Choosing the right hood for a Mitsubishi Lancer can significantly impact both performance and aesthetics, especially for business owners involved in automotive services. Understanding the available hood types, including OEM replacements, carbon fiber options, and aftermarket performance hoods, is crucial for making an informed business decision that meets customer expectations. Each chapter will delve into these options, detailing their specifications, advantages, and limitations, providing a comprehensive perspective for professionals looking to optimize or offer upgrades for Mitsubishi Lancers within their portfolios.

null

null

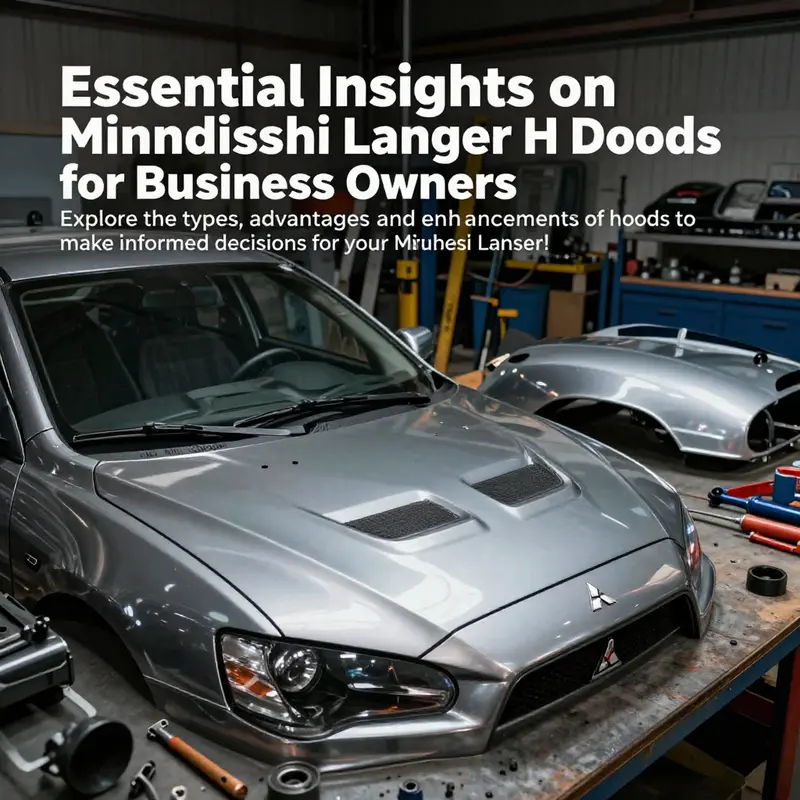

Original Fit, Lasting Reliability: The Case for OEM Replacement Hoods on the Mitsubishi Lancer

A hood is more than a panel that covers the engine; it is a carefully tuned interface between a car’s powerplant and the world outside. For the Mitsubishi Lancer, particularly in its high-performance lineage, the hood carries a dual promise: it must shield the engine bay from the elements and road debris while preserving the car’s intended aesthetic and aerodynamic behavior. When owners consider an OEM replacement hood, they are often weighing reliability and factory fidelity against the allure of lighter, more aggressive aftermarket options. The decision, in this sense, becomes a narrative about preserving what the car was designed to do, rather than chasing what it might do with a different silhouette. OEM replacement hoods, by their very nature, are engineered to the exact specifications of the original design. They align the hood, fenders, and headlights with surgical precision, ensuring the airflow that the factory engineers anticipated continues to flow as intended. This precise fit is not incidental; it is a function of the way the hood interacts with the entire front end of the car. When the panels line up perfectly, the aerodynamic profile remains intact, and the downforce and balance at speed stay predictable. For someone who daily drives a Lancer and wants a seamless restoration to stock after a collision or wear, that exactness matters more than a flashy alternative. The OEM path thus offers a form of future-proofing in a different sense. It preserves the car’s original design language and its predictable repair pathways. The hood is not a flashy accessory to be swapped in and out; it is a component that must perform consistently across a wide range of temperatures, humidity, and road conditions. The implementation of such reliability begins long before the hood meets the car. Materials, stamping, and coating processes are selected to maintain structural integrity under impact, resist the corrosion cycle driven by road salt and moisture, and provide a surface that can be painted to match the rest of the body with minimal color drift over time. The emphasis on a factory finish is not merely cosmetic. Color consistency across panels reduces the likelihood of mismatched appearances after repainting, and it supports resale value by preserving the vehicle’s original look. The factory aesthetic, in this sense, is a statement of authenticity as much as it is a matter of appearance. For a Lancer owner who values the comfort of a seat with a familiar contour, the hood’s finish and fit represent a similar guarantee. When the hood is replaced with an OEM unit, there is a sense that the vehicle’s construction remains intact, with the same mounting points, hinge alignment, and prop rod or hydraulic stay that the factory engineers designed. The installation, by design, does not require alterations to the hood structure. No drilling, no cutting, and no improvisation with brackets are needed. The OEM hood is intended to drop into place as a direct replacement, respecting the original chassis tolerances and attachment points. This simplicity is a practical virtue, especially for mechanics and owners who want a straightforward repair that preserves the vehicle’s structural integrity. On the road, this translates to a steady, predictable response during everyday driving. The front end does not suddenly change its weight distribution or its moment of inertia because a panel is slightly misaligned. The car behaves as the engineers envisioned, with the same steering feel, the same pedal response, and the same cadence of wind noise and cooling performance that shaped the Lancer’s character from new. The corrosion resistance offered by OEM hoods can be a meaningful advantage, particularly in climates where road salt or coastal humidity accelerates wear. An OEM hood is typically finished to Mitsubishi’s exacting standards, with coatings designed to resist blistering, peeling, or rust under standard conditions. A hood that ages in step with the rest of the body prevents the visual and structural problems that can arise when non-OEM parts diverge from the original metallurgy or surface treatment. In many cases, OEM hoods come with factory-painted finishes, which means color matching is not an ancillary concern but a guaranteed outcome. The match extends beyond color; it includes the subtle gloss, texture, and even the depth of the paint layer that underpins the car’s overall appearance. This level of concordance is particularly important for owners who intend to keep the car for years, during which paint aging and panel-to-panel shifts could otherwise become noticeable and unsightly. A direct-fit hood also simplifies service and maintenance. There is less room for error when aligning with the pre-existing hood latch mechanism, wiring harnesses for any integrated lighting, or the headlight assembly. The more a replacement disrupts the factory interface, the greater the chance of incidental wiring damage, misaligned seals, or unexpected wind noise. OEM parts minimize these risks because they are built to match the exact geometry and interface of the original parts. The functional advantages are complemented by a quiet advantage: a sense of continuity that many enthusiasts associate with the original driving experience. When a replacement hood preserves the same opening geometry and latch timing, engine bay access remains consistent. This matters not only for routine maintenance but also for the places where quick checks and cleanups occur during a race weekend or a long road trip. Beyond the sense of continuity, there is a practical matter of resilience. The OEM hood, being built to the original safety and performance specifications, tends to wear in a way that aligns with the rest of the front-end structure. This harmonized wear pattern reduces the likelihood of unexpected deformation or failure in the event of minor impacts or road debris contact. It also means the hood’s reinforcement structure has been designed with the same load paths as the other front-end components, a factor that can influence repair costs and time. The cost question, however, remains central. OEM replacement hoods are generally more expensive than some aftermarket options. The price reflects not only the brand name but also the quality control, supply chain reliability, and guaranteed compatibility with the Lancer’s front-end architecture. For some owners, this investment is worthwhile because it safeguards the vehicle’s resale value and reduces the risk of misfit repairs that may require ongoing adjustment. For others, the economic calculus pushes toward lighter, more aggressively styled alternatives that promise performance gains or a distinct look. The material itself is a defining factor. Most OEM hoods are manufactured from steel or aluminum, materials known for strength and durability but often heavier than carbon-fiber composites or certain advanced composites used in aftermarket offerings. This weight difference matters because every additional pound at the front end adds a measure of inertia that can alter braking balance, corner entry, and steering effort, especially in a car that already balances speed and agility with a finely tuned suspension. In addition, weight considerations influence fuel efficiency and front-end grip, albeit subtly, across many driving scenarios. For the daily driver, the extra mass of an OEM hood may be negligible in the face of reliability, fit, and longevity. But for a track-day enthusiast or a rally participant who demands every incremental performance advantage, the weight tax can be a deciding factor. When customization is a priority—whether for a more aggressive visual stance or for enhanced cooling—OEM hoods may feel limiting. They offer the factory look and the same surface preparation as the rest of the car, which means paint options are constrained to the factory palette and finishes. Enthusiasts who crave a dramatic carbon-fiber weave or a vented aesthetic with purpose-built intake routes may find aftermarket hoods more aligned with their goals. The OEM path, by contrast, emphasizes compatibility, safety, and a worry-free maintenance arc. You may see this most clearly in the realm of repairs after minor front-end incidents. With an OEM hood, the path back to a road-ready state tends to be shorter, with more predictable costs and faster service times. The repair ecosystem already understands this part; the availability of matching panels and the standardization of mounting points simplify the ordering process and reduce the risk of suboptimal compromises. It is also worth noting that the decision is not simply binary. Some owners adopt a hybrid approach, choosing an OEM replacement for street-driven cars and reserving carbon-fiber or lightweight steel hoods for track-equipped builds where weight reduction and improved cooling are the priority. In these cases, the OEM hood serves as a reliable baseline, preserving the car’s identity and functionality, while the high-performance option lives in the garage for a different kind of outing. For readers navigating this landscape, a practical recommendation emerges. If maintaining factory aesthetics, warranty coverage, and a straightforward maintenance path is the priority, an OEM replacement hood remains an excellent option. If your aim is to optimize front-end weight, enhance aggressive styling, or push cooling efficiency to the limit, you may wish to explore lighter materials and ventilated designs available in the aftermarket spectrum. To anchor these reflections in real-world choices, consider examining a direct OEM option that preserves a near-identical appearance to the original and provides a seamless installation experience. For a sense of how a genuine factory-style option is presented to enthusiasts, see discussions around OEM hoods for the Lancer Evolution line, including a phantom-black finish that aligns with the factory’s color logic and mounting interface. You can explore a representative example through related OEM listings which describe a direct-fit hood designed for the Lancer Evolution X, featuring a color-matched finish and a true factory alignment. This option exemplifies how the OEM approach translates into a straightforward, reliable upgrade that keeps the car’s identity intact while delivering the expected level of performance and protection. For readers who want to understand the nuance of these choices in a concrete context, consider a closer look at the specific OEM hood designed for the Evolution X front end, which demonstrates the alignment of the hood with the vehicle’s mounting points and its compatibility with the original sealing interfaces. The end result is a vehicle that retains its stock silhouette and predictable maintenance workflow, while delivering the confidence of knowing the part originated from the same engineering philosophy that built the car in the first place. The balance between reliability and customization remains central to the conversation about hoods in the Lancer community. OEM replacement hoods reinforce the car’s lineage, offering a stable platform for daily use and long-term ownership. They acknowledge the reality that many owners prize consistency, legal compliance with safety standards, and the ease of service that comes with parts designed to the original spec. Yet they also sit within a broader ecosystem where enthusiasts weigh the appeal of weight savings, aesthetic boldness, and engineered ventilation that can unlock additional cooling capacity under demanding conditions. In the final assessment, the choice of hood becomes a reflection of the owner’s priorities. If you value a transparent, efficient path back to a like-new condition after maintenance, and you prize a body line that remains faithful to the factory design, OEM replacement hoods offer a compelling package. They respect the car’s architecture, support long-term durability, and deliver a finish that looks and feels like a continuation of the factory story. For those who want to push the envelope on performance and appearance, the OEM route may still be part of a broader strategy that includes selective aftermarket components, all while keeping the core identity of the Lancer intact. It is this tension between fidelity and experimentation that defines the chapter of hood choices for the Lancer era. External resources that map the broader landscape of hood design and evolution offer valuable context for readers who want to compare the OEM path with the options that promise more radical performance gains. A comprehensive guide to hood evolution and specifications provides a backdrop for understanding how hoods influence cooling, aerodynamics, and front-end behavior across generations. For further reading, see the detailed hood guide that surveys these design aspects across the Lancer Evolution family. https://www.motortrend.com/cars/mitsubishi/lancer-evolution-x/hood-guide/ Internal references can illuminate how OEM options physically integrate with the car’s architecture. For example, an OEM-style hood designed for the Evolution X demonstrates direct fitment, color matching, and alignment with the surrounding panels. If you are interested in exploring a specific OEM option that preserves the phantom-black aesthetic while maintaining factory fitment, you can find a representative listing here: 08-15 Mitsubishi Lancer Evolution Evo-X hood phantom black OEM U02. This example illustrates how an OEM hood can deliver both the performance reliability and the visual cohesion that many owners want, without compromising the structural integrity that the chassis members and mounting points have come to rely on over years of use. In closing, OEM replacement hoods for the Lancer present a compelling case for owners who prize a seamless blend of reliability, aesthetics, and ease of maintenance. The decision is not simply about weight or looks; it is about preserving the car’s intended behavior and ensuring that the front end remains a faithful expression of the engineering that powered the Lancer through its most dynamic years. By choosing OEM, you are selecting a path that honors the original design intent, supports long-term ownership, and keeps the door open for future service without the friction of incompatible parts or unexpected fit issues. For many drivers, that clarity alone justifies the investment, turning the hood from a mere accessory into a trusted backbone of daily performance and enduring value.

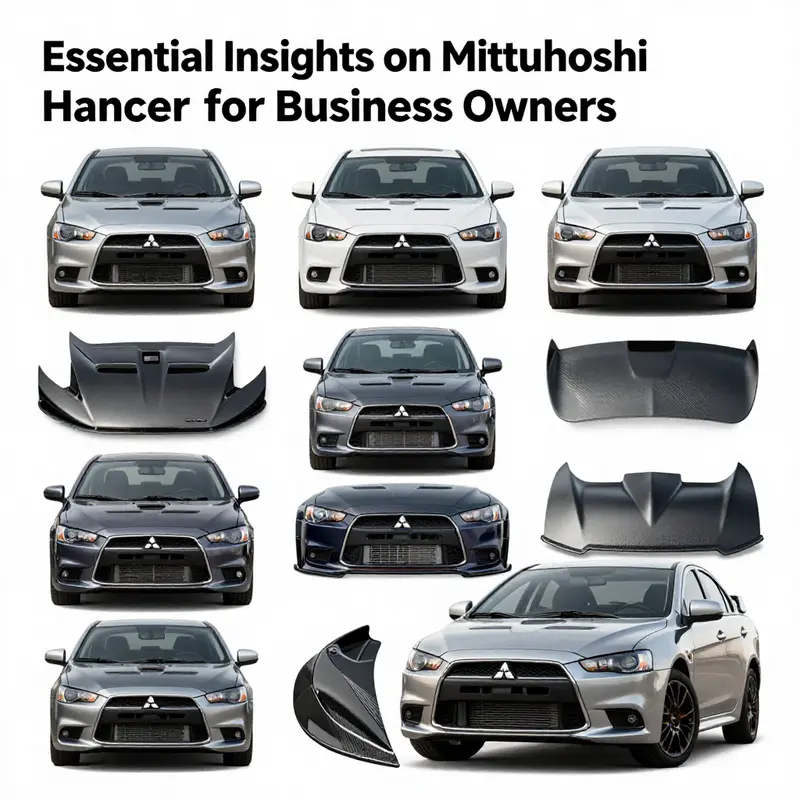

Weighing Speed and Style: Carbon Fiber Hoods for the Mitsubishi Lancer

The hood is more than a cover for the engine bay; it is a statement. In the Mitsubishi Lancer, a car known for its rally heritage and street presence, the hood acts as a bridge between performance potential and daily usability. When you choose a carbon fiber hood for this platform, you’re not merely swapping materials—you’re redefining the way the car feels, sounds, and performs at the edge of what it can do. The Lancer’s front end has always been a focal point—the point where form meets function. A carbon fiber hood tightens that intersection by shaving weight from the front of the car, altering weight distribution and improving the balance between the front axle and the rest of the chassis. This is not just a visual upgrade; it is a tangible shift in dynamics that can be felt in corners, on the straight, and during rapid deceleration into a hairpin. The material’s intrinsic properties—high strength, low weight, and resistance to corrosion—align with the expectations of enthusiasts who push their Lancers toward the track or toward aggressive street tuning. In this context, carbon fiber emerges as a natural ally, offering a path to more precise handling without demanding a complete overhaul of the car’s structure or powertrain. Compatibility is a practical consideration, of course. Carbon fiber hoods are engineered to fit the factory mounting points with a level of precision that mirrors OEM parts, but with a lighter, stiffer core. That combination reduces the risk of flex under high loads, which can be especially important in long bends where the hood’s rigidity matters for aero consistency and hood alignment. It also preserves the essential safety and aerodynamic standards that a high-performance daily driver relies on, ensuring that the hood latch, hinges, and reinforcements work together as a coherent system rather than as disparate components slapped onto a metal shell. Beyond the mechanical fit, the aesthetic impression of a carbon fiber hood is unmistakable. The signature weave, protected by a clear coat, communicates a motorsport ethos that resonates with enthusiasts who want their Lancer to look the part when parked or tearing down a back road. The visual impact is not merely about shine; it’s about the way the eye reads light across the hood’s surface, revealing a texture that hints at the engineering underneath. Yet the choice of a carbon fiber hood is not a unilateral decision. It sits in a spectrum of options ranging from OEM replacement steel hoods to full aftermarket cooling variants. Each choice presents its own mix of trade-offs, and the decision should be framed by a driver’s goals: whether the priority is factory warranty and a stock look, or a weight-focused performance edge that doubles as a track-ready upgrade. In this spectrum, carbon fiber hoods offer the most compelling balance for many Lancer owners who seek measurable performance gains without departing entirely from the car’s original design language. The weight reduction, for instance, is not just a number on a spec sheet. Lighter front-end mass translates into improved acceleration and more agile steering response, especially when you consider the momentum shift that happens as the car exits corners and the front tire load shifts toward the outside. On a track, where every kilogram counts and the car spends time in high-velocity states with significant brake demands, the small gains from a lighter hood accumulate into meaningful improvements in braking efficiency and corner entry performance. The weight reduction also contributes to better overall handling and stability. Because the hood is part of the front-end geometry, removing even a modest amount of weight from that region can help redistribute mass toward the vehicle’s center of gravity. The result is a more composed chassis attitude under hard cornering, with less pitch and body roll, which in turn enhances driver confidence. In practice, the cooling aspect of carbon fiber hoods often takes center stage for performance-minded drivers. Many carbon fiber designs incorporate vents strategically positioned to promote heat extraction from the engine bay. During sustained high-load driving—such as track sessions or spirited mountain runs—engine temperatures can climb quickly, and effective venting becomes a critical factor in maintaining power delivery and turbo response. The vented sections not only help temperature management but can reduce the need for aftermarket cooling ducts or extra front-end openings that might disrupt the car’s aerodynamics. The engineering intent is to balance air extraction with air intake. Too many or poorly placed vents can compromise rigidity or disturb airflow; a well-designed carbon fiber hood maintains structural integrity while enabling adequate cooling airflow. The interplay between vent design and weight savings adds to the complexity of the choice, but it is precisely this complexity that makes carbon fiber hoods attractive to the dedicated enthusiast. The aesthetic and functional advantages dovetail with a sense of ownership that goes beyond bolt-on improvements. A carbon fiber hood is as much a statement about commitment to a higher standard of build quality as it is about performance. Owners often note how the hood’s presence aligns with other upgrades—wider tires, refined suspension, or a refined braking package—to create a cohesive platform that feels more purpose-built than stock. It becomes part of a narrative of progress, a signal that the car’s driver is willing to invest in refining the underlying physics of speed rather than merely chasing numbers in a brochure. Alongside these benefits, there are practical challenges that deserve careful consideration. Cost is one of the most immediate and persistent. Carbon fiber remains a premium material, and the price reflects not only the raw materials but the manufacturing process, layup quality, and protective coatings that preserve the weave’s appearance over years of sun exposure and road use. For some, the premium is well worth the payoff in weight and rigidity; for others, it remains a barrier that pushes them toward lighter steel alternatives or fiberglass composites. Repair can also be more complex and costly compared to a steel hood. Damaged carbon fiber panels often require specialized repair techniques, and in some cases they may need to be replaced rather than repaired, given the risks to stiffness and surface finish. For this reason, drivers who frequently navigate rough roads or off-road routes may weigh the long-term durability against the initial savings and weight benefits. Installation is another practical factor. While many carbon fiber hoods are designed for direct fit, the surrounding hardware and alignment can demand careful attention. Some setups may call for upgraded hood pins or additional safety hardware to comply with track-day or high-speed requirements. Misalignment can lead to poor seal against the engine bay, potential moisture intrusion, or noise, which detracts from the driving experience. Maintenance is not negligible either. The glossy clear coat that protects the weave needs regular care to fend off micro-scratches, UV damage, and oxidation. Cleaning routines should avoid abrasive cleaners that can dull the finish. Routine waxing or sealing helps preserve the sheen and guard against yellowing that can creep into clear coats with repeated sun exposure. Beyond the material and maintenance considerations lies the important question of long-term ownership. A carbon fiber hood has a distinct lifecycle that may involve periodic inspections of the frame, hinges, and latch system. While these components are designed to be robust, the lower mass of the hood means the mounting points can become more critical to overall performance under aggressive driving. In this sense, the decision to adopt a carbon fiber hood is not simply about the current season’s performance; it is about anticipating how the car will behave after hundreds of laps, thousands of miles, or countless road trips. For the Lancer, the appeal of carbon fiber hinges on compatibility with the car’s broader upgrade path. The hood should not work in isolation; it should feel like a natural extension of the vehicle’s chassis and power delivery. Drivers who see their Lancer as a project vehicle—where track days, weekend spirited driving, and long-range road trips share equal importance—often find that carbon fiber hoods fit the bill. They provide a measurable weight reduction, a clear performance signal, and a visual cue of commitment that resonates with the car’s rally-inspired lineage. While some may fear that carbon fiber is fragile or overly delicate, the material’s real-world durability is a function of design and execution. A well-made carbon fiber hood, with properly engineered layups, resin systems, and protective coatings, can stand up to the same general wear and tear as a steel hood, while delivering the additional advantages of weight savings and improved cooling. It is also worth noting the broader context of hood choices in the Lancer community. OEM replacement hoods, carbon fiber alternatives, and aftermarket cooling hoods each serve different intents. An OEM replacement hood prioritizes fit and factory compatibility, often at the expense of weight savings. Carbon fiber hoods, by contrast, emphasize performance and aesthetic impact, with a strong emphasis on arching toward the track-ready end of the spectrum. Aftermarket cooling hoods may push further, offering large vents and tailored airflow paths to maximize engine bay temperatures under extreme conditions. For the serious track enthusiast, the choice may come down to a balance among weight, ventilation, and the practicality of daily use. In this regard, the carbon fiber hood is a compelling choice for those who value a track-oriented mindset without sacrificing street manners. The decision to pursue such an upgrade can be reinforced by exploring real-world examples of how similar builds have performed under demanding conditions. A practical approach is to study the hood’s effect on front-end weight distribution and how that interacts with the suspension geometry, tire selection, and overall aerodynamics. When the car is tuned with a balanced suspension, appropriate tires, and a carefully designed braking system, the carbon fiber hood serves as a multiplier of the investment, enhancing the perceived and measured performance gains. The pursuit of performance is often accompanied by a sense of responsibility. Carbon fiber materials carry an environmental footprint associated with manufacturing and resin systems. Savvy buyers look for sources that demonstrate quality control, certifications, and responsible handling of the raw materials. They also seek out options that provide clear integration with existing vehicle systems, ensuring that the upgrade presents no hidden electrical or structural conflicts. This mindfulness helps preserve reliability while enjoying the visible and tangible benefits of a lighter front end. For those who want to explore further, one practical route is to review options that emphasize both fitment and features. A carbon fiber hood with venting can be understood as a tangible step toward improved thermal management, especially for engines that operate near the edge of their thermal envelope during sustained performance driving. The hood’s architecture—its core material, layup pattern, and weave protection—contributes to a predictable and repeatable performance profile. While the upfront costs are higher than steel, many owners justify the investment through increased driving enjoyment, enhanced aerodynamics, and a stronger visual identity. In moving toward a final decision, it is important to weigh the hood’s potential benefits against daily needs. If you frequently drive in areas with coastal humidity or winter weather, the corrosion resistance of carbon fiber is a practical advantage. If you are more focused on pure reduction of front-end weight for track days, the aerodynamic and cooling capabilities can offer meaningful gains in corner speed and throttle response. The chapter’s research synthesis suggests that the optimum choice depends on your priorities: weight savings and aesthetics, or ultimate cost efficiency and ease of maintenance. The Lancer’s history as a performance platform invites a thoughtful approach to upgrades that honors the car’s engineering heritage while embracing modern materials science. When done with care, a carbon fiber hood can be more than a component—it becomes part of a wider system of performance upgrades that work together to improve pace, balance, and confidence behind the wheel. For readers who want to see a concrete example of what this upgrade looks like in practice, consider exploring resources that focus on carbon fiber construction, venting effectiveness, and fitment considerations. The goal is not to chase a one-size-fits-all solution but to find a hood that aligns with your driving style, climate, and maintenance expectations. This approach will help you avoid common misalignments between appearance and performance, ensuring that the hood upgrade complements the vehicle’s powertrain, braking, and suspension without compromising reliability. In the end, carbon fiber hoods for the Mitsubishi Lancer offer a compelling blend of weight reduction, thermal management, and visual appeal. They present a thoughtful, performance-oriented path for owners who want more precise handling and a more aggressive stance, while still keeping daily usability in view. For some, the investment is a natural extension of a broader program of enhancements; for others, it’s a singular, satisfying upgrade that signals intent every time the car leaves the garage. The decision lies in balancing the thrill of marginal gains with the practical realities of ownership, but the benefits—when executed with quality materials and proper installation—make the carbon fiber hood a meaningful addition to the Lancer’s ongoing story. External resource reference: https://www.alibaba.com/product-detail/Wholesale-Lancer-Carbon-Fiber-Hood-Enhanced_1600854927143.html

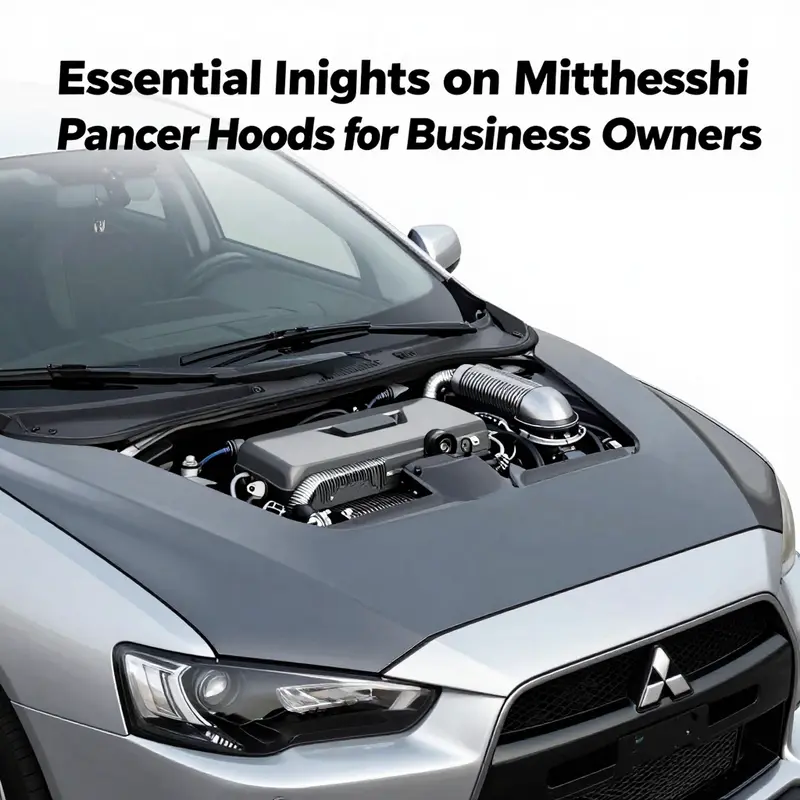

Lancer Hoods in Motion: Weight, Airflow, and the Upgrade Path

The Mitsubishi Lancer, especially in its Evolution iterations, invites a conversation about balance—between weight and rigidity, cooling and aerodynamics, and the visual message of performance. The hood is more than a cover; it sets front-end weight distribution, affects airflow into the radiator, and signals intent from the curb. Choices range from OEM replacement panels to carbon fiber and other aftermarket options that redefine the engine bay and the car’s relationship with the road. The spectrum runs from factory symmetry to carbon fiber and beyond, with each path offering distinct trade-offs in fit, price, and maintenance. The modern hood, then, is a practical statement of how you want the car to move through space and how much you are willing to invest in that motion.

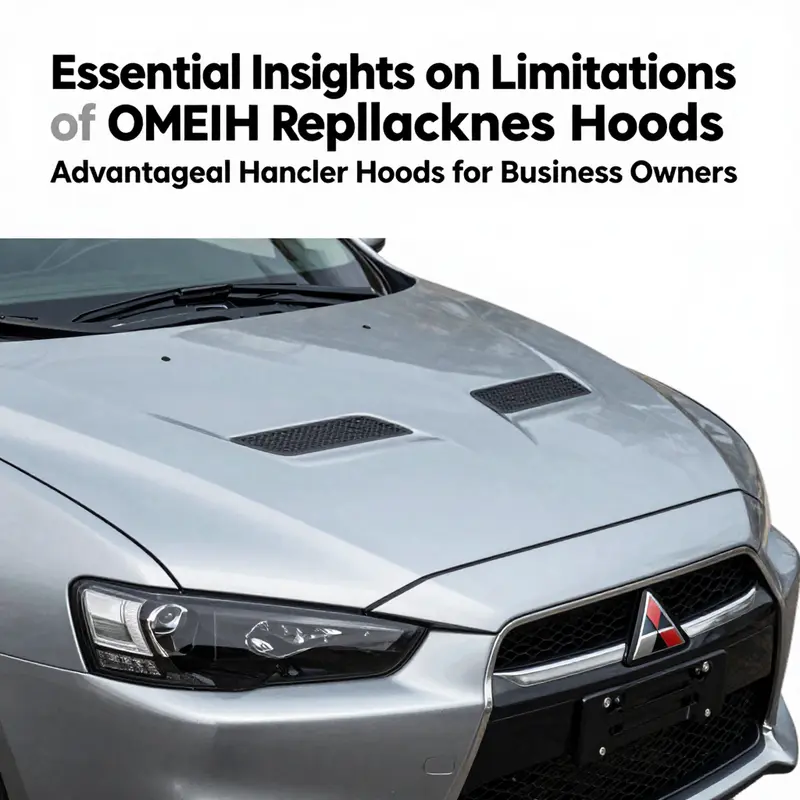

The OEM replacement hood remains the most conservative option. It preserves factory fitment at the hinges and latch, keeps the original safety and aerodynamic characteristics, and often provides a paint-matched finish that flows with the vehicle’s lines. For many owners, this path preserves warranty coverage and minimizes the risk of misalignment. Yet it also tends to use steel or steel-rich alloys that can be heavier, and the performance gains from simply replacing the hood are modest. Surface wear and paint chips are still a consideration in rough climates, but the stock appearance is often the cleanest and most dependable choice.

Carbon fiber hoods represent the pinnacle of performance-focused upgrades. Carbon fiber delivers significant weight savings, improves front-end balance, and can enhance engine bay cooling when vents and heat extractors are thoughtfully integrated. A carbon hood can reduce mass at the front of the car, sharpening throttle response and steering feel while reducing the moment of inertia. Practical gains are most noticeable during track sessions or spirited driving, where every gram and airfoil matters. Corrosion resistance and modern finish options are appealing in coastal or winter climates, though carbon fiber comes with a higher upfront price and potentially more involved maintenance or repair if the panel is damaged. Repairing carbon is not the same as repairing steel; it may require specialized materials and processes.

Alloy and plastic hoods offer a middle ground. They can cut weight compared with OEM steel and still accept custom finishes, with or without integrated venting. Alloy hoods provide a durable option that keeps a factory-like feel, while plastic variants push weight further downward but may demand reinforcement in high-stress driving environments. Many aftermarket designs in this category add functional features such as venting or airflow ducts that actively assist cooling and intake temperature management under load. These features are not merely cosmetic; they contribute to more consistent performance when the engine is under stress.

Beyond the hood itself, some enthusiasts opt for full-body aero kits that reimagine the entire front end. These packages aim to reduce lift, improve downforce, and create a cohesive, rally-inspired silhouette. Front extensions and redesigned bumper elements can enhance stability at speed, but they also heighten installation complexity, impact curb clearance, and increase maintenance when components are more integrated than a single hood.

The practical decision process is also climate- and use-driven. Carbon fiber’s corrosion resistance is appealing in salty or wet climates, while OEM replacements can be the simplest route for drivers who value reliability and ease of service. Track or rally-focused users may prioritize the gains from dedicated venting and heat management, accepting the higher cost and potential fragility that comes with carbon or advanced alloys. Aesthetics play a major role too: the weave of carbon fiber or the clean lines of a paint-matched hood can define the car’s overall stance and how it is perceived on the street or at the track.

Installation considerations matter as well. Hood swaps often require latch recalibration, hinge alignment, and sometimes adjustments to ensure correct edge gaps. Weight changes can subtly alter ride height and panel fit, so test-fitting and careful measurement are prudent steps before driving the car. The finish choice—factory-look paint, bold color, or raw carbon—must be planned with surface preparation and protective layering to prevent premature chipping.

Ultimately, the hood should align with your goals, budget, and willingness to engage with the maintenance that high-performance components demand. For some, the upgrade begins with the hood alone; for others, it is the first step in a broader evolution toward lighter weight, cooler engine bays, and a front end that communicates readiness to perform. If you want to explore carbon options that align with these goals, consider listings that emphasize complete carbon fiber bonnets designed for the Lancer Evo X, and look for integrations that blend with the car’s geometry while offering venting for sustained performance. For practical context and product options, external guides and listings can provide a helpful overview, such as cylinder-specific discussions on hood implementations in performance forums and official product galleries. The choice, ultimately, is about how you want your Lancer to move: light and fast, or composed and reliable, with a front end that mirrors your driving philosophy.

Final thoughts

Ultimately, selecting the right hood for a Mitsubishi Lancer is more than just an aesthetic upgrade; it represents a strategic decision that can enhance vehicle performance and customer satisfaction. Understanding the strengths and weaknesses of OEM, carbon fiber, and aftermarket hoods allows business owners to cater to diverse needs, whether enhancing efficiency, preserving vehicle aesthetics, or maximally utilizing performance options. Profound knowledge of these components ultimately empowers you to make informed decisions that not only elevate your offerings but also foster customer trust and brand credibility.