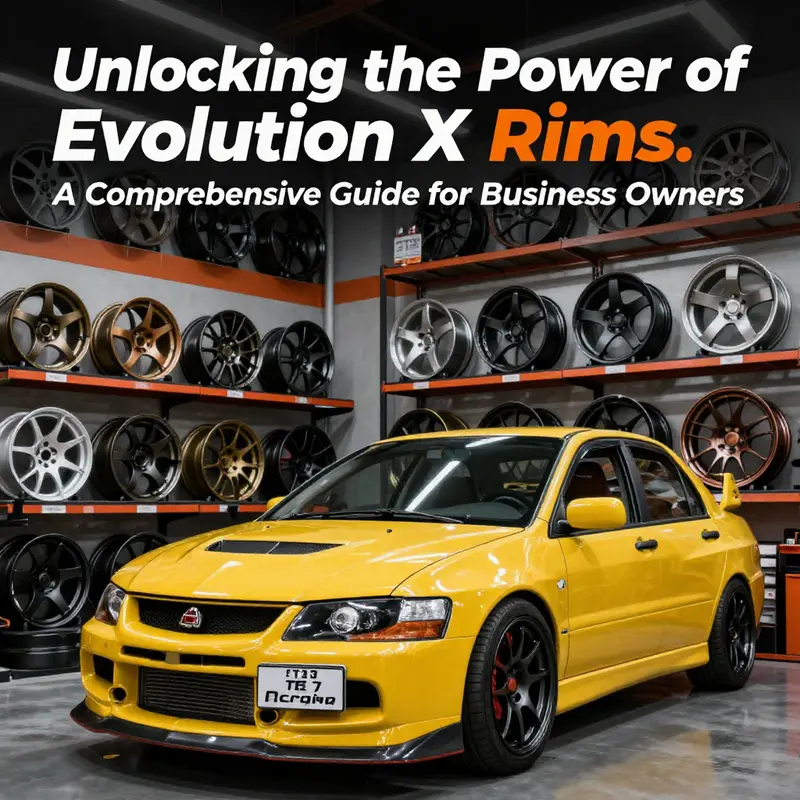

The Mitsubishi Lancer Evolution X (Evo X) is a hallmark of performance engineering, where every detail contributes to its driving prowess. Among these details, the wheels play a pivotal role, influencing both the vehicle’s aesthetic appeal and its handling dynamics. For business owners within the automotive industry, understanding the intricacies of Evo X rims is essential in catering to customer preferences and enhancing offerings. This guide will delve into OEM wheel standards, the significance of high-performance upgrades, enticing aftermarket options, the relationship between wheels and performance, and the market trends driving their demand. Each chapter will provide insight into how wheels define the Evo X experience, equipping business professionals with the knowledge needed to serve this niche market effectively.

Rim Anatomy: OEM Wheel Specifications and the Evolution X’s Handling Backbone

Wheels do more than complete a car’s look; on a performance machine like the Mitsubishi Lancer Evolution X, they are an integral part of the chassis sensation. The stock wheels set the baseline for steering response, braking efficacy, tire footprint, and suspension communication. In the Evo X, the wheel pairing was chosen to harmonize with the advanced all-wheel-drive system and a chassis tuned for both street and high-performance driving. The front and rear wheels were designed as a unified set to ensure consistent aesthetic and predictable handling balance across the vehicle.

The factory setup featured 18-inch rims in a uniform size, with front and rear shares mirroring each other in diameter and width. This symmetry helps with rotational inertia, brake cooling, and tire contact patch behavior under varying conditions. For enthusiasts seeking authenticity, the OEM dimensions serve as a benchmark against which upgrades are measured. Beyond baseline, the Evo X offered a high-performance forged option on the MR trim, delivering a stronger-to-weight ratio, lower unsprung mass, and improved heat management. In MR, the forged option measured 18 inches in diameter with an 8.0-8.5 inch width depending on the specific wheel design, balancing tire profiles and brake clearance.

For those chasing aggressive looks or tire setups, aftermarket wheels have long been part of the Evo X journey. The market favors lightweight, stiff designs that pair with wide tires to enhance lateral grip and steering response. Typical upgrades push wheel diameters toward 18 inches with broader widths such as 8.5 to 9 inches, enabling low-profile tires like 265/35R18. Combined with a high-friction brake system and tuned suspension, these configurations sharpen turn-in and chassis feedback while maintaining controllable ride quality.

OEM fitment and dimensional data are defined by core parameters: five-lug pattern (114.3 mm bolt circle), center bore of 64.1 mm for hub-centric fit, and an offset of about 40 mm. The diameter options span 17 or 18 inches, with 17×8 and 18×8.5 common sizes. Aluminum alloy with a die-cast process provides strength and lightness, while finishing options range from matte to polished to resist corrosion and keep aesthetic integrity under heat and wear.

These specifications are designed to work with the Evo X’s braking system, the S-AWC architecture, and the suspension geometry, preserving steering feel and predictable behavior under load. The 40 mm offset supports the scrub radius and caliper clearance, while the 17×8 or 18×8.5 footprint aligns with tires that deliver reliable grip and consistent feedback during cornering.

From a collector’s view, MR forged wheels mark a notable peak in wheel engineering for the model, offering weight savings and heat management advantages that translate into sharper throttle response and braking punch on track days. The forged MR option reduces rotational inertia relative to a comparable cast wheel, which influences how quickly the car responds to driver input, especially during aggressive driving.

Looking to the aftermarket, iconic designs such as the TE37 have become synonymous with the Evo X wheel scene. When paired with wide, low-profile tires, these wheels emphasize grip generation and chassis feedback, pushing for a broader footprint and stiffer sidewalls that demand careful setup to maintain ride quality.

For ongoing restoration or upgrade planning, the OEM specs furnish a reliable baseline for fitment, brake clearance, hub engagement, and track width balance. The center bore, bolt pattern, and offset ensure accurate hub engagement and consistent rotor alignment, while chosen wheel size preserves the intended handling balance and steering feel.

External resource: official Mitsubishi Motors Global specs page for Lancer Evolution X. Access the exact dimensional data, compatibility notes, and model-year variations at https://www.mitsubishimotors.com/en/models/lancer-evolution-x/specs/.

Forged Precision: Reimagining the Evolution X Through a High-End Wheel Upgrade

When you stand back and study the Evolution X, it’s easy to marvel at its aggressive stance, its taut lines, and the way the car seems to fuse rally-bred intent with street-ready composure. Yet the truth about performance isn’t written in only the engine’s torque curve or the suspension’s stiffness. A wheel is a compact, living piece of the drivetrain’s choreography. It is the interface between the car and the road, the conduit through which grip, braking force, and steering feedback travel to the driver. On a machine designed to balance brutal speed with precise handling, choosing the right rims becomes a decisive act. The Evolution X has a legacy of strong, purpose-built wheels. The factory setup from the era paired front and rear hoops with a diameter and width calibrated to maintain balance across the car’s all-wheel-drive system, ensuring predictable behavior under heavy braking and aggressive cornering. But enthusiasts often reach for an upgrade that preserves this balance while shaving away mass and inviting more cooling air to the brakes. In this light, a high-end forged wheel—crafted by a brand with deep motorsport roots—emerges not merely as a cosmetic enhancement but as a functional re-tuning of the Evo X’s dynamic personality. The shift from a cast or flow-formed design to a forged one is more than a weight comparison. It is a reimagining of how the car responds to throttle, how quickly the chassis communicates with the driver, and how efficiently the brakes dissipate energy during track sessions and spirited street drives alike. The appeal is both rational and visceral: less unsprung weight means more of the tire’s contact patch remains in play as the suspension travels. That translates to sharper turn-in, more accurate steering, and a chassis that can settle more rapidly after a corner exit. Braking performance also benefits, because the wheels themselves contribute to heat management. Forged wheels, by their very construction, tend to be stiffer and lighter than their cast counterparts. They resist torsional flex better and hold their geometry under stress, which helps during fast, repetitive braking where heat soaks into every component. It’s not just about reducing mass; it’s about preserving the tire’s ability to maintain an optimal contact patch under demanding conditions. The result is a more composed car at the limit, with a steering feel that communicates precisely what the front tires are doing at any given moment. In practice, this translates to quicker lap times and more confidence when pushing into tight apexes. The carryover effect is a more predictable car in daily driving, where you often face variable road surfaces and mid‑corner adjustments. The wheel’s design itself also matters from a brake-cooling perspective. A multi-spoke layout, while aesthetically striking, provides an uninterrupted pathway for air to reach the brake rotors and calipers. The pattern chosen must balance airflow with structural integrity; a strong, evenly distributed spoke force helps resist deformation under braking while keeping the rotor surface cooler and more consistent in temperature. The visual language of a forged wheel—its clean, purposeful silhouette and the way it catches light in a way that hints at its performance purpose—enhances the Evo X’s already assertive stance. It’s a kind of visual data point that communicates a track-ready intention. Yet the upgrade process is not simply about swapping rims. Fitment remains paramount. The Evolution X follows a precise set of factory standards for wheel mounting. A wheel upgrade must respect bolt pattern, offset, and center bore. For the Evo X, the common baseline uses a 5×114.3 bolt pattern, a standard that many performance wheels share with a wide range of modern sedans and coupes. The offset is another critical variable; it must align with the car’s suspension geometry and calliper clearances to ensure the wheel sits in the correct position relative to the fenders and the brake assembly. Even small deviations in offset can alter steering feel and introduce rubbing, cornering stiffness changes, or uneven tire wear. Center bore compatibility also matters, because a hub-centric fit reduces runout and ensures the wheel is seated true against the hub. In some cases, owners consider adapters or spacers to achieve the desired wheel width or brake clearance, but these components must be top-quality and properly sized. Any misstep risks safety concerns and inconsistent handling. The message here is simple: the most exciting performance upgrade can falter if fitment is negligent. The allure of a forged wheel should be matched by meticulous attention to the details of the vehicle’s architecture. Beyond the mechanical and engineering considerations, there’s a lasting value in the durability of forged wheels. They generally offer superior resistance to corrosion and a longer service life in the face of the elements and the stresses of aggressive driving. The material science behind forged wheels yields a favorable strength-to-weight ratio, enabling a lighter wheel that still handles the loads generated by high-speed cornering, repeated laps, and the heat cycles of aggressive braking. Depending on the exact manufacturing route—whether the wheel is fully forged or produced as a high-strength variant through flow-formed processes—the result is a wheel that not only reduces unsprung mass but also remains resilient under real-world punishment. The aesthetics, naturally, are part of the equation as well. The visual language of a high-end forged wheel tends toward clean, disciplined lines that echo the Evo X’s original ethos: the car looks ready to chase down a circuit, and the wheels draw the eye with a purposeful geometry. A design that emphasizes brake cooling, while maintaining a sculpted profile, communicates a message about the car’s intended use: this is a machine that should be driven with discipline and confidence, not merely admired from behind the wheel. In the end, the choice to invest in a forged wheel for the Evolution X represents more than a upgrade in spring rates and brake temps. It is a deliberate decision to align the car’s physical soul with the driver’s intent. The combination of reduced weight, improved stiffness, and enhanced heat management gives the Evo X a sharper edge in how it accelerates, how it tracks through turns, and how it recovers from the aggressive inputs that define performance driving. The car feels lighter on its feet even as it remains rooted to the road with a sense of precision that only a carefully chosen wheel can convey. The result is a more connected driving experience, where the chassis communicates with the driver with clarity, and the road surface—whether smooth asphalt or a rough backroad—becomes a more honest partner in the act of driving. For enthusiasts who crave a blend of form and function, the upgrade toward a forged wheel becomes a narrative about control, confidence, and the satisfaction of a vehicle that’s been tuned not just in the engine bay but in the wheelhouse itself. In a machine built to perform at the edge, every component has a voice, and a forged wheel makes a strong case for listening closely to what the road is telling you. If you’re considering this path, remember that the journey isn’t simply about the brand or prestige. It’s about understanding how the wheel’s mass, stiffness, and cooling dynamics interact with the Evolution X’s all-wheel-drive systems, suspension geometry, and braking setup. The payoffs—improved steering response, sharper turn-in, more consistent braking temperatures, and a refined balance between acceleration and grip—are tangible, translating into a more engaging, more confident drive on mountain passes, on track days, or even on windy, twisty back roads. The Evo X accepts a wheel that changes its character, and in return, it rewards the driver with a keener sense of control and a more visceral connection to the road. For those who want to explore this path further, a visit to the following resource can provide deeper technical context about high-performance wheel design and specifications. brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans While the exact fitment must be confirmed for each build, the core principles—reduced unsprung mass, improved brake cooling, and precise alignment—remain universal truths when elevating the Evolution X’s wheel setup. For those who want to read more about the engineering and material science behind forged wheels, the official product overview offers a thorough technical foundation: https://www.bbs-wheels.com/en/products

Rim Evolution: Forged, Flow-Formed, and Replica Wheels in the Evolution’s Aftermarket Arena

The wheel is more than a circle of metal. On a high-performance chassis, it is the primary interface between the road and the car’s intent. For enthusiasts chasing the Evolution’s edge, the choice of aftermarket rims becomes a central tuning tool. It is not merely about looks; it is about how a wheel transforms the balance of unsprung mass, how it interacts with brakes under heat, and how it fits within the car’s suspension geometry and chassis stiffness. The Evolution’s performance pedigree rewards a wheel setup that respects those dynamics while delivering the aesthetics that owners crave. In practice, this means understanding a spectrum of options that range from faithful OEM-style replicas to forged and flow-formed designs, each with its own trade-offs in weight, strength, cost, and reliability. The journey through these choices reads like a concise lesson in vehicle dynamics and engineering, packaged for the enthusiast who wants more than a bold rim; they want a wheel that works as hard as the driver behind it.\n\nThe baseline is familiar to any Evolution owner: factory wheels that pair 18 inches of diameter with a broad, practical width, designed to accommodate the high-performance tires that the car requires. The front and rear wheels share the same diameters in many trims, a symmetry born from the need to balance steering response with rear-end stability at the limits. In the higher tiers of the lineup, a forged, lightweight option appears as a meaningful upgrade. Forging, as a manufacturing approach, produces rims that boast superior strength-to-weight characteristics compared with traditional cast designs. The resulting reduction in unsprung weight translates directly to crisper steering, improved suspension compliance, and sharper turn-in. It also fosters more effective heat management during aggressive braking, helping to maintain consistent performance on tracks or winding roads where heat soak would otherwise degrade braking feel and fade.\n\nBut not every upgrade has to be forged to deliver performance gains. There is a broad family of high-performance wheel designs built on form-factors that emphasize weight efficiency through advanced manufacturing techniques such as flow-forming. In the right combination, these wheels can deliver weight reductions akin to forged designs while holding out against the practical realities of street use—durability, curb resistance, and cost control. The performance calculus expands when you consider the tire pairing. A wide, low-profile tire profile, typical of 18-inch rims in the Evolution’s realm, interacts with the wheel’s inner geometry and spoke pattern to influence rotational inertia, brake clearance, and even aero behavior at speed. A 265/35R18 tire, a common dimension in this sphere, exemplifies the balance many enthusiasts seek: enough sidewall to absorb road irregularities and enough width to anchor the contact patch for confident grip and predictable breakaway characteristics.\n\nBeyond the physics, a quieter revolution is occurring in the factory’s shadow: the rise of near-OEM-size replicas produced in specialized manufacturing hubs. These wheels aim to mimic the look and fitment of original designs while offering compelling price-to-performance value. The essence of this trend lies in engineering precision—near-identical stamping footprints, hub bore compatibility, and reliable center bore alignment—coupled with raw material choices and process controls that keep tolerance bands tight. The critical caveat for buyers is not just the visible finish, but the hidden economies of scale that impact weight consistency, straightness, and runout. In practice, these replica designs rely on a sophisticated combination of forging technology and flow-forming processes using aerospace-grade aluminum alloys. The result is a wheel that looks the part, but more importantly, behaves in a predictable, road-hold way when loaded with spirited driving, or when subjected to the rigors of a hot, technical highway cross-country run.\n\nIf you consider pursuing OEM-style replicas, the first compass point is safety and certification. It is tempting to chase a price or a look, but the human and mechanical costs of a mismatch in load rating, impact resistance, or hub compatibility can be steep. A robust supplier evaluation framework is not an optional luxury; it is a necessity. ISO certifications, documented load capacity ratings, and independent impact and fatigue testing are the kind of assurances that separate a reputable source from a perfunctory one. The engineering brief is straightforward: a wheel must survive the legal-in-traffic demands of street use, plus the unpredictable stresses of fast cornering and occasional kerb contact, without compromising the brake system’s ability to shed heat under sustained braking. For the buyer, this means demanding technical documentation, clear material specifications—such as the use of a particular heat-treated aluminum alloy—and verifiable production traceability. The logistics side should not be an afterthought. Export-ready documentation, reliable packaging, and transparent lead times all contribute to a smoother upgrade path and reduce the risk of costly delays or damage in transit.\n\nIn the landscape of choices, fitment is king. The Evolution platform’s suspension geometry, brake caliper clearance, and hub pattern must be synchronized with the wheel’s offset, center bore, and width. A wheel that looks spectacular but interferes with brake hardware or rubs the fender at full lock is not a performance upgrade; it is a constraint that will be learned in harsh daylight, not on a dream test drive. The offset, in particular, is a subtle but crucial parameter. Push the wheel outward too far, and you disturb the steering axis and tire contact patch; pull it inward, and you risk brake clearance problems or the wheel not seating properly on the hub. The appeal of replica wheels often lies in their combination of true-to-design aesthetics and practical tolerances that, if properly spec’d, preserve the handling envelope the car’s engineers originally laid out. The careful buyer negotiates this space by balancing aesthetic intent with the mechanical realities of the car’s brake system, caliper size, and wheel well clearance.\n\nQuality, in this theater, is ultimately a matter of consistency. A reputable, OEM-style supplier can provide a technical dossier that covers material grade, forging or flow-forming processes, and post-production heat treatment. It is not merely about a glossy finish in the showroom light. It is about ensuring dimensional stability under temperature swings, resisting fatigue from repeated loading, and maintaining spoke patterns that do not introduce stress risers or imbalances. The best options are backed by a track record of consistent manufacturing quality, with a documented history of performance in similar applications. For Evo X owners who see wheels as an investment in both performance and identity, this is where the value proposition becomes tangible: higher confidence in daily driving and more consistent, repeatable performance during spirited drives or sanctioned track days.\n\nAs a practical matter, the upgrade journey often begins with a careful assessment of ownership goals. If the aim is a stealthy, track-ready setup that can also pass daily duties, a forged or high-quality flow-formed wheel with a modest weight reduction and proven heat management becomes compelling. If the aim is more about bold styling and eye-catching profiles, a replica wheel that mimics a classic, timeless look can deliver the aesthetic payoff without radically increasing cost, provided it is sourced from a supplier with documented quality controls. The cost calculus, too, deserves close attention. The sticker price is only part of the story; the total cost of ownership includes the risk of misfit, longer lead times, potential warranty challenges, and the long-term consequences of inferior heat management.\n\nTo illustrate the spectrum without naming brands, consider the route of OEM-style replicas perfected for high-end street and track use. The engineering premise is to deliver a wheel with reliable hub compatibility, predictable fatigue characteristics, and a finish that holds up under road grit and brake heat. The market has become sophisticated enough to offer a range of wheel geometries that honor the original aesthetic while delivering modern improvements in metallurgy and manufacturing control. In this era, a buyer can pursue a wheel that provides a noticeable improvement in unsprung mass and rigidity, while also preserving the Evolution’s signature stance and handling balance. The decision point remains clear: are you seeking the best possible weight-to-strength ratio for aggressive driving, or are you prioritizing a look that faithfully echoes the car’s original intent? In practice, many enthusiasts find that a balanced approach—lightweight, stiff, and with adequate brake clearance—delivers the best of both worlds.\n\nFor those curious about OEM-style replicas and how they are marketed in the M-vehicle ecosystem, this resource offers insights into how manufacturers present and certify these wheels in a B2B context: Original BBS rims set of 4 for Lancer sedans. The page is not Evo X-specific, but it captures the broader principles at work: specification transparency, packaging, and the emphasis on performance-to-cost ratios that guide professional buyers through a global supply chain. It serves as a useful reminder that the wheel is a component of a larger system—one that responds to a careful balancing act between engineering, aesthetics, and practical realities.\n\nAs the Evolution’s aftermarket wheel landscape continues to mature, the prudent approach is to engage with suppliers who articulate a clear performance narrative backed by data—tactual load ratings, precise offsets, stringent quality controls, and robust logistics. The buyer’s diligence pays off in the form of predictable behavior, consistent performance, and a wheel that aligns with the car’s dynamic character rather than simply its outward appearance. And when uncertainty arises, the external world of automotive aftermarket knowledge remains a well of guidance. A well-chosen wheel not only lowers unsprung mass but helps preserve the car’s chassis feedback, providing the driver with an honest, communicative sense of the road ahead. That is the essence of a true upgrade: one that respects the vehicle’s engineering while enabling a more personal expression of its potential.\n\nExternal resource: For detailed procurement considerations and deeper exploration of OEM-style wheel sourcing in this space, see this external guide: https://www.autosourcinginsider.com/b2b-guide-mitsubishi-evo-x-bbs-wheels-china-manufacturers.

null

null

Rims as Identity: How Evolution X Wheels Signal Value, Function, and Collectibility

The Evolution X carries the spirit of Mitsubishi’s rally heritage, but its wheel design does more than frame the brakes and tires. It translates performance into presence. The wheel is the most visible link between chassis tuning, brake cooling, and the road, and for the Evo X that link is tight enough to become a recognizable badge in its own right. The factory setup—18-inch wheels that balance weight, strength, and heat management—was not chosen by accident. Front and rear wheels alike, the Enkei RPF1 18×8.5 forged a standard of consistency across most GSR and MR models, ensuring a uniform platform for the car’s aggressive stance and predictable handling. The Enkei’s usability across both ends of the drivetrain meant the Evo X could be tuned for road and track without introducing a wheel-yielding variable that would unsettle the chassis. Yet even within the same wheel size, the performance story shifts with material and construction. In the MR trim, Mitsubishi pushed further by pairing the Evo X with BBS forged lightweight aluminum wheels, sized at 18×8.0. The shift to forged construction mattered beyond mere aesthetics. Forged wheels reduce unsprung weight, which translates into crisper suspension response and better braking torque transfer. The lighter wheel also aids heat dissipation during high-stress braking, a factor engineers consider when the car is used on a circuit or pushed hard on a long backroad run. Collectors and enthusiasts still track that MR wheel set because it marks a high-water point in the Evo X’s wheel story—an official, factory-forged option that signals a commitment to performance without sacrificing daily drivability.

Beyond the OEM script, the Evo X wheel narrative expands into the broader world of aftermarket options. The aftermarket scene often gravitates toward wheels like the iconic RAYS Volk Racing TE37, a design that has earned a near-ritual status among enthusiasts for its strength-to-weight ratio and its clean, timeless lines. The TE37’s presence on Evo X builds illustrates a simple fact about performance wheels: the right design can shift the perception of a car from capable machine to a statement of intent. When paired with wide, low-profile tires—think 18x10J widths paired with aggressive tire compounds—the Evo X can achieve a stance that mirrors its performance goals. The result is a wheel-and-tire package that communicates not only grip and braking performance but also a philosophy of balance: lightness, strength, and the capacity to push the envelope without inviting excessive susceptibility to road irregularities.

From a collector’s vantage, the market’s attention to Evolution X rims is not purely about the moment of purchase. It hinges on how these wheels contribute to a car’s overall condition and its originality. The OEM wheels carry a particular weight because they are the car’s original signature. They are, in a very practical sense, part of the vehicle’s identity, and their condition can influence a car’s perceived authenticity and its resale trajectory. In the secondhand market, a complete Evo X with its original wheel set, especially one that preserves the intended finish and alignment of the factory design, often commands a stronger premium than a similar car fitted with a mixed bag of aftermarket rims. The sense of belonging to a designed package—a package that includes the bodywork, the suspension calibration, and the intended brake setup—creates a narrative of completeness that buyers frequently value. It is a kind of provenance that extends beyond the engine bay and the interior, reaching into the wheel wells themselves.

The market’s signals for Evolution X rims extend beyond the wheels’ aesthetic. Black alloy finishes, the subtleties of the wheel’s spoke geometry, and even the presence of the logo as part of the wheel center all contribute to how a wheel is perceived. The summarized view from recent market commentary highlights a few key trends. First, the wheels that come with the car—whether Enkei RPF1s in standard form or the forged BBS units in the MR—serve as anchors of value. When a car retains these wheels in good condition, the overall asset tends to carry a higher residual value. Second, the aftermarket segment—where TE37-like designs or other performance-oriented forged wheels are popular—demonstrates how the Evo X remains relevant to enthusiasts who seek performance gains, not just aesthetic refreshment. This aftermarket interest keeps the wheel market active, with buyers evaluating both the tangible benefits of a lighter, stiffer wheel and the intangible appeal of a known, iconic design.

The cultural and collectible dimension of Evolution X rims is nuanced. It rests on a balance between ongoing performance relevance and the nostalgia for a platform that has come to symbolize a certain era of Japanese performance cars. The car’s limited runs, distinct badges, and the occasional commemorative colorways contribute to the wheel’s collectible aura. Where a particular edition or a rare finish becomes associated with limited production or a specific market, the wheel’s intrinsic value can rise in the eyes of collectors who prize originality and limited provenance. In this sense, rims are not merely functional parts; they are vessels of history. They preserve the visual identity that cars like the Evo X presented to onlookers—the dark, assertive silhouette, the crisp lines of the fenders, and the way a wheel’s profile catches light and attitude in a way that few other components can.

In practical terms, the market’s temperature for Evolution X rims is shaped by several evolving factors. First, the condition and originality of the wheels matter. A set of OEM wheels that shows care—proper wheel finishes, minimal curb rash, intact logo emblems, and verified sizes—tends to improve a car’s value and can reduce the friction involved in resale. Second, documentation and provenance play a significant role. A wheel set still paired with its original parts log, service history showing routine maintenance of the brake system and suspension aligned with the wheel choice, and even a record of the wheel’s miles can tip the scales for buyers who want a car that truly reflects its early-era performance intent. Third, the market’s collective memory of the Evo X’s performance envelope—the car’s balance between grip, cornering stability, and brake fade resistance—will influence how much the wheel package matters to potential buyers who are assessing long-term value. If more official editions or color packages appear in the future, the wheels associated with those variants could assume greater significance as references for authenticity and styling cues.

To bring this into a practical frame of reference for enthusiasts and potential buyers, consider how preservation of the original wheel configuration affects the overall car story. A well-kept Evo X that retains its original Enkei RPF1s, or a factory-forged BBS set in MR trim, carries a narrative advantage when the car is evaluated by collectors or shown at gatherings where provenance matters. The wheel’s story intersects with the car’s mechanical and visual identity. When a car is being prepared for sale or display, wheels are more than mere accessories; they are a summary of how the car was used and cared for. An Evo X with pristine, correctly sized wheels, matching the car’s intended ride height, alignment, and tire choice, presents a coherent performance picture that resonates with buyers who seek a complete, original feel. In contrast, a car that has swapped wheels in a way that disrupts the original geometry or aesthetics invites questions about how the car was used and maintained, which can dampen perceived value.

For readers who want a tangible reference to OEM and original-wheel relevance, one can look to specific listings that preserve the spirit of the car’s original equipment. For example, a genuine, brand-new original BBS rim set offered for similar platforms demonstrates how a wheel package can be presented and valued as a factory-standard upgrade or refinement. Such listings, though not Evo X-specific, illustrate how the wheel’s identity translates into market opportunity. These references underscore the idea that the wheel is not merely a part but a statement of engineering intent that survives as the car evolves in the used market.

As the Evo X moves through its years and into the broader dialogue of classically tuned Japanese performance cars, the market for its rims will likely reflect a combination of practical performance appeal and collectors’ sentiment. Enthusiasts will continue to weigh the benefits of forged versus cast wheels, the visual impact of black finishes, and the way wheel designs age with the car’s overall silhouette. The market’s trajectory will hinge on how well these wheels endure in both function and form, how readily original sets can be authenticated, and how future special editions spark renewed interest in the car’s wheel language. In that sense, Evolution X rims offer a compact case study in how performance hardware can outlive the moment of manufacture, turning into a durable signal of a vehicle’s enduring character. For deeper context on what influences the Evo X market and the role of interior and exterior cues in assessing value, see the Evo X guide, which frames these considerations against a broader view of the car’s design language and aftermarket ecosystem.

For additional context and a broader discussion of Evolution X nuances, you can explore more details here: https://www.carinterior.com/evolution-x-guide

Internal reference note: To see how original BBS rims have been positioned in related Mitsubishi projects and their impact on overall value, you can review this listing: brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans. This example helps illustrate how OEM hardware is framed within the market as a touchstone of authenticity and preserved performance intent. It offers a practical lens through which to view the Evo X’s wheel identity and the way collectors assess complete, original condition across the entire vehicle package.

Final thoughts

Understanding the specifications and options for wheels on the Mitsubishi Lancer Evolution X is pivotal for anyone looking to engage with this specific automotive niche. OEM wheels provide foundational performance, while high-end upgrades like BBS and aftermarket options allow owners to express personal style and enhance driving capabilities. The relationship between wheels and the overall performance of the Evo X cannot be understated; it is crucial for both aesthetics and driving dynamics. Finally, staying abreast of market trends surrounding these rims can be key for businesses aiming to cater to a passionate audience. The collectors’ market adds an additional layer, making knowledge of these wheels not only beneficial for performance but pivotal for aligning with buyer interests. As this community grows and evolves, so does the opportunity for service and product offerings in this specialized market.