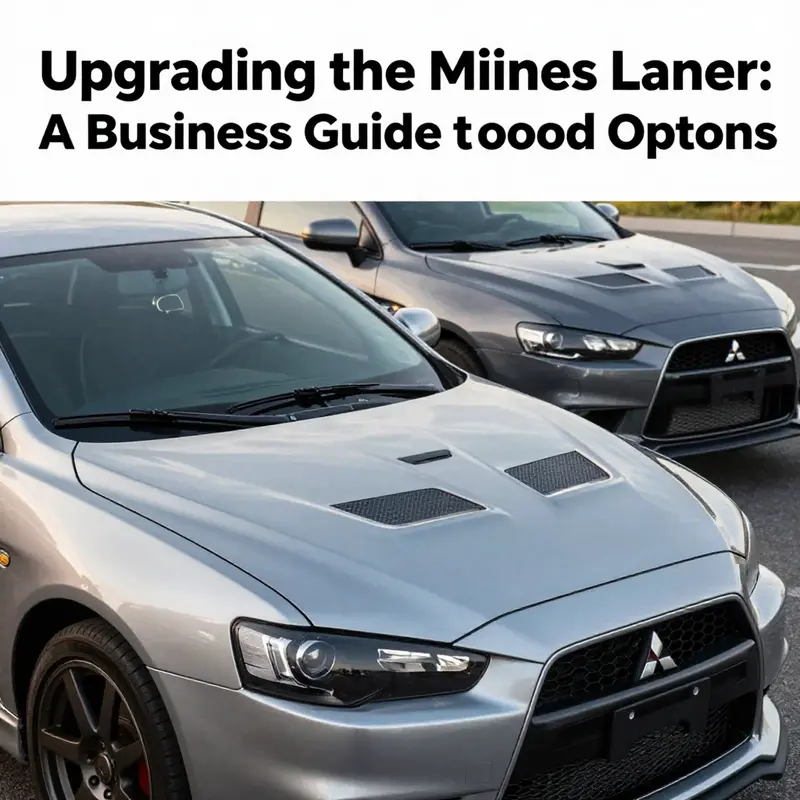

The hood of a Mitsubishi Lancer serves as a crucial exterior component that not only protects the engine bay but also enhances the vehicle’s aesthetic and aerodynamic profile. For business owners in the automotive industry, understanding the various options available for Lancer hoods can lead to better product offerings and improved customer satisfaction. From OEM replacements ensuring quality and compatibility to lightweight aftermarket hoods that enhance performance, each type plays a distinct role. Enthusiasts particularly value performance-enhanced hoods that meet the demands of racing and track usage, showcasing the vehicle’s potential. This article delves into OEM replacement hoods, aftermarket lightweight options, performance-enhanced variants for Evo models, and key considerations for businesses looking to cater to Mitsubishi Lancer customers effectively.

Factory-Fit Choices: Navigating OEM Replacement Hoods for Your Mitsubishi Lancer

OEM replacement hoods deserve close attention when maintaining or restoring a Mitsubishi Lancer. They restore the car’s original silhouette, preserve factory crash performance, and simplify installation. Choosing an OEM hood begins with understanding what the factory offered, and why those options still matter. The term OEM signals a part built to the vehicle maker’s original specifications. For a Lancer, that usually means a hood that lines up perfectly with fenders and bumpers, accepts all original hardware, and keeps the car within expected safety and aerodynamic tolerances.

Most OEM hoods are steel. Steel remains the default because it balances cost, strength, and ease of repair. It resists deformation under moderate impacts, and it can be hammered back into shape or welded when needed. The downside is weight: a stamped steel hood adds mass up front, which affects handling and fuel economy compared with lighter alternatives. Steel also needs protection against corrosion, so proper paint and undercoating are essential for longevity. For owners restoring older Lancers, confirm the hood’s coating condition and look for hidden rust near the hinge pockets and along the underside seams.

Aluminum is the other established factory-grade option. It reduces weight while retaining structural integrity. An aluminum hood typically improves front-end balance and may slightly enhance acceleration and braking feel. It resists rust, though it can corrode galvanically if improperly mated to steel components. Repair techniques differ from steel; aluminum requires specialized welding and filler materials. For drivers who plan to keep a Lancer long-term, an aluminum OEM hood can be a sensible upgrade when offered as a factory option.

On higher-performance Lancer variants, like certain performance models, factory-grade composite hoods exist. These are molded from advanced materials and often come with integrated vents or specific thermal qualities. Factory composites deliver a distinct look and weight advantage. They also retain engineered fit points and mounting options. The trade-off is cost, and sometimes fragility to localized impacts. If you plan daily driving in mixed conditions, consider how a composite hood will stand up to road debris, shopping lot dents, and hail.

Fitment is the key advantage of an OEM hood. Factory pieces use precise mounting locations and consistent geometry. That means the hood latch lines up with the striker, the hood rest pads contact where expected, and the seam gaps match factory tolerances. Good fit reduces wind noise, prevents water ingress, and keeps the air management around the engine bay predictable. When comparing options, measure hood-to-fender gaps and check the hinge mounting holes. An OEM hood should slide into place with minimal adjustment.

Finish quality on an OEM hood is usually high. Paint adhesion, primer application, and corrosion protection follow manufacturer processes. That matters for color matching and longevity. Many OEM replacements arrive with primer only, while others come fully painted to the factory shade. If a hood arrives unpainted, plan for professional surface prep and color matching. Modern paint codes ensure a close match, but some older cars show patina or subtle fading. A fresh OEM hood on a sun-faded car can draw attention to color differences. Addressing this requires blending and possibly refinishing adjacent panels.

Interior details also matter. The hood insulator pad, hood latch, and hood bumpers may come attached or need transfer from the original hood. These items contribute to noise suppression and heat management. Insulation reduces engine noise and protects the paint from heat cycling. When ordering a replacement, confirm which parts are included. OEM hoods typically accept factory wiring for washer jets, hood sensors, or under-hood lighting without modification. That integration preserves the vehicle’s electrical integrity.

Corrosion and long-term durability are practical concerns. Steel hoods require sealed seams, proper undercoating, and regular washing to remove road salts. Aluminum is less prone to rust, but it needs careful attention to fastener corrosion and sacrificial anodes where it mates to steel components. For coastal or winter-driven cars, consider additional corrosion prevention measures. Waxing the underside and using seam sealers at weld points can extend service life. When inspecting a used OEM hood, probe around hinge areas and mounting flanges for hidden rust or hairline cracks.

Installation remains straightforward for OEM parts. Alignment tends to be less time-consuming than with some aftermarket panels. Still, attention to detail is necessary. Start by confirming the hood latch and safety catch operate before final torqueing. Adjust hood bumpers so the hood closes without rubbing the fender. Check hood release cable routing for smooth operation. If the hood includes washers or nozzles, ensure plumbing is intact and spray alignment points to prevent overspray on the grille. When in doubt, a professional body shop can align and paint an OEM hood in a day or two.

Cost considerations often drive the choice between OEM and aftermarket hoods. OEM panels usually command a premium over generic replacements. The price reflects fitment accuracy, finish quality, and attached warranty support. For many owners, the extra expense pays off through fewer installation hours and better long-term reliability. However, if weight savings or aggressive styling is the priority, lightweight aftermarket options can justify their higher cost. OEM hoods are the right choice when authenticity or resale value matters most.

Sourcing OEM hoods requires diligence. Verified dealer suppliers follow part-number cross-references to ensure compatibility. Third-party platforms also list genuine panels, often including model years and part codes. When purchasing remotely, confirm the exact model year fitment, trim differences, and whether the hood supports any special features. For example, performance trims sometimes use vented or reinforced hood shells. Order with clear photos and return policies so you can inspect the panel on arrival. Shipping a hood demands proper crating to prevent edge dings and to protect mounting faces.

Warranty and support are part of the OEM package. Dealer-backed components may include limited warranties that cover defects in material and workmanship. That protection can be valuable when dealing with painted surfaces and fitment issues. Keep a record of part numbers and purchase receipts. If a panel arrives damaged, document it immediately. Most reputable vendors will offer replacement or compensation for transit damage when notified promptly.

Choosing between steel, aluminum, and composite OEM hoods comes down to priorities. Steel fits most budgets and simplifies repairs. Aluminum cuts weight and resists rust. Factory composites reduce mass and can add performance value. Think about how you use the car. For daily commuting, steel often makes sense. For spirited driving or track use, consider factory aluminum or composite options where available. If authenticity and resale value are goals, a true OEM hood that matches factory specs is difficult to beat.

Inspection on arrival is non-negotiable. Check the hood for straightness, verify hinge and latch mounting points, and inspect the paint for runs or orange peel. Test-fit the hood before final painting. This step reveals minor alignment needs and prevents costly paint mistakes. Transfer small components like rubber stops and insulation during test-fitting to confirm fit and function.

Small details influence long-term satisfaction. Hood stopper pads affect panel height and reduce vibration. The hood release cable should move freely. Washer nozzles should align with the windshield. If your Lancer originally had a heat shield or hood vent grommets, ensure replacements are present. These small parts preserve the original function and feel of the car.

When OEM is the decision, several practical rules help. Confirm part numbers and compatibility. Prefer shipping options that cradle the hood to avoid damage. Inspect immediately upon delivery and photograph any defects. Ask sellers whether the hood includes internal components or arrives as a bare shell. Finally, plan paint and alignment work together to avoid repeating labor.

OEM replacement hoods offer a reassuring path to restore a Lancer’s form and function. They keep tolerances tight, replacement labor predictable, and the car close to factory performance. For restorations, dealership service, or daily drivers, an OEM hood remains a sound investment. If you want to see a factory-spec Evo X hood listing for reference, review this OEM Evo X hood listing for details and compatibility: 08–15 Lancer Evo X OEM hood (Phantom Black).

For sourcing a variety of genuine replacement hood panels and verifying part numbers, consult verified online listings and parts databases. Start with a comprehensive search of OEM hood panels to compare availability and pricing:

https://www.ebay.com/sch/i.html?_nkw=OEM+Hood+Panels+for+Mitsubishi+Lancer

Featherweights at the Front: Aftermarket Lightweight Hoods for the Mitsubishi Lancer

The Mitsubishi Lancer offers a platform where form and function meet in the front end. When enthusiasts consider performance upgrades, the hood is a natural focal point. Aftermarket lightweight hoods promise quicker responses, sharper handling, and a visual statement that communicates intent before the engine fires. The core appeal is simple: less mass at the front reduces inertia, which helps the suspension and steering respond more readily to driver input. In the Lancer’s balance of weight and rigidity, a lighter hood can improve turn in, help with throttle response, and support more consistent behavior under spirited driving.

Material choices shape the benefits. Aluminum hoods trim weight while offering good stiffness and repairability, and carbon fiber hoods push lightness further at a premium price with greater stiffness. Each material has tradeoffs in durability, heat management, and cost, and buyers should consider climate, usage, and long term ownership when choosing.

Design and fitment are as important as the material. Vented and heat extracting designs can aid cooling during high load driving, while maintaining hood geometry that clears the grille and headlights. A well conceived venting strategy supports engine temps and can contribute to a cohesive front end aesthetic.

Weight distribution matters. Reducing weight in the front end lowers front axle inertia and can sharpen turn in, but it must be balanced against chassis rigidity and latching reliability. Proper installation, with alignment checks and proper fasteners, preserves safety and the intended aero balance.

Maintenance and care follow the same logic. Carbon fiber finishes require attention to resin and clear coat integrity, while aluminum surfaces need corrosion protection and paint durability checks. Regular inspections help preserve the gains from a lighter front end and prevent long term issues.

In practice, choosing between aluminum and carbon fiber comes down to budget and goals. Aluminum offers a practical path to weight reduction with easier living at street or occasional track days. Carbon fiber delivers the most aggressive front end reduction and a race inspired feel for drivers who push the Lancer at the limit.

For readers seeking a broader view, a careful comparison of materials, fitment, and installation considerations can help guide a balanced decision that respects the car’s existing architecture. The payoff is a front end that feels leaner, more responsive, and better aligned with the driver’s intent without compromising daily usability.

That’s the essence of the aftermarket lightweight hood story for the Mitsubishi Lancer—a thoughtful upgrade that harmonizes weight, heat, form, and function to sharpen the driving experience.

Evo-Grade Hoods: Engineering Cooling, Weight Savings, and Aerodynamic Bite for the Mitsubishi Lancer

Performance-driven hood design for Evo models blends function and form in one structural panel. For owners pushing a Lancer into spirited street use, track days, or rally-style events, the hood becomes more than a cover for the engine bay. It is a thermal management tool, a mass-reduction strategy, and a key element of aerodynamic balance. The choices made at this junction—material, venting strategy, and structural execution—directly alter how the car behaves under load, how reliably it sustains power, and how it looks in motion.

A high-performance hood starts with its role in engine cooling. Turbocharged 4G63 engines and other high-output mills generate intense under-hood heat during repeated hard runs. Heat trapped in the bay raises intake and intercooler temperatures, increases the likelihood of heat soak, and saps both power and component life. Vented and ducted hoods relieve that heat by providing direct escape paths for hot air. A well-placed vent above the turbo manifold or intercooler top tank turns the hood into a passive extractor, letting buoyant hot air escape instead of recirculating into intake ducts. This reduces intake air temperature, stabilizes boost behavior, and helps maintain consistent lap times.

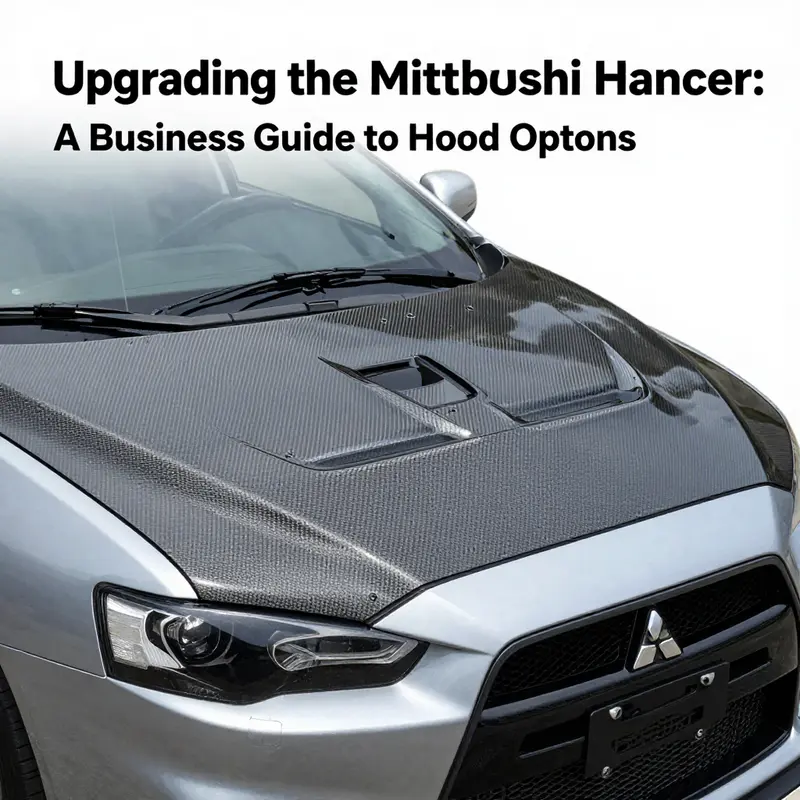

Material selection governs more than weight. Steel OEM hoods provide predictable crash performance and perfect fitment. They are familiar to technicians and align with factory mounting systems. Yet, steel is heavy, and that weight sits at the front axle, affecting steering feel and transient response. Aftermarket alternatives—fiberglass, aluminum, and carbon fiber—each trade off cost, durability, and performance. Fiberglass is cost-effective and repairable, making it a popular choice for enthusiasts on a budget who still want styled vents and aggressive contours. Aluminum offers a middle ground: lower mass than steel, good thermal conductivity, and resistance to rust. Carbon fiber is the high-performance choice for serious builds. Its superior strength-to-weight ratio and rigidity reduce hood flex under aerodynamic loads. High-grade carbon parts made with controlled processes offer precise fitment and durable finishes, but they sit at a premium price point.

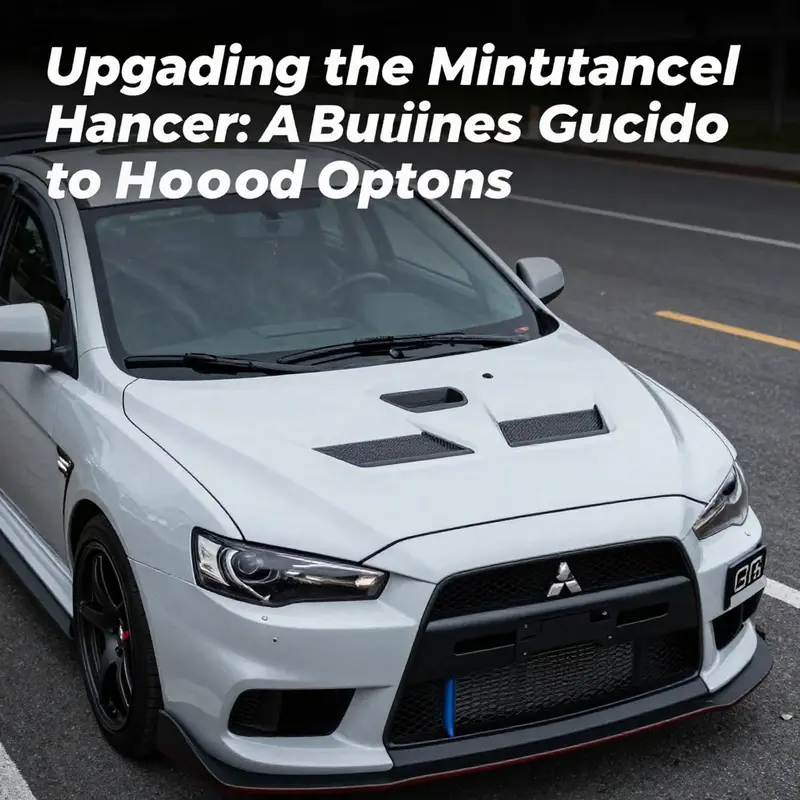

Design details matter as much as material. A functional vent is not merely a hole. The shape, lip, and internal ducting determine how effectively air exits the bay without creating turbulence that upsets the front aerodynamics. Some vents are passive slots that allow hot air to bleed upward naturally. Others are shaped collectors that channel air toward a single exit point, improving extraction efficiency at speed. In rally-inspired designs, raised ridges and scoop geometries integrate with the front bumper and fender lines. These elements manage pressure differentials across the hood, creating slight downforce at the front. That downforce improves tire loading and directional stability at high speed, which is crucial when cornering hard or when driving on loose surfaces.

Manufacturing quality is a hidden performance factor. Skin thickness, weave orientation for carbon fiber, and the use of reinforcements at hinge and latch points determine long-term fitment and durability. Poorly reinforced hoods can warp, creating gaps that let moisture and dust into the engine bay. Dimensional accuracy also impacts secondary systems: washer nozzle placement, sound insulation fit, and hood prop clearance. High-end manufacturers use processes like vacuum infusion or autoclave curing to produce consistent parts with tightly controlled resin-to-fiber ratios. This yields predictable stiffness and good surface finish—qualities that matter when the hood must interface with OEM hinges and latches without additional modification.

Installation often reveals the trade-offs between originality and performance. Swapping an aftermarket hood may require relocating washer nozzles, changing hood prop arrangements, and addressing hood pin locations for safety in motorsport applications. Some hoods come with pre-cut vents and reinforcement plates, simplifying installation. Others require trimming or reinforcement kits to align with factory mounting points. When planning a swap, consider the hood’s interaction with other exterior elements. Vented hoods can expel water and debris into the engine bay. Proper ducting, deflectors, and splash guards mitigate this. Also, a lighter hood may alter the vehicle’s front ride height and balance, suggesting a need to recalibrate suspension settings or corner weights for optimal handling.

Aerodynamics are often the least visible but most impactful aspect of a performance hood. The hood is a large, flat surface sitting in the vehicle’s high-pressure zone. Altering its shape changes airflow over the windshield, roof, and rear wing, thus shifting the car’s aerodynamic center. Well-executed vents reduce pressure build-up in the engine bay. That reduction translates into less lift at the front axle. When combined with a front splitter or lip, the hood’s vents help maintain consistent downforce distribution, keeping the car stable under braking and through fast sweepers. Conversely, poorly designed vents can create buffeting or direct turbulent air toward aerodynamic devices, decreasing their effectiveness.

Durability and maintenance are practical considerations for daily-driven or mixed-use vehicles. Fiberglass can chip or crack from repeated stone impacts on public roads, while carbon fiber resists deformation but can suffer glossy clearcoat damage. Aluminum hoods are resilient to small impacts but may dent more easily than composites. Surface protection strategies—ceramic coatings, reinforced clearcoats, and stone guards—extend component life. Insulation is another practical factor. Many performance hoods omit factory sound-deadening pads to save weight. This increases perceived engine noise inside the cabin. For some owners, the added soundtrack is desirable. For others, adding lightweight acoustic inserts provides a compromise between comfort and weight.

Choosing the correct hood for a given Evolution variant is about matching goals to characteristics. Track-focused builds benefit most from high-quality carbon fiber hoods with well-tuned venting and structural reinforcement. These hoods reduce mass and aid cooling during repeated high-temperature cycles. Rally or gravel setups should prioritize robust vent shapes and protective coatings, while ensuring vents do not allow excessive water ingress. Owners seeking a mix of appearance and function may find aluminum hoods with subtle venting the most practical choice. For those prioritizing originality, OEM replacements preserve factory crash characteristics and maintain resale value, while still allowing for targeted venting kits if needed.

Fitment precision is non-negotiable for cars that see competition. If the hood does not close smoothly or sits unevenly relative to the fender and bumper, aerodynamic inefficiency and increased drag will follow. In racing classes with strict tech inspections, hood modifications must maintain safe latch engagement and meet required tethering standards. Hood pins are a common solution for securing lightweight aftermarket hoods in motorsport, but they change the hood release dynamics and may void insurance or warranty in some cases. Modern approaches use reinforced latch assemblies that preserve a nearly stock closure feel, while providing the required safety for high-speed running.

Aesthetic integration completes the package. The hood is a focal point of the car’s front view. Aggressive vents, pronounced channels, and exposed carbon weave convey purpose. Yet, visual aggressiveness should be matched to complementary elements: fender vents, front splitter, and rear aero. Cohesion between these parts creates a believable performance narrative. Subtle design choices—matte versus gloss finishes, visible laminate lines, or painted vents—alter perception without changing function. Many builders choose visible carbon as a status symbol, while others prefer color-matched finishes for a stealthy, cohesive look.

Real-world performance gains are measurable but context-dependent. A well-vented carbon hood on a turbocharged Evo can lower intercooler and intake temperatures over a session. That reduction often translates to steadier power delivery and less engine management intervention. Weight savings improve turn-in and reduce inertia in quick direction changes. However, gains are most pronounced when combined with matching upgrades: intercooler efficiency, intake routing, and tuned engine management. The hood is not a silver bullet, but it is a multiplier—when integrated thoughtfully, it amplifies the effectiveness of other upgrades.

Selecting the right hood is an exercise in balancing priorities. Evaluate intended use first: daily driver, weekend track, or competition. Match material to durability needs and budget. Inspect manufacturing methods and reinforcement details. Plan for installation changes and any required adjustments to supporting systems. And finally, consider how the hood will integrate with the car’s overall aerodynamic plan. For owners who want a direct example of high-quality carbon options for later Evo series, a readily available carbon-fiber bonnet designed specifically for Evo X platforms illustrates how fit-focused manufacturing and robust venting converge to create a product that serves both show and function—see this carbon-fiber bonnet option for Evo X for reference.

When these elements come together, the hood ceases to be mere sheet metal. It becomes a precision piece of engineering, shaping airflow, shedding weight, and protecting vital systems. For the Mitsubishi Lancer Evolution family, a performance-enhanced hood is one of the most visible and effective upgrades. It influences cooling, handling, and the car’s persona on the road and track, making it a cornerstone component of any serious build.

Under the Hood: Weighing Weight, Heat, and Style in the Mitsubishi Lancer’s Front End

The hood is one of those front-line components that rarely receives the reverence it deserves, yet it steers the character and performance of a Mitsubishi Lancer more than most exterior panels. It is, in essence, a shield and a statement at once. It protects the engine bay from road debris, glare, and the elements, while also shaping how the car greets air at speed. For a model family that has lingered in the public imagination for decades, the choice of a hood speaks to a broader philosophy: how much weight are you willing to carry in the nose, how seriously do you take cooling at the track, and how far do you want to push the sensorium of style? The decisions around hood selection—whether the aim is to restore factory authenticity, shave kilos, or dial up track-ready cooling—unfold as a dialogue between performance engineering and visual identity. In this conversation, the Lancer’s hood becomes a tuning tool, a statement piece, and a cardinal point for every build narrative that spins around the wheel hubs and the bumper lines.

To begin with, the spectrum of hood options centers on three broad families. There are OEM replacement hoods, which exist to preserve factory geometry and proven fit. Then come aftermarket lightweight hoods, crafted from fiberglass, aluminum, or carbon fiber, which promise noticeably reduced mass at the front end. Finally, performance-enhanced hoods tailored to high-performance variants—especially those within the Evolution lineage—are designed with intensified heat management and reinforced structures to withstand higher intake and exhaust temperatures during aggressive driving. Each path carries its own ethos and tradeoffs, and the right choice depends on how the car is used, the climate, and the budget. The OEM option prioritizes reliability and a seamless, paint-to-panel match. It is the most predictable route for daily drivers who want a trouble-free installation and a front end that behaves like the car left the showroom. The comfort here is the comfort of known fitment and predictable weight, but the tradeoff is typically a heavier component, often with steel construction and less aggressive exterior geometry. The aftermarket lightweight routes, by contrast, lean into performance aspirations. Fiberglass and carbon fiber hoods can shed substantial mass, improving suspension response and steering feel because front-end weight is a critical multiplier of momentum. Aluminum hoods sit in a sweet spot between steel and carbon, offering weight savings with robust resistance to corrosion—a meaningful factor for cars living near salt, humidity, or winter road treatments. Then there are the performance-oriented hoods designed for Evo models, which not only reduce weight but also incorporate heat-dissipating vents and strategically reinforced panels. These offerings acknowledge that cooling efficiency and structural rigidity become binding constraints when drivers push a car toward the limit. The result is a trio of design philosophies that each tell a different story about how a Lancer is meant to perform and how much the owner wants the front end to contribute to the overall package.

Material choices sit at the core of these stories. Carbon fiber logically captures the attention of enthusiasts who chase the ultimate in weight reduction. Its strength-to-weight ratio is unmatched by most other composites, and it excels at both stiffness and heat resistance in the hood’s upper region. The weight savings aren’t just about acceleration; they translate into crisper steering and more responsive front-end feel, especially when the rest of the chassis remains otherwise unchanged. But carbon fiber is not a universal solution. The price premium is real, and the repair landscape for carbon fiber can require specialized techniques beyond the usual dent repair playbook. For a car that might see daily use as well as occasional track sessions, carbon fiber is a high-ticket, high-reward option that aligns with a focused performance goal. Aluminum provides a more economical path to lightening the nose while preserving corrosion resistance, which matters to owners in coastal climates or environments where road salt is a regular feature of winter maintenance. Aluminum hoods strike a balance: they’re lighter than steel, more durable against the elements than steel alone, and generally easier to source and repair than carbon fiber. They are especially appealing to drivers who want that performance edge without stepping into the territory of carbon-fiber fragility and the associated repair complexity. Steel is the baseline, the most budget-conscious option that delivers durability and straightforward repairability. It remains heavier than the other materials but can be perfectly adequate for a daily driver or a project that prioritizes long-term ease of maintenance and cost containment. The choice of material should be a reflection of the driver’s environment, the intended use, and the willingness to navigate the financial and maintenance implications long after the purchase is complete. The science here is not merely about grams saved or a second shaved from a lap time; it is about the congruence of the hood with the rest of the vehicle’s architecture, aero balance, and the mental model the owner has for how the Lancer should behave.

Fitment is the practical hinge on which all these choices turn. The Lancer’s chassis has seen a wide range of years, trims, and performance variants, especially across the Evolution spectrum. A hood that fits perfectly on a certain era Evo may not align with a non-Evo generation, and mismatches in mounting points or radiator clearance can create a cascade of problems—from misaligned gaps to more serious safety concerns at speed. The best approach is to confirm compatibility with the exact model year and trim: 1999 through later generations present different hood profiles and latch mechanisms, and even the hood’s curvature must meet the contours of the fenders and hood lines for a clean, gap-free installation. When shopping, reputable sellers frequently advertise “Guaranteed Fit” or provide precise fitment tables that map to vehicle year and trim. For the discerning buyer, such indicators are a non-negotiable part of the decision process. It would be prudent to ensure that the selected hood aligns with the vehicle’s hood release mechanism, hinge alignment, and the hood’s edge alignment relative to the cowl line. A well-fitting hood does more than improve aesthetics; it preserves the vehicle’s safety envelope by maintaining proper closure against the weather, wind, and debris, and it ensures the hood works harmoniously with the hood shocks and safety latch.

The design language of the hood also communicates intent. A vented or scooped hood immediately signals a focus on cooling and performance. In high-heat, high-load conditions, vented designs can help evacuate hot air from the engine bay, reducing under-hood temperatures and potentially extending the life of intake hoses, intercooler piping, and nearby sensors. The aesthetic payoff is equally important: a hood with vents or a bold contour line can transform the face of the Lancer, giving it a more aggressive presence that aligns with track-oriented builds or sportier trims. Yet this styling comes with considerations. Vent endpoints must be carefully integrated with the car’s cooling system to avoid drawing in debris or influencing the engine’s intake temperatures adversely. A misaligned vent can become a liability, letting dust into the engine bay or creating airflow patterns that destabilize the intended cooling strategy. The ideal hood, in this sense, functions as a precise instrument: it directs air with a purpose, neither obstructing the engine bay nor introducing irregularities in the under-hood environment. For drivers who value the clean, factory-like lines, a non-vented, well-finished hood will deliver a subtle enhancement in both aesthetics and handling without inviting the headaches that sometimes accompany more complex vented designs.

From a usability perspective, installation, maintenance, and care form the scaffolding that supports any choice. A hood swap is not simply dropping one panel onto the car and pinning it in place; it requires attention to mounting points, alignment, paint prep, and often hood alignment adjustments after installation. Depending on the material, care regimens differ. Steel will benefit from rust prevention and periodic resealing, particularly if the hoodline faces salted roads. Aluminum resists corrosion better than steel but can be susceptible to galvanic reactions if in contact with incompatible fasteners or coatings. Carbon fiber, while highly desirable for weight savings, can require special paints and finishes to avoid clearcoat delamination or microcracking under certain temperature cycles. Fiberglass presents its own maintenance profile, with a tendency to be a little less rigid than carbon or aluminum, which can impact long-term fit as heat cycles expand or contract the panel. The practical takeaway is that the best hood is one that remains functional and visually consistent across seasons and miles, not just the one that looks striking in a showroom or on social media. Investing in a hood that comes with proper mounting hardware, weatherproof seal compatibility, and clear instructions for paint and finish maintenance helps ensure that the aesthetic payoff is matched by durability and reliability.

The microcosm of a hood choice, then, becomes a larger narrative about balance. For a driver who wants to restore a classic Lancer or to maintain the original look while improving reliability, OEM replacements can deliver a straightforward, predictable path. For a racer-in-training or a weekend track enthusiast, a lightweight carbon or aluminum hood with venting can offer meaningful gains in turn-in and lateral grip, thanks to the front-end weight reduction and improved air management. For Evo models that live at the edge of performance, a purpose-built, performance-enhanced hood can offer the twin benefits of weight savings and heat management that are essential during extended sessions on a closed course. Regardless of the path chosen, it is essential to keep in view the overall integration of the hood with the rest of the car’s aero profile, chassis balance, and the driver’s long-term maintenance plan. The hood can be a bridge between the engineering discipline of the drivetrain and the expressive language of the car’s exterior, a place where technical aspiration meets street-ready practicality.

For readers curious about the carbon-fiber bonnet avenue specifically, there is a direct example available through a dedicated product page that showcases a brand-new original carbon fiber bonnet hood for a Lancer Evo-X. This option illustrates how a hood can transcend mere component status to become a decisive element of performance intent. The exact choice—whether to pursue carbon fiber, aluminum, steel, or a composite—hinges on how the owner weighs the tradeoffs between weight, rigidity, cost, and the aesthetic resonance they want the Lancer to convey. Not every build demands the full carbon-fiber solution; some owners find the aluminum path satisfies both performance and practicality without the premium price tag. Others seek the factory-like reliability of OEM parts but want minimal modification and straightforward installation. The nuanced conclusion is that there is no single “right” hood for every Lancer; there is a hood that aligns with the driver’s goals, climate, and budget, while preserving the car’s structural integrity and visual identity. The conversation around hoods thus becomes a conversation about longer horizons—about how much weight you’re willing to remove, how aggressively you want to manage heat, and how you want the Lancer to present itself to the world on the road or the racetrack.

As the chapter closes, the road ahead for hood selection on the Mitsubishi Lancer is one of thoughtful stewardship. It is about choosing a path that respects the car’s original intent while enabling a practical evolution toward better cooling, sharper handling, or a more assertive silhouette. The decision is not merely about a single panel; it is about how the hood interacts with every other element—engine layout, bumper geometry, fender lines, and the aerodynamics that govern high-speed stability. It is about acknowledging that every gram saved and every vent opened can ripple through the dynamics of a car that has long lived in the limelight of performance culture. In the end, the hood is a microcosm of car culture itself: a place where engineering constraints meet personal taste, and a well-chosen upgrade can translate into measurable gains in confidence, speed, and presence. The path from stock to statement is a carefully plotted map, and the right hood is the compass that keeps the journey true.

For further reference on hood materials and broader automotive body engineering, see external resource: https://www.caranddriver.com/ (as a general guide to materials and performance considerations in modern cars). And for readers seeking a direct, internal example relevant to the Evo-X hood family, explore the brand-new-original-carbon-fiber-bonnet-hood-for-mitsubishi-lancer-evo-x page to understand how carbon fiber choices translate into real-world fit and finish. This link provides context on how a hood can be integrated with the Evo-X’s front-end geometry, illustrating the alignment of engineering goals with aesthetic ambition. The overall lesson remains consistent: the hood is more than a cover; it is a strategic instrument in the Lancer’s evolving story of speed, handling, and identity, a component whose selection should be grounded in a holistic view of performance, climate, and long-term care, rather than in a single metric or momentary look. The next chapters will continue to unfold this story, linking the hood decision to other critical upgrades that define how a Lancer moves through time and terrain alike.

Final thoughts

Choosing the right hood for a Mitsubishi Lancer is crucial for both aesthetic appeal and functional performance. OEM replacement hoods offer the reliability and authenticity that some customers desire, while aftermarket lightweight options provide enhancements that can optimize vehicle performance. Performance-enhanced options like those for the Lancer Evolution cater to enthusiasts looking to maximize their vehicle’s capabilities on the track. By understanding the variety of hood options available and the specific needs of your clientele, business owners can effectively tailor their inventory to meet the demands of Mitsubishi Lancer owners, ensuring satisfaction and loyalty.