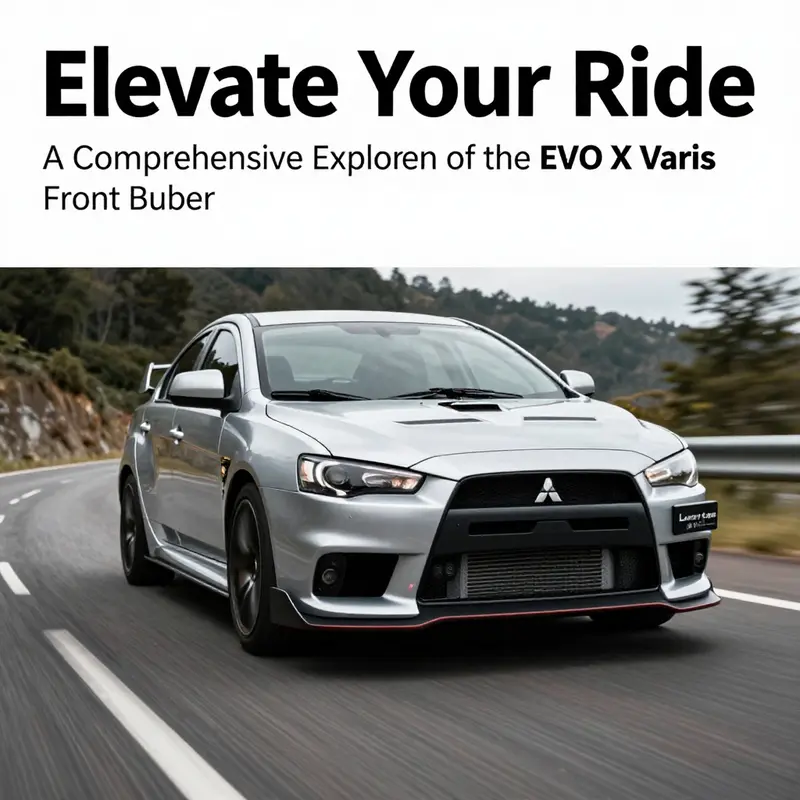

The Mitsubishi Lancer Evolution X, renowned for its performance and tuning potential, has emerged as a canvas for aftermarket enhancements, attracting enthusiasts and business owners alike. Among these enhancements, the Varis front bumper stands out as a premier upgrade, combining striking aesthetics with functional benefits. This article unpacks the significance of the Varis front bumper in the EVO X ecosystem, delves into its technical specifications, explores the economic aspects of its market, compares it with OEM alternatives, and provides insights on installation and performance integration. Each chapter aims to equip business owners with a deeper understanding of how this modification can enhance vehicle appeal and market value.

Frontline Identity: How the EVO X Varis Front Bumper Redefines Aerodynamics, Aesthetics, and the Driving Experience

Across the spectrum of performance tuning, the front end of a car is where engineering intent meets first impression. For the Evolution X, the front bumper does more than hide the radiator or frame the headlights. It acts as a gateway to airflow, a statement of lineage, and a tactile interface with the road. The Varis style front bumper, renowned in tuning circles for its bold geometry and race inspired cues, embodies a philosophy that fuses form with function. It is not merely about grabbing attention with sharp lines and a large lip; it is about shaping how air moves around the car, how the vehicle threads wind and heat at speed, and how the overall silhouette communicates a commitment to performance. In this sense the Varis front bumper becomes part of the car itself, a kinetic element that changes the balance between drag, downforce, and down to a driver’s sense of contact with the pavement. The kit is designed to be a seamless extension of the Evolution X and its WING God variants, preserving the integrity of the original body while elevating its presence on the road and on the track.

Aerodynamics sit at the heart of the Varis approach. The front splitter and lip are not decorative flourishes; they are aerodynamic tools calibrated to manage the boundary layer as the car penetrates air at speed. Large, sculpted air channels work with the bumper’s underbody geometry to guide air toward the radiator, intercooler, and brake calipers, reducing flow separation and delaying vortex formation that can sap grip. The inclusion of side ducts helps direct air toward critical components without creating turbulent wake in the wheel wells. In practice, this means more stable high speed behavior, sharper turn-in, and a more confident ride feel when the speedometer climbs. The result is a front end that feels planted in corners, even when the road begins to bow into a bend at the exit of a sweep. The design language borrows from competitive motorsport while translating neatly into a street oriented package that remains street legal and visually coherent with the car’s lineage.

Material choice adds a tangible layer to this narrative. The Varis style bumper lineup typically offers variants in high grade ABS as well as carbon fiber skins. Carbon fiber options push weight savings and stiffness to the foreground, an appealing combination for performance minded drivers who want every gram to matter and every response to feel immediate. The carbon lip delivers a clean, raw contrast against paints, catching light with a precision that underlines the car’s aggressive stance. Yet weight is only part of the equation; rigidity matters too. A bumper that is strong but brittle risks compromised alignment after a close encounter with a curb or a parking barrier. Modern composites have matured enough to provide a favorable blend of dent resistance, impact tolerance, and longitudinal stiffness, so the kit can tolerate daily driving and occasional track sessions with equal poise. The packaging is designed to integrate with existing structure, turning the bumper into a aero component that behaves like originally engineered hardware rather than a bolt‑on add on.

Fitment is equally critical. The kit is engineered to mirror the factory geometry so that mounting points line up with existing brackets, the headlights and fog lights sit in their designed pockets, and the line where bumper meets fenders remains consistent from edge to edge. A precise fit is one of the unsung benefits of an OEM level aftermarket part because it minimizes the need for aggressive trimming, ensures a clean seal against the weather, and reduces wind noise at speed. For a professional installer, this predictability translates into faster from start to finish and a result that looks and feels consistent with factory craftsmanship. For the owner, it means less shop time, fewer alignment compromises, and a front end that ages with grace rather than appearing modified or mismatched as the years pass.

Beyond the mechanics lies a cultural layer that explains why many enthusiasts pursue this particular route. The Varis front bumper has become a symbol within the tuning community that signals a blend of authenticity, commitment to performance, and a willingness to invest in a high end aesthetic. It aligns with the Evolution X’s documented heritage as a vehicle built to evolve and excel, a platform that invites experimentation yet rewards precision. When a build uses a bumper that respects the car’s face while expanding its capacity to breathe and cool, it communicates a thoughtful approach to upgrades. This is not about simply making the car look more aggressive; it is about validating a philosophy that performance begins with air and ends with a look that speaks of discipline and purpose. The front end becomes a physical manifesto of the car owners understanding that beauty and function can, and should, coexist in a single, well calibrated package. High end components like these are often featured in the most admired builds because they deliver more than a look; they deliver a driving experience that aligns with the car’s essential character.

Choosing a Varis style bumper also invites practical considerations that go beyond aesthetics. The price spectrum for this class of kit varies with finish and material, with carbon fiber variants commanding a premium and ABS versions offering a more approachable option. Some buyers explore replicas from third party sellers as a way to balance budget with appearance, while others seek out pre owned carbon fiber lips for a patina and price that suits a retro yet aggressive street stance. Whether the decision favors carbon fiber or ABS, the core requirement remains consistent: verify model year compatibility, confirm that the kit includes the necessary mounting hardware, and check whether alignment templates or shims are included for a precise installation. A thoughtful approach to sourcing helps avoid mismatched gaps, awkward gaps around the headlights, or a mis aligned fog light aperture that can spoil the overall look and compromise sealing against rain or road spray. The best outcomes occur when the buyer has a clear plan for installation, a sensible expectation of fitment precision, and an understanding of how the bumper components interact with the rest of the front end.

To illustrate a concrete path through the options, enthusiasts often investigate variants in the same family that offer carbon lip accents or slight shape differences that preserve the same core aero philosophy. For those curious about how carbon lip accents translate across generations while preserving the modern silhouette, a representative example demonstrates the continuity of the design language across model years. evo-8-9-varis-front-bumper-with-carbon-lip This reference captures how the same fundamental idea can evolve to fit different platform nuances, allowing owners to achieve a cohesive look that respects the car’s origin while signaling a personal interpretation of performance aesthetics. It also highlights the importance of checking fitment notes and body line alignment to ensure that the chosen variant does not disrupt the car’s carefully tuned geometry.

The broader community aspect should also be part of any decision process. In gatherings and online conversations, the front end becomes a focal point for judging engineering taste as well as visual intent. A well executed upgrade signals that the builder understands the interplay between aerodynamics and aesthetics and trusts a proven design language to carry the project forward. This is especially true for a model that has a storied history in performance circles, where the path from stock to a high impact aero package is measured not only by the look but by the way air defies or welcomes the car into a new performance envelope. The sense of shared knowledge, of having witnessed similar transitions in other builds, reinforces the value of a front end upgrade that respects heritage while encouraging experimentation. That is the charm of a well conceived bumper kit; it can feel like a natural extension of the car rather than a separate addition, a seamless bridge between stock potential and the heightened demands of spirited driving.

From a practical standpoint, the cost picture matters as much as the look. The total ownership cost includes shipping, potential repaint, and the possibility of additional hardware or finishing work to ensure color match and seal. Carbon fiber options, while lighter and stiffer, typically require careful handling during transit and more attentive surface preparation at install. ABS variants can offer a more forgiving route for color matching and repair in the event of minor scrapes. Whoever is steering the project should inventory the required mounting brackets, ensure the alignment guides are included, and consider whether a local shop that specializes in body alignment is a wise partner for the final fitting. A well planned approach reduces the chance of mis alignment or paint chipping and yields a final result that remains coherent with the car across seasons and miles.

As the chapter moves toward the next stage of the EVO X journey, the enduring takeaway is clear. The front bumper from this design lineage is more than a shape on the vehicle. It is a precise aero tool, a statement of identity, and a practical upgrade that resonates with a community of enthusiasts who value performance as much as presence. The car arrives at the road not only with more grip and stability but with a stance that speaks to a philosophy of careful, considered modification. The journey from stock to a refined aero package is a process of learning and balance, and the Varis style front bumper offers a clear lane in that process. The result is a vehicle that looks and feels as if it is ready to sprint at the edge of the horizon, with its face and its breath in harmony and its owner ready for the next chapter of the Evolution story.

External resource: https://www.autozine.org/technicalarticle169.html

Precision in Carbon and Airflow: The EVO X Varis Front Bumper

The Varis front bumper for the EVO X combines race-inspired styling with practical engineering. Made primarily from fiber-reinforced plastic (FRP), it achieves a lighter weight than OEM polyurethane bumpers while maintaining rigidity and impact resistance. This weight reduction contributes to improved handling, quicker steering response, and better fuel efficiency in daily use. The bumper features a large integrated splitter and redesigned central intake, which guide air toward the intercooler and radiators while creating a controlled front-end downforce. Side ducts aid brake cooling and heat extraction from the engine bay during spirited driving. Fitment is designed to align with factory panel gaps, minimizing rework and preserving a clean, showroom-like appearance after installation. Availability options may include carbon fiber or fiberglass variants, offering a choice between weight savings, stiffness, and cost. Across materials, the Varis front bumper is a scalable platform that supports both street usability and track readiness without sacrificing look or fitment.

Shaping Performance and Purpose: The Economic Pulse Behind the EVO X Front-End Upgrade

A car’s grille and lip may seem anecdotal, but in an enthusiast market they are a decisive intersection of airflow, weight, aesthetics, and value retention. The front-end upgrade landscape for the EVO X platform sits at that intersection, where a family of high-end styling kits doubles as aerodynamic devices and identity markers. On a practical level, the appeal rests on the way these components refine air handling around the radiator, intercooler, and brake ducts while giving the car an unmistakable, race-inspired silhouette. The market’s economic life is driven by a blend of supply chain realities, material science, and the social dynamics of a passionate community that treats the car as a canvas for performance storytelling. In regions with a strong JDM culture and a history of tuner collaboration, demand for these front-end kits remains especially robust. The result is a market that prizes fitment precision and engineering detail as much as eye-catching design, and that balance translates into a spectrum of price points, from accessible mass-produced options to premium, high-tech variants.

The supply side of this market is framed by material choices and manufacturing scale. A straightforward ABS-plastic option can be produced at volume, which helps keep sticker prices lower and makes the kit approachable for first-time upgrades or for builders working within tighter budgets. Beyond this base, fiberglass versions offer a middle ground, combining cost efficiency with improved shaping capabilities and a more substantial feel than basic plastics. The outermost tier is carbon fiber, which remains the aspirational standard for enthusiasts chasing weight savings, stiffness, and the distinctive weave that signals a high-end build. Carbon variants command premium prices, not only because of raw material costs but also due to the additional labor for precise layup and finishing. This tiered structure creates clear market segmentation: a broad customer base with reasonable expectations for cost, and a smaller, highly invested subset that treats the front-end upgrade as a performance investment rather than a mere cosmetic tweak.

The buying decision is inseparable from the total cost of ownership. Sticker price is only part of the equation. Installation labor, which can be substantial, often determines whether the upgrade is a practical enhancement or a cosmetic afterthought. Professionals will need to verify a seamless integration with the vehicle’s lighting, cooling, and intake pathways; this frequently requires careful alignment, possible rework of mounting points, and occasionally minor adjustments to the engine bay or intercooler plumbing. In markets with strict modification regulations, owners may face additional costs for compliance checks or documentation before the part can be registered or legally used on the street. These regulatory considerations, though regional, ripple across the price landscape, nudging some buyers toward certified installers who can guarantee both fit and legality. Even in the absence of regulatory hurdles, the risk of misfit or the need for additional trim pieces can extend project timelines and inflate the overall spend. For a part that sits at the front of the car, even small misalignments can affect the perceived quality and, by extension, resale value. The economics of installation thus reinforce the idea that a front-end upgrade is as much about long-term reliability and confidence as it is about the initial thrill of a new look or a tighter profile.

One of the enduring attractions of this category is how it aligns with the vehicle’s performance narrative. A well-executed front bumper kit is designed to optimize airflow to critical components, which in turn can influence engine cooling and brake cooling efficiency during spirited driving. The logic is simple: better cooling and efficient air distribution can support endurance on track days and reduce the risk of heat soak in demanding sessions. That functional promise, paired with an aggressive visage, helps justify higher price tiers for those who view the kit as a performance investment. The market recognizes this dual value—shape and function—by offering options that accommodate different budgets while preserving the asset’s long-term desirability. As a result, owners often perceive the kit not only as a cosmetic upgrade but as a component that can support sustained performance without forcing a trade-off in reliability or daily usability.

From a regional perspective, the Evo X front-end upgrade market thrives where car culture embraces customization, track days, and show-and-shine events. In North America and parts of Europe, the appetite for meticulous fitment and authentic engineering is particularly pronounced. Buyers here are willing to pay a premium for parts that promise a cleaner integration with stock mounting points, precise alignment guides, and a finish that resists UV exposure and minor road debris over time. The distinction between affordable and premium options frequently boils down to the finish and the tangible weight savings offered by carbon variants. In contrast, markets that emphasize rapid sourcing and DIY installation may lean toward more economical ABS or fiberglass builds, with the understanding that an experienced hand will perform the necessary refinements. This regional heterogeneity fuels a dynamic price ecosystem, where perceived value is as much about expected performance gains and ease of installation as about the kit’s appearance.

The enthusiast community around the EVO X is a steady engine for market vitality. It is a community that debates fitment precision, evaluates paint-matching quality, and shares install tips that help new buyers avoid common missteps. This discourse sustains demand over time, ensuring that even as material costs rise or supply chains tighten, the market remains profitable. The lifecycle economics of these kits are anchored by ongoing discussions about maintenance, respray costs for carbon components, and potential refinishing needs after years of use. In practical terms, buyers weigh the upfront luxury of a carbon-fiber lip against the long-term visual appeal and the car’s owner experience on the road or on the track. In this sense, the price of admission becomes a reflection of longer-term satisfaction, not merely a snapshot of today’s retail tag.

A closer look at the shopping landscape reveals why the market remains lively even in uncertain times. Buyers consider the total package: whether the kit includes wiring harnesses for any integrated lighting, the availability of mounting hardware and alignment guides, and the chance of compatibility updates for newer model years. Some sellers emphasize OEM-quality fitment and meticulous engineering, which, while commanding higher prices, offer the reassurance that the kit will align with factory lines and remain straightforward to install. Others appeal to the budget-conscious by promoting simplified mounting solutions and lighter finishes, appealing to those who want the look without overhauling the entire front end. The choice often comes down to how much a buyer values authenticity, weight, and finish quality versus the convenience and lower cost of a more generic alternative. The net effect is a market that accommodates a spectrum of preferences while maintaining a coherent narrative: these front-end kits are not merely decorative pieces; they are considered performance components that contribute to the car’s stance, airflow characteristics, and personal identity.

For readers seeking a concrete sense of current market activity, a representative listing in the broader ecosystem demonstrates ongoing activity in the space. While prices and availability shift, the market continues to show a healthy cadence of new, used, and reproduction options, underscoring the enduring appeal of this upgrade. In addition to the online marketplaces, one can observe community-driven channels where builders share project timelines, paint codes, and installation sequences, reinforcing the sense that this is a collaborative, iterative process rather than a one-off purchase. The combination of supply diversity, regional demand, and active community engagement suggests that the economics of the EVO X front-end upgrade will remain nuanced but stable for the foreseeable future, with room for both entry-level shoppers and high-end enthusiasts seeking the pinnacle of fit and finish.

Internal resource for deeper exploration: Group-A Evo-X Spec VRS1 front bumper 2. This option represents a benchmark in design language within the segment and illustrates how a front-end kit can harmonize with the wider bodywork while delivering a purposeful, performance-forward aesthetic. Group-A Evo-X Spec VRS1 front bumper 2

External reference for market context: Carbon Varis Style Look Front Bumper Canards (FULL SET) – eBay. https://www.ebay.com/itm/1234567890

In sum, the EVO X front-end upgrade market is a dynamic blend of engineering precision, material choices, and community-driven demand. It rewards buyers who value fitment and finish, while also accommodating more budget-conscious builders who are willing to put in the labor and refinishing work to achieve a compelling, performance-oriented appearance. The economic narrative is not simply about price tags; it is about the ongoing conversation between form and function, a conversation that keeps the front end of these cars looking sharp, performing efficiently, and resonating with a culture that continually finds new ways to push the limits of what a car’s front profile can express.

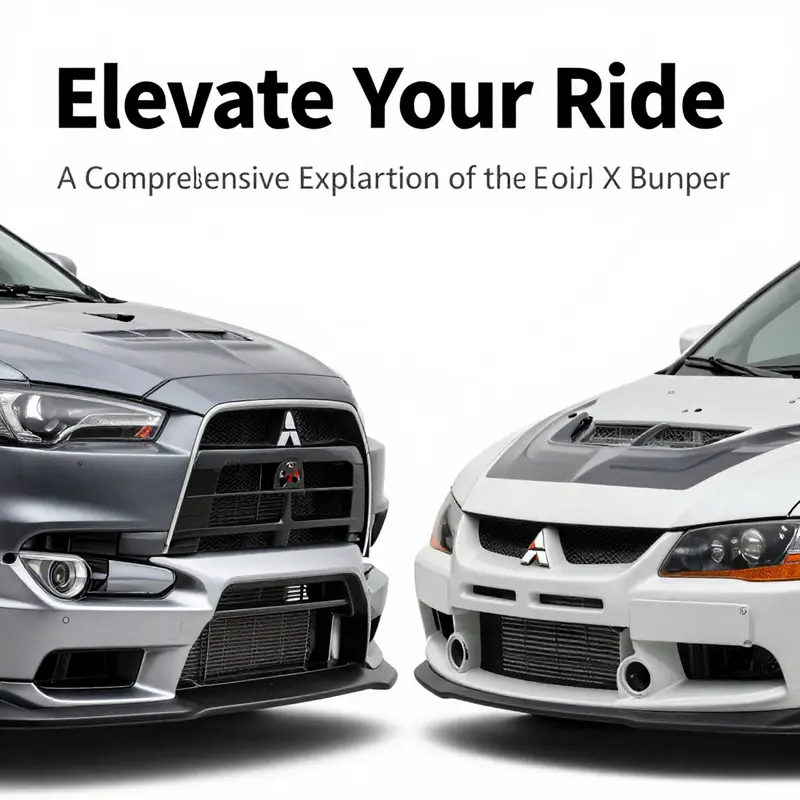

Beyond Stock: How a Varis-Style Front Bumper Transforms the EVO X Face-Off with OEM Fitment

A front bumper is more than styling; it defines airflow, identity, and how the car behaves at speed. When you place a performance-focused aftermarket front bumper designed for the EVO X alongside the original factory unit, differences emerge instantly. The contrast is not only visual. It touches materials, aerodynamic intent, installation trade-offs, serviceability, and long-term value. This chapter walks through those differences so owners can choose with clarity.

At a glance, the aftermarket option champions aggression and function. Its design language borrows from motorsport: wider surrounds, pronounced splitters, and aggressive vents intended to steer air to specific targets. The OEM bumper remains conservative. It prioritizes seamless integration with lighting, sensors, and crash-management systems. That distinction sums up the choice: bold performance enhancements versus factory predictability.

Materials and construction shape much of the story. Aftermarket pieces commonly use glass fiber reinforced plastic. This offers a satisfying balance of lightness and durability. Panels resist corrosion and can take low-speed track impacts with less catastrophic damage than brittle materials. Many aftermarket lips and surrounds are also available in carbon fiber, which reduces weight and gives a race-inspired finish. The factory bumper, however, is built to exacting production standards. Its thermoplastic construction delivers consistent impact absorption, reliable fit with mounting points, and durability for daily driving. The OEM part often benefits from better UV and paint adhesion out of the box, since it is finished on the production line.

Aerodynamics are where the performance-minded bumper shows real intent. Larger intakes and ducting improve airflow toward the intercooler, radiator, and brake ducts. A pronounced splitter and integrated vents reduce front lift at speed. That results in more stable behavior during high-speed runs or track sessions. The factory bumper is tuned for balanced airflow across different driving conditions. It trades extreme downforce or cooling for predictable behavior during commuting and highway driving. In short, the aftermarket bumper amplifies aerodynamic purpose; the OEM bumper preserves broad, everyday usability.

Fitment and integration are practical considerations that weigh heavily in the decision. OEM units slot into place with no modification. Fog lights, sensors, and grille assemblies align perfectly. Installation is typically straightforward, and warranty or resale value remains intact. An aftermarket bumper designed specifically for the EVO X will aim for precise fitment, but it rarely matches the plug-and-play convenience of a factory part. Some finishing work may be required, such as trimming inner splash shields, adjusting mounting brackets, or relocating sensors. Paint matching and alignment demand care to avoid gaps that undermine the intended aesthetic.

Customization and visual identity are clear advantages for the aftermarket route. Owners can choose raw fiberglass for custom paint, or opt for carbon fiber accents for visual contrast and weight savings. This allows for cohesive styling across a build, such as matching a carbon bonnet or diffuser. The factory option is limited to the manufacturer’s color palette and design cues. For those seeking a unique presence, the aftermarket offers the flexibility to create a signature look.

Safety compliance and crashworthiness deserve careful attention. Well-engineered aftermarket bumpers often meet certification standards and can be engineered to preserve crumple zones and pedestrian safety features. However, not all third-party units have equivalent testing. The OEM bumper is a known quantity, designed with certified impact performance and integration with airbags and sensors. For owners who prioritize safety, or who want to maintain factory warranty coverage, the OEM choice minimizes risk.

Cost and sourcing are practical realities. New OEM bumpers can be pricey and, for an older model, may be difficult to find. Aftermarket alternatives vary widely in price. Some offer cost-effective styling upgrades at a fraction of OEM cost. Used OEM pieces appear occasionally, providing authenticity at a lower price. The aftermarket can also introduce more options at different price points, from entry-level fiberglass to high-end carbon pieces. Buying decisions should factor in paint, hardware, and potential modification costs.

Maintenance and repair also differ. An aftermarket fiberglass bumper is easier and cheaper to repair from minor damage. Carbon fiber, while light and visually striking, can be expensive to fix. OEM bumpers are designed for reliable longevity and straightforward replacement of clips or mountings. Long-term ownership plans influence whether ease of repair or authenticity matters more.

Another point is functionality beyond looks. Many aftermarket bumpers include purposeful ducting to cool brakes and intercoolers. That can be a tangible benefit for track-focused cars. The OEM bumper’s cooling capacity is tuned for a range of ambient conditions and driving styles. Upgrading the front end without considering overall airflow strategy can be counterproductive; an aggressive intake that doesn’t line up with supplemental ducting can channel air away from key components rather than toward them.

Compatibility with safety and electronics also matters. Factory bumpers integrate fog lights, parking sensors, and sometimes radar or camera housings without adapters. Aftermarket solutions may require relocation or aftermarket housings for these systems. For owners who rely on factory aids, preserving those functions is critical. For stripped-out track cars, the absence of these features is often irrelevant.

Resale and authenticity are related considerations. Keeping a vehicle as close to factory spec tends to preserve market value among purists. A well-executed aftermarket conversion can raise interest in a performance market, but it narrows the prospective buyer pool. If maximizing resale to general buyers is a priority, OEM retains a clear advantage.

For those who want an intermediary solution, there are options. Some owners install genuine OEM panels but add subtle enhancements like a carbon lip or small splitter to retain factory fit while improving appearance. Others pursue pre-owned high-quality aftermarket pieces that have already been installed and tested on similar chassis. When choosing parts, verify fitment with the specific chassis code and model year, and confirm whether required hardware is supplied.

Choosing between the two comes down to goals. If you need unmatched factory integration, warranty preservation, and predictable safety performance, the OEM bumper is the safe choice. If your priority is aggressive styling, improved high-speed stability, and customization, a well-engineered aftermarket bumper delivers significant gains. In either case, consider installation quality, compatibility with lighting and sensors, and how the change affects cooling and serviceability.

For owners leaning toward aftermarket upgrades, inspect the part for certification, ask about crash compatibility, and plan for professional paint and fitment. If keeping things stock appeals more, look into sourcing genuine panels through verified sellers to avoid ill-fitting clones. For a closer look at selection criteria and fitment checks, consult the detailed guide on how to choose a front bumper designed for this chassis: How to Choose a Varis Front Bumper for Evo X?.

If you want to compare specific front bumper options for the CZ4A chassis, review a genuine front bumper listing and photos to understand factory contours and mounting points. A useful reference is the CZ4A genuine front bumper entry found here: CZ4A genuine front bumper.

Decide with intent. The right front bumper matches your driving use, aesthetic goals, and maintenance preferences. Whether that means keeping the original face or swapping in a race-minded surround, choose to benefit the whole car, not just its looks.

Seamless Fit and Function: Installing the EVO X Varis Front Bumper for Real Performance Gains

Seamless Fit and Function: Installing the EVO X Varis Front Bumper for Real Performance Gains

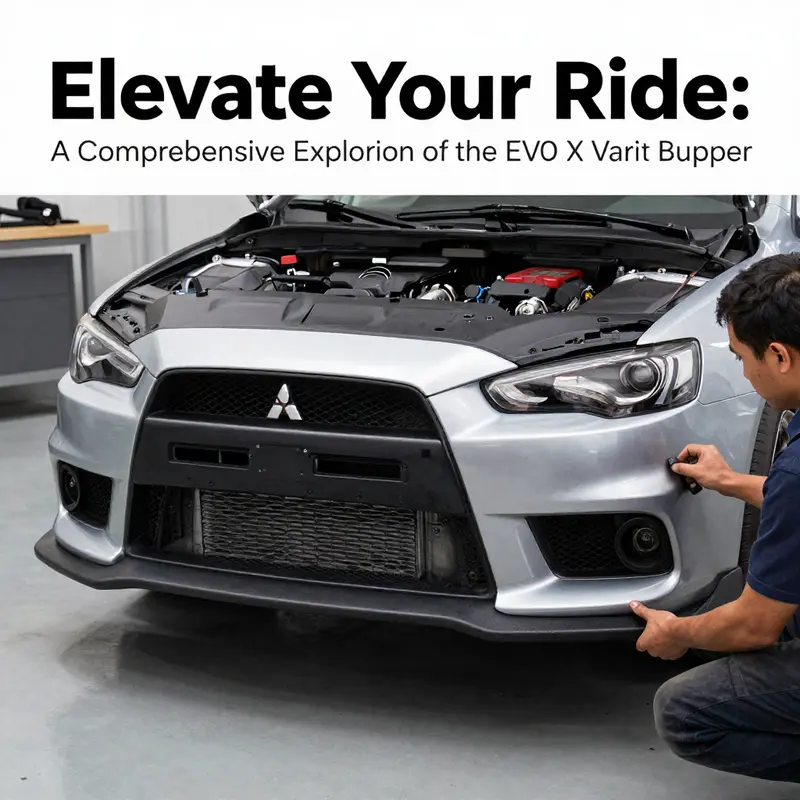

Installing a Varis-style front bumper on an EVO X is more than a cosmetic swap. When done correctly, it becomes a structural and aerodynamic upgrade that alters airflow, cooling, and the car’s visual stance. The unit’s FRP construction reduces weight while keeping rigidity, but its benefits only appear when fitment, alignment, and integration are carefully handled. This chapter walks through the practical considerations and installation mindset that deliver both looks and measurable performance.

Prepare the car and the bumper as if precision matters—because it does. Start by comparing the new bumper to the OEM piece. Look for mounting points, tabs, and the shape of the front surround and splitter. Test-fit before painting or final fastening. The goal is a flush, gap-free join with fenders and bonnet. Any misalignment creates turbulence and compromises cooling efficiency. Use protected surfaces and soft supports to avoid scratching the FRP while you trial-fit.

Hardware and reinforcement matter. Many aftermarket bumpers ship without the full set of OEM fasteners. Acquire stainless hardware and nylon clips that match factory locations. Where the bumper relies on thin tabs, add reinforcement plates on the backside to reduce stress cracking from road vibration. If a front lip or splitter is included, secure it with countersunk bolts and nutserts; this prevents movement under downforce. For track use, consider additional bracketry to transfer aerodynamic loads to subframe points rather than bumper shells alone.

Alignment goes beyond aesthetics. With the bumper loosely bolted, close the bonnet and inspect the gaps at the fenders and lights. Adjust mounting points and shims to achieve even spacing. The flush fit reduces drag and prevents pockets of high pressure that disrupt airflow to radiators and intercoolers. Minimizing these pockets will improve both engine and brake cooling under load. Use thin rubber shims where needed to dial in the spacing and absorb vibration.

Airflow tuning is a critical advantage of the Varis front surround. The larger intake openings, combined with integrated side ducts, channel air more effectively to the intercooler, radiator, and brakes. To maximize this, map out the airflow path from grille to core. Remove obstructions behind the bumper and consider redirecting under-bumper plastic to funnel air where it is most needed. Adding ducting to the brake cooling ports will maintain rotor temperatures on track, while a well-sealed shroud around the intercooler improves pressure differentials and cooling efficiency.

Thermal management should be treated as a system upgrade. If you pair the bumper with a higher-capacity intercooler or aluminum radiator, ensure the cores fit without rubbing the bumper shell. Reinforce the radiator mounts if necessary. Small air gaps or misaligned mounts can create hotspots and coolant stress. Where high-load driving is expected, add thermostatic fans or upgraded fan shrouds to maintain stable operating temperatures.

Consider ride and handling when integrating the bumper with other body kit components. Side skirts and rear diffusers complete the aerodynamic balance. A large front lip creates downforce, but without rear stability the car may become unsettled. When installing a Varis surround, think holistically: the full kit produces the intended aerodynamic profile. If you are fitting pieces one at a time, keep records of bolt locations and trim panels to allow straightforward reassembly when the full kit is ready.

Vibration and longevity depend on mounting strategy. FRP resists impact but is brittle at concentrated loads. Use rubber grommets at bolt points and distribute load with backing plates. Where tabs are thin, consider bonding an internal brace with structural adhesive and fiberglass patch. Proper edge sealing after paint will prevent moisture intrusion and stress cracks along seams.

Electrical and sensor integration often gets overlooked. Modern EVO X models include sensors and washer nozzles in the bumper area. Before final assembly, verify sensor alignment and reconnect wiring harnesses. Reposition washer jets if required to match the new lip geometry. If the bumper removes fog light housings, plan for either dummy plugs or aftermarket fogs that maintain airflow characteristics and electrical integrity.

A clean finish requires surface prep and paint sequencing. If the bumper is unpainted FRP, sand with progressive grits and apply flexible primer designed for fiberglass. Use a urethane or two-stage paint system with UV-stable clearcoat. Keep the paint layers flexible to avoid cracking from chassis flex. If you prefer a raw carbon look for a lip or splitter, seal the weave with epoxy and clearcoat to protect from stone chips and contaminants.

On the subject of fitment variations, factory and widebody EVO X variants differ. Confirm the bumper is specified for your chassis code. Many sellers list compatibility broadly; do not assume a perfect fit. When possible, consult a verified parts listing or a resource specialized for EVO X front bumpers to confirm mounting hole locations and trim differences. For a direct comparison and parts reference, see this resource on genuine front bumper fitment, which helps clarify OEM versus aftermarket fitment considerations.

Final checks before the first drive should include torqueing all fasteners to appropriate specifications and confirming no contact with moving components. Lift the car and inspect the inner apron for rubbing or misaligned ductwork. Road-test at low speeds to listen for rattles and observe bumper movement. Re-torque after the first few miles. Track preparation may demand additional checks after each session.

Repairability and serviceability are practical concerns. FRP can be repaired with fiberglass patches and resin if damaged. Keep a small repair kit with matching paint and some spare hardware. For serious impacts, the modular nature of the Varis-style bumper makes component replacement easier. Replace reinforced tabs rather than attempting to salvage heavily fractured sections.

Integrating a Varis front bumper into an EVO X is a blend of careful fitting, smart hardware choices, and aerodynamic understanding. When aligned and supported correctly, the bumper enhances cooling, reduces weight, and produces a race-inspired presence without sacrificing daily drivability. Treat the installation like a system upgrade. Align gaps, manage airflow, reinforce mounting points, and pair the bumper with thermal and intake upgrades to unlock its full potential.

For a technical walkthrough and guidance on choosing and installing a front bumper on an EVO X, consult this detailed guide from a specialist resource: https://www.carinterior.com/how-to-choose-a-varis-front-bumper-for-evo-x/.

For parts reference related to genuine EVO X bumper fitment, see this internal resource on CZ4A front bumpers: cz4a-lancer-evolution-evo-10-front-bumper-genuine.

Final thoughts

The Varis front bumper represents a key enhancement for the Mitsubishi Lancer Evolution X, combining aesthetic appeal with functional benefits that can significantly elevate the vehicle’s market value. Understanding its specifications, economic dynamics, and installation process empowers business owners to effectively market these aftermarket upgrades. By emphasizing the unique enhancements provided by the Varis kit compared to OEM options, businesses can cater to the growing demand among performance enthusiasts, thus fostering greater sales and clientele satisfaction.