Mitsubishi 3000GT headlights serve as a cornerstone for both aesthetic appeal and functional performance in this celebrated sports car. For business owners, understanding the landscape of replacement options, LED enhancements, and procurement strategies can optimize their offerings to customers passionate about this automotive classic. Each chapter will delve into essential information about available parts, the benefits of modern upgrades, insights on suppliers in key manufacturing regions, and future technological advancements that are shaping the automotive lighting market, ensuring a comprehensive grasp of Mitsubishi 3000GT headlight solutions.

Illuminating the Legend: Replacement Paths and Modern Headlight Upgrades for the Mitsubishi 3000GT

The Mitsubishi 3000GT stands as a benchmark of 1990s performance design, a silhouette that still captivates both collectors and drivers who value a blend of speed, handling, and a distinct, era-defining aesthetic. The headlights on these machines are more than just a functional component; they are a core element of the car’s character. When their original units wear out, crack, or simply refuse to meet modern visibility standards, owners face a crossroads: seek faithful replacements that preserve the car’s classic look, or pursue aftermarket and modernized lighting that can transform night driving without sacrificing the car’s integrity. This chapter traces the terrain of headlight replacement and aftermarket options for the 3000GT, weaving together the practical realities of sourcing, the evolving technology of automotive lighting, and the practical considerations that guide a restoration or upgrade project toward a durable, satisfying result.

In the current landscape, the global market for 3000GT headlight components is shaped by two interlocking forces. first, the demand to maintain authenticity and fitment with the original design, which matters to purists and concours participants. second, the momentum of modern lighting technology, which promises brighter, safer night driving with longer service life and improved efficiency. From a sourcing standpoint, the most active manufacturing ecosystems are concentrated in parts-rich regions where the supply chain for automotive lighting is deeply established. Within this framework, one finds that China functions as a major hub, thanks to its mature industrial clusters, efficient logistics, and a broad spectrum of capabilities—ranging from CNC machining and die casting to precision assembly and quality control. These strengths translate into a robust supply of both fresh assemblies and remanufactured units, offered at price points that are competitive with global markets while maintaining reliable delivery performance. For anyone pursuing a restoration or a small-scale aftermarket service, this combination of capability and efficiency makes the Chinese supply chain an essential consideration when planning long-term sourcing strategies.

The practical implications of this manufacturing landscape become clear when one looks at the kinds of options that are typically available for the 3000GT’s headlight assembly. For a purist, the most straightforward route is to restore the car with a factory-style unit that mirrors the original geometry and glass, preserving the vehicle’s classic look. When factory replacements align with the original housings and bezels, the fitment is straightforward, and the visual impact remains faithful to the design language of the era. For those who want to project a brighter future onto a vintage vehicle, broader aftermarket options come into play. In many cases, aftermarket headlight assemblies use the same electrical interfaces and mounting points as stock units, but employ modern optics and housings. These include updates to reflector geometry, improved sealing against moisture, and more efficient light sources, all of which contribute to better nighttime visibility while keeping the exterior appearance within the familiar silhouette. It is important, however, to verify fitment against the car’s specific year and model variant, since the 3000GT’s headlight design did evolve across its production span and certain housings are shared across different trims or regional versions.

A further layer of options emerges as lighting technology itself advances. LED retrofits and modern LED assemblies offer a route to brighter, crisper illumination with lower power draw and longer service life. In the context of a classic car, the temptation to install modern LED units must be weighed against issues of beam pattern, color temperature, and compatibility with the vehicle’s original reflectors and lenses. One common approach is to select LED assemblies that are DOT-certified and designed for plug-and-play installation, preserving the car’s OEM mounting points and wiring harness compatibility. This reduces the risk of misalignment or electrical incompatibilities while delivering a marked improvement in nighttime performance. For enthusiasts who enjoy the technical challenge, there are also opportunities to rework the interior optics with modern lens and reflector elements that preserve the exterior profile while optimizing beam distribution. In all cases, attention to sealing, ballast or driver compatibility for LED systems, and thermal management remains critical to long-term reliability in the demanding environment of a headlight assembly.

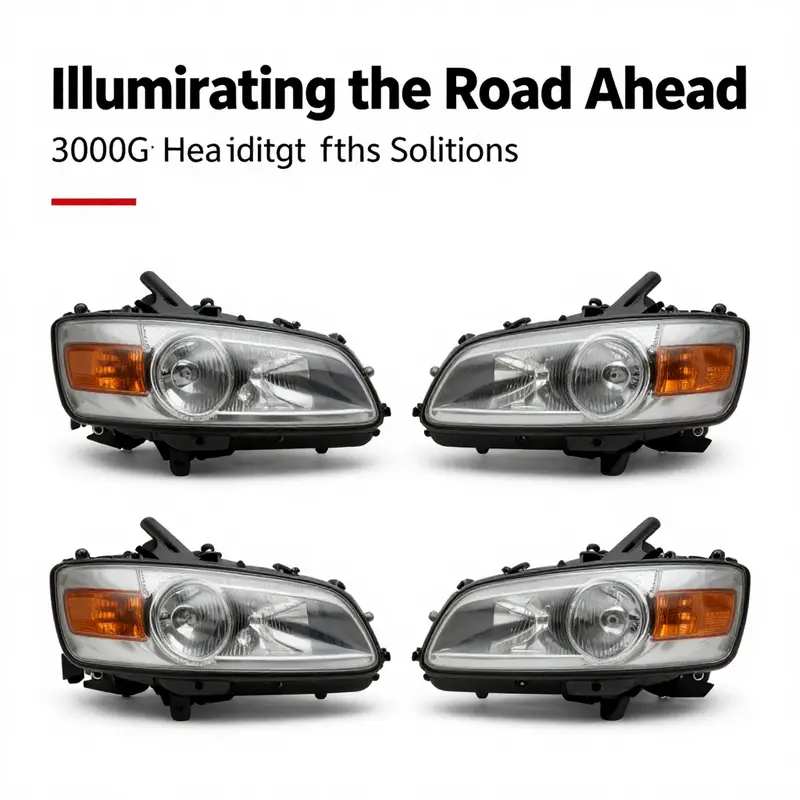

Within this ecosystem, the market also serves the DIY community through accessible platforms that connect restorers with listings offering compatible assemblies. For example, there are ready-made options that align with the 1995–1999 headlight configuration, designed to fit the car’s original housings and mounting geometry. Enthusiasts who prefer a straightforward restoration path can explore these listings to source assemblies that reproduce the factory appearance while delivering improved optics or glass clarity. For those who want direct access to a broader catalog, a widely used parts marketplace provides a spectrum of options, including OEM-equivalent and remanufactured units. The advantage of such platforms lies in the breadth of availability and the potential for more cost-effective solutions, particularly for projects with tighter budgets or longer restoration timelines.

When planning a procurement strategy, buyers often consider a two-track approach: OEM or OEM-equivalent replacements for authentic restoration, and aftermarket or remanufactured units for a more flexible, performance-oriented build. For business-to-business operations, this translates into a capability to source at scale, with attention to supplier reliability, lead times, and the ability to customize. In practice, this means evaluating the supplier’s track record for on-time delivery, consistency in quality across batches, and the capacity to accommodate specific requests, such as preserving the exact lens curvature or ensuring a particular glass clarity. For restoration shops, the ability to standardize parts across multiple vehicles can dramatically reduce inventory complexity and expedite service timelines. For individual restorers, the choice often centers on balancing authenticity, cost, and performance, recognizing that a visually faithful unit can be paired with modern lighting technology that enhances nighttime visibility without altering the character of the car’s front end.

The possibility of integrating more advanced optical technology into a classic 3000GT is a theme that recurs in discussions about headlight upgrades. As lighting technology has evolved, some shops and enthusiasts have begun exploring high-end retrofit concepts that use advanced lens configurations to maximize light delivery, including what some describe as matrix-style LED approaches. While such systems have predominantly appeared on newer models, the underlying idea—precise control over light distribution and the ability to tailor beam patterns to different driving conditions—has clear appeal for the 3000GT as a platform for customization. In practical terms, a retrofit of this sort would typically involve a careful assessment of how the new optics interact with the car’s original reflector geometry, the available space within the headlight housing, and the thermal and electrical demands of the chosen technology. In other words, the classic headlight assembly becomes a bridge between a revered design and contemporary safety standards, a bridge that must be crossed with due regard for the vehicle’s heritage, reliability, and ongoing maintenance needs.

From a sourcing and quality perspective, the modern market for 3000GT headlight components emphasizes a few core practices. First is the importance of verified supplier capabilities. Buyers should seek vendors with demonstrated CNC machining, die-casting proficiency, and rigorous assembly processes. This is not merely about obtaining a part that looks right; it is about ensuring the part’s tolerances, seal integrity, and mounting alignment hold up under real-world use. Second is the value of robust quality assurance and a proven delivery track record. For a shop, high on-time delivery rates and responsive supplier support translate directly into smoother project workflows and fewer delays on critical restoration milestones. Third is the opportunity to pursue customization when needed. For example, a shop might require a slightly different lens tint to suit a particular climate or to achieve a specific aesthetic result, or to adjust the lamp’s internal reflector geometry to optimize a given beam pattern. The Chinese supply chain, with its breadth and depth, makes such customizations more feasible, provided the buyer engages in clear, precise specifications and a trusted quality-control process.

In the broader narrative of sourcing, it helps to ground decisions in real-world references. For readers who want to explore practical pathways for obtaining headlight components, there are curated resources that map the aftermarket landscape, offering guidance on supplier evaluation, pricing, and quality assurance practices. These guides illuminate the key questions to ask a supplier—about material quality, component compatibility with the 3000GT’s unique headlight design, and the level of post-purchase support a buyer can expect. Such knowledge supports confident decision-making, especially for owners who plan to keep their car on the road for many more years and want to ensure that each part they install performs reliably alongside the car’s other aging systems.

For readers who want to see a concrete example of a source early in the journey, the following listing can serve as a practical reference point for the kind of headlight assembly that preserves the car’s original silhouette while offering a modernized touch. The link below points to an internal marketplace listing that corresponds to a headlight option aligned with the 1995–1999 configuration, providing a familiar appearance for restorers seeking authenticity. You can explore it here: 95-99 Mitsubishi 3000GT SL VR4 clear headlights glass. This kind of resource demonstrates how the market has organized itself to support both classic fidelity and practical upgrade opportunities, making the path to a reliable restoration or upgrade less risky and more transparent.

Beyond individual parts, the community around the 3000GT often emphasizes the long-term implications of any upgrade. A headlight change, even when aimed at safety and visibility, interacts with other components: the electrical system, the fuse and relay layout, and the calibration of auxiliary lighting systems, including daytime running lights. A thoughtful approach considers how to balance the gains in illumination with the car’s overall electrical load, ensuring that new headlights do not trigger unwelcome fuse trips or cause heat-related wear in nearby wiring. For owners who maintain their vehicles as daily drivers, the reliability and ease of maintenance become as important as the improvement in beam performance. The best projects reconcile these factors by selecting assemblies designed for straightforward installation, with durable seals and proven performance in the climates where the car is used most often.

As the 3000GT’s legacy continues to inspire new generations of enthusiasts, the headlights stand as a microcosm of the broader automotive hobby: a blend of heritage, craft, and forward-looking technology. The mature aftermarket ecosystem offers a spectrum of paths—faithful restorations, upgraded optics for safety, and even experimental concepts that push the limits of what classic headlights can do. The key to success lies in aligning the choice with the owner’s goals, the car’s use case, and the reliability expectations of a vehicle that has earned its reputation not just for speed, but for enduring presence on the road. The journey from cradle-to-curve of a headlight is not only about light output; it is about preserving a coherent, emotionally resonant connection between driver and machine. The headlight thus becomes more than a safety feature; it becomes a narrative device that keeps the 3000GT’s dramatic identity alive while inviting modern engineering to extend its storytelling into the night.

For researchers and practitioners in restoration shops alike, the market signals an encouraging trend: high-quality, compatible headlight solutions are accessible, and the capacity for customization is growing in ways that respect the car’s original design rather than erasing it. The convergence of authentic fitment options, reliable supply chains, and intelligent lighting technology creates a practical path forward for owners who want both to honor the 3000GT’s past and to ensure its future on the road. The result is a headlight experience that keeps pace with contemporary safety expectations while preserving the vehicle’s distinctive presence. In practical terms, that means meticulous evaluation of each potential upgrade, careful testing for beam pattern and alignment, and a readiness to engage with knowledgeable suppliers who understand the nuances of this iconic machine. The reward is a nighttime driving experience that feels both immediate and faithful—a clarity of vision that allows the 3000GT to live on as a bridge between classic performance and modern reliability.

External resources can provide additional perspective on sourcing and quality assurance practices for aftermarket parts in this market. For a broader view of how suppliers are evaluating quality, pricing, and sourcing in the China-based aftermarket, readers may consult industry analyses such as the following overview: https://www.autoblog.com/2026/01/29/mitsubishi-3000gt-aftermarket-parts-supplier-guide-china-sourcing-quality-pricing/.

Lighting the Night: Practical LED Upgrades for Mitsubishi 3000GT Headlights

Lighting the Night: Practical LED Upgrades for Mitsubishi 3000GT Headlights

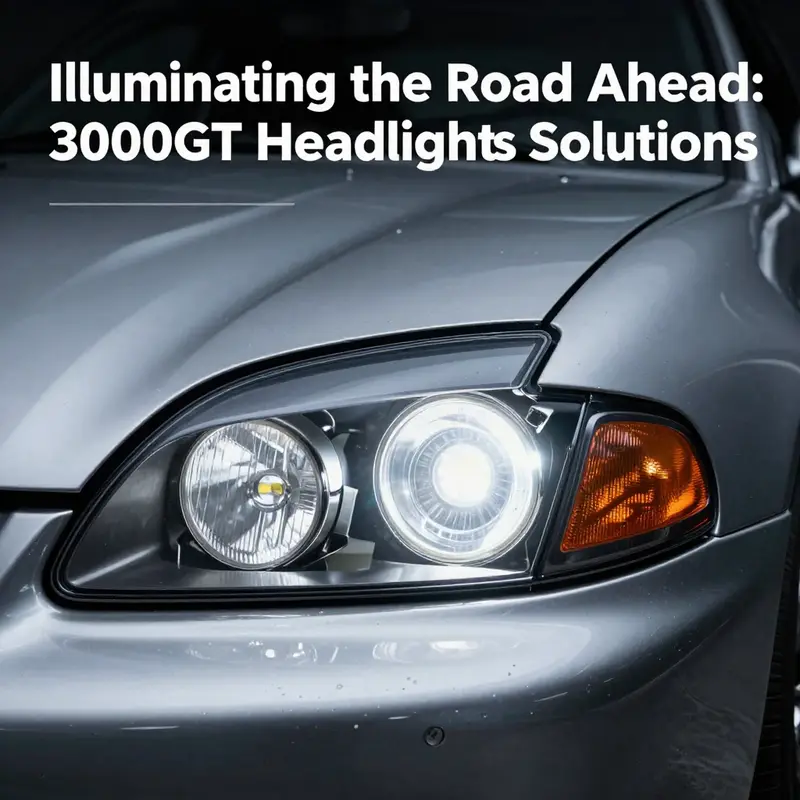

The Mitsubishi 3000GT’s headlight systems reflect its era: stylish, mechanical, and ultimately limited by halogen technology. Pop-up or fixed housings and classic lamp assemblies were designed for a different standard of nighttime driving. Today’s drivers demand brighter, whiter light, longer service life, and consistent beam control. Upgrading to modern LED solutions is one of the most effective ways to bring the 3000GT’s lighting into alignment with contemporary safety and usability expectations without sacrificing the car’s character.

LED upgrades for the 3000GT are not merely about swapping bulbs. They involve evaluating light output, beam pattern, heat management, electrical compatibility, and physical fitment inside the unique housings of this model. Many owners pursue LED kits that use common headlight sockets—often the 9005/9006 combination for high and low beams—or a direct-fit square 4×6 replacement where applicable. These kits can raise luminous output dramatically, often quoted in the tens of thousands of lumens for the set, and provide a cool white color around 6000K. The result is a crisper, more readable roadway and better peripheral illumination during fast driving.

Beyond raw brightness, light distribution matters most. A powerful LED that throws light haphazardly can create glare and reduce safety. Quality LED upgrades are engineered with precise optics and beam-cutoff designs to ensure the light projects where it is needed. That keeps the light on the road, not in the eyes of oncoming drivers. Certification and compliance are important indicators of a kit’s suitability; products tested for DOT or SAE standards give a stronger assurance of legal and functional performance.

Heat management is the technical heart of LED retrofits. Halogen lamps shed heat behind the filament, but LEDs concentrate heat at the diode and base. Effective upgrades incorporate robust heat-sinking, often combined with silent fans or passive fin arrays. For the 3000GT, fitment can be tricky: pop-up housings and sealed reflectors offer limited space. Choose LED designs with compact thermal solutions to avoid interference with pop-up mechanisms or risk to seals. Passive designs reduce moving parts and the risk of fan failure, while active cooling may be necessary for the highest-output units. Consider the balance between cooling efficiency and space constraints during selection.

Electrical compatibility is another common hurdle. Modern LED drivers often require stable current control and may draw different signatures than halogen bulbs. A simple swap can trigger dashboard warnings or flickering without proper resistors or CANbus-compatible drivers. Reliable kits provide built-in circuitry to mimic halogen draw, prevent error codes, and protect against voltage spikes. For older vehicles like the 3000GT, which lack modern ECU lamp diagnostics, these protections still help prevent flicker and thermal mishaps.

Physical mounting and beam alignment cannot be overlooked. Proper aiming defines the safety benefits of a brighter lamp. Even with a perfect LED beam pattern, misalignment causes glare or poor road coverage. After installation, aim the headlights using a dedicated wall or aiming tool, and verify beam cutoff height with a measured tape method. Conduct a night test on a quiet road to fine tune lateral and vertical alignment. Also ensure that the LED assembly does not obstruct or overload the pop-up mechanism. Lightweight retrofit assemblies tend to preserve the original motor performance.

Sealing and moisture protection are critical long-term concerns. Original headlight housings often suffer from aged seals or micro-cracks. Installing a modern LED headlight without addressing these issues invites condensation and premature failure. Inspect gaskets, lens clarity, and housing integrity. When needed, replace or refurbish lens glass or housings before upgrading. There are OEM-style replacement glass lenses for 1995–1999 models that restore clarity and sealing. Choosing the right replacement or refurbishment extends the life of the new lighting system and keeps beam performance stable.

Sourcing and supplier considerations matter for reliability. Whether you buy a ready-made kit or commission a custom retrofit, evaluate manufacturers on delivery stability, quality control, and technical support. Many capable suppliers operate out of industrial regions with advanced manufacturing capabilities, including precision machining and assembly. When sourcing internationally, use B2B platforms to vet partners and review on-time delivery metrics. Prioritize vendors with clear testing reports, responsiveness to technical questions, and options for small-batch customization.

A practical installation plan reduces surprises. Start by verifying bulb sizes and the physical space within your housing. If replacing sealed beam or square lenses, confirm the available aftermarket 4×6 LED drop-in assemblies fit your model year. Next, test-fit heat sinks and drivers to ensure nothing interferes with moving parts. Route wiring away from sharp edges and heat sources. Use dielectric grease on connectors to prevent corrosion. If the kit requires resistors or relays, mount them in ventilated areas. Finally, re-check the headlight motor function after installation to confirm the added components don’t compromise the pop-up mechanism.

For enthusiasts pursuing higher-end customization, advanced optics offer dramatic improvements. Matrix-style LED systems and laser-assisted lens modules provide adaptive beam shaping and exceptional range. These systems are more complex and often require custom housings or retrofitted projector shells. A professional installer can adapt these modules while preserving the vehicle’s external appearance. Expect a larger investment and careful planning, but the potential for superior visibility, adaptive high beams, and reduced glare is real.

Maintenance and long-term care are straightforward but essential. Keep lenses clean and polish them periodically to avoid light scatter. Inspect seals annually and re-seal if necessary. Monitor cooling fans and replace if audible noise or reduced airflow appears. Track lumen output over time. High-quality LEDs decline slowly, but early detection of degradation helps avoid nighttime visibility loss. Consider purchasing kits with explicit thermal protection and warranty coverage for peace of mind.

Legal and safety considerations should guide every decision. Different regions apply varying laws to headlight color, beam intensity, and replacement methods. Always confirm local regulations before selecting a kit. Even within legality, prioritize beam control and cutoff to ensure you are not unintentionally creating hazards. Good upgrades reduce driver fatigue, improve reaction time, and enhance corner illumination. Those benefits justify a careful selection and professional installation when in doubt.

Cost versus benefit is a pragmatic conversation. LED upgrades range from modest, affordable kits to high-end, bespoke projector systems. Budget options can deliver a meaningful improvement in brightness and color without complex modifications. Premium solutions provide superior optics, adaptive features, and refined thermal management. Choose based on driving habits: frequent night driving, long highway runs, and adverse weather conditions favor higher-spec systems. For occasional night use, a mid-range LED with proper beam control typically meets needs at a reasonable price.

Finally, integration with restomod or restoration projects deserves a brief note. When restoring a 3000GT, the headlight choice affects aesthetic and functional outcomes. Period-correct restorations may prefer OEM appearance with upgraded internals. Performance-focused builds often embrace modern optics discreetly tucked into classic housings. Either path benefits from attention to sealing, alignment, and electrical harmony. When parts of the lighting assembly are replaced, consider matching upgrades for fog lights and auxiliary driving lights to maintain balanced color and intensity across the vehicle’s front end.

For owners ready to act, begin with a careful assessment of your car’s housing condition, wiring health, and driving needs. Select kits with clear beam-cutoff engineering, proven thermal solutions, and driver circuitry designed for older vehicles. If you plan significant modifications, collaborate with an experienced installer. Properly executed, an LED upgrade transforms the 3000GT’s nighttime performance. It preserves the car’s iconic look while delivering a safer, more confident driving experience after sunset.

For resources on product compatibility and detailed comparisons, see the LED headlight compatibility and testing information available online.

For replacement lens and glass options appropriate to late-90s 3000GT models, review the 95–99 Mitsubishi 3000GT headlight glass replacement page.

External reference: https://www.ledbulb.com/led-headlights-for-mitsubishi-3000gt

Steering the Beam: Supplier Landscapes and Procurement Paths for Mitsubishi 3000GT Headlights

The headlight is more than a pair of lenses and bulbs on a Mitsubishi 3000GT; it is a defining element of the car’s stance, night visibility, and the authenticity a restoration seeks to preserve. For owners seeking replacements or upgrades, the choices extend far beyond simple fitment. The modern landscape blends OEM heritage, aftermarket adaptation, and advanced lighting technology, all coordinated through a global network of suppliers that must balance precision, cost, and reliability. In this ecosystem, headlights are both a safety-critical component and a focal point for aesthetic and performance ambitions. The journey from concept to beam, therefore, hinges on understanding where the light comes from, who makes it, and how procurement decisions ripple through the build or restoration project. The story of sourcing these parts is not merely a catalog search; it is a tactical exercise in aligning design intent with manufacturing realities, supplier practices, and the practicalities of international logistics.\n\nThe supplier landscape for Mitsubishi 3000GT headlights has evolved markedly in recent years, with China emerging as a central hub. Clusters in Zhejiang, Guangdong, and Shandong have consolidated capabilities across CNC machining, die casting, remanufacturing, and precision assembly. This geographic concentration creates a robust, integrated supply chain capable of delivering a spectrum of headlight options—ranging from faithful OEM-style replacements to performance-oriented variants and modern lighting technology upgrades. For a project that requires both reliability and timeliness, these regions offer practical advantages: proximity to ports for international shipping, mature logistics networks, and established quality-control practices that can translate into short lead times, typically in the realm of two to four weeks for many standard orders, with faster cycles possible for smaller, high-demand runs. The result is a marketplace where a restoration shop, a specialty garage, or a private enthusiast can scale orders without sacrificing delivery predictability.\n\nThe procurement story, however, is more intricate than simply finding a vendor who can supply a certain component. It rests on a framework that weighs operational consistency, technical transparency, and post-sale accountability as heavily as price. For international buyers, the most effective approach is to employ a disciplined supplier evaluation process that emphasizes on-time delivery performance, responsiveness to inquiries, and the capacity to customize or remanufacture parts to fit an aging model’s tolerances. A proven supplier demonstrates not only the ability to produce a part but also the capacity to align its production with predictable schedules and clear communication throughout the order lifecycle. In this sense, a strong supplier can bridge the gap between modern manufacturing pragmatism and the historical nuances of a classic performance car, offering solutions that preserve authenticity while meeting contemporary safety and performance expectations. In practice, many buyers look for on-time delivery rates consistently above the 98% mark, rapid response to questions, transparent documentation of materials and processes, and a demonstrated ability to handle customization without sacrificing fitment or function. These are the benchmarks that translate into dependable partnerships and fewer surprises when a project timeline tightens.\n\nWithin this landscape, a practical procurement strategy begins with a precise specification of what is needed and a clear understanding of the available pathways. First, there are OEM-style replacements designed to slot into the vehicle with minimal modification. These assemblies mimic the factory geometry and optics, preserving the car’s original appearance while offering improved manufacturing tolerances or newer internal materials that enhance durability. Second, there are aftermarket alternatives conceived to maintain compatibility while delivering enhanced performance or durability. These parts may feature updated reflectors, improved sealing, or optimized lens designs that resist fogging and weathering. Third, for owners chasing night-driving performance, modern lighting technology—particularly LED-based systems and, in more advanced cases, matrix or laser-enhanced configurations—offers greater brightness, more precise beam patterns, and extended longevity. These upgrades can dramatically improve nighttime visibility but require careful assessment of electrical compatibility, air- and water-sealing integrity, and the ability to mount or retrofit without compromising the car’s electrical system or aesthetic balance. Each pathway demands a careful balance of fitment, compliance, and user expectations for how the lights should perform in real-world conditions—driving at highways, backroads, or race-oriented environments.\n\nAs buyers navigate these pathways, they often tap into international sourcing platforms and regional manufacturing networks. Platforms such as global B2B marketplaces enable buyers to compare configurations, request samples, and gauge supplier responsiveness before committing to large orders. In parallel, the regional manufacturing ecosystem in China supports end-to-end production, from CNC machining of precise bezels to die-cast housings and meticulous assembly. This integrated capability is particularly valuable when a project requires custom tweaks or a limited run of assemblies that deviate from mainstream offerings. The ability to customize is a critical advantage in the classic-car arena, where owners may seek materials, coatings, or finish levels that reflect a specific era or a unique restoration goal. The trade-off, of course, lies in balancing customization with lead times and costs, but a well-vetted supplier can deliver a tailored solution without sacrificing reliability or scale.\n\nTo operationalize these advantages, buyers build a procurement rubric that embraces both process discipline and technical due diligence. Beyond measuring delivery punctuality and responsiveness, it is essential to verify the supplier’s quality-management posture. Documentation such as process flow diagrams, material specifications, assembly procedures, and inspection records provide the buyer with confidence that the part was produced under controlled conditions. Certifications—whether they align with international standards or reflect the supplier’s own rigorous internal controls—further anchor trust in the supply relationship. A robust supplier also demonstrates a transparent and actionable after-sales stance, including clear warranty terms, straightforward returns, and accessible technical support should issues arise after installation. These elements reduce risk, especially when servicing rare or aging models whose parts are not widely standardized. A practical example of this discipline can be seen in how an established regional supplier coordinates its internal teams—from order intake and production scheduling to quality control and shipping—so that a single headlights order can progress smoothly from concept to delivery, regardless of order complexity.\n\nOn the topic of sourcing pathways and risk management, a balanced procurement approach favors diversification. Relying on a single supplier for a niche component introduces vulnerability to supply disruption, quality surprises, or rate changes. A diversified strategy—while maintaining strict evaluation standards—enables buyers to hedge against such risks. It is common to maintain a small core of trusted partners trusted for core replacements while engaging additional suppliers for non-core or upgraded configurations. In this approach, the buyer retains control of compatibility and performance expectations while expanding options for price, lead times, and customization. The ecosystem also rewards buyers who combine traditional procurement with modern e-commerce conveniences such as online fitment guarantees, easy returns, and documented compatibility checks. While a classic model like the 3000GT might appear straightforward, the practicalities of aging hardware mean that a credible supplier must be capable of handling variations in lens clarity, reflector geometry, and housing sealing performance. These subtleties matter because they directly affect beam pattern, glare control, and weather sealing—factors that influence both safety and the overall driving experience.\n\nIn this context, an informed buyer will seek reliable test and evaluation pathways. It is prudent to request sample assemblies for inspection and fitment verification, particularly when contemplating non-OEM solutions or upgraded lighting technologies. Any test should include a check of beam alignment, color temperature consistency, and electrical compatibility with the vehicle’s power system. The practical goal is to avoid late-stage rework and to ensure that the final installation preserves the car’s iconic lines while delivering the intended improvements in visibility and safety. A thoughtful procurement plan also accounts for long-term ownership. This includes establishing a maintenance regimen that incorporates regular inspection of seals and connectors, monitoring for fogging or moisture ingress, and scheduling periodic recalibration if necessary. Over the long haul, a supplier that supports ongoing service—whether through spare parts, gasket sets, or lens protectors—becomes more valuable than a one-off transaction. In the end, the quality of the supplier relationship governs how successfully a headlight project meets its safety, performance, and aesthetic goals.\n\nFor readers seeking a concrete example of the path from source to street, consider how a typical international buyer might approach a 1995–1999 3000GT headlight retrofit or replacement. The effort begins with clarifying whether OEM-fit replacements are still available and whether the expected performance aligns with modern lighting standards. If the aim is preservation with incremental improvement, the buyer may favor parts designed to preserve original geometry and lens curvature while injecting improved sealing and durable materials. If the goal is a more aggressive aesthetic or enhanced night-time performance, upgrading to brighter optics and more efficient light sources can be pursued, provided the electrical system supports the higher current or different control electronics. In either case, it is essential to confirm that the replacement integrates seamlessly with the vehicle’s harness and aligns with safety and regulatory expectations. The supplier should be able to provide documentation that substantiates compatibility, performance specifications, and installation procedures. The buyer then evaluates quotes, lead times, and possible customization fees, balancing these against the project’s timeline and budget. Throughout this process, effective communication remains the cornerstone of success. Clear expectations, timely updates, and transparent problem-solving foster a relationship in which both sides feel confident about the path forward.\n\nThe practical takeaway for anyone entering or expanding in this market is straightforward. Start with a precise specification of the desired outcome, including the intended level of lighting performance, the preferred form factor, and the tolerance for modification. Then map out viable sourcing routes, weighing OEM-like replacements against aftermarket options and potential LED or matrix-based upgrades. Establish a rigorous supplier evaluation framework that emphasizes on-time delivery, responsiveness, and the capacity for customization. Leverage the regional strengths of manufacturing hubs, but temper expectations with robust quality verification and post-sale support. And remember that the goal is not a mere component swap, but a coherent upgrade path that preserves the car’s character while enhancing safety and driving enjoyment. If the project includes older models in a broader restoration, treat headlights as a keystone element that binds historical authenticity to modern performance expectations. The right supplier will not only deliver a part that fits but will also contribute to a reliable workflow that keeps the project on track, from initial inquiry to the moment the headlight beam cuts cleanly through the night.\n\nFor readers who want to explore the broader context of where these components come from and how the market is evolving, the landscape is increasingly shaped by cross-border collaboration and standardized expectations. A recent synthesis of insights into China’s role in the global 3000GT aftermarket ecosystem highlights how manufacturing districts, logistics networks, and quality controls converge to support a diverse, resilient supply base. This broader perspective helps explain why procurement decisions for a classic performance car have become as strategic as any performance modification. It is not merely about finding a part that fits; it is about ensuring that the part integrates with the vehicle’s identity, meets reliability standards, and supports a long-term ownership experience. External resources that examine the sourcing dynamics and pricing benchmarks can provide a useful frame of reference for buyers who want to compare options and assess value across different supplier models. External resource: https://www.sourcingguide.com/mitsubishi-3000gt-parts-supplier-guide-china-sourcing-quality-pricing\n\nIn closing, sourcing headlights for the Mitsubishi 3000GT is a careful act of balance. It requires acknowledging the car’s iconic silhouette and safety demands while navigating a landscape that blends OEM heritage, aftermarket ingenuity, and cutting-edge lighting technology. The strength of the procurement approach lies in choosing suppliers with solid processes, transparent practices, and a willingness to support long-term service. It also rests on recognizing the role of regional manufacturing ecosystems that can offer responsiveness and flexibility without compromising the car’s character. When executed with discipline, the procurement journey becomes a collaborative process—one that aligns the artistry of restoration with the precision of modern illumination, letting drivers experience the road in safety and style after dusk. The beam, in this sense, is not just about light; it is about connection—between a car’s past and its present, between a hobbyist’s ambition and a supplier’s capability, and between the road ahead and the clarity of the night it reveals.

Headlights Through Time: Upgrading the Mitsubishi 3000GT in the LED Era of Automotive Lighting

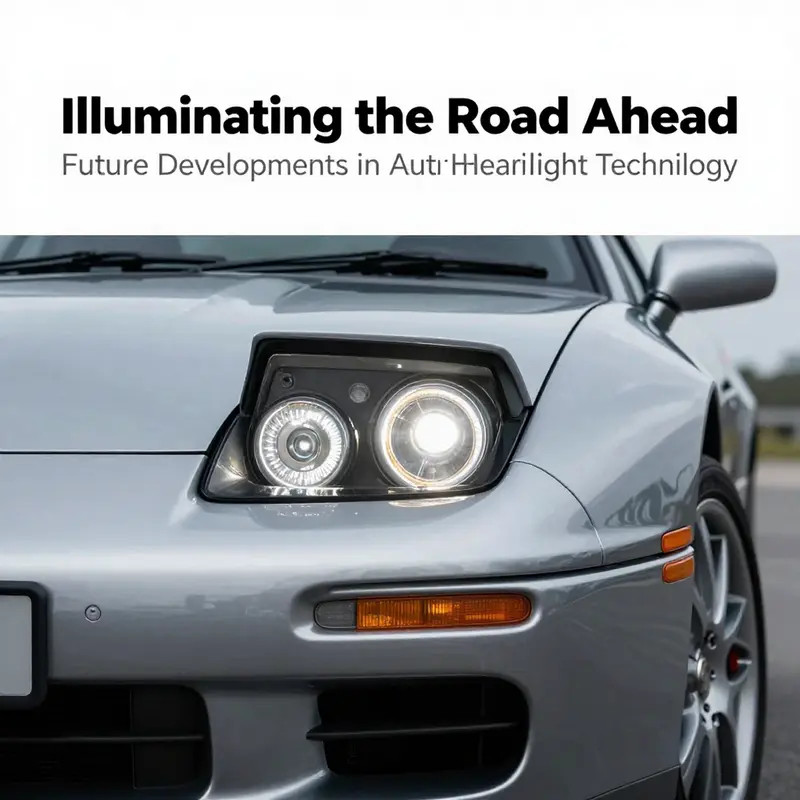

The Mitsubishi 3000GT is remembered not just for its blistering performance and distinctive silhouette, but for a headlamp design that felt ahead of its time when the car rolled off the showroom floor. The original headlights were a product of the era’s lighting philosophy: halogen technology, carefully sculpted lenses, and reflectors tuned to deliver a mix of usable road illumination and a certain automotive poise. Since the mid-1990s, however, the world of automotive lighting has undergone a revolution driven by brighter, smarter, and more efficient light sources. The arc of this transformation runs from the dawn of halogen replacement kits through the arrival of LEDs and, more recently, adaptive matrices and laser-based options that some new models now showcase. For owners of classic performance icons like the 3000GT, the question is not simply about upgrading brightness. It is about balancing authenticity with safety, about choosing a pathway that respects the car’s character while embracing the practical advantages of modern lighting technology.

In the broad arc of this evolution, the first realistic turn for a 1990s performance coupe was to move from the dim, warm glow of halogen bulbs to brighter, whiter light with improved focus. The basic approach—replacing the filament with a more efficient light source—carried its own set of constraints. The older reflector geometry was engineered around a specific light source, and simply dropping in a brighter bulb could yield inconsistent beam patterns, glare, or even electrical strain. Yet the market adapted with a range of aftermarket options that ranged from modest upgrades to more ambitious replacements designed to emulate a modern low beam and high beam synergy. What started as a practical improvement quickly grew into a discussion about how much of the car’s original character should be preserved while pursuing better visibility and safety. For enthusiasts, the answer lies in understanding the trade-offs and selecting a solution that aligns with how they use the car on the road, not just how it looks in a showroom catalog.

Today’s aftermarket scene for classic Japanese performance cars is shaped by a global supply chain that stretches from traditional manufacturing hubs in Asia to the online marketplaces that connect buyers directly with producers. In markets with dense manufacturing ecosystems, like several coastal provinces that host CNC machining, precision casting, and rapid assembly capabilities, replacement parts—ranging from basic housings to refurbished units—are available with varying degrees of fidelity to the original. The challenge for buyers is to sift through a spectrum of offerings, focusing on delivery reliability, product compatibility, and the level of customization a supplier can provide to suit the 3000GT’s headlights without compromising safety or legality. This careful evaluation is essential because a well-chosen upgrade should enhance nighttime visibility while preserving the car’s visual identity and ensuring that beam patterns remain within regulatory expectations for road use. The landscape has become accessible enough that even international buyers can leverage global platforms to compare options, assess supplier credentials, and initiate a project with a trusted partner who understands the delicate balance between vintage aesthetics and modern performance.

For owners who are drawn to a straightforward, plug-and-play upgrade that preserves the classic look while delivering a noticeable jump in illumination, LED replacement kits have become a popular entry point. These kits typically feature a multi-LED array designed to replace a single halogen module, often built around a 16-chip LED array to deliver brighter, more focused light with improved color temperature and longer life. One practical path is to adopt a kit that is engineered to fit the 9005 high-beam and 9006 low-beam positions, mirroring the conventional lamp design that supplied the night-driving experience the car’s drivers remember. The advantage is immediate: more light on the road, an improved boundary between the lit roadway and the dark shoulder, and less frequent maintenance over the long term. The caveats accompany the benefits, though. A higher intensity output can alter glare dynamics if the optics are not matched to the new source. In some cases, reflections from the inner surfaces of the headlamp housing can create unwanted artifacts, and color temperature differences can shift the perceived distance of objects, affecting depth judgment for drivers accustomed to the original light flavor. These considerations underscore the importance of selecting a kit that is specifically designed for compatibility with the 3000GT’s headlamp geometry and electrical system, rather than relying on generic universal kits that may demand additional adapters, resistors, or wiring harness work.

The upgrade conversation is also deeply tied to the broader reality of modern automotive lighting technology. The future of lighting in high-end street cars has trended toward matrix LEDs, with individual diode blocks capable of shaping the beam in response to traffic, weather, and road geometry. The largest impact of such systems is not simply brightness; it is adaptive control, where the beam pattern can dim or brighten in precise segments to avoid blinding oncoming drivers while keeping the path visible for the vehicle’s operator. A 3000GT, as a classic, does not come with such technology from the factory, but the aftermarket has begun to explore paths that simulate these capabilities through more sophisticated LED arrays and controller modules. The result is a practical compromise: a lighting system that delivers enhanced night visibility and a safer driving experience, even if it does not fully replicate the dynamic behavior of modern matrix systems. As an intellectual exercise and a real-world upgrade, this approach invites owners to consider how much of the next-generation lighting experience they want to introduce into a car whose design heritage rests in the era of halogen efficiency and luminous simplicity.

In parallel with the lighting technology shift, the way enthusiasts source and install upgrades has evolved. The classic car community benefits from a global market where parts can be sourced from a wide range of suppliers and assembled by specialists who understand the peculiarities of aging electrical systems and vintage lighting optics. This ecosystem is not merely about new components; it is about a collaborative process that includes verifying fitment, ensuring thermal management, and maintaining the integrity of the original front-end styling. For many owners, the choice hinges on whether they want a faithful reproduction of the original headlamp performance with a brighter, crisper output, or a clearly modern upgrade that transforms nighttime driving dynamics while still preserving the car’s classic face. Each choice requires careful planning: some solutions rely on refurbished or rebuilt housings to preserve an authentic silhouette, while others opt for modern housings that accommodate a contemporary LED array with improved sealing, thermal control, and mounting precision.

Beyond fit and optics, the practical logistics of procurement and installation matter a great deal. The aftermarket marketplace for headlight components can be navigated through global B2B platforms and specialized shops that offer a spectrum of services, from simple swap-outs to complete reassemblies that require meticulous alignment and calibration. In practice, buyers should emphasize supplier reliability and delivery performance, particularly when the buyer is engaging with overseas manufacturers. A high on-time delivery rate and a swift response to customization requests are as important as the technical fit of the lighting kit. For international buyers, this means looking for suppliers who can demonstrate consistent fulfillment performance and who offer support for technical questions about fitment relative to the 3000GT’s headlight assembly. The goal is to secure a reliable long-term partnership that reduces the risk of misalignment or part failures, which could otherwise compromise safety on the road.

The practical path of upgrading is also about educating oneself on what constitutes acceptable lighting performance for a street-legal vehicle. In the current environment, the market offers a range of options that address the general need for better nighttime visibility without entering the realm of dramatically altering the vehicle’s appearance. A typical upgrade path emphasizes higher luminance, improved beam focus, and extended life cycles that minimize maintenance. These attributes translate into tangible benefits: improved detection distance for pedestrians and obstacles, more precise detection of road irregularities, and a generally more balanced distribution of light that reduces glare for oncoming drivers. Importantly, a responsible upgrade respects the car’s original character, ensuring that the headlight design remains visually coherent with the vehicle’s shape and proportions while delivering a more secure and confident night-driving experience.

As the conversation about automotive lighting evolves, hybrid approaches begin to appear. Some enthusiasts experiment with modern LED kits that maintain a classic look yet offer advanced features such as color temperature tuning and improved resistance to harsh road conditions. Others explore more ambitious upgrades that push toward smarter integrations—system enhancements that tie the headlights to sensors for auto-dimming, or to a vehicle control unit that could, in the future, coordinate with other driver-assistance systems. While these advanced features are more commonly associated with newer models, they illustrate a broader trend: the desire to bring the best of current lighting technology into older cars, bridging the gap between heritage and modern usability. The 3000GT, with its storied performance legacy, represents a compelling case study in how a classic sports coupe can be upgraded to meet contemporary expectations without erasing the personality that made it special in the first place.

For readers who want to explore concrete options, the landscape features a spectrum of headlight replacements and upgrade kits designed to fit the 3000GT’s headlight housings. A logical starting point is to look for LED assemblies that are dimensionally matched to the original housings and that provide a straightforward installation, ideally with an adjustable beam pattern that can be fine-tuned after mounting. The decision to transition from halogen to LED is, in many cases, a question of risk versus reward. On the reward side, there is brighter, more efficient illumination, longer bulb life, and a lower thermal load on the headlight components. On the risk side, an owner may encounter issues with compatibility, potential electrical noise, and the need to recalibrate the alignment to ensure the beam cuts properly across the road without creating dangerous glare for other drivers. These are not trivial concerns, but with careful choice of a kit designed for the model, plus professional installation when needed, the upgrade can be both safe and satisfying.

For those who value historical fidelity, there remains a strong appeal in preserving the original headlamp aesthetics while introducing a modest improvement in performance. In such cases, refurbished or carefully reproduced housings that maintain the classic contours can be paired with modern LED inserts that respect the geometry of the lens and reflector. This approach honors the car’s styling while yielding a visible upturn in illumination. It is a path that demands attention to the electrical and thermal compatibility of components, as well as to the mechanical tolerances of the headlight mounting points. In other words, the upgrade is not merely a swap of bulbs; it is a small engineering project that requires a thoughtful plan, a disciplined execution, and a keen eye for the car’s overall balance.

As the chapter closes on this reflection of how the 3000GT’s headlights sit at the intersection of heritage and progress, the broader implication becomes clear. Classic performance cars do not need to become relics of a bygone era to benefit from contemporary lighting technology. They can, with intention and care, adopt modern LEDs that brighten the night and improve safety while preserving the essence of what makes the car beloved by enthusiasts. The journey from a halogen-based system to a modern LED-enabled headlamp is more than a hardware upgrade; it is a narrative about evolving a driver’s experience without surrendering the car’s personality. It invites owners to consider not only the immediate gains in brightness and reliability but also the longer arc of automotive lighting: a future where even iconic classics stay current through adaptive, intelligent light management. While the most cutting-edge systems—such as matrix or laser headlights—may remain the domain of new models, the practical, well-considered LED upgrades available today offer a meaningful bridge to that future. In this sense, the 3000GT’s headlights become a focal point for a broader discussion about how we care for and upgrade performance classics in a world where lighting technology continues to stride forward with striking speed.

Internal link reference: For a sense of the available original-era headlight options, see the page dedicated to 95-99 Mitsubishi 3000GT SL VR4 headlights, which preserves the look while informing the upgrade path. 95-99 Mitsubishi 3000GT SL VR4 clear headlights.

External resource: For a broader sense of how modern LED headlight kits are marketed and evaluated in today’s market, see the latest consumer-focused overview at https://www.amazon.com/Mitsubishi-3000GT-LED-Headlights-Combo-White/dp/B0BQZ4V8FQ.

Final thoughts

In summary, the Mitsubishi 3000GT’s headlight solutions exemplify a blend of vintage allure and modern technological advancements. Business owners have a unique opportunity to capitalize on a robust aftermarket ecosystem while exploring innovative upgrades that attract enthusiasts seeking enhanced performance. Investing in knowledge about replacement options, LED technologies, and the supplier landscape ensures that businesses can deliver top-quality products for this remarkable vehicle, catering to growing consumer demands for safety and performance. The future developments promise exciting paths for customization and upgrades, setting a new standard for both practicality and style.