As the automotive industry continues to evolve at a rapid pace, the focus on optimizing vehicle performance and driver safety remains paramount, especially in high-performance vehicles. Evolution X Seats, particularly designed for models like the Chevrolet Corvette C5, exemplify an innovative approach to ergonomic seating that enhances both driving experience and safety. This article will delve into the design and features of Evolution X Seats, explore their performance enhancement in racing scenarios, and discuss the crucial safety aspects these seats offer. Business owners looking to upgrade their vehicle offerings or those involved in automotive performance will benefit significantly from understanding the integration of advanced seating solutions in their high-performance vehicles.

Fixed-Back Precision: How Ergonomics, Rigidity, and Harness Integration Shape Evolution X Seating for Track-Ready Cockpits

The seat is more than a cushion against the body during a hard day at the limits; it is the first interface between driver intention and vehicle response. In performance contexts, where every millisecond of feedback matters and fatigue can ruin a lap, the design of a fixed-back sport seat becomes a critical element of the driving experience. The Evolution X-style seat, where discussed in performance circles, embodies a philosophy that blends ergonomic precision, material resilience, and safety-conscious engineering into a single, cohesive package. Though the surface story is about comfort, the deeper narrative is about how a well-conceived seat translates human control into disciplined vehicle behavior, especially under demanding track conditions. The seat’s contour, padding, and breathing dynamics are not cosmetic choices; they are tacit agreements between body and machine, promising reduced fatigue, improved control, and a more predictable seat of experience when the road narrows and the corners demand exacting technique.

The ergonomic shape is the starting point. A contoured rear and waist region mirrors the natural curvature of the spine, providing sustained lumbar support that resists the compressive forces generated by aggressive cornering. In practice, this means the driver can sit in a balanced posture for longer without the body migrating toward the roof or the wheel shaft. The lumbar region is not a solitary feature but part of a broader sculpting that wraps around the hips and thighs. This interaction minimizes micro-movements that would otherwise translate into micro-adjustments of steering input or throttle control, particularly at the apex where concentration must be constant and unbroken. The goal is to keep the driver’s torso stable while the legs operate with precision, ensuring that inputs remain consistent lap after lap rather than drifting with fatigue.

Behind the visible form sits a carefully chosen material stack engineered for durability and shape retention. High-density foam padding is more than a luxury; it is a functional component that resists the flattening that comes with repeated hard braking, aggressive g-forces, and long-duration sessions. The seat’s padding maintains its supportive geometry, which in turn preserves the ergonomic relationship among the shoulders, hips, and knees. This is essential because, on the track, a seat must resist deformation that would otherwise alter driving posture and consequently steering leverage, brake modulation, and throttle control. The integrity of the foam helps the seat’s side bolsters perform as intended: not merely decorative side cues but active guardians of body alignment during lateral loads. When a chassis experiences roll and yaw, the seat’s structure, including its foam, works to keep the driver’s limbs positioned for optimal input accuracy, preventing fatigue from eroding a driver’s sense of control long before the session ends.

Breathability and climate comfort might seem secondary in a high-performance piece, but they play a surprisingly influential role in consistency and focus. Premium fabrics used in these seats are selected for air-flow characteristics that wick moisture and allow air exchange without compromising durability. In the heat of competition or summer track days, a driver who stays cooler enjoys clearer thinking and steadier nerve. Heat and sweat can sap grip strength and delay reaction times as fatigue accumulates. A breathable surface helps keep the body cooler, which in turn supports steady hands and a calm driving mind. The material choice also contributes to comfort in longer sessions, where a small, perceptible difference in surface feel can translate into a measurable improvement in drive quality. The seat must feel familiar but not stifling, a balance achieved through careful upholstery design that respects heat dissipation while providing an engaging tactile experience for the driver.

Integrated side bolsters are a keystone of the seat’s performance geometry. These features do more than hold the torso in place; they shape the dynamic envelope within which the driver can maneuver under fast, complex cornering. The bolsters offer lateral support during high-G transitions, guiding the torso into an efficient angle for steering inputs and weight transfer. This support reduces the tendency for the torso to slide across the seat during aggressive maneuvers, which can disrupt the driver’s line and timing. In practical terms, the bolsters give the driver confidence: the body remains anchored to the seat’s centerline, allowing more precise weight shifting and more consistent corner entries. The result is a driving experience that invites the driver to push further with less fear of losing contact with the seat’s intended geometry. A well-tuned bolster system also helps protect the spine and reduce upper-body muscular fatigue, as the torso does not have to fight against shifting contact points during the most punishing portions of the lap.

A seat that handles the extremes must also be adaptable, and this is where headrest design and adjustability enter the conversation. Adjustable headrests offer a simple but meaningful way to tailor the seat to a driver’s neck length and preferred seating position. In a performance setting, where neck and spine alignment matters for visibility, helmet clearance, and fatigue management, the ability to set the headrest to a supportive but non-intrusive position contributes to an uncluttered field of view and comfortable head posture. Some configurations even offer more nuanced adjustability, allowing a driver to find a sweet spot that reduces craniocervical strain during long runs. This adjustability complements the fixed-back nature of the seat by ensuring that the driver’s posture remains optimal across a variety of driving stances, from low, aggressive crouches on tight tracks to more upright positions on longer road sessions.

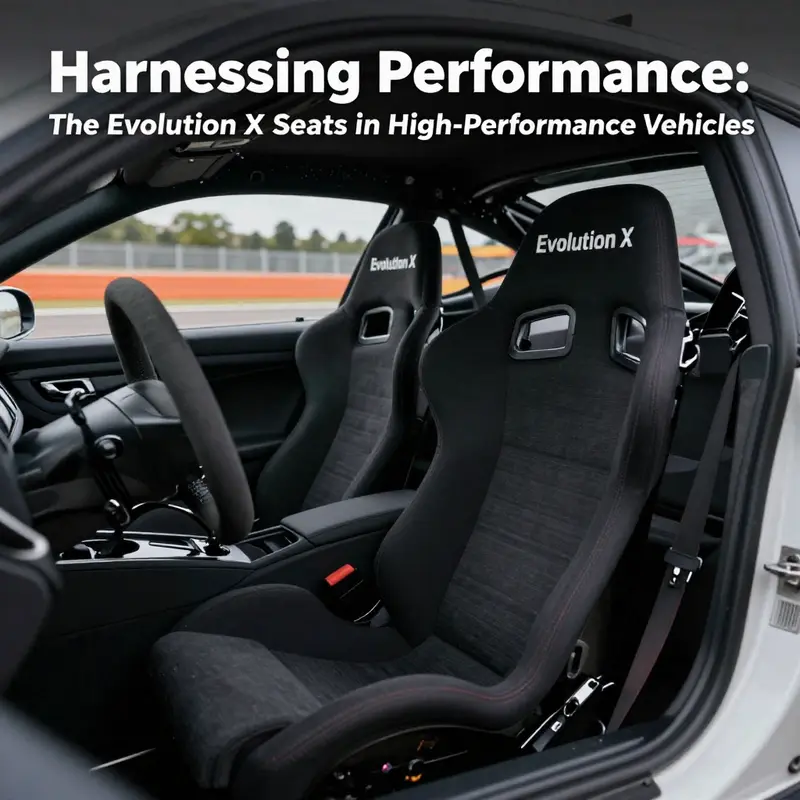

The safety architecture of a fixed-back seat is inseparably linked to harness compatibility. In racing contexts, where harness systems replace standard seatbelts, the seat’s mounting geometry and bolt holes must support three-, four-, or five-point harness configurations. The seat’s fixed-back design is instrumental in maintaining rigidity, reducing unwanted flex that could otherwise translate harness forces into uncomfortable or unsafe body dynamics. When a driver is strapped into a harness, the seat is not merely a comfort feature; it becomes a crucial component of the vehicle’s overall restraint system. The rigid back ensures that the upper torso and pelvis are restrained in a controlled envelope, allowing the harness to distribute load predictably across the shoulders, chest, and hips. This is especially important during abrupt deceleration, high-speed braking, or a high-G corner where force vectors become complex and dynamic. The architecture of the seat, its attachment points, and its integration with the vehicle’s safety harness system all converge to deliver not only protection but also a sense of purposeful stability.

Optional heating and ventilation represent a practical extension of the seat’s design philosophy. In climates where weather can influence driver performance, the ability to heat the seat for cold mornings or ventilate it during hot days can reduce the onset of numbness, stiffness, or distraction caused by uncomfortable temperatures. The optional features are not mere luxuries; they can be vital for maintaining a consistent driving rhythm across variable conditions. They work in harmony with the seat’s core responsibilities—ergonomics, support, and safety—by ensuring that comfort does not become a cognitive load during a session. When drivers feel heat in cold start conditions or a cooling breeze during a hot afternoon, their focus remains anchored in the road rather than diverted to bodily discomfort. The end result is a cockpit that stays cohesive under pressure, enabling a more deterministic response to each steering input and throttle modulation.

From an installation and integration perspective, a fixed-back seat in a performance environment calls for precise mounting and alignment. The seat’s rigid structure means that mounting points must be robust, shimmed if necessary, and aligned to preserve the intended geometry of the seating position. A thoughtful mounting approach also preserves seat travel and adjustability where applicable. Even with a fixed back, there may be vehicular constraints such as wheel clearance, pedal box geometry, and the driver’s line of sight to the gauges. Engineers and technicians approach these challenges with a methodical mindset: verify fit, ensure chassis compatibility, and test the seating position under load with a range of driver physiques. The payoff is a cockpit that feels purpose-built for the driver, where entry, exit, and long-lasting sessions are governed by a chassis-integrated seating solution rather than a modular add-on.

In discussing the broader implications of seat design on driving behavior, it is important to appreciate how this component interacts with the vehicle’s overall dynamics. A seat that stabilizes the upper body and anchors the hips can influence steering leverage and throttle control by reducing parasitic movement. The driver can focus on the subtleties of a line through a curve, rather than compensating for shifting contact with the seat. This translates into smoother weight transfer, more predictable tire contact with the road surface, and better feedback through the steering wheel and pedals. Even the faint sensations from the seat—firmness, pressure points, and airflow—become part of a feedback loop that helps a driver calibrate inputs with increasing precision. In track environments where fractions of a second matter, such refined perception becomes a meaningful advantage that compounds over a session, turning a capable driver into a consistently faster one.

Finally, the aesthetic dimension of seat design should not be overlooked. In performance cars, the seat’s lines and finishes convey a sense of purpose that reinforces the driver’s relationship with the vehicle. A seat that looks as serious as it feels invites a different mental stance—one of readiness, confidence, and a commitment to technique. The two-tone stitching or color accents, whether bold or understated, become a visual cue for the driver about the seat’s role in performance. The design language communicates that this cockpit is optimized for control, not comfort alone, and that every material choice has been made to sustain performance under the severity of track use.

To readers who are curious about the practical realities behind these design choices, the story is not only about comfort or style but about how seating geometry, material durability, harness integration, and climate control converge to shape a driver’s capability. The seat becomes a performance instrument in its own right, an element whose characteristics ripple through the driving experience—from posture stability and fatigue management to input precision and even on-track psychology. When the driver straps in, they are not simply resting; they are aligning body, mind, and machine in a disciplined partnership that unlocks the vehicle’s potential. The fixed-back philosophy, with its emphasis on rigidity and secure contact, anchors this partnership, ensuring that the human operator remains the primary source of control rather than reacting to the seat’s foibles.

For enthusiasts who explore upgrade paths and seek a comprehensive understanding of seat design, it is worth noting how these concepts translate into real-world choices. The seat’s ergonomic integrity and its capacity to maintain form over time are closely tied to the driver’s satisfaction and confidence. A seat that holds its shape under load will preserve the vital geometry that keeps the driver aligned with the vehicle’s steering axis, pedal box, and line of sight. In a world where track days and competitive events demand sustained performance, the value of such a seat extends beyond immediate comfort. It becomes a foundation for repeatable performance, a baseline from which drivers can measure progress lap after lap.

As the discussion moves toward real-world selection and installation, the broader takeaway centers on the interplay of form and function. Comfort is important, but only as a vehicle for reliable performance. Stability and support are not luxuries; they are prerequisites for consistent lap times. The seat must live up to the demands of spirited driving, offering a predictable, repeatable platform for the driver’s body to behave in harmony with the car’s dynamics. The fixed-back design, with its emphasis on rigidity and harness compatibility, embodies this principle. It is a tangible embodiment of the idea that performance seats are not a mere accessory but a strategic component of the vehicle’s dynamic architecture.

In closing, the evolution of seat design in performance applications is a story about the disciplined integration of ergonomics, materials science, and safety engineering. It is about how a single element—well conceived and precisely executed—can influence a driver’s confidence, reduce fatigue, and sharpen the car’s responsiveness at the limits. The Evolution X-style seat, within its context, stands as a case study in how a fixed-back approach can deliver all of these benefits when the design focuses on the body’s natural geometry, steadfast support, and reliable harness integration. The result is a cockpit that feels natural, purposeful, and ready for the challenge of the track, where every centisecond of stability translates into a more confident and capable driver at the wheel.

Internal link reference for further context on seat materials and racing-inspired options can be found here: brand-new-alcantara-front-recaro-seatsoriginal.

External reference: For a broader look at official seat design details and specifications across compatible configurations, see the broader design and features resource at https://www.evolutionx.com/seats.

How Evolution X–Style Seats Transform Racing Control and Driver Performance

Seating Dynamics and Track Performance

Seats are far more than cushions bolted to a floor. In a racing environment they form an essential interface between human and machine. The right seat repositions the driver, reduces unwanted movement, and channels forces into the chassis. For cars in the Evolution X class, the cabin’s seating is deliberately engineered to match the car’s rally-inspired handling. The result is a compact cockpit where body, suspension, and driver act as one.

A fixed-back, semi-bucket or full-bucket layout is common in purpose-built machines. By removing adjustment complexity and reinforcing the shell, fixed-back designs increase structural stiffness. This stiffness translates to a predictable platform for harnesses and driver input. When the driver is rigidly held in place, lateral loads from cornering go to the skeleton of the vehicle, not to the spine of the occupant. That steadiness lets a driver maintain pedal, wheel, and sight alignment through long cornering stints.

Lateral support is the single most noticeable attribute on any performance seat. Bolstering at the hips, waist, and shoulders keeps the torso centered. Thigh bolsters cradle the legs, preventing sliding under high G-loads. With the pelvis stabilized, the driver can operate controls with less corrective movement. Less movement equals quicker steering corrections and more consistent throttle application. Those marginal gains compound over a lap, trimming tenths and stabilizing lap time variance.

Harness compatibility is another defining factor. A seat engineered for multi-point harnesses provides reinforced belt paths and clearance for shoulder straps. Proper harness routing reduces slack and helps distribute deceleration forces across the pelvis and chest. Bolt holes or reinforced slots for three-, four-, and five-point harnesses are standard on competitive seats. That engineered interface not only increases safety but also improves the driver’s ability to feel chassis behavior. With the driver held by a well-routed harness, small sensations from the suspension and tires are transmitted to the hands and hips with less attenuation.

Material choices influence both function and feel. Shells can be molded from composite fibers, thermoplastics, or steel. Composite shells prioritize light weight and can be shaped into tight, enveloping profiles. Steel shells add durability and can integrate mounting features easily. Interior surfaces use dense foams and performance fabrics to balance grip and comfort. Alcantara-like materials combine tackiness with breathability, reducing lateral slip while wicking sweat during extended sessions. Stitching and trim choices, such as contrasting thread, offer visual accents without altering performance.

Ergonomics in a racing seat focus on three things: foot-pedal geometry, steering reach, and sightlines. The seat’s base and cushion height affect pedal angles and heel-to-toe operation. A low, flat seat base allows for precise heel movement between brake and throttle. Seat side bolsters should not obstruct rapid lateral weight shifts, yet must remain supportive. Shoulder bolsters sit higher for track cars to resist roll, but they must not impede arm movement. A thoughtfully designed geometry ensures the driver’s head stays aligned with sightlines over the dash, improving spatial judgment at speed.

Fitment is a practical but crucial concern. A seat may excel on paper, but if it does not align with the car’s mounting points, the value is lost. Fixed-back seats demand stronger mounts and often require a custom adapter or reinforced floor plates. Proper seat rails or fixed brackets establish a secure connection to the car. When combined with a race-prepped chassis, the seat becomes an integrated anchor point for the driver, safety gear, and sometimes roll-cage interfaces. This integration is why professional installation is recommended for track-focused builds.

Weight distribution and center of gravity are subtle, yet significant. Moving to a lighter seat can drop unsprung weight? Not directly, but it lowers overall vehicle mass and can slightly affect rotational inertia. More importantly, the seat’s position influences driver mass placement. Shifting the driver rearward or lower changes front-to-rear balance, affecting turn-in feel and mid-corner stability. Teams and enthusiasts often reposition seats by small amounts to fine-tune handling balance. Those small adjustments can influence throttle sensitivity and the car’s tendency to understeer or oversteer.

Comfort still matters. The most aggressive bucket can be unbearable over an hour of endurance racing. Designers use graduated foam densities to provide support where needed. Firm bolsters resist lateral motion while softer seating areas relieve pressure points. Ventilation channels and breathable surfaces help manage seat temperature. Even in sprint formats, driver fatigue is a limiting factor. A seat that mitigates fatigue allows drivers to maintain concentration and deliver consistent inputs.

Safety features must never be overshadowed by performance. A reinforced shell and secure mounting points are core safety elements. Seats intended for racing often include compatibility for head and neck restraint devices. Properly designed shoulder bolsters help limit lateral head motion in severe impacts. Meanwhile, harness slots should be shaped and reinforced to avoid belt wear and to ensure straps remain in the correct plane during a crash.

Trade-offs are inevitable. A fixed-back bucket sacrifices recline and on-road comfort for rigidity and control. Full containment seats improve high-G performance but make ingress and egress slower. Reclining, street-oriented seats offer daily comfort but allow micro-movements that blur the driver’s feel. The correct choice depends on intended use. A weekend track car benefits from a firmer, more contoured seat. A daily driver with occasional track days might favor a removable racing seat or a modular solution that balances comfort and sport.

Integration with chassis setup is often overlooked. Suspension tuning and interior ergonomics are reciprocally linked. Tight lateral containment complements a firm suspension, because the driver’s body remains a consistent mass. Conversely, a soft suspension blurs the benefits of an aggressive seat, as body roll and isolation reduce the feedback reaching the driver. In rally-derived platforms that emphasize quick changes in direction, a secure seat helps the driver apply precise steering inputs as the chassis unsettles on varying surfaces. The cabin’s configuration should therefore be planned alongside suspension changes to capture full performance gains.

Installation and geometry adjustments make a major difference. Proper seat rake and height support optimal pedal angles and sightlines. Many competitive drivers prefer a slightly reclined angle to brace against longitudinal loads while preserving hip flexibility. Seat mounting eyes must align with harness strap planes to maintain safe belt trajectories. When adding harnesses, ensure that lower anchor points are positioned low and behind the pelvis. High belt anchors can promote submarining under load.

Practicalities such as egress and daily usability deserve attention. In endurance events, quick driver changes are crucial. Seats with excessive lateral containment slow that process. A compromise is semi-bucket designs that retain lateral support while allowing faster exits. For street and occasional track use, removable inserts or pads can tune the seat feel without replacing the entire unit. Keep in mind that any modification to seating or mounts must be inspected periodically for wear or corrosion.

Aesthetic choices should not be dismissed. Stitching color, material texture, and contrast piping give the cabin personality. These design elements influence perceived quality and driver confidence. A well-trimmed interior suggests attention to detail and care, which often correlates with an owner’s commitment to maintenance and performance.

When seats are chosen as part of a performance upgrade, they should be evaluated alongside other components. Wheels, tires, brakes, and suspension define the car’s ability to stick and stop. The seat defines whether the driver can exploit those capabilities consistently. A performance seat multiplies the effect of handling upgrades by stabilizing the driver’s platform.

Longevity and maintenance are practical concerns. High-friction materials must withstand constant abrasion from harnesses and clothing. Reinforced fabric edges and durable stitching extend service life. Detachable covers and removable cushions simplify cleaning. In corrosive climates, stainless hardware prevents degradation of mounts and bolts.

For many enthusiasts, seats are also a statement. A purpose-built seat signals a shift from casual driving to serious performance intent. It changes how a car is driven and how the driver perceives that car. The psychological effect is real: occupants report increased focus and confidence when securely harnessed to a supportive shell. That confidence often yields cleaner lines, earlier braking, and consistent throttle application.

A final point links seats back to the overall handling package. Seats are not isolationist upgrades. They belong to a system that includes suspension geometry, tire choices, and chassis stiffness. When these elements are tuned together, the benefits of a race-oriented seat are multiplied. A secure, well-mounted seat enables the driver to sense minute variations in grip and respond more quickly. Over the length of an event, that heightened sensitivity becomes measurable in lap times, tire wear, and consistent pace.

For deeper technical context about how interior components complement suspension tuning in rally-inspired vehicles, consult OEM documentation on suspension systems and handling calibration. The official guide to suspension components clarifies how chassis behavior pairs with seating dynamics: https://www.mitsubishi-motors.com/en/technical/evolution-x-suspension

For a practical parts reference related to seat options and trim materials, consider reviewing brand-new Alcantara front seats available through specialist outlets: brand-new Alcantara front seats.

Balancing Performance and Protection: Safety Considerations for High-Performance Seats in Modern Cars

Driving a high-performance car places the seat at the center of a broad safety conversation. The seat is more than a comfortable cradle; it is a fundamental interface that affects how the vehicle handles, how the driver perceives traction, and how safety executes in the event of a crash. Performance seats promise a more intimate connection to the car: deeper side bolsters that hold the torso in cornering, thigh supports that minimize leg shift during acceleration, and a lower, more communicative seating position that makes steering feel immediate. When chosen wisely, such seats can reduce driver fatigue on long sessions and sharpen reflexes on the track. When chosen unwisely, they can upset the delicate balance of the car’s safety architecture, especially in models that rely on precise occupancy data to determine airbag timing and deployment. The interplay of seat design with airbag logic is not a niche concern; it is a central safety truth for any enthusiast considering a seating upgrade. The following reflections examine how fixed-back or bucket-style seating interacts with modern occupant safety systems and how to navigate that intersection responsibly.

At the heart of safety are occupant detection and airbag deployment systems. Modern vehicles use sensors that estimate the occupant’s weight and position to decide if a front airbag should deploy, along with whether side airbags should be active. Those sensors relay to an electronic control unit that calculates risk and timing. Replacing a seat with aftermarket components can alter the weight distribution seen by the system or shift the seat’s reference position relative to the airbag modules and seat-mounted sensors. It is not just a mechanical change; it is a potential recalibration of the crash response itself. Even seats that visually look identical can change reading patterns if they mount differently, have padding with different compressibility, or introduce extra layers of fabric that interfere with pressure sensors embedded in foam. The consequence is a misalignment between the actual occupant risk and the system’s protective response, a mismatch that can degrade protection at exactly the moment airbags are supposed to help.

Official guidance issued in early 2026 emphasizes that any modifications to the front passenger seat—including aftermarket seats, seat covers, cushions, blankets, or accessories—can interfere with the occupant classification system. The document stresses that such interference may cause incorrect airbag deployment decisions and, in the worst case, serious injury or death, particularly when a child is seated in the front. The warning is explicit: avoid modifications that could affect the seat’s ability to sense occupancy, avoid covers that insulate sensors, and avoid accessory cushions that alter pressure profiles. The guidance also notes that even cosmetic seat covers can distort the sensor readings in subtle ways, shifting the threshold at which the system recognizes an occupant. Because the occupant classification system is intimately tied to how the car deploys its airbags, any uncertainty about compatibility should trigger a conservative approach: do not rely on the front passenger seat until a certified assessment confirms it does not compromise safety.

Further, installation procedures themselves matter. A February 2026 guide on installing performance seats cautions that improper mounting can disable or mislead safety sensors. It highlights the critical need to maintain correct sensor wiring paths, ensure that seat-mounted airbag harnesses remain connected to their control modules, and avoid altering seat height or tilt in ways that shift the occupant’s posture during a crash. The guide uses cautionary language and points to thorough testing after installation. It is not enough to bolt the seat into the factory pattern; the entire safety network must be evaluated for integrity. In practice, this means technicians must verify that the vehicle’s occupant detection module still reads consistent weight data, that the seat wiring does not fracture or abrade in a way that triggers fault codes, and that the car’s diagnostics show no faults related to airbag systems before the car is driven again.

From a mechanical perspective, a fixed-back seat offers clear advantages for track discipline. The rigidity of the shell translates into a stable seating platform where the upper body remains in a predictable plane during aggressive maneuvers. But that same rigidity demands compatibility with the car’s safety system architecture. The seat’s lateral support must not compress or deform in a way that compresses the airbag modules or alters sensor geometry. Designers often integrate harness anchor points with careful attention to the seat’s frame to ensure that the restraint system remains effective without interfering with sensors. The bolt pattern, seat track geometry, and anchor hardware must be matched to the vehicle’s safety architecture. If the replacement seat changes how weight is distributed, the system’s calibration could drift, potentially unsettling the airbag timing or the status of the occupancy sensor. The objective is to preserve both the driver’s secure hold and the system’s ability to interpret that hold correctly when a crash occurs.

Harness compatibility is an area that deserves careful planning. Many performance-oriented setups use multi-point restraints to maintain torso and shoulder alignment under high-load events. These harnesses require anchor points on the seat frame that can withstand forces beyond standard seat belts. The mounting arrangement should not obstruct sensors or create ground paths that could distort the sensor signals. Additionally, the seat’s weight and cushion geometry can influence the calibration of occupant sensors, especially in vehicles where the sensor module is integrated into the seat base. In short, a harness-ready seat must be installed with an eye toward sensor integrity, harness routing, and the preservation of the seat’s relationship to the occupant classification system. If any doubt remains, professionals should revert to stock components or select certified aftermarket options that explicitly advertise compatibility with the car’s safety system.

Within the realm of design tradeoffs, the trade between grip and sensor interaction becomes apparent. A seat with aggressive side bolsters improves driver containment but can alter how the pelvis and spine compress during a crash, affecting the seat’s perceived height and posture. The system wants a known reference position to compute force and occupant status. If the seat prompts the occupant to sit slightly higher or lower than the calibration baseline, the airbag timing logic might respond differently. Therefore, installers must consider not only the seat’s cushioning but also its internal geometry and how those measurements feed into safety controllers. Where possible, seats designed and tested for a particular vehicle should be preferred, and the installation should be performed by specialists who can verify that the final geometry remains within the safety system’s expected tolerances.

Beyond sensor compatibility, the entire safety ecosystem must remain coherent. The car’s electronic control units coordinate with seat sensors, airbag modules, and the pretensioner circuits in a synchronized manner. Any aftermarket seat must be compatible with this network. A misstep can manifest as fault warnings, illuminated indicators, or degraded protection during a real collision. For this reason, many safety-conscious builders adopt a strict policy: only mount seats that have undergone platform-specific testing and certification, and insist on post-install diagnostics to confirm system integrity. This approach preserves the performance gains while maintaining the confidence that the airbag and sensor networks will function when needed.

From the perspective of the track enthusiast, performance gains from upgraded seats must be viewed as part of a broader risk management strategy. The improved hold and reduced fatigue can extend laps and improve lap times, but those advantages assume that the safety systems remain fully functional. In practice, experienced technicians will help design a seat package that does not compromise the occupant sensing system. They might suggest alternative configurations that keep critical sensor pathways intact, or propose seats with documented compatibility, or advise on harness integration that preserves sensor performance. The goal is not to choose between performance and protection, but to ensure both are harmonized so the car behaves predictably under both normal driving and emergency conditions.

On the topic of information sources about seat options and installation guidelines, there is value in exploring related discussions about materials and fit. For instance, see the page on brand-new-alcantara-front-recaro-seatsoriginal, which discusses how materials and mounting hardware interact with occupant comfort and safety. Such discussions help frame the broader conversation about what a seat does beyond mere support, including how it can affect sensor readings and occupant recognition when installed in a given platform.

Even with caution, the reality remains that upgraded seats are appealing. The enhanced hold translates into a more confident steering input, reduced slip under cornering, and a tactile sense of precision that makes track sessions more predictable. The seat’s geometry communicates immediate feedback to the driver, which in turn influences how the driver modulates inputs. The critical caveat is this: any upgrade must preserve the car’s safety architecture. The seat should complement the airbag and sensor network, not undermine it. Proponents emphasize that when the upgrade is matched to the vehicle’s safety framework, a driver can enjoy the benefits of improved control without compromising protection.

Prudence also means vetting the installation with a qualified professional. A safety assessment after installation should review the occupant classification module, airbag circuits, seat belt pretensioners, and seat mounting hardware. If anything seems amiss, the technician should return the vehicle to its original configuration and arrange further testing before returning to service. Should a problem be suspected, guidance in the guidance documents is explicit: direct passengers to the back seat and seek professional service to verify compatibility and safety features. The process may add time and cost, but it protects occupants and preserves the intended protective function of the airbags.

Ultimately, the choice to install a performance-oriented seat must be informed by careful risk assessment and professional advice. The gains in control and comfort must be weighed against the potential for misclassification, incorrect deployment timing, or compromised side airbag function. The optimal path is to select seats and harnesses that either come certified for the platform or are supported by a vendor with explicit testing data and installation guidelines. When integration is done correctly, a performance seat can deliver peak driving satisfaction while preserving or even enhancing protective responses in a crash.

The broader point extends beyond any single make or model: in modern performance cars, safety is a dynamic, not a static feature. The seating system, occupancy sensing, airbag control logic, and software that governs deployment form a cycle of checks and responses. A change in one component triggers a cascade of considerations across the safety chain. The responsible approach is to adopt a coherent package that has been tested, documented, and certified for the vehicle. Enthusiasts who pursue this path will find that the line between prowess and protection can be drawn clearly, with a clear plan for validation and verification.

To close the loop on practical guidance, treat any modification to the front passenger seat as a safety-critical decision. Swap or embellish only with components that carry explicit compatibility certification or testing results for the platform. If you observe any abnormal readings, fault codes, or unexpected sensor behavior after installation, revert to the original seating arrangement and consult a professional immediately. This conservative approach protects both occupants and the vehicle’s safety architecture, while still enabling the performance upgrades that make spirited driving more immersive.

Education and ongoing awareness are essential. As safety technologies evolve, and as a vehicle platform receives updates, owners should actively monitor guidance on seating changes and their interaction with airbag timing, sensor networks, and occupant detection. The landscape shifts with new materials, new sensor architectures, and new testing standards. Committing to certified, tested components and professional installation preserves the integrity of protection, even as performance ambitions rise. In this light, the seat becomes a conduit for responsibility as much as for capability: a tool that unlocks the car’s potential while safeguarding those inside it on every mile of road and every second of track time.

External resource and continued education are part of responsible ownership. As safety technologies advance, the best practice is to stay informed about how seating changes influence airbag timing and sensor data. The exchange between engineers, technicians, and drivers is ongoing, and keeping that dialogue open reduces risk and improves outcomes for all occupants. For authoritative information regarding safety system compatibility and recommended practices, refer to official guidance on occupant safety: https://www.tesla.com/support/occupant-safety

Final thoughts

In conclusion, Evolution X Seats represent a significant advancement in the automotive industry, combining exceptional design, performance enhancement, and rigorous safety features. For business owners involved in high-performance automotive offerings, investing in such seats can dramatically improve vehicle appeal and driver satisfaction, thereby enhancing overall client experiences. Understanding the importance of these seats in the racing context can also guide future innovations and upgrades for your vehicle lineup.