It is the reason the Evo X can be driven squarely into a corner with a measured throttle, the reason it can exit with a controlled surge of torque that grips the pavement, and the reason it can be both a practical daily driver and a serious performance machine when the road presents an opportunity to explore its limits. It is also worth noting that the Evo X, in its production form, did not pursue wheel-mounted electric propulsion. The discourse around electrification or “on-wheel” motors belongs to future technology speculation and assessment of evolving performance paradigms, not to the car’s original, mass-produced powertrain. The engine and drivetrain described here are the product of a time when internal combustion, turbocharged efficiency, and a sophisticated AWD system defined the chassis’s character. In that sense, the Evo X offers a coherent snapshot of gasoline performance engineering—one where the 4B11T, the MIVEC timing, the IHI turbo, and the S-AWC drive system combine to form a complete and usable performance package. This unity resonates with the way the car handles on track days and how it remains a compelling option for drivers who want a legitimate rally-bred experience without sacrificing everyday usability. The meticulous tuning across markets can be attributed not only to different emission and safety standards but also to the varying needs of customers who demand a car that is at once tractable in normal traffic and capable of serious performance when asked. The Final Edition’s ability to push horsepower to 303 and torque to 422 Nm is less about spectacle and more about delivering a matured, final expression of an engine family that started with a clear mission: to provide a robust, engaging, and trustworthy performance sedan that could be driven hard yet remain reliable enough for daily use. In practice, this means you can navigate a windy road with confidence, feeling the torque blossom as you roll into a corner, and then plant your foot on the exit to experience a balanced surge of propulsion. When you think about the Evo X’s motor in the broader context of performance engineering, the significance lies in how the 4B11T has been calibrated and integrated with the chassis to deliver a coherent sensation—an experience that is at once precise, rewarding, and repeatable. The engine’s design philosophy—prioritizing linear power, robust cooling, and a drivetrain that manages grip with instinctive efficiency—illustrates why the Evo X remains a benchmark among enthusiast drivers who seek a modern interpretation of a classic rally ethos. For readers exploring this topic further, the 4b11t billet block stands as a reminder that even in a production-focused platform, there is room for high-performance engineering details that can influence reliability, responsiveness, and the potential for future enhancements. Accessing official data and more exhaustive engineering insight can provide a window into how such components are conceived and validated, underscoring the care that goes into preserving the character that has made the Evo X a beloved reference in the world of performance cars. External references and deeper technical exploration can be found on established official resources, which document the engine’s fundamentals, its calibration, and the broader technical ecosystem that supports it. For those who want to dig deeper into the engine’s architecture and the way it interacts with the drivetrain, the official Mitsubishi platforms and technical catalogs offer a comprehensive foundation for understanding how the 4B11T powers this legendary machine. As with any performance-focused platform, the Evo X rewards informed driving, consistent maintenance, and thoughtful upgrades that respect the car’s original design intent. The combination of a capable turbocharged engine, a responsive valvetrain, and a sophisticated all-wheel-drive system makes the Evo X a compelling reference point for how modern rally-inspired technology can translate into a gratifying, well-rounded driving experience. It is a reminder that horsepower numbers, while important, are only part of the story; the full narrative lies in how those numbers are delivered, managed, and harnessed to create a car that is as thrilling on a winding road as it is reliable when used day to day. External reference: https://www.mitsubishi-motors.com/

The 4B11T Engine: How EVO X’s Motor Engineering Delivers Turbocharged Precision

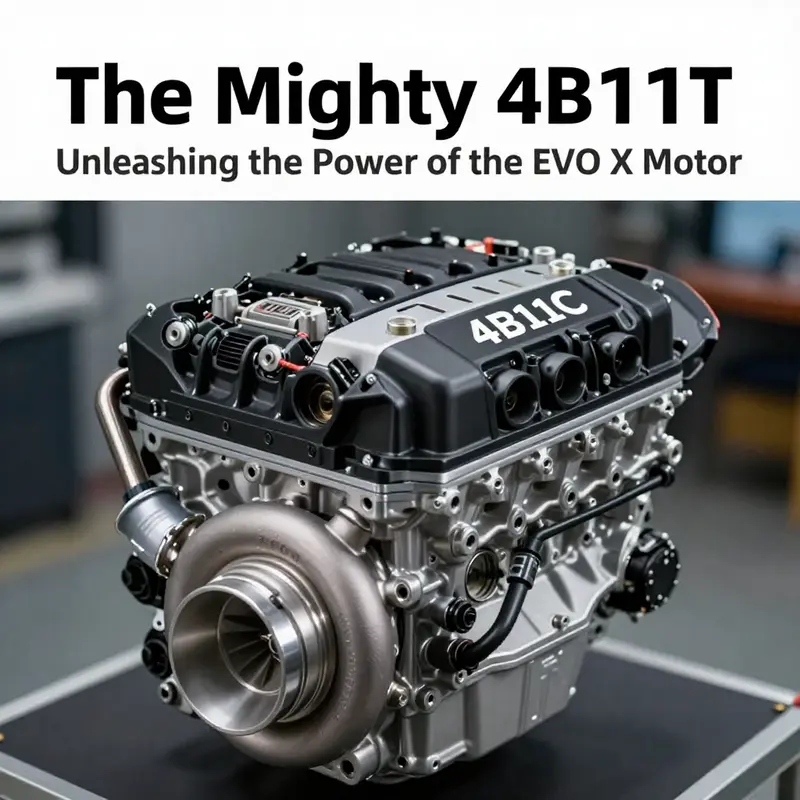

The 4B11T Engine: A Compact Powerhouse and Its Purpose

At the heart of the EVO X sits a 2.0-liter, all-aluminum inline-four turbocharged engine known by its code, 4B11T. This powerplant is more than a number. It is the result of focused choices that balance peak power, packaging, and the torque delivery needed for a high-performance, all-wheel-drive sedan. The factory figures vary slightly by market and model year, but most versions produced between 291 and 303 horsepower, with peak torque in the range of 366 to 422 newton-meters. Those numbers matter, but how the engine makes its power matters more—and that is where the engineering choices reveal themselves.

The 4B11T was designed as a modern replacement for an older, more traditional performance four. Engineers prioritized a compact architecture, lightweight materials, and flexibility for tuning. The all-aluminum construction reduces mass and improves weight distribution. Using a turbocharged four-cylinder keeps the frontal area tight. That benefits the car’s aerodynamics and allows a lower hood line. The net result is an engine that can be packaged deep and low in the chassis. This packaging reduces polar moment and improves steering responsiveness.

A key technological focus was valve control. The engine employs MIVEC variable valve timing. MIVEC alters valve timing to balance low-end drivability and high-rpm breathing. At low engine speeds, valve timing favors torque and throttle response. At higher revs, timing shifts to improve volumetric efficiency and power output. This variable timing softens the compromise between driveability and peak performance. The result is a motor that feels tractable in daily driving, yet animated when the driver pushes for speed.

Turbocharging is central to the 4B11T’s character. The turbocharger provides a compact, efficient way to increase air mass into the engine. The engine breathes through an intercooler and carefully routed plumbing, designed both for thermal management and responsive boost delivery. Turbo sizing and turbine housing geometry were chosen to deliver useful boost across a wide rev range. That keeps low-end acceleration immediate, while preserving midrange and top-end strength. Boost delivery also works in tandem with engine management to keep the throttle response crisp, which is essential for driver confidence in spirited driving.

Thermal and oil management are crucial in a turbocharged layout. The 4B11T uses an oiling system and cooling architecture designed to handle the extra heat load from the forced induction. Managing residual heat helps preserve power consistency during repeated hard driving and prevents detonation. Heat shielding and efficient intercooling ensure that intake air temperatures remain stable, which protects both performance and reliability.

Forging a fast car requires integrating the motor with the drivetrain it feeds. In the EVO X, the 4B11T does not act alone. It cooperates tightly with an advanced all-wheel-drive system. That AWD system was calibrated for torque-vectoring and active handling, allowing the engine’s output to be directed where traction favors lap times and control. Engineering the engine and AWD together changed the way a driver experiences power. Instead of a simple front or rear bias, the car can modulate torque front to rear and side to side. This dynamic distribution amplifies cornering precision and straight-line acceleration.

Electronics and engine management complete the package. The ECU monitors dozens of parameters to coordinate ignition timing, fuel delivery, boost control, and valve timing. That coordination keeps the engine on the safe side of performance limits while maximizing output. The mapping accounts for different fuel qualities across markets. It also accounts for ambient temperatures and altitude, allowing the car to perform predictably in varied conditions.

Engineering choices extended to durability and serviceability. While the factory engine was built to deliver strong performance out of the box, designers left room for progression. Enthusiasts and professional shops often explore strengthened blocks and upgraded components to extract greater power. For those who want a beefier foundation, aftermarket billet block options exist to support heavily modified builds. One such resource discusses a billet replacement for the 4B11T block, a modification commonly pursued by those targeting higher boost and sustained power levels: 4B11T billet block. The existence of these aftermarket paths reflects the original design’s adaptability and the strong community that formed around extracting more from the platform.

Tuning potential is both a benefit and an engineering challenge. The 4B11T responds well to bolt-on upgrades, intercooler improvements, and careful ECU calibration. However, each change alters thermal, mechanical, and drivetrain loads. For example, higher boost increases cylinder pressures and stresses the crankshaft, pistons, and rod bearings. Engineers and builders manage these risks with stronger internals, improved oiling, and better cooling. Upgrades therefore follow a systems approach. It’s not just about adding a larger turbo. It’s about ensuring the entire engine and drivetrain ecosystem can handle the increased performance.

Another factor that sets the motor apart is its calibration for the vehicle’s handling systems. Engine torque maps are adjusted to complement stability and traction controls. That creates a natural synergy between throttle input and chassis behavior. When a driver opens the throttle mid-corner, the system can modulate torque to aid rotation without upsetting balance. This subtle coordination makes the car feel more predictable and assists drivers who want to extract performance without losing control.

Real-world driving brings engineering tradeoffs into focus. The motor’s relatively compact displacement with turbocharging balances fuel economy against peak output. In everyday driving, variable valve timing and direct engine management help keep consumption reasonable. Under demanding driving, the engine produces the power that makes the platform competitive. Owners often praise the combination of linear part-throttle response and explosive midrange, a trait engineered into the motor’s physical and electronic design.

Serviceability and maintenance remain practical concerns. Turbocharged engines need attentive oil changes and cooling system checks. The thermal loads introduced by forced induction mean oil quality and cooling capacity are not optional. Long term reliability hinges on scheduled maintenance and using fluids that meet the engine’s demands. Owners who respect these needs commonly enjoy both strong performance and durability from their motors.

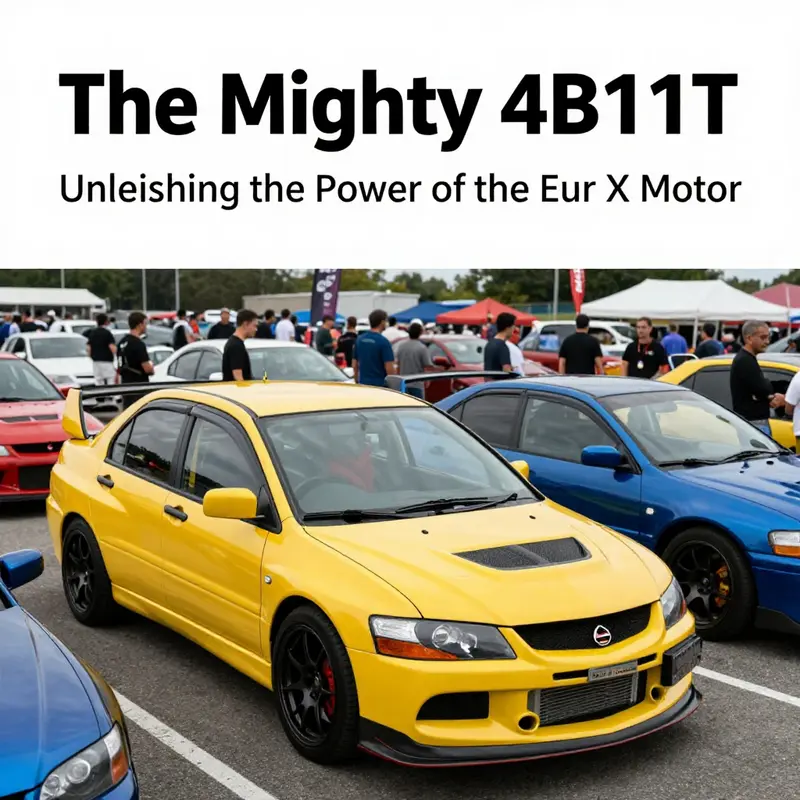

The EVO X motor also shaped the car’s legacy in motorsport and tuning culture. Its engineering choices—compact turbocharged displacement, variable valve timing, and tight packaging—made it an attractive base for rally and track work. Builders could adapt the motor for high-power applications while preserving the chassis balance that the car’s AWD system offered. This versatility amplified the platform’s appeal and helped it remain relevant within enthusiast circles.

Even as technology evolves, the engineering lessons embedded in the 4B11T remain relevant. Packaging a potent, lightweight engine that integrates seamlessly with a sophisticated drivetrain shows how coordinated engineering elevates a car’s driving character. The EVO X’s motor was not a single innovation but a set of deliberate design choices. Each choice—materials, valve timing, turbo sizing, thermal strategy, and ECU mapping—worked with the others to produce a performance profile that was both usable and thrilling.

For readers seeking deeper technical details, authoritative reviews and engineering breakdowns provide structured analysis of the motor and vehicle systems. A comprehensive overview of the platform’s features and performance can be found at MotorTrend: https://www.motortrend.com/cars/mitsubishi-lancer-evolution-x/.

Overall, the 4B11T illustrates a measured approach to high-performance engine design. It favors systems thinking over single-component heroics. That approach delivered a motor that fit the car’s mission: immediate throttle response, wide usable torque, and a resilient platform for further tuning. The EVO X’s motor engineering remains a case study in balancing modern turbocharged performance with real-world usability and chassis integration.

Powering Prestige: The EVO X Engine and Its Economic Echo in Motorsports

The Mitsubishi Lancer Evolution X, often remembered for its rally-bred poise and track-ready chassis, centers its performance on a compact yet formidable heart: the 2.0-liter inline-four turbocharged 4B11T. This engine, crafted with an aluminum block and a carefully tuned variable valve timing system (MIVEC), delivers horsepower in the vicinity of 291 to 303 when factory spec is respected, with peak torque commonly ranging from 366 to 422 Newton-meters. In the eyes of engineers and drivers alike, those figures are not merely numbers; they are a signal of how a compact powertrain can translate into a driving experience that feels expansive on both road and stage. The EVO X’s engine does not exist in isolation. It is paired with a sophisticated all-wheel-drive platform and a sport-tuned suspension that exploit the turbocharged surge, delivering a cohesive, communicative feel that invites the driver to push closer to the limits. The result is a car that communicates with the road at a level that makes performance tangible, not abstract, in every kilometer traversed and every lap completed. Although some speculative discussions about “on-wheel” or electric horizons hover around the EVO X’s lineage, the production reality shows a traditional internal-combustion engine powering a machine designed for immediacy and engagement rather than the quiet efficiency of an electrified future. This is not to dismiss the value of electrification in the broader motorsport discourse, but to acknowledge that the EVO X line, in its commercially available form, remains firmly rooted in combustion power, refined through decades of Mitsubishi’s rally experience and engineering discipline. The engine’s 4B11T designation, its aluminum architecture, and its turbocharged character combine to create a powerband that remains extremely live in the mid-rev to high-rev range, a quality that resonates with driving enthusiasts who chase a direct line from pedal to road feedback. The engine’s torque curve, delivered through a carefully selected gearing strategy and a well-calibrated turbocharger, ensures that the car remains responsive across a broad spectrum of speeds, allowing for the kind of confident mid-corner acceleration that characterizes competitive driving on both smooth asphalt tracks and winding rally stages. In this sense, the EVO X engine acts as a bridge between raw performance and the practical reality of racing and high-performance road use. The motor’s integration with Mitsubishi’s all-wheel-drive system and its sport-tuned chassis creates a cohesive package where power and control reinforce each other, producing a driving experience that can be both thrilling and precise, depending on how the driver engages the throttle, the steering inputs, and the behavior of the traction system. Yet the conversation around this engine extends beyond the drive itself into the realm of economics and industry, where the engine becomes a point of contact for a network of manufacturing, aftermarket tuning, and motorsport activity that interacts with regional economies and global markets. While the published research on the EVO X’s economic impact is not compiled into a single quantified dataset, the available material invites a broader contemplation of how high-performance engines contribute to the economic fabric of motorsports and related industries. The engine’s reputation as a capable power unit fuels demand not only for ready-made cars but also for a thriving ecosystem of components, services, and knowledge transfer that sustains a wide spectrum of activities—from the precision machining shops that craft billet blocks to the specialist tuning shops that optimize turbocharged performance, and from track days and rally events to the sales of reproduction parts and performance accessories. In practical terms, this ecosystem translates into a chain of economic activity: suppliers of lightweight materials, engineers who calibrate engine maps and boost curves, technicians who fit and tune aftercare parts, and race teams or private entrants who invest in equipment to compete, learn, and showcase their craft. The engine’s reputation thus becomes a catalyst for a broader market that benefits from improved machining capabilities, new software and simulation tools, and a culture of performance that has spillover effects into mainstream automotive innovation. The economic dimension of such a motor rests not only on its direct use in competition but also on the way it spurs demand for high-performance components and specialized services. The 4B11T’s architecture—an efficient balance of power density, weight savings through an all-aluminum block, and a turbocharged response—encourages the development of modular performance parts. In turn, this drives a motorcycle-level precision in manufacturing and a car-building ecosystem that thrives on small-batch, high-value production. Even when direct race participation data remains elusive, the broader pattern of activity around this kind of powertrain suggests that motorsports economies are reinforced by a steady stream of demand for tuning work, bespoke exhaust systems, intercoolers, intake systems, and suspension components. Enthusiasts seeking higher performance often look beyond raw horsepower to the total package: weight reduction, improved aerodynamics, chassis stiffness, and reliability in demanding conditions. Within this framework, the EVO X engine becomes a hub of innovation whose effects radiate into both the street and the track. A key dimension of this impact lies in the aftermarket and the service economy it supports. Tuning shops and performance centers are not mere retailers of parts; they are hubs of expertise where engineers and technicians translate a closed-loop system of feedback from the track into practical upgrades for road cars. These operations nurture specialized skills, provide employment, and cultivate a culture of technical curiosity that keeps pace with evolving materials science, control systems, and calibration techniques. In this sense, the EVO X engine is not just a propulsion unit; it is a conduit for knowledge transfer, a vector for new technologies to permeate into production cars, and a driver of talent development in automotive disciplines. The economic narrative around the EVO X must also acknowledge the broader context of motorsports as a driver of innovation and branding. In sports like Formula One and other high-profile series, the economic impact is widely studied because such events attract tourism, sponsorship, and media attention that create a multiplier effect across economies. While the EVO X’s footprint is smaller and more boutique by comparison, the logic is analogous: successful performance breeds demand for engineering excellence, which then stimulates investment in local suppliers, testing facilities, and skilled labor. This chain reaction can energize regional clusters around automotive engineering, not only in manufacturing regions but also in places where race teams, tuning houses, and performance shops cluster to support a vibrant, knowledge-rich ecosystem. The lack of a precise numeric tally for the EVO X’s direct economic contributions should not obscure the qualitative signal: a high-performance engine, married to a capable all-wheel-drive system, can become a focal point for a network of activities that generate measurable employment, investment, and market activity. In this sense, the engine under discussion serves as a case study in how a single power unit can spark economic vitality beyond the stopwatch. The conversation often returns to the balance between heritage and modernity. Enthusiasts cherish the EVO X for its lineage, its rally-bred ethos, and its tangible, communicative driving experience. Yet the market for such a car is not merely nostalgic; it is anchored in ongoing demand for maintenance, upgrades, and restoration, all of which require skilled labor, parts manufacturing, and logistics networks. Consider the typical lifecycle of a high-performance engine in this ecosystem: from initial sales to ongoing maintenance, from the availability of billet blocks and carbon-fiber components to the installation and tuning services that extract maximum performance in varying weather and track conditions. Each phase feeds a segment of the economy, reinforcing jobs and creating opportunities for small businesses and specialized craftsmen. It is also worth noting how such engines influence the broader perception of automotive engineering capabilities within a region. When a power unit exhibits reliability and tunable performance, it becomes a bench for testing ideas that can migrate to other platforms. The process of refining turbocharging strategies, improving cooling efficiency, and optimizing valve timing often yields transferable insights that can benefit other engines, including those used in touring cars or research platforms. In this sense, the EVO X engine becomes an informal platform for cross-pollination of ideas across the automotive sector, pushing the boundaries of what is practical in mass-market performance while maintaining a connection to the sport and culture that gave rise to it. The chapter of this engine’s economic story is not complete without acknowledging its limits and the need for careful, methodical study. The absence of quantified, direct economic contributions for the EVO X does not imply insignificance; it highlights the challenge of isolating the engine’s effect from a dense network of factors that influence motorsport economics. Nevertheless, the narrative remains meaningful: the engine is a symbol of a compelling intersection between high performance, technical craftsmanship, and a vibrant ecosystem of commerce around parts, services, and events that collectively sustain a specialized market. Enthusiasts’ willingness to invest in performance, education, and restoration services sustains a micro-economy that is surprisingly robust given the niche visibility of the platform. In sum, while precise, stand-alone financial figures may be elusive, the EVO X motor clearly contributes to an economic milieu in motorsports that values engineering rigor, skilled labor, and the cultural capital of speed. Its existence reinforces a feedback loop whereby performance capability drives demand for expertise, which in turn catalyzes innovation and market activity across a spectrum of related industries. This synergy between engineering excellence and economic vitality is a defining feature of modern motorsports ecosystems, and it helps explain why engines like the 4B11T continue to be celebrated, not merely as power sources but as engines of local and regional economic life. For readers seeking a tangible glimpse into how enthusiasts and professionals shape the material culture around high-performance engines, the story of a carbon-fiber bonnet and other lightweight components offers a concrete example. The idea of shedding weight, reducing inertia, and preserving structural integrity is a microcosm of the larger economic dynamics at play: small, targeted investments yield outsized returns in performance and, by extension, in the vibrancy of the communities that sustain it. Interested readers can explore a representative example of such componentry in a dedicated listing that highlights the brand-new original carbon fiber bonnet hood for the EVO X, a piece that epitomizes the intersection of performance engineering and consumer enthusiasm. brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x. As the chapter closes on this facet of the EVO X, it invites a broader reflection on how high-performance power units anchor an ecosystem that merges engineering prowess, market demand, and community passion. The engine’s legacy, then, is not only the speed it delivers, but the way it catalyzes an economic microclimate around parts, services, and shared expertise that keeps the sport alive and evolving. For those who study motorsports economics, this is the connective tissue that binds the thrill of the track to the durability of the economies that sustain it. The larger frame of reference—how global motorsports, including Formula One, shape economies—offers a useful lens for understanding the scale and reach of such dynamic relationships. In a broader sense, the economic footprint of high-performance engines in racing contexts can be understood through the lens of innovation diffusion, talent development, regional manufacturing clusters, and the tourism and media ecosystems that attend major events. An illustrative external perspective on this broader topic can be found in analyses of the economic impact of Formula One on global economies, which unpack how a premier racing series stimulates activity across technology, hospitality, transportation, and media sectors. External resource: https://www.motorsport.com/f1/news/what-is-the-economic-impact-of-formula-one-on-global-economies/.

null

null

Final thoughts

The EVO X motor stands as a testament to Mitsubishi’s commitment to performance and innovation. From its impressive specifications to its technological prowess, the 4B11T engine not only reshaped the landscape of motorsports but also cemented its place in automotive culture. As we have explored its performance capabilities, engineering innovations, economic impact, and cultural significance, it is clear that the EVO X is more than just a vehicle; it is a phenomenon that reflects the passion and dedication of automotive enthusiasts around the globe.