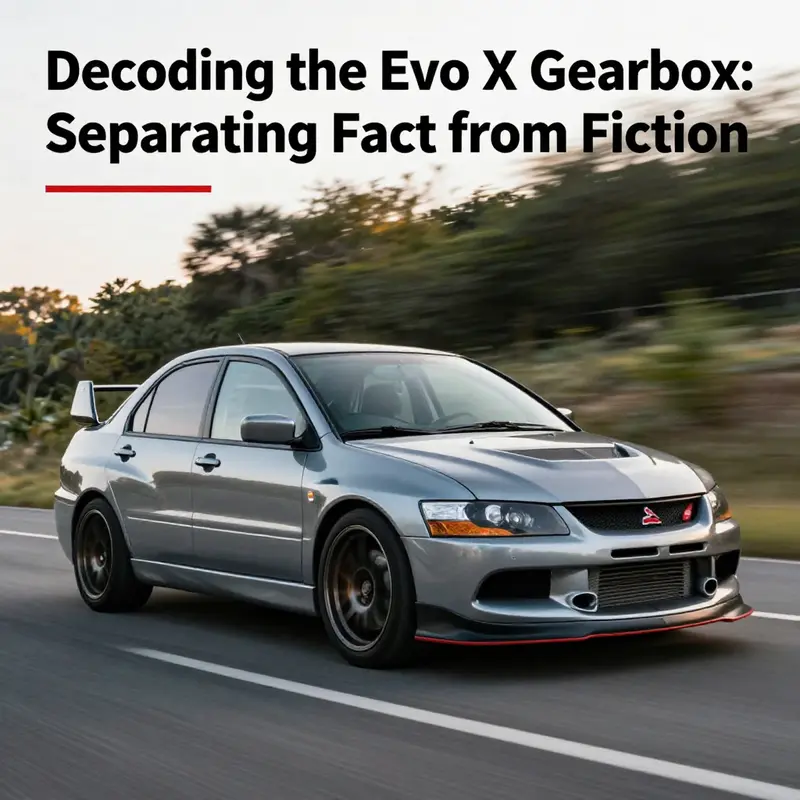

The Evo X has garnered a reputation for its performance capabilities, but there exists a significant misconception regarding its transmission system. Many enthusiasts believe it features a sequential gearbox, a hallmark of racing vehicles designed for quick gear shifts and superior performance. However, this is not the case. In this piece, we will dissect the myths surrounding the Evo X sequential gearbox, closely examine the characteristics of its 6-speed manual system, delve into its performance and reliability, and explore the market strategies and modification options that business owners can leverage to cater to drivers seeking high-performance vehicles.

Evo X Sequential Gearbox: Debunking the Myth and Unpacking the Semi-Automatic Reality

The idea of a sequential gearbox has a certain halo in the world of performance cars. It conjures images of air-dried race tracks, helmets crackling with the sound of clutches and data logs, and shifts that feel almost instantaneous. Yet even among enthusiasts who chase peak throttle response, there is a persistent misconception about the Evo X’s transmission. Many assume that the Evolution X, the high-performance variant born from a lineage of turbocharged sedans, hides a true sequential gearbox behind its glossy badge. In truth, what the car offers is strikingly close to a racing-style setup, but not a true sequential unit in the conventional sense. The distinction matters, because it shapes how drivers experience the car on a track, on a winding road, or even in spirited street driving, and it also clarifies why the Evo X behaves the way it does when you push it to the limits of grip and precision.

To begin with, it helps to define the core terms clearly. A true sequential gearbox, as used in many racing disciplines and in certain exotic road cars, is designed so that the driver can only move one gear at a time in a fixed sequence. You shift from 1 to 2 to 3 and so on, or you reverse in the same discrete steps. Importantly, a true sequential system typically relies on a fully automated clutch or a clutchless design that eliminates pedal input altogether. This setup prioritizes speed and reliability under race conditions, where every fraction of a second matters and the possibility of skipping a gear is either undesirable or simply not permitted by the system’s architecture. In contrast, a traditional manual transmission—whether in a rally car, a street sports car, or a race-spec model with a modern clutch system—allows the driver to select any gear in any order, using a clutch pedal to disengage the engine from the gearbox during a shift. The driver’s choice is not constrained by the gearbox’s sequence, and the tactile feedback of a manual shifter interacts with the driver’s control over torque and engine speed in a direct, mechanical way.

This is where the Evo X enters the conversation with nuance. What many observers call a sequential gearbox in the Evo X is better described as a semi-automatic or sequential-automatic transmission. The car uses a sequential shifter—often paired with paddle shifters—that gives the driver the sense of a rapid, one-gear-at-a-time shift. The crucial difference lies beneath the surface: the clutch operation is automated. Sensors, actuators, and control software manage the clutch engagement and disengagement automatically as the driver makes gear selections. The driver’s role is to pick the gear in the desired direction, but the engine’s connection to the gearbox is handled by an electronic system rather than a foot-operated clutch. In other words, you experience the speed and precision of a sequential-like shift, without the need to physically press a clutch pedal. This design delivers a compelling blend of engagement and convenience that is particularly appealing in performance driving contexts, such as track days or spirited weekend runs, where fatigue and repetitive clutch work can become a limiting factor.

The resonance of this setup becomes clearer when you compare it to both ends of the spectrum. On one side, a typical six-speed manual—often celebrated for its tactile feel and direct driver feedback—requires deliberate pedal work and a certain amount of physical effort, especially during aggressive upshifts at high rpm. On the other side, a true sequential gearbox shines in a competition setting because it locks the driver into a strict sequential order and minimizes the time spent between gears. It also often features an automated clutch system that ensures consistent engagement and repeatability under heavy load. The Evo X’s system sits comfortably in the middle: it preserves the sense of deliberate gear selection and instant shift feel that enthusiasts crave while removing the need for a clutch pedal and reducing the physical demands that come with sustained track driving. The result is a powertrain personality that rewards precise timing, quick reflexes, and thoughtful gear choice rather than raw pedal effort.

From a mechanical standpoint, what makes this arrangement work is the clever pairing of a sequential shifter with an electronically controlled clutch mechanism. When the driver selects a gear, the system engages the new gear through timing that’s carefully synchronized with engine speed, torque, and wheel load. The clutch, controlled by actuators and feedback sensors, engages and disengages without requiring input from the driver’s foot. This coordination is not simply a convenience feature; it’s a deliberate engineering choice that helps deliver consistent shift quality across a range of operating conditions. In performance driving, consistency is a valuable asset. A well-tuned semi-automatic system can maintain stable shift timing even as the driver’s inputs become more aggressive, and it can reduce the risk of missed gears or abrupt shifts that might upset the chassis balance at high speed or on a corner’s apex.

The Evo X’s transmission, as many observers note, is paired with a highly capable all-wheel-drive system and a naturally balanced engine layout. The horizontally opposed engine, with its low center of gravity, benefits from the car’s drivetrain geometry and the AWD system’s torque distribution. The result is a chassis that responds crisply to gear changes while maintaining a predictable feel through corners and straights alike. In this context, the semi-automatic sequential system is not merely a gadget; it is a tool that complements the vehicle’s dynamic philosophy. It provides the driver with fast, precise shifting while preserving a sense of involvement in the mechanical process, which is a core element of what performance drivers value in a car that blends street usability with track-ready potential.

Historical context also helps illuminate why the Evo X pursued this path. In the broader market, the line between manual and automatic has evolved significantly over the past two decades. Manufacturers have sought to capture the involvement that enthusiasts crave while delivering the efficiency, repeatability, and reliability demanded by high-speed driving. The Evo X’s approach reflects that balance. It gives you a compact, high-torque powerplant singing through a gearbox that is engineered to deliver rapid shifts when the driver commands them, yet it does so with a clutch operation automated under the hood. It’s a compromise that, in many driving scenarios, achieves the best of both worlds: the engagement of a manual without the fatigue or the learning curve of a fully automatic with a torque-converter or dual-clutch setup that behaves differently under load.

There are practical implications to this setup. For one, rapid shifts can be executed with impressive consistency—an attribute that matters on the track where every hundredth of a second counts. The feel of the shifter, the short throw, and the positive engagement of gears provide tactile feedback that keeps the driver connected to the drivetrain. Yet because the clutch action is automated, the driver is spared the step of modulating clutch slip during each shift. This can be a double-edged sword. On the one hand, it lowers the barrier to high-performance shifting and reduces fatigue during long sessions. On the other hand, it can feel less “hands-on” than a pure manual, especially to drivers who relish the nuance of a clutch-operated shift. The middle ground—semi-automatic sequential—thus becomes a matter of personal preference, track discipline, and how one values repeatability over raw engagement.

A broader point emerges when we look at market narratives and the way enthusiasts describe their experiences. The Evo X’s system has sometimes been read as a true manual due to the way the shifter is engineered to provide rapid, decisive gear changes that resemble the immediacy of a manual. But the deeper truth is that the driver’s gear choices are correspondingly precise, while the clutch operation is electronically managed. This distinction matters for maintenance, diagnostic work, and even the way engineers tune the drivetrain. If a technician approaches the gearbox as a traditional manual, misinterpretations can arise about clutch wear patterns, shift sharpness, or the configuration of hydraulics and sensors. In contrast, recognizing the semi-automatic nature clarifies why certain failure modes or wear patterns appear differently. As with many high-performance systems, the exact failure signatures and service intervals hinge on the control software, sensor health, and actuator integrity as much as on the metal components themselves.

In the realm of aftermarket perception, the Evo X’s reputation has sometimes been bolstered by modifications that emphasize shift responsiveness. A number of enthusiasts gravitate toward electronic tuning, paddle-mounted shifts, or even electronics that simulate a more aggressive shift cadence. While these modifications can heighten the sensation of speed, they do not convert the system into a true sequential gearbox. The fundamental architecture—the automated clutch, the sequential selector, and the control logic—remains distinct from a race-spec sequential unit. This is where the discussion often bifurcates: the driver feels a sportier, more instantaneous shift cadence and attributes that to the gearbox, while the engineering reality stems from the automated clutch and precise control software guiding it.

To illustrate with a concrete reference, consider how official technical documentation often frames the Evo X’s transmission. While primary sources emphasize the six-speed configuration, they also underscore the performance-oriented behavior of the shifting system, particularly when paired with the car’s drive modes and engine management. The driver’s interaction with the gearbox happens through a sequential shifter and paddle system that bypasses the need for pedal clutch work, while the engine, sensors, and actuators coordinate to deliver smooth, rapid gear changes. In this sense, the Evo X’s transmission is a carefully engineered semi-automatic solution designed to offer the speed of a race-inspired system without imposing the physical demands typically associated with traditional sequential machinery.

For readers who want to see how this concept sits in the broader landscape of performance transmissions, there is a useful point of comparison in genuine sequential gearboxes used in other brands and models. Some models incorporate a full sequential gearbox with a dedicated clutch mechanism and a fixed gear progression, while others use semi-automatic systems that emulate the sequential experience with electronic supervision. The Evo X’s approach sits between these poles, offering the essence of rapid, one-gear-at-a-time shifts while preserving automations that make it practical and durable for everyday track days and spirited road driving. Its design philosophy aligns with the car’s overall mission: deliver a high level of driver involvement without sacrificing reliability, accessibility, or comfort under a wide range of driving conditions.

If you’re curious to explore what truly distinguishes a genuine sequential gear system from the semi-automatic approach, there is a practical path to deeper understanding. A dedicated option that some specialists advertise is a full sequential gearbox retrofit or replacement kit, designed to convert a conventional transmission into a true sequential setup. Brands and suppliers offer specialized assemblies that maintain critical interfaces with the engine, drivetrain, and electronics but change the internal architecture to a step-by-step, single-gear-at-a-time progression with a fully automated or semi-automated clutch. This route illustrates the core point: the Evo X’s stock system is not a classic race sequential, but it embodies a high-performance, electronically controlled, sequential-like experience rooted in a tradition of rapid shifting and driver-focused engagement.

For readers who want a hands-on sense of the completeness of this topic, consider exploring the dedicated option that discusses the concept of a full sequential gearbox for Mitsubishi Evo-4-9 and X. It provides a concrete example of what a true sequential system looks like in a context that shares lineage with the Evo X’s architecture. full sequential gearbox for Mitsubishi Evo-4-9 and X.

The takeaway from the discussion is nuanced but clear. The Evo X delivers a sophisticated, semi-automatic shifting experience that borrows the speed and decisiveness of a sequential system while preserving a manual-like control surface for the driver. It stands as a practical engineering compromise—one that emphasizes consistent performance, reliability, and a driving experience that keeps the driver intimately connected to the car’s behavior, even as the car handles the heavy lifting of clutch operation behind the scenes. The chapter that follows will build on this understanding by linking the gearbox’s behavior to chassis dynamics, throttle response, and the ways in which a performance-minded driver can exploit the system to extract the most from track sessions and spirited mountains roads alike.

External reference for deeper technical context: Mitsubishi Evo X Specifications. https://www.mitsubishimotors.com/vehicles/evo-x/specifications

Evo X Sequential Gearbox: Debunking Myths and Tracing the Real-World Edge of the 6-Speed Manual

The Evo X, born from a lineage of rally-honed performance, sits at a crossroads where engineering precision, driver skill, and marketing language intersect. What many enthusiasts remember most about this generation is not merely its all-wheel-drive chassis or its turbocharged heart, but a sense that the gearbox might be something closer to a sequential racing unit than a conventional manual. The chapter you are reading reckons with that perception. It asks not only what that box really does, but how the experience it delivers—whether labeled sequential or not—shapes the driving discipline on the street and on the track. To understand the Evo X’s gearbox, we must first anchor the discussion in what a true sequential gearbox actually is, and then examine how the Evo X’s six-speed manual aligns with or departs from that standard, both in principle and in practice.

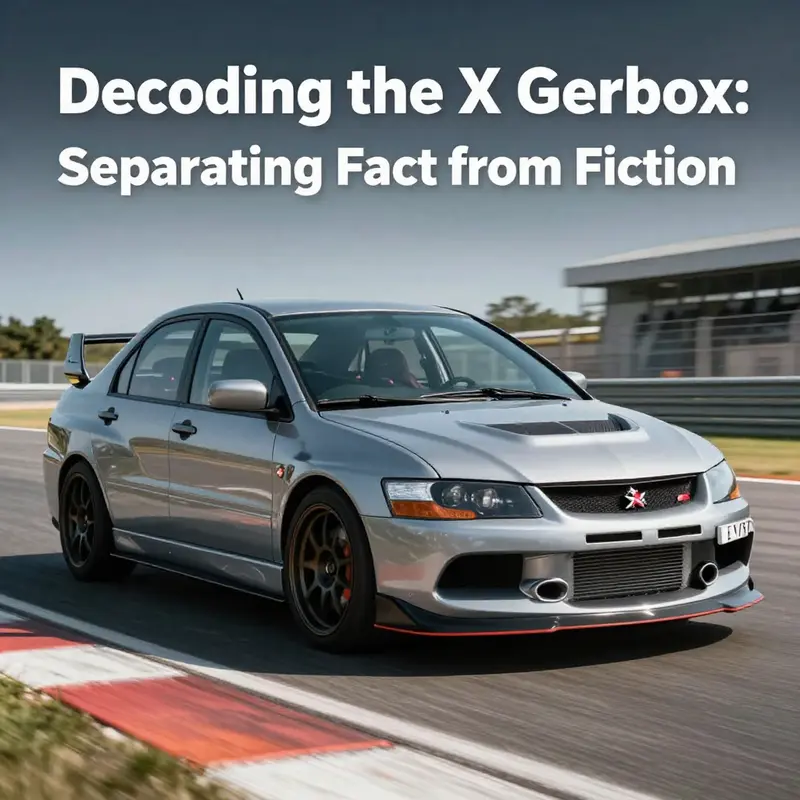

A sequential gearbox, by design, imposes a strict stepwise progression. Shifts move in a single direction along a fixed sequence: up or down one gear at a time, with no skipping allowed. This constraint is not an aesthetic preference; it is a performance doctrine. In racing contexts—from MotoGP to Formula 1 and rally stages—sequential gearboxes minimize shift time and maximize reliability under duress. The mechanism behind a sequential system is tuned to deliver ultra-rapid changes, with the engine’s torque collapse minimized as gears engage in near-simultaneity with the driver’s command. In such systems, the driver’s focus is trained on maintaining rhythm, aligning revs, and selecting the next gear with split-second precision. The appeal is clear: fewer moments of drivetrain interruption, more sustained acceleration, and a cadence that fuels the perception of raw speed.

Against that benchmark, the Evo X presents a contrasting reality. The car’s transmission is widely described as a six-speed manual. This architecture—an H-pattern layout with synchronized gears and a traditional manual clutch—offers the tactile and mechanical engagement that performance drivers often prize. The unity of a manual gearbox with the car’s symmetrical all-wheel-drive system and the engine’s torque curve creates a coherent, responsive, and highly communicative driving experience. The six-speed unit is celebrated for its durability, its short-throw shifter, and the precise feedback that makes shifts feel almost race-ready, even as the driver negotiates city streets or harmonizes throttle with traction on wet pavement. In practice, the Evo X’s box provides rapid gear engagement relative to other conventional manuals, but it does not lock into a fixed sequential ladder in the way a true racing sequential would. The ability to skip gears—1 to 3, for example—remains, by design, a feature of H-pattern configurations, not a property of a dedicated sequential system.

This distinction matters in both engineering and experience. Engineers talk about gear tooth profiles, synchronizer design, and shift forks that resist misalignment under high torque. In the Evo X, the gearset and synchronizers are optimized for strong torque handling and quick, clean engagement. The shift lever movement is deliberately short, and the linkage is tuned to provide crisp feedback. The result is a system that, while not sequential in the strictest sense, delivers a shifting experience that many track-focused drivers rank among the best in its class. The catch is nuance. The same short-throw feel and rapid engagement that evoke the sense of a sequential box are achieved within the boundaries of an H-pattern system. The gloves come off only when one considers the broader challenge of maintaining continuous acceleration through the apex, the need to modulate torque delivery to avoid wheelspin, and the way the engine’s rev range and the gearbox’s spacing interact with the car’s all-wheel-drive dynamics.

To appreciate the Evo X’s gearbox, one must map its strengths onto the demands of real-world driving. The six-speed unit’s robust gear teeth and the use of high-strength alloy components are not merely about endurance; they are about the confidence to push the engine toward the upper end of its torque band without trepidation. Short throws shorten the arc of each shift, reducing the time your hands leave the wheel and the amount of control you cede to a long, deliberate motion. The synchronization system, optimized for reduced drag during engagement, helps maintain a smooth transition even when the driver is hard on the throttle coming out of corners. And because the Evo X pairs this transmission with an all-wheel-drive layout—engineered to channel power efficiently to all four corners—the car feels both planted and responsive as soon as the clutch is released and the next gear engages.

The market’s misperceptions around the Evo X often stem from how quickly a well-tuned manual can feel like a sequential system when driven aggressively. Enthusiasts may install aftermarket electronic shift systems or paddles, and some modifications simulate a quicker, more linear cadence. In such cases, the sensation borders on sequential; yet technically, the core architecture remains a manual. The difference is not only semantics but consequence: sequential gearboxes in racing are designed to minimize derailment risk under extreme loads, delivering almost instantaneous gear swaps with almost no torque interruption. A tuned manual can approach that cadence, especially with optimized gear spacing and a short-throw shifter, but it cannot eliminate the fundamental possibility of skipping gears, a feature that most sequential systems do not permit by design.

If you look at the Evo X through the lens of racing heritage, you can recognize why the chassis and drivetrain pairing is so compelling. The engine’s torque delivery — especially in a turbocharged configuration — thrives when the driver can modulate RPM as the car accelerates out of a corner. The six-speed manual provides a direct line of feedback from the driver’s hand to the road, inviting a level of involvement that modern, fully automatic sequential transmissions often reduce. Yet the performance advantage that a racing sequential gearbox claims—near-zero interruption during gear changes—remains a benchmark that the Evo X, with its manual, meets not by eliminating interruptions but by compressing them into an experience that rewards precision, timing, and a harmonized throttle and steering rhythm.

It is also essential to consider the role of the drive system that accompanies the transmission. The Evo X’s performance story is not only about gears but also about how power is delivered to the wheels. The car’s all-wheel-drive dynamics, coupled with the gearbox’s quick, decisive shifts, creates a feedback loop that translates driver intent into immediate, measurable speed. A sequential system can theoretically optimize that loop further by eliminating parasitic delays at the clutches and linkages. The Evo X achieves a similar outcome through mechanical precision and electronic aids that fine-tune engine response and traction control. The SI-Drive—engine management software that aligns with driver input—enhances the synchronization between torque output and wheel grip, enabling a driver to exploit the gearbox’s fast, sure shifts without losing composure on low-traction surfaces. The combination of a refined six-speed manual with a sophisticated drive system gives the Evo X a performance envelope that feels obsessively tuned for track days while remaining adaptable for everyday use.

This dual reality—the elegance of a manual that can feel almost sequential, and the reality of a gearbox that remains truly manual—creates a fertile ground for discussion about what enthusiasts want from a performance car. Some drivers crave the sterile, switch-fast cadence of a true sequential, where every gear change is a data point in a measured lap time. Others prize the tactile connection and the drama of a fully engaged manual where the driver is always in explicit control. The Evo X’s gearbox sits squarely in the latter camp, offering a compelling middle ground. It gives you a gearbox that is remarkably quick and precise, but it does so with the muscular, mechanical charm of a conventional manual. The result is a car that rewards practiced, deliberate shifting: you gain speed not by micro-optimizing a clutched interval but by mastering rev matching, throttle modulation, and the point at which the torque peak is most effectively harnessed as you drive for speed through corners.

For those who still crave a true sequential experience, the landscape offers two paths. The first involves a factory or factory-supported option in other models that deliver a sequential gearbox out of the box. The second is more adventurous: aftermarket or aftermarket-inspired systems that retrofit a sequential mindset into a car that originally uses a traditional manual. In practice, these conversions are sophisticated, often expensive, and require careful integration with the vehicle’s engine, drivetrain, and electronics to preserve reliability and safety. The discussion around these options underscores a broader point: a “sequential” feel is not solely a gearbox designation; it is also about how the entire drivetrain package communicates with the driver and how quickly the car can translate a shift command into propulsion without distracting interruptions.

The Evo X teaches a valuable lesson about performance engineering: you can design a system that excels in life on the track without abandoning the engaged, hands-on feel that enthusiasts cherish. The six-speed manual, with its robust construction and short-throw precision, remains a strong foundation for a car whose ultimate strength lies in the synergy between engine, transmission, and chassis. As the driving environment shifts—from wet, street-driven compromises to dry, sticky track heat—the gearbox’s role evolves, guided by electronic aids that ensure the driver’s inputs translate into consistent, measured performance. The result is a car that offers an exceptionally confident platform for exploring high-speed dynamics, even if the box is not technically sequential in the racing sense.

For readers curious about the deeper technical specifics or interested in exploring the broader ecosystem of shifting technologies, a broader look at sequential systems and their real-world implementations can be instructive. There are documented options that explicitly advertise full sequential gearboxes for models spanning multiple generations—an emphasis on speed, torque management, and rapid engagement that extends beyond a traditional manual. These discussions are not just about hardware; they reveal how teams and tuners balance reliability, weight, and drivability when they push beyond the stock design. If you want to see how one avenue of this exploration unfolds, you can explore a resource that examines a full sequential gearbox option that spans various Evo generations, including the X, as a concept for track-focused builds.

The narrative above should not imply that all high-performance road cars require a true sequential system to achieve championship-like performance. The Evo X demonstrates that with careful tuning, driver training, and a drivetrain philosophy that prioritizes immediate response and controllable torque delivery, a traditional manual can deliver a level of performance that feels almost—though not entirely—sequential to the seasoned eye and ear of the track veteran. The car rewards a driver who respects its rhythm: smooth, precise hand work, deliberate throttle application, and a commitment to maintaining a clean power band through the corners. In this light, the true value of the Evo X’s gearbox is not merely how fast you can shift, but how well a driver can read the engine’s breath, the tires’ grip, and the track surface’s mood, weaving them into a shifting cadence that keeps the car balanced and ready for what’s next—whether the goal is a spirited canyon run or a time-attack session.

For those who crave direct, technical references, the Mitsubishi Motors documentation provides formal specifications that help distinguish the actual design from interpretive descriptions. These official sources ground the discussion in engineering clarity, reminding readers that the Evo X’s transmission, while remarkably capable, remains a six-speed manual unit geared for reliability and driver involvement rather than a true sequential racing gearbox. To connect these ideas to a broader ecosystem of performance upgrades, consider exploring the possibility of a dedicated sequential unit as an aftermarket option, which reflects a broader trend in performance engineering: pushing the boundaries of what a road-going performance car can do without sacrificing the essential driver-car relationship that makes this category so compelling. For a deeper, official reference on the topic, see the technical documentation from the manufacturer, which outlines the drivetrain architecture and the role of the manual gearbox within the car’s overall performance package: https://www.mitsubishi-motors.com.

Internal linking note: for readers curious about how a full sequential gearbox is positioned within the ecosystem of Evo-focused builds, there is a detailed discussion available on specialized parts sites that compare sequential concepts across generations and illustrate a practical path for incorporating sequential behavior into a track-focused project. A representative entry that explores a full sequential gearbox option spanning Evo generations, including the X, can be found here: full sequential gearbox for Mitsubishi Evo 4-9 and X.

In sum, the Evo X’s gearbox embodies a refined balance: a robust, precise six-speed manual that delivers near-sequential speed in feel and cadence, paired with electronic and mechanical controls that help manage traction, engine torque, and overall vehicle dynamics. It is not a true sequential gearbox by the strictest mechanical definition, but it does not prevent the car from delivering track-ready performance and an engaging, driver-centric experience. The lesson extends beyond one model: true sequential gearboxes remain the benchmark for shift speed and consistency in racing, yet a skilled engineering package can convincingly emulate that cadence through thoughtful design choices in the manual realm. The Evo X stands as a compelling example of how modern performance cars can fuse old-school driver involvement with state-of-the-art dynamic systems, achieving a compelling, highly capable balance that continues to inspire discussions about what constitutes speed, control, and mastery on four wheels.

External reference note: for detailed, official technical specifications, consult the Mitsubishi Motors documentation, which provides authoritative context on drivetrain architecture and the role of the manual gearbox within the Evo X performance framework: https://www.mitsubishi-motors.com.

Evo X Sequential Gearbox: Performance, Precision, and Reliability in a Track-Ready Machine

The Evo X has long lived in the automotive imagination as a benchmark of move-fast, breathe-hard performance. Its gearbox, often singled out as the defining mechanical interface between driver intent and road-or race-ground reality, sits at the core of that identity. Within the lore of high-performance shifting, the Evo X’s sequential gearbox is described not as a mere transmission but as a system engineered to fuse race-grade speed with the street’s demands. What follows is a close look at how this device operates, why it matters for dynamics, and how enthusiasts come to trust it in real-world contexts that range from track days to road-hungry, twisty mountain passes. The narrative here is built from the consolidated technical portrait of these transmissions as semi-automatic, paddle-shifted systems whose control strategy is as much about timing as it is about gear ratios. In this view, the sequential gearbox is not merely a faster shuffle of gears; it is a carefully tuned choreography between clutch actuation, gear engagement, and the car’s broader torque delivery, all orchestrated to keep the engine in its sweet spot while preserving traction and stability in demanding corners.

Design and mechanism sit at the heart of the explanation. The Evo X sequential setup operates as a semi-automatic arrangement that merges manual intent with automated precision. The driver commands shifting with paddles mounted behind the steering wheel, a stance that places gear changes within an arm’s reach and reduces the time between decision and execution. But the critical heart of the system lies beyond the pedals and levers. An electronic control unit (ECU) governs the clutch through hydraulic actuators, translating a split-second paddle pull into an almost instantaneous mechanical response. In practice this means ultra-fast shift times—often reported to be on the order of tens of milliseconds. The speed is not merely about sensation; it translates into a real performance edge in environments where every millisecond counts, such as track laps that demand rapid lane changes, quick re-acceleration after braking zones, or seamless downshifts that hold the engine in a productive torque window while negotiating a corner. The mechanical engagement itself benefits from reinforced gear sets and a robust housing, designed to resist the peak torques produced by a high-boost, turbocharged powertrain. The result is a system that remains calm at full tilt, providing a predictable interface even as engine speed climbs and the chassis demands such predictability most.

The architecture of the Evo X transmission embodies a balance between performance and durability. The gear sets are reinforced to withstand the torque that a performance-oriented four-cylinder arrangement can deliver. The housing is engineered to resist the dampening and micro-movements that arise during aggressive changes in load from braking to throttle. In tandem with this hardened mechanical backbone, a carefully tuned shift logic ensures that each engagement occurs with clean synchronization and minimal interruption to the drive force. The objective is to maintain engine RPM within the most favorable band for acceleration out of corners while preventing grip loss that could upset the chassis’ balance. The result is a sensation of directness: the gear you select feels like the gear you get, with as little interruption to propulsion as possible. This immediacy of response becomes a key driver for driving enthusiasts, who prize not just speed but the feeling of being masterfully aligned with the machine’s behavior as it travels from apex to apex.

The Evo X’s drivetrain synergy cannot be explained in isolation from its all-wheel-drive system and its active control technologies. The car’s powertrain management works hand in glove with stability and traction tools to maximize grip under aggressive throttle input and during corner exit. The gearbox’s rapid shifts complement the all-wheel-drive configuration by preserving momentum and by enabling the system to rebalance torque distribution quickly as the driver commits to steering inputs. This level of integration is particularly evident in the car’s ability to maintain traction on a throttle-rocket-straight or while probing the car’s grip limits on a high-speed bend. The sequential gearbox, in this sense, functions not only as a speed tool but as a control amplifier—an amplifier that translates the driver’s will into a rapid sequence of gear engagements, while the chassis follows its own physics-based logic for slip, yaw, and lateral stability.

From the perspective of performance characteristics, the sequential setup is designed to handle the power and torque of a turbocharged engine without sacrificing reliability or daily usability. The gear ratios are chosen to balance acceleration with top-end accessibility, ensuring a linear, predictable thrust progression from one gear to the next. Because the gear engagement is controlled electronically, the system can optimize engagement timing for the current engine speed and load, reducing slip and ensuring the engine remains in a zone of high responsiveness during shifts. This is particularly valuable when the vehicle is in a demanding driving scenario where throttle response and immediate re-engagement matter. The result is a compact, tightly integrated unit that keeps the engine in its power band, so the driver can press hard on the throttle and know that the transmission will respond in the manner expected of a race-bred machine.

Yet, the strength of the Evo X’s sequential gearbox is not simply in raw shift speed. It also lies in the way it preserves drivability during high-stress driving. A key virtue is the gearbox’s capacity to synchronize engine and drivetrain dynamics with very little perceptible interruption to torque delivery. In the track environment this translates into quicker laps because the driver can stay on the gas earlier after downshifts and brake later into corners knowing that the drivetrain will deliver immediate, predictable response as the car comes off the corner apex. It is this interplay between tactile feedback and mechanical efficiency that forms the essence of the Evo X’s appeal—the sense that you are operating a device that has been tuned for precision and control, not just brute acceleration.

That said, no complex, high-performance system comes without caveats. The elegance of electronic clutch actuation and rapid gear engagement introduces a level of complexity that has real maintenance and reliability implications. The hydraulic clutch system and its control electronics demand careful servicing and proper fluid management. When these components are neglected, the system can lose its precise timing, and the very speed advantages it promises can be compromised by creeping play, erratic engagement, or delayed responses. In everyday driving, such issues might manifest as slightly inconsistent shift feel or a momentary reluctance to engage under certain temperatures or wear conditions. For enthusiasts who push the car on track or during aggressive rally-style driving, the cost and diligence of maintenance become more acute. The gearbox becomes a high-precision instrument that rewards regular, meticulous attention. It is not a hands-off system; it requires the same discipline of maintenance that any high-performance machine demands, including periodic checks of hydraulic lines, clutch wear, and ECU calibration.

Of course, the allure of a semi-automatic sequential setup extends beyond the gearbox itself. The driver’s engagement is not diminished by the absence of a clutch pedal in normal operation; instead, the system harnesses the driver’s inputs through paddle shifters to deliver a direct, race-inspired interface. The tactile quality of paddle-induced shifts—short, decisive, and with immediate feedback—fosters a sense of connection that many drivers equate with the essence of performance driving. At the same time, the system’s automatic aspects empower a broader range of drivers to approach high-speed dynamics with confidence, since the electronic management of the clutch can help prevent mis-shifts and abrupt torque interruptions that might unsettle the chassis.

For those seeking to explore the outer edges of what a sequential gearbox can offer within a road-legal package, there are aftermarket pathways worth noting. The landscape includes implementations that go beyond the stock configuration, where engineers and tuners offer complete or partial upgrades to further optimize shift speed, torque handling, and reliability under extreme conditions. In some cases, this has involved integrating full sequential gearboxes that push the envelope beyond the factory hardware. A notable example within the broader ecosystem of Evo models is the availability of full sequential gearboxes designed for the evolution family, including options that cover multiple generations. Such upgrades illustrate how the underlying design philosophy—rapid, controlled gear changes with robust mechanical support—remains compelling even as the market explores higher-intensity applications. For readers who want a glimpse into the kinds of configurations that exist beyond stock, a reference point can be found in discussions of a full-sequential-gearbox-for-mitsubishi-evo-4-9-and-x. This link is a window into the notion that the Evo’s legendary shift speed can be extended even further through purpose-built transmissions while still preserving the thread that ties all performance-focused gear systems together: speed, precision, and reliability under load.

In the end, the Evo X sequential gearbox is a defining feature because it embodies how modern performance engineering translates driver intention into tangible track behavior. The system’s speed is not a novelty; it is a purposeful design choice that supports the car’s broader dynamic intentions. It helps maintain traction, supports rapid acceleration out of corners, and preserves the chassis’ composure when the driver wants to push the car’s performance envelope. For the faithful, the gearbox is a sacrament of the performance-driving experience: it is the mechanism that translates the visual excitement of the car’s aggressive lines and its turbocharged soundtrack into real, track-ready performance. For others, it is a compelling technical focal point that reveals how a high-performance vehicle can balance speed and control, precision and reliability, in the same breath. In either case, the sequential gearbox remains a central feature that helps define the Evo X as a race-inspired, road-legal platform whose shifting cadence and mechanical resilience live up to the expectations set by its storied lineage.

For readers who want to delve deeper into the data and the engineering specifics, reference materials and official documentation offer further context on how these systems are intended to function and how they perform under real-world conditions. The most authoritative sources provide a detailed account of the evolution of the gearbox design, the controls that govern clutch actuation, and the interplay with other drivetrain systems. External resources such as official technical documentation give a broader view of the architecture, performance envelopes, and maintenance considerations that accompany this level of high-performance engineering. External reference: Mitsubishi Motors technical documentation.

Evo X Sequential Gearbox Unpacked: Market Strategy, Modification Pathways, and the Quest for True Sequential Shifts

This chapter examines the Evo X sequential gearbox concept, exploring market strategy, modification pathways, and the challenges of integrating a true sequential system into a car originally designed around a manual transmission and all-wheel drive. It discusses why a turnkey, modular approach matters, what buyers value—reliability, installability, and serviceability—and how cooling, control strategies, and calibration drive the feasibility and ROI of such upgrades.

Final thoughts

In recap, the Evo X’s gearbox is often misconstrued as a sequential system due to its performance-oriented features, yet it solely consists of a sophisticated 6-speed manual transmission. This misunderstanding highlights a broader need for education regarding automotive technologies among enthusiasts and potential buyers. Business owners and industry stakeholders should inform customers about the true capabilities of the Evo X, promoting its undeniable appeal while demystifying its technical specifications. By understanding each aspect of the Evo X’s gear system, one can appreciate the engineering prowess behind it and correctly position it within the high-performance vehicle market.