The Mitsubishi Galant has earned a reputation as a reliable and versatile mid-size car, making it a popular choice among automotive enthusiasts and everyday drivers alike. This article delves into the critical components and parts of the Galant, focusing on the hood, body kits, and turbo kits that not only enhance aesthetics but also elevate performance. By understanding the specifications and compatibility of the Galant hood, the benefits of body and turbo kits, and the importance of maintenance and repairs, business owners can better serve their customers in the aftermarket automotive market. This exploration will highlight the key aspects of each chapter, providing a comprehensive overview of how these components contribute to the overall performance and longevity of the Mitsubishi Galant.

Steel Crown, Quiet Power: The Mitsubishi Galant Hood Within a Network of Galant Parts

The hood of a car is more than a metal cover for the engine; it is a quiet mediator between the harsh realities of motion and the refined expectations of daily driving. In the Mitsubishi Galant, the hood acts as a steel crown for the front of the car, shaping how the car breathes, how it looks, and how it engages with the road and the weather. When the hood is intact and properly aligned, it whispers confidence to the driver, a signal that the vehicle’s heart is properly housed and protected. Yet this crown sits within a broader ecosystem of Galant parts, a network of panels, trim, and performance components that together determine the car’s character on the street and on the track. The discussion that follows pivots on the Galant hood not just as a replacement part, but as a hinge point for fitment, durability, and the possibilities that arise when a front-end panel is integrated with other systems in the car. In a sense, the hood is the gateway panel that connects exterior design with the engine’s performance reality, a place where aesthetics meet engineering discipline and where every bolt capture becomes a note in a larger symphony of maintenance and modification.

For models produced in the late 2000s and early 2010s, the Galant hood was crafted to meet precise OEM specifications that matched the dimensional tolerances of the fenders, grille, and surrounding bodywork. The 2009–2012 Galant, in particular, offered a front steel hood designed to fit both the 2.4-liter and 3.8-liter engines that powered those sedans during this period. The material choice—steel—was deliberate. Steel provides a proven balance of rigidity, dent resistance, and surface finish that supports consistent alignment and paint adhesion over time. In practical terms, this means an original-style hood can help preserve even gaps along the edges, maintain the intended silhouette of the front end, and minimize the risk of fender or grille misalignment after replacement. The consistency of these characteristics is especially important for owners who want to preserve the car’s original appearance or who seek a seamless canvas for a paint job that matches the factory style.

The specifications emphasize a fit that aligns with factory dimensions, ensuring that the hood lines up with the fenders and the grille in a way that preserves the car’s intended geometry. The installation is designed to be straightforward, with pre-drilled mounting holes that guide the new hood into position and factory-style hinges that allow for a direct swap without requiring exotic tools or invasive modifications. This focus on ease of installation is more than a convenience; it reflects the broader philosophy of modern automotive replacement parts: retention of original assembly logic so that owners can restore the vehicle to its intended state with minimal risk and downtime. The one-year unlimited mileage warranty that accompanies this hood underscores the manufacturer’s confidence in the product’s durability and performance under normal driving conditions. A warranty of this kind signals to the buyer that the panel has been engineered to withstand the everyday rigors of road debris, weather exposure, and typical maintenance cycles without compromising structural integrity or alignment.

Compatibility must always be verified, a reminder that the Galant’s journey from factory assembly line to repair bay involves a series of identifiers that confirm whether a specific hood will truly fit a given vehicle. The model designations linked to the hood in this narrative—MN150295 and MI1230209—anchor the discussion in a precise cataloging system used by replacement-part suppliers. These designations are more than alphanumeric codes; they are keys that unlock the guarantee of proper fitment across years and across variations in trim and production runs. The scope of compatibility includes Galant models produced from 2009 to 2012 and engines ranging from 2.4 liters to 3.8 liters. This range captures the practical reality that a replacement hood is not a one-size-fits-all proposition; it must align with the engine bay geometry, the hood latch geometry, and the adjacent panels that define the car’s front-end profile.

To the buyer, this means a careful validation step before purchase. VIN verification and exact model trim checks are not merely bureaucratic hurdles but essential steps in ensuring that the hood you receive will seat correctly and function as intended. A misalignment between the hood and the fenders or between the hood and the grille can lead to persistent gaps, misaligned gaps, or even impaired hood operation. The installer must confirm that the chosen hood honors those original tolerances and supports reliable latching, secure hood alignment, and consistent paint coverage. The official product listing provides further specifics on material thickness, available paint finishes, and hinge types. While the exact thickness may vary slightly by production batch and market, the core message remains: a hood is a precision component whose success depends on adherence to the vehicle’s intended geometry and the quality of the installation process. This is not just a matter of appearance; it is a matter of function, safety, and long-term reliability.

In practice, the replacement hood’s fitment also interacts with the broader front-end architecture. The hood closes against the firewall seam with a definite resistance, and the seam itself is designed to minimize water intrusion while ensuring that the engine-to-hood clearance remains within tight tolerances. When the hood is properly aligned, the edges present a consistent line that resonates with the car’s overall design language. The paint finish on a replacement hood must be matched to the existing body color and texture, a task that may involve buffing, color matching, and sometimes a panel repaint to ensure uniform gloss and depth. The instruction to refer to the official listing for particular details on material thickness and paint options is not mere rhetoric; it is a practical reminder that the hood is part of a broader finish and protection strategy, one that involves coating layers, primer, and a careful curing process that all contribute to the panel’s longevity.

Beyond the hood itself, the Galant’s front-end ecosystem includes a range of related components—upgraded bumpers, body kits, and performance-oriented enhancements—that owners may explore as part of a broader renovation or customization project. A modern Galant can be the subject of tasteful upgrades that maintain street-legal practicality while offering improved aerodynamics, heat management, or aggressive aesthetics. In some enthusiast circles, this spirit of customization extends to performance-oriented components such as turbo kits and enhanced cooling systems that complement the engine bay’s footprint. These modifications can magnify the benefits of a solid, correctly installed hood, particularly if the goal is to manage engine bay temperatures more effectively during spirited driving or track use. Yet with any enhancement, the rule remains the same: maintain proper fitment, ensure harmonized clearances, and respect the vehicle’s foundational design. The hood’s role as a protective cover, a sealing surface against weather, and a visual anchor for the front end makes it a critical component that should be approached with care and a clear understanding of its place within the broader Galant parts ecosystem.

For readers who explore the wider landscape of Mitsubishi hood options, it is instructive to imagine how cross-model practices inform decisions about a Galant hood. In the world of performance and weight-reduction, some builders look to carbon fiber or lightweight composites used on other Mitsubishi models. A concrete example that illustrates this cross-model thinking is a carbon fiber hood associated with the early- or late-model performance-mindset cars in the Mitsubishi family. The point is not to advocate for any particular brand or product, but to recognize that the hood carries a philosophy: lightness where possible, strength where required, and a design that respects the car’s geometry. In this sense, the Galant hood can be seen as part of a larger dialogue about how front-end panels evolve over time, how engineers balance protection with weight, and how designers preserve the silhouette that defines the car’s identity across generations. The idea of borrowing lessons from other models, while maintaining structural integrity and factory-fit accuracy, underscores the importance of rigorous specification adherence and careful installation.

The practical implications for a modern Galant owner are clear. When replacing the hood, one should work with components that promise proper factory fit, ensure reliable mounting, and support consistent alignment with surrounding panels. The pre-drilled holes and hinges are designed to be compatible with the Galant’s existing latching and mounting framework, reducing the risk of unexpected panel movement or misalignment after installation. Any painting or finish work should be planned with attention to color fidelity and surface preparation, so the final look presents a seamless, uniform appearance. And because the hood is a front-line defense against road debris and weather, buyers should consider the hood’s performance under real-world conditions: rain, sun exposure, road grit, and temperature swings can all test the longevity of the paint and the underlying metal if the hood is not properly treated or installed.

The broader implication of this discussion is that the Galant hood acts as a microcosm of the car’s maintenance culture. It reveals how modern owners approach replacement parts: with a disciplined emphasis on fit, finish, and functional integration. It also invites a broader reflection on how the market for Galant parts has evolved to accommodate both restoration projects and contemporary upgrades. The hood, while seemingly modest in its daily presence, anchors a larger conversation about how owners sustain the car’s reliability and preserve its character over time. In this sense, the hood is a small but telling symbol of the care that goes into preserving a vehicle that carries the echoes of design language, engineering discipline, and the shared aspirations of a community that values both durability and precision.

For readers curious about cross-model possibilities in the realm of performance-inspired modifications, consider the broader landscape beyond the Galant. In some communities, enthusiasts explore carbon fiber or other high-strength, lightweight materials for hoods that can be adapted to a variety of Mitsubishi models. This cross-model thinking highlights a core principle: the pursuit of better performance often begins with a front-end panel that maintains the vehicle’s geometry while reducing weight and improving heat management. Even when one remains focused on factory-spec replacements, the conversation about the Galant hood inevitably touches on the importance of accurate fit, a reliable latch system, and a finish that endures under the elements. These are not glamorous details, but they are the quiet work that ensures a vehicle remains dependable and visually coherent as it ages.

To connect this discussion back to concrete choices, buyers should consult the official product listing for specifics such as the exact material thickness, appropriate paint finish options, and the types of hinges supplied with the hood. These details, while technical, are the practical signals a buyer uses to decide whether a replacement hood will integrate smoothly with the car’s existing systems. The guidance offered by these listings helps ensure that the installation proceeds without surprises and that the owner can enjoy the car’s front-end appearance and protection for years to come. In this sense, the hood becomes not just a panel to be replaced, but a focal point around which maintenance, aesthetics, and performance-oriented thinking converge.

For readers who want to see related discussions about front-end components and fitment across the Mitsubishi family, a broader exploration of hood and bumper compatibility can be enlightening. The hood’s relationship with the front bumper, the grille, and the fenders is a reminder that the car’s face is a composite of panels that must work in harmony. A misfit in one component can cascade into trim gaps, misalignment of the grille, or uneven paint edges. The practical takeaway is that a careful assessment of model year, engine specifications, and VIN is essential before purchasing a hood. When in doubt, leaning on the listing’s stated compatibility and consulting with a trusted installer can save time, effort, and the potential for aesthetic or functional disappointments down the line.

As the chapter closes, it is helpful to keep in mind a small, but important, distinction: the Galant hood embodies a philosophy of maintenance and upgrade that respects the vehicle’s original intent while opening doors to thoughtful customization. It is not merely a component to swap; it is a point of continuity that ties the car’s past to its present and to the future projects that owners may undertake. The hood’s specifications—steel construction, OEM fit, pre-drilled holes, and included hinges—represent a disciplined approach to replacement that values reliability and alignment. The one-year warranty protects the investment, but the true return is in the quiet assurance that the front of the car remains as robust and visually coherent as when the car left the factory. It is precisely this blend of durability, fit, and finish that makes the Galant hood a meaningful entry point into the broader world of Galant parts and the ongoing conversation about how cars age gracefully while still inviting fresh ideas and renewed purpose.

Internal link note: For those curious about cross-model, performance-oriented hood options from other Mitsubishi lines, see this example: 1994-1999 Mitsubishi 3000GT carbon fiber hood. External resource: For a comprehensive specification and warranty overview from a dedicated Galant hood supplier, you can review the official listing here: https://www.garage-pro.com/mitsubishi-galant-hood-2009-2012

Aerodynamics, Power, and Presence: Upgrading the Mitsubishi Galant with Body Kits and Turbo Upgrades

The Mitsubishi Galant occupies a unique position in the stories of modern cars that blend everyday reliability with a latent potential for driven personalities. It is the kind of chassis that responds well to thoughtful, deliberate changes rather than to heavy-handed overhauls. When approaching the Galant as a platform for enhancement, the conversation naturally turns toward two complementary strands: body kits and turbo kits. Each on its own changes the car’s character, but when thoughtfully combined they can transform the sedan into a coherent package that looks capable at a standstill and behaves decisively on the road. This is where the artistry of modification meets the precision of engineering, where aesthetics and performance intersect to create a Galant that not only draws noticed glances but also translates those first impressions into confident, controlled speed and stability.

A body kit on a Galant is more than a cosmetic upgrade. It is a system, a set of carefully selected shapes and surfaces that manage air as it flows over and under the car, shaping both how the car sits at rest and how it behaves at speed. The front bumper, with its broader air intakes, is a strategic feature. It is not merely about a more aggressive look; it is about engine cooling and radiator efficiency under the stress of spirited driving. Larger intake mouths reduce pressure drop and can help deliver cool air to the intercooler and radiator during sustained high-speed runs. Side skirts, often overlooked in casual conversations about appearance, are a crucial component of the whole. They guide the boundary layer along the underbody, reducing lift and improving directional stability. They also contribute to reducing the amount of air that sweeps underneath the car, which in turn lowers the risk of negative lift at highway speeds. The rear bumper, often the last visual cue of a kit, matters too for a couple of reasons. First, it can incorporate more integrated sensors and cameras that assist parking and proximity awareness, which is increasingly important in otherwise ordinary-looking sedans. Second, the rear profile completes the aerodynamics, refining drag characteristics and, in some setups, providing mounting points for a subtle diffuser that further stabilizes the car as it gathers speed.

The practical benefits extend beyond the aesthetic. A well-designed body kit works with the Galant’s chassis dynamics to improve high-speed stability and road feel. Wind tunnel wisdom suggests that when air flows cleanly around a vehicle, there is less buffet and less tendency for the car to yaw when gusts hit or when lane lines become less distinct at speed. In this sense, the body kit becomes a passive, constant companion on every journey, a set of features that performs even before the driver presses the accelerator. The material and construction quality of the kit, of course, determine the real-world outcome. A kit built from durable composites or high-grade fiberglass with precise tolerances will offer light weight without compromising impact resistance. Yet, the installation itself cannot be treated as an afterthought. Precision alignment is essential; misalignment of a front bumper can alter airflow in unpredictable ways, sometimes creating more drag or even interfering with the operation of sensors and cameras that are now commonly integrated into modern bumpers. The same attention to detail applies to wiring for any integrated lighting or sensor arrays. The result is a cohesive, purposeful appearance—one that communicates a clear message about how the car behaves when pressed into action as much as how it looks parked at the curb.

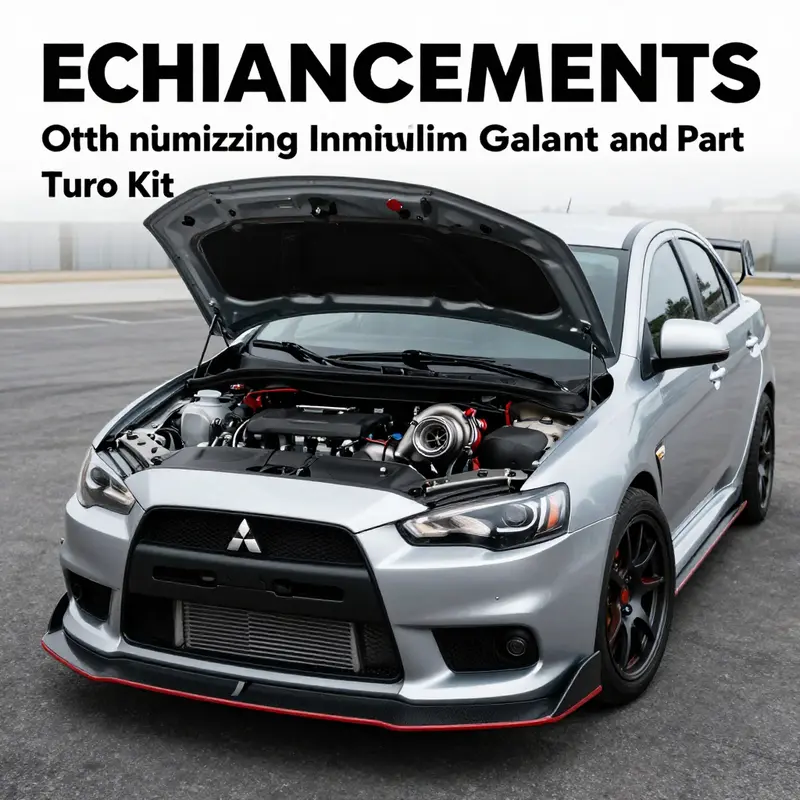

The turbo kit narrative for the Galant introduces a different axis of transformation. Turbocharging is the language of power, yes, but it is also the language of systems integration. The purpose of a turbo upgrade is not to build a monster but to unlock a predictable and usable increase in performance. The mapping of power to the Galant’s existing architecture depends first on the engine family in question. An 1.8-liter configuration will respond differently from a larger displacement or a multi-valve VR4-style setup. The essence of turbo work lies in matching air intake, cooling, and exhaust flow to the engine’s capabilities and fears. A modern turbo kit typically includes a turbocharger with an appropriately sized compressor and turbine, an intercooler to reduce intake air temperature, a suitably engineered intake plenum, upgraded fuel delivery with calibrated injectors, a revised ECU map to manage timing and fueling, and an exhaust system designed to minimize back pressure while preserving emissions constraints and noise limits. The goal is not simply horsepower; it is driveable performance across the rev range. For urban driving, the emphasis may be on improving throttle response and mid-range torque; for track-oriented applications, the focus shifts to sustaining boost with robust thermal management and careful tuning to avoid detonation or heat soak.

In practical terms, the VR4 or four-wheel-drive variants with turbo aspirations present unique challenges and opportunities. The VR4 framework is historically associated with higher torque and a more robust drivetrain capable of handling the power with a measured sense of stability. A turbo kit in this context must address thermal management, since higher boost levels push air and exhaust through the engine more aggressively. An upgraded cooling solution—intercoolers with larger cores, efficient charge-air cooling, and even redesigned radiator configurations—helps ensure that the engine breathes cleanly even on hot days or during long stretches of high-speed driving. Exhaust system improvements matter too because the path from combustion to the tailpipe must carry away the increased thermodynamic energy safely. These changes often ripple outward, necessitating upgraded fuel delivery systems, revised calibration for the engine control electronics, and sometimes reinforced internal components to withstand the additional stress of sustained boost. For the 2.4-liter variants, the emphasis often lies in maximizing low-end torque and mid-range power, providing a more spirited response in city traffic while maintaining daily drivability. The truth is that a turbo kit is not a single component but a chain of optimized parts that must work in harmony with the Galant’s suspension, brakes, and chassis geometry. A well-executed kit respects the car’s weight distribution and aims to preserve, or even improve, steering feel and braking control.

The synergy between a body kit and a turbo kit is where the Galant can truly evolve from a dependable sedan into a more cohesive performance proposition. The body kit sets the stage by shaping the aerodynamics around the car, generating downforce where it helps and reducing drag where it matters for efficiency. This aerodynamic groundwork makes the most of the power delivered by the turbo system, improving stability under acceleration and cornering. At the same time, the added power from the turbo kit shifts the dynamic balance, potentially increasing mechanical grip needs. This is where the wider conversation about upgrading supporting systems comes in. Upgrading the suspension to handle the increased cornering forces, refining the braking system for confident deceleration from higher speeds, and adopting a power management strategy that keeps the engine within safe operating limits all play a part in achieving a balanced, integrated result. The practical takeaway is that modifications do not exist in isolation. The chassis responds to one change by requiring a thoughtful readjustment of other systems to maintain harmony.

Often, those planning a Galant transformation begin with a precise assessment of usage goals. Is the aim to conquer twisty back roads with a more planted stance, to enjoy a refined highway cruiser that can still surprise with a quick surge, or to build a showpiece that turns heads at car meets? The configuration of a body kit will reflect that choice. For some, a mild, well-fitting front bumper with integrated airflow features and understated side skirts may be all that is needed to improve both aesthetics and function. For others, a more aggressive rear diffuser, a lowered ride height, and a broader stance may be part of the plan, as long as it remains compatible with daily usability and maintenance realities. The turbo upgrade, meanwhile, should be approached with the same seriousness: a calibrated plan that considers fuel system reliability, intercooler efficiency, ECU tuning strategy, and thermal management as well as the availability of tuned exhaust and intake components. The two upgrades, when pursued with careful attention to compatibility and the car’s intended role, create a refined identity for the Galant that plays to its strengths while avoiding the pitfalls of over-claiming power without corresponding handling and cooling improvements.

From a practical standpoint, sourcing quality components matters just as much as fitment and tuning. A reliable body kit should come with properly matched mounting points, corrosion-resistant fasteners, and a paint process that yields long-lasting color consistency. The finish should be chosen with attention to UV resistance and stone-chip protection, because the Galant’s daily duties will inevitably involve urban driving and gravel-filled rural roads. For turbo systems, the emphasis is on parts engineered to withstand boost pressure, with attention to the compatibility of the exhaust, intercooler, and intake routes. The best outcomes arise when buyers work with reputable suppliers who can provide engineering-grade materials, along with a reasonable expectation of customer support during installation and aftercare. The logistics of acquiring these parts—especially if the Galant is an older model in need of restoration—should be factored into timing and budgeting. The reality is that a complete, well-tuned package can require careful planning and a collaborative approach with technicians who understand the interplay of aerodynamics, cooling, metallurgy, and electronics.

In this broader context, the decision to pursue a combined body kit and turbo kit should be anchored by a clear project vision and a realistic appraisal of the car’s baseline condition. Weight is a recurring theme in these conversations. While a body kit can shave a little mass from the car by replacing heavy factory panels with lighter composite materials, the turbo system adds thermal and mechanical loads that the chassis must carry. The net effect is a refined dynamic profile that rewards precise setup, proper alignment, and consistent maintenance. The Galant, with its proven platform, can benefit from a thoughtful upgrade strategy that treats the car as a single project rather than a sequence of independent parts. This approach helps preserve the car’s everyday usability while elevating its performance envelope, so that the moments of acceleration, cornering, and braking feel deliberately connected to the road and to the driver’s intent rather than simply to the latest aftermarket trend.

It is essential to recognize that a successful modification program for the Galant recognizes constraints and opportunities in equal measure. The kit-selection process is not about chasing the most extreme parts but about understanding the car’s physics and the driver’s aspirations. The aerodynamics must be balanced with the engine’s power curve so that the car remains predictable and forgiving in normal driving, with a clear, tangible performance edge when conditions demand it. The powertrain must respond linearly to the driver’s input, avoiding abrupt surges or lag that can surprise the vehicle’s chassis at the limit. The suspension and brakes must be upgraded to meet the demands of the new performance profile, while steering feel and feedback remain communicative rather than numb. In short, this is a holistic undertaking that respects the Galant’s original design intent while enabling a coherent, modern interpretation of its potential.

As with any serious modification program, documentation and planning help ensure success. A well-documented build narrative—covering the rationale for each component, the alignment and paint steps, the wiring integration, and the calibration strategy—serves as a guide for future maintenance and upgrades. It also helps maintain the integrity of the car when it returns to the road after long stints in the shop or the track. The end result is not simply a faster car but a more confident one: a Galant whose exterior hints at its capabilities, whose powertrain delivers in a controlled, repeatable way, and whose dynamics remain predictable across a broad spectrum of driving scenarios. In that sense, the body kit and turbo kit together form a partnership of form and function, a synergy that respects the sedan’s lineage while inviting it to express a bolder, more purposeful personality.

null

null

Final thoughts

In conclusion, the Mitsubishi Galant hood and its associated parts play a pivotal role in enhancing the vehicle’s performance and ensuring longevity. By understanding the specifications of the hood, implementing performance-boosting enhancements like body kits and turbo kits, and committing to regular maintenance and repairs, business owners can significantly improve their service offerings. This comprehensive approach not only benefits customers through improved vehicle function but also reinforces the value and reliability of the Mitsubishi Galant in the automotive market. The integration of high-quality parts and modifications will cater to a wide range of customer preferences and driving styles.