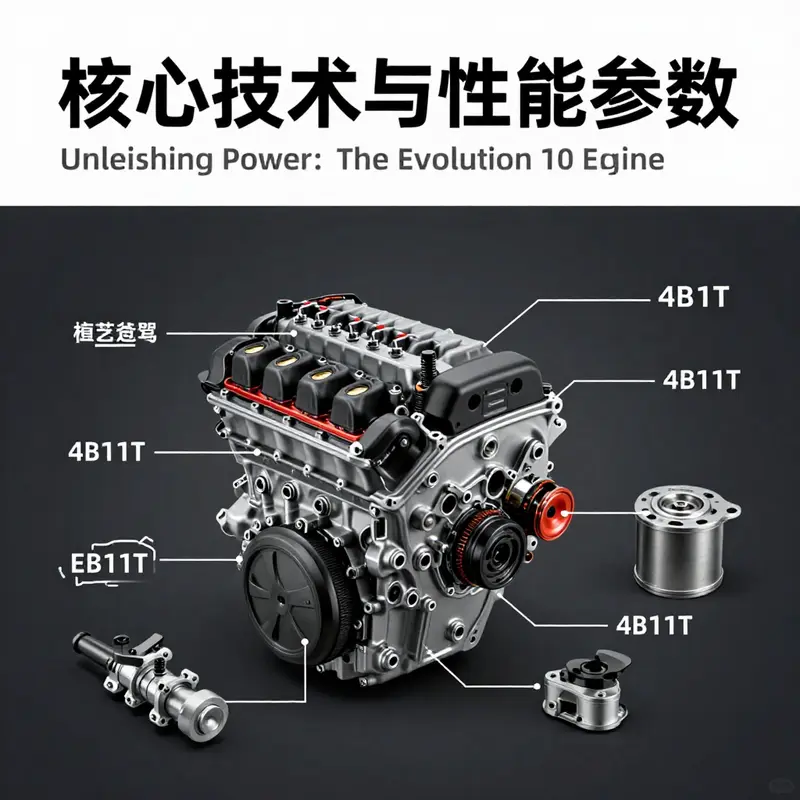

The Mitsubishi Lancer Evolution X (EVO 10) features a remarkable 4B11T engine, which stands as a testament to advanced automotive engineering. This turbocharged 2.0-liter inline-four engine combines performance and efficiency, making it ideal for driving enthusiasts and business owners alike. Each chapter of this article will explore crucial aspects of the EVO 10 engine, including its core technologies and performance parameters, its matched transmission systems, the key innovations that propel its capabilities, and concluding insights that reiterate its significance in the automotive landscape.

Heartbeat of a Rally Legend: The 4B11T Engine That Defines Evolution X

Behind the wheel, the Evolution X reveals itself as more than a silhouette of speed; it is a meticulously engineered organism whose heart is the 4B11T engine. This 2.0 liter inline four, forged in aluminum and tuned for a balance between raw power and practical civility, embodies a philosophy of performance that Mitsubishi has pressed into service across generations. The engine block and cylinder head material choices are not mere weight saving tricks; they are deliberate decisions that shape the way the car accelerates, how it cools, and how the chassis responds to driver input. The all aluminum construction reduces unsprung mass and lowers the overall vehicle weight, a factor that matters as much in daily driving as it does on a winding mountain road or a late afternoon track session. Weight reduction is not isolated to the engine bay; it echoes through the entire chassis by improving throttle response, sharpening steering feel, and mandating smaller, more responsive suspension strokes. This attentiveness to mass is the quiet preface to what becomes a loud, undeniable performance signature when the boost comes on. The power output is not just a headline figure but a byproduct of a philosophy that treats air, fuel, and timing as a chorus rather than a solo. The engine achieves its peak power of 217 kilowatts at 6500 revolutions per minute, translating to roughly 295 horsepower, and it does so with a torque curve that uncorks 366 newton meters of twist starting already at around 3500 rpm. That midrange surge is the essence of how Evolution X progresses from a highway cruiser into a capable canyon runner. The torque peak at comparatively low revs means the car feels eager and tractable in everyday traffic yet still absolutely unleashed when the road tilts upward and the torque demands a living, breathing shove. This power delivery is underpinned by a trio of core technologies that transform potential into actual performance. The first is MIVEC, Mitsubishi’s variable valve timing system, which acts like a conductor for the engine’s air and fuel choreography. At low and mid engine speeds, MIVEC orchestrates a valve timing profile that favors torque and smoothness, while as the revs climb, it shifts the balance toward a timing that favors high rpm breathing and top end power. The system does not rely on a single setting; it continuously adapts, providing a real world benefit that drivers feel as a seamless, linear acceleration rather than a sudden spike in power. This is not just about horsepower; it is about the character of the engine, the way it responds to the driver’s right foot, and how efficiently it converts hydrocarbons into forward momentum. Alongside MIVEC sits multi point fuel injection, a refinement over simple shared fuel distribution methods of the past. The engine’s fuel is atomized with precision, each cylinder receiving a carefully metered spray that atomizes in a way that promotes complete and consistent combustion across the chamber. This uniformity matters not only to peak performance but also to the engine’s ability to sustain power across a broad operating range and to bead the air-fuel mixture into an efficient, clean burn. The third thread in this technical fabric is the turbocharger paired with an intercooler. Boost is not a mere afterthought appended to the bottom end of the engine; it is integrated into the design so that the air charge arriving at the cylinders remains dense and cool enough to resist detonation while maintaining a robust density as the engine accelerates through the midrange and into the upper registers. The intercooler is a critical component here, cooling compressed air so that the density of the intake charge remains high while the engine breathes in the heat of compression that turbo systems inevitably generate. When combined with the mass reduction achieved by the aluminum architecture, the turbocharged intake becomes a reliable, consistent supplier of air to the combustion chamber rather than a fickle source of power that declines as the engine warms up. The result is a powertrain that feels cohesive, a package where the engine breathes with restraint but violently responds when the pedal is pressed. The 4B11T’s design supports a dual-pronged approach to driveability: torque that arrives with confidence and a peak power band that executes a clean crescendo at high revs. In everyday driving, the configuration yields a robust, usable midrange; once the tach climbs and the turbo spools, the engine reveals its capability for sustained high speed without the typical plateau that can hamper acceleration in some turbocharged four-cylinders. The engineering narrative continues with the transmission choices that partner with this engine to deliver power to the pavement. The Evolution X offers a six-speed dual clutch transmission, frequently referred to in shorthand as the TC-SST. The appeal of a dual clutch layout lies in its ability to deliver lightning-fast shift times, with responses on the order of a fraction of a second, while maintaining smoothness that makes the car feel composed in the most demanding driving scenarios. The rapid, decisive shifts amplify the sense of directness when the vehicle is asked to chase a corner ahead or sprint from one apex to the next. The SST’s ability to execute near-instantaneous gear changes translates into a driving experience that feels almost telepathic; the engine’s power is transmitted with minimal interruption to the flow of momentum, enabling a driver to maintain rhythm through a demanding sequence. For the purist, the Evo X also offers a six-speed manual option in markets where such a configuration remains cherished by enthusiasts. The manual path embraces a more intimate relationship with the engine’s torque curve and the turbo’s response, encouraging a more deliberate cadence that some drivers prize as a purer form of connection. The pairing of the 4B11T with either the TC-SST or the manual transmission underlines a broader aim: to keep the engine’s character accessible yet capable across a spectrum of driving styles, from daily commuting to track-day intensity. Yet the engine is more than the sum of its parts; it is the heart of a drivetrain ecosystem designed to exploit a carefully orchestrated balance of traction, grip, and stability. Central to this system is S-AWC — the Super All Wheel Control — a comprehensive four-wheel control platform that integrates not only a sophisticated center differential but also an active rear differential and a motion-oriented ABS. The result is a chassis that can distribute torque to the wheels that have the best chance of preserving grip and accelerating decisively, even as road surfaces and conditions change. The central differential helps allocate power to the front and rear axles with an intent that favors both stability and agility, while the active rear differential locks selectively to unlock cornering performance when push and grip demand it most. The ASC, or active stability control, complements this by modulating braking force and engine torque to maintain directional integrity, particularly in dynamic driving situations where grip is challenged. The design philosophy behind S-AWC acknowledges that a performance car does not live in a single moment of maximum acceleration; it lives in the continuity of a drive where traction must be both assured and exploitative. In this context the engine becomes a force multiplier because the chassis responds with predictability and precision, letting the driver exploit the engine’s torque curve and the turbocharged surge in real time, with the system guiding the car toward its limit in a controlled, repeatable fashion. The engine’s velocity and the car’s response are not separate chapters but two sides of the same equation. The advanced materials and engineering choices within the 4B11T also contribute to reliability and longevity by better handling heat and reducing mechanical friction where it matters most. The all aluminum construction, while light, also requires careful thermal management to keep the engine within its optimal temperature window. Modern power units thus rely on the intercooler and efficient cooling pathways to maintain performance across a wide range of temperatures and driving styles. In the Evo X, cooling is a partner to power; hot exhaust gases and compressed intake air must be managed so that the engine can sustain high output without sacrificing efficiency or durability. The resulting balance between cooling, fuel delivery, and valve timing creates a broad, usable power band that the driver can lean into without fear of sudden power loss or unpredictable throttle response. The MIVEC system deserves particular emphasis because it embodies the core philosophy of the engine’s behavior across different RPM ranges. In low to mid rpm, the system emphasizes torque and smoothness, a trait that makes the car tractable off the line or in urban traffic. As revs climb, MIVEC alters the valve timing and lift to optimize the air charge, enabling the engine to breathe more efficiently at high speed. This dynamic timing capability reduces pumping losses and improves utilization of the turbo’s boost, which in turn means that the engine is not starving for air as it climbs toward its redline. This is a crucial point, because turbocharged engines often wrestle with a narrow window where boost pressure remains sufficiently high without introducing detonation risks. The 4B11T’s integration of MIVEC, multi point fuel injection, and a well-maired turbo setup ensures that the engine sustains a strong torque output while offering a predictable and linear power curve that suits both aggressive driving and refined cruising. The transmission and drive system work in concert with this engine to deliver the momentum where the road demands it most. The SST or manual choice influences how often the engine can hold a certain torque delivery in a given gear, and how effectively the driver can manipulate the torque through the corners. In high-speed straightlines, the dual clutch’s ability to shift nearly instantaneously means the engine never cedes momentum to an interim gear; the car maintains the pace without the lag that sometimes accompanies traditional automatics. In cornering or on a track, the automatic’s quick shifts can preserve a rhythm that keeps the driver in the zone, particularly when G forces are high and the line cadence through a sequence of bends must be maintained. The interplay between the engine, the drivetrain, and the four-wheel control system becomes most apparent in dynamic conditions, where grip is tested and the car must respond with stability and confidence. The aluminum block and head, the lightweight design, the precise fuel delivery, the variable valve timing, and the turbocharged air charge coalesce into a machine that can deliver its promised performance with a sense of inevitability. This is not simply a matter of horsepower; it is the confidence that comes from a powertrain that feels coherent from the moment the throttle is pressed until the exhaust note fades from the horizon. The chassis and suspension also participate in this coherence, translating the engine’s energy into an actual track or road experience. The Evolution X has been celebrated by driving enthusiasts for a reason: the engine is not a standalone statistic but the central actor in a film where the vehicle’s handling, balance, and traction are choreographed to deliver a race-bred sensation that remains accessible to skilled street drivers. The result is a vehicle that can understeer slightly under heavy load in a way that invites correction, rather than one that snaps suddenly into a dangerous fishtail. The architecture that enables this behavior is deeply mechanical, but it is also a product of a philosophy that values driver feedback and the tangible sense of propulsion. In this sense, the 4B11T is less about raw numbers and more about how those numbers translate into a felt experience: a taunt of torque gripping the pavement, a surge of air and force through the intercooler, and a shifting chorus of gears that makes the car feel alive with purpose. For those who seek the engineering narrative behind a formidable compact car, the 4B11T remains a compact, efficient, and thoroughly modern solution. Its lightness, its ability to hold torque in the midrange, its precise fuel delivery, and its commitment to a stable yet eager response all define the engine as a performance landmark in this class. When paired with the S-AWC system and the two transmission choices, it becomes a propulsion architecture that is not just about top speed but about the experience of speed itself—how it gathers, how it flows, and how it returns control to the driver just when the road demands it most. The deep synthesis of aluminum design, MIVEC timing, multi point injection, and turbo cooling is a reminder that performance engineering today is a ballet of accuracy and balance. It is a reminder that a car like this, born from competition discipline and refined for road realism, invites a driver to explore and to trust the machine through every twist and turn. In the end, the engine is not a collection of impressive specs; it is a living system that defines the taste of acceleration, the cadence of upshifts, and the sensation of laying down grip when the chassis asks for a push. The Evo X thus delivers more than speed. It offers a compact, coherent, and highly engineered path from the pedal to the pavement, a demonstration that when power is curated with thoughtful engineering, the result is a driving experience that feels both exhilarating and profoundly controllable. For enthusiasts who crave the connected feel of a well-sorted performance car, this is the moment when the engine becomes not only a source of power but a partner in the act of driving. The 4B11T is the unmistakable heart that makes the Evolution X more than a car; it makes it a statement about how performance engineering can blend lightness, precision, and turbocharged momentum into a single, repeatable, and endlessly engaging driving experience. To explore further the hardware behind this architecture, consider the 4B11T billet block as a focal point for the kinds of upgrades that enthusiasts often pursue, because strengthening the core can enable more robust performance while preserving the engine’s lightness and responsiveness, a principle that underpins the reliability and efficiency that contribute to the car’s broader appeal. 4B11T billet block. External reference: https://www.mitsubishiautopartsshop.com/04a-evo-x-hardware/ or for a canonical spec overview, see the official resource. External reference: https://www.mitsubashi-motors.com/en/models/evo/

传动的共振:Evolution X 4B11T 引擎与六速传动的协同艺术

当谈到 Evolution X 的核心动力时,人们往往聚焦于这台代号为 4B11T 的2.0 升涡轮增压发动机如何在中后段展现出惊人的爆发力与平顺的扭矩曲线。然而,真正将这份潜力转化为可感知的加速与稳定牵引的,是一整套设计紧密协同的传动系统。发动机本身以全铝合金材料打造气缸盖和缸体,显著降低了整车重量与热阻,配合高效的涡轮增压与中冷器,确保在 3500 转/分时就能爆发出持续的扭矩,使车轮在第一时间获得来自地面的抓地力。此时,传动系统的任务便是准确、迅速地把这份扭矩带到轮端,同时在不同路面与驾驶需求之间实现平滑切换与精准控制。换言之,传动系统不仅是一道机械分配扭矩的桥梁,更是一位理解驾驶者意图、预测路况并在瞬间做出响应的合作者。就此背景而言,Evolution X 提供了两种最核心的变速系统选项——6 速双离合变速箱与6 速手动变速箱。前者以极致的换挡速度和极高的响应性成为大众市场的主流选择,后者则以原始、直观的驾驶乐趣吸引追求纯粹操控的人群。官方资料与技术解析显示,6 速双离合变速箱在换挡时间上能达到约0.1 秒的极速响应,换挡过程平顺且几乎无缝,能够让涡轮增压的高转速输出持续稳定地维持在驾驶者的预期扭矩区间内。这种快速的换挡节奏,配合发动机在中高转速区段的强大扭矩,意味着在起步、超车以及高速巡航时,动力始终处于可控的高效区间。与此同时,6 速手动变速箱以其强烈的参与感和机械的清晰反馈,成为追求“手控呼吸”的驾驶者的选择。手动版本的换挡机械结构虽不及双离合在速度上的优势,却能提供极致的路感和调校空间。尽管在某些市场,尤其是国内市场,手动版本相对罕见,但官方仍然保留了这一配置,满足对驾驶乐趣有极致追求的车迷,并在技术上体现了对不同文化和驾驶传统的尊重。两种传动系统的存在,既是对性能边界的探索,也是对驾驶体验多样性的尊重。与此同时,Evolution X 的传动系统并非孤立运作。它与 S-AWC 超级全轮控制系统共同作用,确保动力在各个路况下的分配与反馈都保持高效、可控。S-AWC 通过对前后轴和左右轮的扭矩分配、以及对前后差速的动态调校,帮助车辆在弯道中的姿态控制更为精准。考虑到发动机在中低转速已经具备强劲扭矩,传动系统的调配便显得尤为关键。若以双离合作为主力,变速箱的快速换挡将迫使驱动力以更紧密的节奏被传递到轮端,这对分配系统的响应速度提出了更高要求,需要 ECU 与扭矩向量化控制的协同工作,以避免在激烈弯道中出现转向不足或轮速差过大而导致的牵引损失。若选择手动车型,驾驶者的换挡节奏与离合点会成为影响扭矩传递成本的核心变量,车载控制系统仍在背后以电子辅助的方式优化换挡时机、油门响应和二次加速的稳定性。对许多热衷于极致抓地力与直线加速的驾驶者而言,TC-SST 的快速换挡与精准时序,能在对油门响应和轮端传递的每一次微调中体现出“力量在手”的信心。另一方面,手动变速箱则以延展扭矩的使用范围为目标,鼓励驾驶者通过齿比的选择来维持对发动机扭矩峰值的控制。与之相配的排布,让中低速阶段的扭矩就能有效传递,避免在城市路况中频繁降档造成的抖动与耗油增加。某些权威信息还提及在更高性能版本的改装领域,传动系统可能采用全序列式方案,以实现更极致的换挡节奏与动力输出的无缝衔接。这类方案的核心思想,是将换挡控制提升到新的层次,使变速箱的每一个齿轮都能在极短时间内完成锁止、开启与同步,进而最大化发动机在涡轮增压下的瞬时输出。若将此类信息放在 Evolution X 的框架中理解,它们并非替代现有的两种核心变速选择,而是在更高性能需求的场景中,成为对“极致响应”理解的延展。要理解传动系统的真正潜力,不能只看单一部件,而应把发动机的高压缩比、涡轮增压的热管理、以及多点喷射带来的高燃烧效率,作为一个整体来评估。MIVEC 可变气门正时系统在转速变化时对进排气门的开启时刻进行实时微调,使发动机在不同负荷下保持高效燃烧。这一技术让发动机在中高速区间的扭矩输出更为连续,减少了因换挡而造成的动力缺口。与多点喷射相结合时,燃油雾化与喷射时序的精密控制进一步保留了火花塞处的燃烧效率,使扭矩曲线在换挡前后保持平滑过渡。涡轮增压与中冷器的作用也不容忽视。在换挡时,进气温度若过高,发动机就需要更大的燃油喷射和更激进的点火策略来维持同样的输出。通过中冷器的降温作用,进气密度得以改善,扭矩输出更稳健、响应更及时,这也让双离合变速箱在短时间内完成高效的扭矩传递变得更加可靠。对经常处在中高速巡航与激烈加速之间切换的驾驶场景而言,双离合变速箱的优点尤为明显。它能在数百分之一秒内完成换挡,以保持发动机始终处在高效工作区间,避免在需要瞬时加速时出现拖延。通过精细的扭矩分配和控速节拍,驾驶者在过弯、进线、出弯的每一个阶段都能感受到来自底盘的即时反馈与来自油门的直接能量注入。对于追求驾驶乐趣的车迷而言,手动版本虽然在直观性上更胜一筹,但在日常应用中,双离合版本以稳定的性能表现和更高的可预测性,往往能提供更强的综合体验。这也解释了为何官方更广泛推广 TC-SST 作为主流配置,同时保留手动选项以维系不同文化对驾驶快乐的理解。对于对改装和极致性能有兴趣的群体,外部资源与论坛中常会提及到某些高端传动系统的选型与整车减重优化,例如全序列式变速箱在赛车化应用中的理论与实作案例。虽然这并非 Evo X 的标准配置,但它们揭示了传动系统设计在高性能领域里不断向极限靠拢的趋势。为进一步了解这类方向,读者可以参考相关的技术资料中对全序列式变速箱的描述以及它在不同车型中的应用实践。若将注意力聚焦在日常驾驶与性能释放之间的平衡点,Evolution X 的两种主流传动形式已经能够覆盖绝大多数场景的需求。无论是以快速换挡来提升爆发力,还是通过手动控制来追求最直接的路感与刻意的节拍,车辆都能在驾驶者的意图与路面条件之间建立起一条清晰的通道。就这一点而言,传动系统不仅仅是机械传动的桥梁,更是驾控艺术与工程科学之间的纽带。正是这种纽带,使得 Evolution X 的动力系统能够在不同路况、不同驾驶风格之间实现无缝的协同,呈现出稳定而富有层次的动力表现。若把目光投向实际路试与日常使用,驾驶者会发现无论选择哪一种传动系统,整车对油门的响应与变速时序的协调都在一个高度成熟的工程体系中被优化。发动机的高输出潜力通过传动系统的智能控制被转化为可控的、可重复的性能体验,这也是 Evo X 之所以能够在同级别车型中占据重要地位的核心原因之一。对于未来的改装与发展方向,开发者和车迷们也在不断探索在不牺牲日常使用舒适性的前提下,进一步提升换挡速度、降低惯性、优化扭矩带来的路感传递。作为对本章节内容的自然延伸,一些资料提及的全序列式变速方案,为赛车化的潜力提供了另一种可能性,但它的应用更多地落在高性能原型与赛事领域。此类信息的存在,说明传动系统作为整车动力传递网络的核心环节,始终处在技术创新的前沿。最后,关于本章节所涉及的传动系统选项的具体细节,读者若希望深入了解某一型号的具体参数与实现原理,可以参考如下内部资料链接中的相关资料,以便获得更为直观的技术要点与实际应用解读。这些内部资源中对传动系统的描述,往往包含换挡逻辑、离合器工作原理、以及与扭矩向量化控制的协同机制等要点。 full sequential gearbox for Mitsubishi Evo 4-9 and X 的相关讨论,便是对高端赛车化传动系统的一种前瞻性描述。此类信息与 Evo X 的两大主流配置共同构成了现代高性能紧凑型轿车在传动领域的多样性图景。外部参考资源可以帮助读者扩展视野,从而更好地理解官方技术背景与改装潜力之间的关系。关于官方的系统背景与发展脉络,读者也可以访问外部资源以获取权威性说明和最新进展:https://www.mitsubishi-motors.com/evolution

How the Evo 10’s 4B11T Redefined Performance: Lightweight Design, MIVEC, and Turbo Control

Key innovations that define the 4B11T and how they work together

The heart of the Evolution 10 is a compact, intensely engineered 2.0-liter turbocharged four-cylinder. At its core sits the 4B11T, an engine that married weight-conscious materials with control systems tuned for both responsiveness and endurance. Understanding why this engine stood out requires looking past isolated specs. The real story is in how construction, breathing, fueling, and drivetrain integration were designed to act as one. The result is a powerplant that delivers strong midrange torque, a linear high-rpm onset, and predictable behavior under load.

The decision to use aluminum for both the cylinder head and block was pivotal. Aluminum reduces mass compared with iron, and the lighter assembly lowers the vehicle’s center of gravity. That improves steering feel and turn-in agility. Less reciprocating mass also aids transient response. Aluminum conducts heat well, which helps manage combustion temperatures. Improved cooling capacity matters most when the engine runs high boost or sustained hard driving. A lighter, cooler engine lets engineers tune for higher specific output without excessive compromises in durability.

Built as a modern inline four, the 4B11T achieves almost 295 horsepower and a torque peak near 366 newton-meters. Those numbers are useful, but how they are delivered matters more. Peak torque arrives low, around 3500 rpm, giving the car urgent, usable thrust in everyday acceleration and midrange passing. Peak power at 6500 rpm ensures the engine can continue to pull strongly at higher revs, supporting rapid upshifts and spirited driving. The torque curve sits broad and usable, not spike-like, which makes the car easier to control at the limit.

A crucial link between the combustion chamber and the driver is variable valve timing. The adopted MIVEC system adjusts valve timing in response to engine speed and load. By altering intake valve timing, the system optimizes cylinder filling at all revs. At low speeds, timing favors torque and smooth idle. At high speeds, it favors breathing for peak power. The net effect is a wider effective power band. Fuel efficiency improves because the engine requires less throttle correction and fewer high-load interventions. Emissions benefit too, since combustion becomes more complete across diverse conditions.

Fuel delivery is equally important. The 4B11T employs multi-point injection to deliver fuel precisely and evenly into each intake port. This promotes consistent air-fuel mixing in every cylinder. Better mixture uniformity reduces detonation risk under boost. It also yields cleaner burn and more repeatable combustion cycles. When paired with variable valve timing and tuned ignition, multipoint injection helps sustain power while limiting fuel consumption and emissions.

Turbocharging is the centerpiece of the engine’s performance. The turbocharger compresses intake air to raise density and increase the oxygen available for combustion. To prevent the heat generated during compression from eroding density gains, an intercooler is used. The intercooler lowers intake temperatures, preserving charge density and preventing knock. Softer charge air yields more stable combustion and permits more aggressive ignition and boost maps. The combined result is faster acceleration and stronger, more consistent power delivery across the RPM band.

Turbo systems introduce challenges. Heat soaks and spool characteristics can undermine performance if not managed. That is why thermal control and boost calibration are essential. The cooling system, oil circulation, and intercooler sizing are balanced for real-world demands. Boost control is tuned to provide strong midrange response without excessive turbo lag or sudden spikes in pressure. Careful matching of turbine and compressor sizes keeps spool reasonable while allowing high-flow capability near peak power.

Beyond the engine itself, the way power gets to the road shapes the car’s personality. The 4B11T was paired with a rapid-shifting six-speed dual-clutch transmission in many markets. That gearbox offers shift times that feel instantaneous. It preserves momentum during aggressive driving and allows near-seamless power transfer. A manual six-speed remained an option for purists, preserving driver engagement and mechanical simplicity. Both options were developed to handle the engine’s torque characteristics reliably.

Full-time all-wheel drive ties the system together. The drivetrain’s capability to manage torque split and wheel slip allows the engine to be driven hard without losing composure. When traction is available, the system routes torque where it can be used most effectively. During mid-corner throttle application, the combination of predictable torque delivery and intelligent drive distribution reduces understeer and improves rotation. The car feels planted even when the engine’s boost is high and the driver demands aggression.

These technical elements are not independent. Material choice affects thermal dynamics, which affects detonation margins and therefore boost strategy. Valve timing alters volumetric efficiency, which changes how the turbocharger is sized and tuned. Fueling precision directly influences the engine control maps, which govern ignition timing and boost targets. The engineers tuned these systems together. The goal was consistent, controllable power rather than only headline numbers.

Serviceability and tuning potential were also considered. The engine’s architecture lends itself to sensible modifications. Coolant routing and oiling provisions support stronger internals for those seeking higher outputs. Upgraded components such as strengthened blocks and forged internals are common modifications in performance circles. For those who want to explore upgrades, an informative reference is available on a billet block adaptation and related support components. This resource discusses approaches to reinforce the base architecture while maintaining reliability: 4B11T billet block.

On the control side, the engine management calibrations were written to balance drivability and performance. Throttle mapping, boost targets, and ignition timing are calibrated to avoid abrupt transitions. That yields a throttle response that feels direct without being twitchy. When the driver demands torque, the engine responds predictably. When cruising, the control systems back off to conserve fuel and reduce noise.

Durability was not sacrificed for performance. Component choices reflect this. Pistons, bearings, and crank design account for high cylinder pressures and the heat of forced induction. Oil supply and cooling pathways are sized to handle sustained loads. These design choices allow the engine to operate at elevated outputs without immediate compromise to longevity, assuming normal maintenance.

The real-world payoff of the integrated design is palpable. Drivers experience a strong initial surge from midrange, aided by the turbo and low-end torque. When pushed, the engine unfolds cleanly toward its redline, thanks to optimized breathing and valve timing. The transmission and all-wheel drive system serve as amplifiers. They let the engine’s character translate into quick, usable acceleration and stable handling. On a twisty road or a track, the synergy between engine and drivetrain yields predictable transitions and sustained performance.

Performance perception is as much about control as about raw force. The 4B11T excels because its behavior under varying loads remains consistent. The combination of aluminum construction, variable valve timing, refined fueling, thermal management, and drive integration redefined what a compact turbocharged engine could offer. It reduced the compromises typically associated with high specific outputs.

Where engineers had to choose trade-offs, they favored systems-level balance. They accepted complexity in engine controls and drivetrain calibration rather than compromise the smooth and usable power delivery. That decision produced an engine that suited a broad set of demands: aggressive street driving, spirited canyon runs, and occasional track use.

For anyone studying modern forced-induction engine design, the 4B11T provides a clear lesson. Lightweight construction and heat control expand options for performance. Variable valve timing broadens the usable powerband. Precise fueling reduces detonation risk and improves consistency. Turbocharger and intercooler choices govern transient behavior and peak capability. Finally, transmission and drivetrain design determine how effectively the engine’s characteristics translate into lap times or overtaking maneuvers. Together, these elements show how thoughtful integration can elevate an engine beyond its displacement.

For additional technical context on kits and applications that explore these design pathways further, see this external technical guide: https://www.gearhead.com/technical-guide-evo-10-kit-specifications-applications/.

The Metal Heart of a Final Chapter: Inside the 4B11T Turbocharged 2.0L Engine

The essence of a high-performance compact car often hides in plain sight it is the engine that speaks first and the chassis that listening follows. In the case of the Evo X’s apex, this dialogue is anchored by a single, remarkably capable unit: a 2.0-liter turbocharged inline-four whose designation, 4B11T, signals a distinct engineering lineage within the era’s performance ambitions. This engine is not merely a power plant; it is the culmination of a philosophy that prizes light weight, thermal discipline, and precision timing. It embodies a balancing act that began years earlier and arrived at a peak poised to redefine what a mid-size performance sedan could deliver on the road and on the track. To understand its character is to understand how an era of compact performance engines matured into something more refined, more responsive, and more capable of translating raw turbocharged thrust into a cohesive, confident driving experience.

The first impression one gets from the 4B11T is its architectural discipline. The entire cylinder block and the head are crafted from aluminum, a choice that reduces mass without compromising rigidity or thermal stability. In a class where every kilogram matters for handling and response, shaving weight from the powertrain is not a cosmetic luxury but a functional imperative. A lighter engine means the drivetrain can respond more quickly to driver input, the suspension has less inertia to manage, and the overall balance of the chassis can be tuned toward agility and immediacy. Aluminum construction also improves heat dispersion. In a turbocharged engine, where heat management governs reliability and sustained performance, the ability to shed heat efficiently can influence how consistently the engine can hold a high level of output across a demanding stint on a winding road or a race-course lap.

Beneath the hood, the 4B11T presents a modern approach to fueling and air management. Multi-point fuel injection delivers precise quantities of fuel to each cylinder, a prerequisite for achieving the smooth, broad-power response that high-speed driving demands. This system ensures that the engine can maintain a stable mixture across a wide range of RPM and load, avoiding lean misfires during rapid throttle changes and supporting refined torque delivery. When the driver pushes through the mid-range, it is the fuel delivery that keeps the flame steady, preventing the surge and dip that can disrupt a corner’s balance or a straightaway’s rhythm. But fuel is only part of the story; the air that accompanies that fuel is what makes the mixture sing. The engine uses a turbocharger complemented by an intercooler to lower the incoming air temperature. Cooler air is denser air, and denser air means more oxygen to burn and more potential energy in each combustion event. The result is a stronger, more linear push as boost builds and stabilizes, rather than a sudden spike that can unsettle chassis balance.

A cornerstone of the 4B11T’s performance is its sophisticated valve timing management. Known in the engineering shorthand as a variable timing system, this technology continuously adapts the opening and closing moments of the intake and exhaust valves depending on engine speed and load. The effect is twofold. First, it broadens the engine’s usable power band, ensuring that peak thrust remains accessible from lower to mid-range revs without forcing the driver to chase a narrow power peak. Second, it improves combustion efficiency, which translates into stronger mid-range torque and better fuel economy for the everyday drive. In practical terms, that means the car can pull with confidence in midfield gears and respond crisply when the accelerator is pressed at highway speeds. The goal is not to chase the numbers alone but to create a feeling of propulsion that is consistent and predictable, a quality highly prized by drivers who demand both performance and control.

The heart of the engine’s torque characteristics is its turbocharging system. A turbocharger paired with an intercooler keeps inlet air density high while restraining the temperature rise that can sap performance under prolonged acceleration. A well-tuned turbo system is as much about response as it is about peak numbers. In this design, peak torque emerges at a relatively approachable RPM, which means the car can accelerate with authority early in the rev range rather than requiring you to wade into the high end before the power arrives. This low-end and mid-range torque synergy is crucial for real-world driving, where street starts, overtakes, and mid-corner bursts benefit from torque that you can feel as soon as you roll into the accelerator.

Power output figures illuminate the engine’s capability. In the standard configuration, the unit develops approximately 295 horsepower (217 kW) with torque peaking around 366 Newton-meters at about 3,500 rpm. Those numbers alone suggest a robust, ready-to-shift engine; they translate into a push that is immediate yet composed, a torque curve that remains broad enough to keep the car in a favorable gear for longer, reducing the need for constant gear hunting. The final edition of this engine family, however, represents a deliberate evolution rather than a sudden leap. Through targeted exhaust improvements and breathing optimizations, the final iteration bumps up to around 303 horsepower and a torque figure near 414 Newton-meters. Those gains are not simply about more power; they reflect a more efficient breathing of the combustion chamber and a more effective use of boost, especially when the engine is loaded in mid to high RPM ranges. The characters of the power curve shift to offer a more expansive, more usable torque band, which in turn fosters a driving experience that feels both quick and controllable at all speeds.

Integral to this engine’s performance narrative is how it is paired with its transmission options. The six-speed dual-clutch automatic combines the immediacy of a direct-drive system with the smooth progression of an automatic reception. Shifts arrive with lightning speed, a trait that the driver can savor during rapid, successive maneuvers on a track or on a spirited back road. The speed of each gear change—often measured in tenths of a second—means the power remains uninterrupted as it flows through the drivetrain, preserving a sense of momentum and a line that remains unbroken through corners and chicanes. The dual-clutch arrangement is complemented by a six-speed manual option, a nod to purist enthusiasts who relish tactile control and a more involved, hands-on connection with the car. In either configuration, the engine’s torque delivery interacts with the gearbox to create a propulsion experience that is immediate, precise, and gratifyingly predictable. Between the two transmissions, there is a bridge that can suit both the drive-enthusiast’s needs and the everyday user’s expectations for smoothness and engagement.

No examination of the engine can ignore the broader drivetrain architecture that supports performance in this class. An integrated all-wheel control system distributes power in a way that prioritizes traction under acceleration while preserving stability through corners. The system negotiates weight transfer, brake-induced yaw, and throttle-induced stability with a choreography that feels almost intuitive. The result is a car that feels planted at speed and confident at the edge of adhesion. This is not a case where power alone wins; it is a case where power, weight distribution, braking, and steering all come into a single, harmonious package. The synergy between a lightweight aluminum block and head, precise fuel and air management, and a well-tuned delivery system makes the engine a reliable partner through varied driving conditions. It produces the sense that the car is not fighting the road but listening to it and responding with measured authority.

Within this narrative of capability, the engine’s engineering choices reveal a philosophy: performance should be tangible, usable, and repeatable across conditions. The aluminum architecture reduces mass, improving both acceleration and handling. The fuel system and valve timing are tuned to deliver consistency rather than transient spikes in power. The turbocharged intake system ensures that you have practical torque and usable power across the rev range, not just at peak RPM. And the chosen transmission pairing makes the engine’s output accessible in everyday driving as well as on a track day. This is a machine designed to reward a skilled driver with trust and precision, a trait that defines its character across the line’s entire lifecycle.

For those who crave an inside view of the engine’s future-proofing possibilities, the engine’s bottom end could be strengthened with performance-oriented hardware, such as a billet block. Such an upgrade speaks to the ongoing appetite for reliability under stronger boost and higher sustained outputs. The internal architecture, with its light yet rigid construction, stands as a foundation that can accommodate additional overhead with relative ease. If you explore the deeper parts of the engine’s ecosystem, you will find a lineage of components designed to resist the fatigue that accompanies aggressive tuning, a trait that underscores the era’s engineering maturity. To give a tangible sense of the internal upgrade path, one may observe how the block architecture and its supporting elements could benefit from a high-strength billet variant, a concept that trades complexity for an even greater stability under load. For readers who want a concrete reference to such an upgrade, the technical option known as a billet block provides a glimpse into how performance-focused hardware can extend the engine’s lifespan under demanding conditions. The link below delves into this specific enhancement and helps illuminate how a core component can be reinforced without altering the fundamental architecture that defines the engine’s character. 4B11T billet block.

Even as the car evolves toward a higher peak in power and torque, the engine’s essence remains anchored in its breathing. The intake and exhaust flows, the valve timing, and the turbo’s response all produce a calibrated cascade rather than a single loud shout. This makes the engine feel less like a raw power source and more like a living system that harmonizes with the driver’s intent. It is a testament to the era’s engineering that a small displacement, modern turbocharged engine can deliver such a balanced mix of speed, control, and efficiency. The final edition of the model captures this balance most vividly. With improved power figures and a torque curve that remains strong across a broad RPM band, the final edition offers a driving experience that is both exhilarating and approachable. It is this duality—an ample, usable surge of power combined with the control to place it precisely where the driver wants—that differentiates a truly great performance engine from a merely powerful one.

From the open road to the track, the engine’s performance story follows a clear arc. It begins with weight-conscious architectural decisions that lower the car’s overall inertia. It continues with a meticulous approach to air and fuel management, ensuring efficient combustion and predictable torque delivery. It then arrives at a turbocharged heartbeat that can sustain boost while resisting heat build-up, culminating in a powerband that remains accessible and usable at road speeds. In this sense, the engine does more than produce numbers; it enables a driving experience defined by confidence and immediacy. The final edition’s heightened output and refined mechanicals reinforce this narrative, pairing a higher peak with a broader, more usable torque envelope. The sensation is one of propulsion that is both eager and composed, a rare combination that makes the car feel equally at home on a winding mountain road and a high-speed straightaway.

As the chapter on this engine nears its end, it remains essential to recognize the ecosystem that makes such performance coherent. The six-speed dual-clutch automatic or the six-speed manual gearbox are not disparate parts; they are partners in a carefully choreographed dance. The engine’s torque delivery shapes the timing of each shift, while the transmission’s response characteristics shape how the driver perceives the engine’s power. The all-wheel control system adds an element of stability and traction that lets the engine’s energy translate into forward motion rather than wheelspin or understeer. In a broader sense, the engine’s design reflects a philosophy of accessible performance: you can feel the acceleration, but you also feel the reassurance that the chassis, brakes, and control systems provide as you explore the edges of grip. That union—engine, transmission, drivetrain, and chassis—paints the complete picture of a powerplant that is as much about engineering discipline as it is about raw speed.

The story of this engine is also a reminder of a broader narrative about automotive engineering in its final chapter. As technologies matured and weight-saving strategies became more sophisticated, teams could extract more from a smaller displacement without sacrificing reliability. The 4B11T embodies that transition: a compact, aluminum-heart turbocharged design that achieved significant power and torque, delivered through a transmission that could be either lightning-fast or hands-on, and supported by a drive system capable of preserving traction and balance across diverse conditions. The result is not simply a car that goes fast; it is a vehicle that invites a driver to go faster with assurance, to push into corners with a calm, controlled cadence, and to enjoy the sense that performance is a dialogue rather than a monologue. In this light, the engine is not merely a component but a storyteller, recounting a period of engineering ingenuity that sought to fuse efficiency, precision, and emotion into a compact, accessible sculpture of motion.

As the era closes and enthusiasts reflect on the 4B11T, it becomes clear that its strength lies in the balance it achieves. It delivers more than numbers; it delivers a philosophy of speed that respects weight, heat, and human control. The final edition’s enhanced outputs underscore that philosophy while highlighting how the architecture was capable of growing with the technology of its time. The engine’s legacy is a reminder that high performance does not require brute force alone; it requires a delicate alignment of breathing, timing, and traction. In that sense, the 4B11T is less a mere engine and more a compact manifesto for a generation of drivers who valued speed with restraint and precision with passion. It stands as a tribute to engineering that knows when to accelerate, how to manage heat and fuel, and when to lean into the curve with confidence. This is the engine that closed a chapter with dignity and prepared the road for what would come next, even as it continued to inspire those who seek a deeper understanding of what makes a performance car feel alive on every mile of tarmac.

External resource: https://mitsubishiautopartsshop.com/brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x/

Final thoughts

The Mitsubishi Lancer Evolution X (EVO 10) embodies a perfect blend of cutting-edge engineering and performance excellence through its 4B11T engine. With features like the MIVEC technology and a robust turbocharging system, the EVO 10 is not just about speed; it’s also about efficiency and innovation. For business owners in the automotive sector, understanding this impressive engine illuminates its valuable role, ensuring that customers receive a superior driving experience while benefiting from improved fuel efficiency. The EVO 10 remains a benchmark in the performance car segment, inspiring new technologies and driving ambitions.