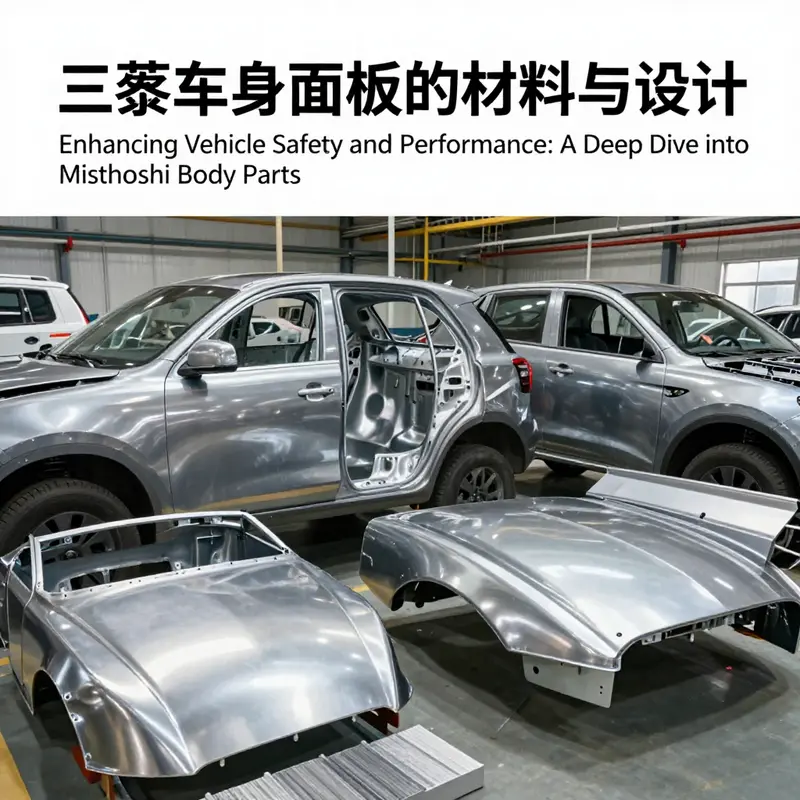

Mitsubishi body parts are integral to the overall functionality, safety, and aesthetic appeal of vehicles. Understanding the unique roles these components play not only enhances vehicle performance but also underscores their significance for business owners involved in automotive sales, service, or customization. This article delves into the protective features of bumpers, the materials and design of body panels, and the multifunctionality of bumpers in Mitsubishi Fuso trucks. Each chapter builds upon the last, providing a comprehensive overview of Mitsubishi body components and their impact on vehicle integrity and operational efficiency.

Protective Interfaces: How Bumpers Embody Mitsubishi’s Balance of Safety, Performance, and Design

The bumper is often the first thing you notice about a vehicle’s face, yet its importance runs far deeper than aesthetics. In Mitsubishi’s lineup, the bumper functions as a carefully tuned interface that bridges safety, aerodynamics, and daily practicality. It is not merely a cover for the front and rear ends; it is an engineered system that sits at the intersection of energy management, pedestrian protection, sensor integration, and visual language. From the urban street to rugged back roads, the bumper’s design and materials are chosen to protect the structure behind it, to minimize repair costs after a minor collision, and to support the evolving sensing and safety technologies that define modern driving. All of this begins with the fundamental task of absorbing energy and distributing it in a controlled way so that the rest of the body panels—doors, hoods, fenders, and the underbody—remain unscathed enough to keep the vehicle operable and safe for its occupants.

At the heart of bumper performance is energy absorption. In Mitsubishi models, the front and rear bumpers are built around a layered approach that combines an outer shell, an energy-absorbing core, and a protective back panel that helps prevent deformation of the vehicle’s primary structural members. In everyday terms, when a low-speed impact occurs—such as a parking lot nudge or a curb strike—the bumper is designed to deform elastically, then recover where possible, while the underlying frame remains within its designed tolerances. The outer surface is typically crafted from robust ABS engineering plastics or polypropylene blends, chosen for their face-shedding capability and resistance to minor scrapes and impacts. Beneath this outer skin lies a honeycomb or foam core that behaves like a small engine of energy management, converting a portion of the kinetic energy into minor deformations and heat rather than allowing it to travel straight into the longitudinal rails or suspension mounting points. This multi-layered approach reflects a broad engineering principle: the most effective protection comes not from a single, ultra-stiff barrier but from a compliant, distributed system that catches and disperses energy gradually.

The practical outcomes of this design are visible in everyday ownership. For technicians and owners, a bumper that is well designed and properly aligned reduces the likelihood of collateral damage. When the bumper can absorb energy without transferring large forces to the bumper mounts, radiator support members, and headlamps, the cost and complexity of repairs drop significantly. In the case of Mitsubishi’s L200 and related pickup variants, this is particularly consequential because the front end also houses a variety of auxiliary systems—cooling ducts, sensors, and optional skid plates. The bumper’s geometry must accommodate these elements without compromising crumple zones, a task that becomes more complex as front-end styling and engine packaging evolve. In this sense, the bumper is a guardian of the vehicle’s heart: it shields not only the lamps and grilles but also the sensor housings that feed ADAS features, and it does so while preserving the vehicle’s structural integrity after a minor crash.

Pedestrian protection has become a central pillar of modern bumper design, and Mitsubishi’s approach aligns with international safety expectations that prioritize human safety without sacrificing vehicle performance. Front bumpers in contemporary Mitsubishi models employ softer, more forgiving materials for the outer layer, combined with energy-dissipating structures in the lower portions. The intention is to reduce the risk of serious leg injuries in a collision with a pedestrian by decoupling and deflecting the point of contact away from the upper legs to more yield-prone areas of the bumper system. In practice, this translates to lower sections that can collapse in a controlled fashion and upper sections that avoid creating rigid strike zones. The result is a broader safety envelope that complements airbags, seatbelt pretensioners, and crumple zones elsewhere in the vehicle. While the exact implementation varies by model and market, the underlying philosophy remains consistent: a bumper should invite lower-impact energy absorption and only transfer residual forces to the passenger cell under extreme circumstances.

Functional integration is another defining trait of Mitsubishi bumpers. In an era when driving assistance systems are becoming pervasive, bumpers double as a nexus for sensors, cameras, and illumination. Modern Mitsubishi vehicles often incorporate parking radars, rear- and front-facing cameras, and, in higher-spec configurations, forward-looking sensors that participate in collision avoidance and adaptive cruise features. The bumper’s structural accuracy—its height, angle, and flushness with the grille and fender lines—directly influences the performance of these systems. A misaligned bumper can disrupt sensor fields of view, degrade calibration, and ultimately threaten the very safety functions it’s meant to support. For this reason, assembly tolerances and mounting points are engineered with precision. The bumper mounts must maintain consistent spacing and stiffness to ensure that radar waveforms and camera optics are not distorted by minor deformations or misalignment after a minor bump.

Aerodynamics and weight are inseparable from safety in the bumper’s role. The bumper’s shape feeds the vehicle’s overall drag coefficient and underbody airflow, which influences fuel efficiency, cooling behavior, and high-speed stability. A well-integrated bumper reduces drag while still accommodating required structural members and sensors. In practice, this means designers often employ sculpted surfaces, air intakes, and diffuser-like elements near the lower edge to channel airflow smoothly around the wheels and along the underbody. For Mitsubishi, the specified geometry is not merely about a clean look; it is a calculated decision to optimize air resistance and thermal management without compromising impact performance. The choice of materials also contributes to this balance. Lightweight plastics and composites help keep the unsprung and overall vehicle weight down, while reinforcing members provide the rigidity needed during a collision. The result is a system that can contribute to better fuel economy and steadier highway behavior, especially when paired with carefully tuned suspensions and wheel alignments.

The discussion would be incomplete without considering the broader ecosystem of body parts and how bumpers relate to them. The bumper sits in a layered relationship with the front and rear body panels—the hood, fenders, doors, and tailgate—that together form the vehicle’s outer envelope. Each component offers its own protective function, but the bumper provides the first line of energy management and the first contact point with the environment. Strong, corrosion-resistant panels protect against the elements, expensive coatings help preserve the finish, and the bumper’s own resilience shields the more sensitive features behind it from stones, salt, and debris. In areas with rough roads or salty winters, routine maintenance—such as inspecting for cracks at the bumper’s periphery, repainting minor chips, and ensuring the paint sealant remains intact—plays a crucial role in preventing accelerated wear that could compromise impact performance.

In practice, the bumper’s performance is often a reflection of choices made across the vehicle’s architecture. A model like the L200, known for its off-road orientation, demonstrates how bumper design can harmonize with chassis protection, skid plates, and wheel arches to form a protective perimeter that keeps off-road capabilites intact. The bumper must clear the ground and clear the underbody components, all while maintaining a robust shelter for the headlamps and fog lamps. The geometry must allow for the safe and effective mounting of tow hooks or winch accessories as well, should the user opt for rugged, utilitarian enhancements. This is not a clash between form and function; it is a purposeful negotiation where the bumper acts as a hinge between environmental reality and engineering intent.

At a broader level, the bumper also communicates the brand’s identity. A Mitsubishi bumper is not a generic mass-market object; it is a component that carries the lines and aggression of the vehicle’s design language. The curve of the bumper, the way it frames the grille, and its relationship to the headlights all contribute to the vehicle’s visual balance. In some configurations, the bumper’s lower edge is sculpted to echo the angle of the side skirts, creating a coherent low-slung silhouette that hints at performance while ensuring function remains on the foreground. The design speaks to the driver’s expectation of safety, reliability, and capability, even before the vehicle’s actual systems engage on the road.

Beyond OEM considerations, owners frequently think about upgrades that retain safety while offering additional function. A bumpers’ upgrade might add protective plating, off-road accessories, or reinforcements to accommodate heavier loads. Such modifications, when done thoughtfully, still honor the bumper’s core roles: energy absorption, pedestrian protection, sensor integrity, and aerodynamic efficiency. The challenge for any aftermarket approach is to preserve the tight tolerances that ensure sensor alignment and the bumper’s ability to manage minor impacts without instigating larger frame damage. This is why the interplay between the bumper and the rest of the body panels remains delicate; every added mass or new mounting point must be weighed against the bumper’s capacity to perform its protective and aerodynamic tasks.

In the end, the bumper is less a single component and more a philosophy of safety through intelligent design. It embodies a balance between resisting ordinary wear and providing room for the vehicle’s evolving safety technologies. It supports the mechanical and electronic lifelines that many drivers rely on every day, from parking sensors to collision mitigation features. It harmonizes with body panels to maintain a clean, cohesive aesthetic that communicates robustness and reliability. And it remains a practical entry point for owners who wish to customize their vehicles—whether they seek higher ground clearance for off-road adventures, extra protection for commerce and transport duties, or simply a more assertive look that still respects the car’s engineering foundations.

For readers who want to explore a practical example of bumper integration and its broader implications for the vehicle’s safety ecosystem, a representative reference can be found in a dedicated front bumper page that discusses how bumper geometry and mounting influence sensor performance and pedestrian safety. This page, though informational in scope, illustrates the ways a bumper system can align with a brand’s safety philosophy and with regulatory expectations. front bumper page for Mitsubishi Outlander 19

The bumper’s story does not end at the bumper cover. Its influence extends to how the car’s other body parts—doors, hoods, fenders, and tailgates—operate under stress and how they age over time. Regular care helps maintain the bumper’s protective role for many years. Cleaning, wax sealing, and timely paint touch-ups guard against corrosion that can propagate into adjacent panels. In coastal regions with salty air or humid climates with heavy road grime, attention to the joint lines, fasteners, and mounting brackets is essential to preserve the bumper’s performance, its alignment, and its appearance. The synergy between the bumper and the rest of the body is a daily reminder that every component has a shared fate: when one link in the chain falters, the effectiveness of the entire system can be compromised. This interconnected reality reinforces the value of a holistic approach to vehicle maintenance, one that treats the bumper as both a protective interface and a design statement—an embodiment of Mitsubishi’s commitment to safety, efficiency, and purposeful engineering.

As the journey toward safer, smarter vehicles continues, the bumper remains a living part of that evolution. It is a boundary between the road and the rider’s expectations, a media of energy that, when correctly engineered, prevents minor mishaps from becoming major repairs. It is also a canvas for innovation, a staging ground where new materials, new manufacturing processes, and advanced sensing technologies converge to deliver tangible benefits—lower risk, lower cost, and higher confidence for drivers who rely on their vehicles every day. In this way, the bumper is not simply a protective shell; it is a symbol of safety-centric design that respects the realities of real-world driving while aligning with the ambitions of a brand that places reliability at the heart of its mission.

External reference for further context on bumper safety and pedestrian protection can be found through professional safety organizations, which continually evaluate how bumper design influences real-world outcomes. This resource provides broader insight into the principles that guide bumper development and how they intersect with pedestrian safety regulations and vehicle testing standards. https://www.iihs.org/topics/bumpers-and-pedestrian-safety

null

null

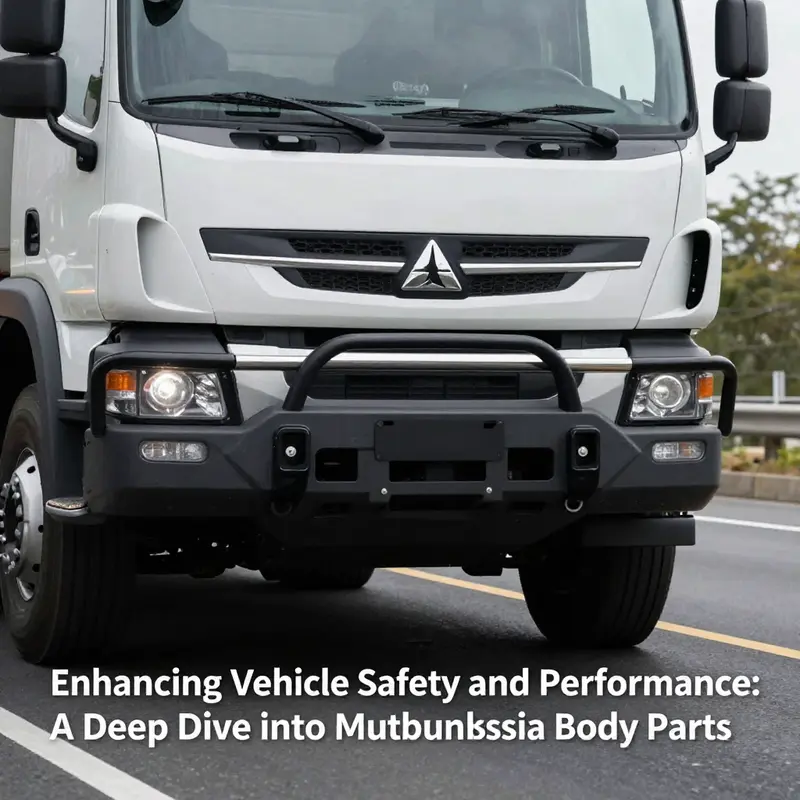

多功能保险杠在Mitsubishi Fuso中的应用与集成

在现代轻型商用车的车身设计中,保险杠不仅是第一道防线,更是一个高度集成的系统,承载着安全、空气动力学、照明、传感与维修便利性等多重功能。以 Mitsubishi Fuso 的Canter为例,多功能保险杠的设计思路体现了一个品牌在安全与实用之间寻求平衡的长期探索。它并非简单的钣金覆盖,而是一体化的结构组件,内部嵌入了关键的辅助系统,通过紧凑而有条理的布局,与前端摄像头、毫米波雷达、雾灯等传感装置协同工作,从而提升整车的环境感知能力与主动安全水平。这个趋势不仅改变了同类车型在日常城市通勤中的应对方式,也在长途运输和复杂路况下赋予驾驶员更高的信心与操作的直觉性。为了理解这种集成的实际意义,必须从它的应用场景、材料与工艺、以及设计哲学三个维度来展开考察,而这三个维度又相互交织,形成一个完整的系统观念。

在应用与功能集成方面,Canter 的改款保险杠呈现出一种极富现代感的左-中-右三段式结构。这种视觉分区不仅提升了车辆在路上的辨识度,更通过模块化的布局,将不同功能单元紧密绑定在同一壳体中。保险杠内部所承载的前视摄像头、毫米波雷达、以及隐藏式雾灯等部件,并非“外置叠加”的扩展,而是被导入到内部腔体的结构支撑中,形成一个协同工作的平台。毫米波雷达作为主动安全系统的核心传感器之一,负责监测前方车辆距离、速度与潜在的碰撞风险,与自适应巡航、前方碰撞预警等系统共同作用,显著提升了在拥堵路况和长途驾驶中的预判能力。在某些配置中,前方保险杠还融入了摄像头与雷达的组合感知,形成全方位的环境信息网格,从而使ADAS在昼夜、雨雾等复杂天气条件下也能保持稳定的工作状态。对驾驶员而言,这些传感装置的协同工作意味着更少的紧急干预需求和更平顺的驾驶体验,尤其是在需要频繁变道、跟车或自动减速的场景中,系统的响应时机与准确性直接关系到安全性与效率。若把安全性看作是保险杠的底线,那么环境感知能力的提升则是这套系统的进阶。

设计与实用性方面,保险杠的裙板与下部轮廓线在视觉与功能之间找到了恰当的平衡。下方的空气导流口、底盘保护板以及可能的保护裙设计,既服务于空气动力学的优化,也为应对碎石道面与越野路况提供了额外的防护。与常见的单一材料结构不同,部分配置采用轻质聚合物复合材料与高强度钢板的混合结构,兼顾了减重与强度,降低车辆在载荷状态下的悬挂与转向负担。这种组合材料的选择,不仅提升了耐腐蚀性能,还为在运输、施工或应急救援等高强度工作环境中可能遇到的冲击与刮擦提供更好的容错空间。更重要的是,整车设计师在序列化生产中保留了原厂配件的升级通道,确保对安全性与性能的影响降到最低,从而使车主在追求个性化与耐用性之间找到一个高价值的权衡点。对于日常维护而言,模块化的内部结构也使得拆装与更换变得高效,方便维修人员在现场快速处理轻微撞击所带来的损伤,而不需要对整车壳体进行大范围的改动。

在特殊用途与区域性差异方面,Canter 的多功能保险杠还展现出对工作场景的灵活适配能力。不同市场对防撞需求、照明配置、以及前照明高度的法规要求各不相同,因此保险杠的结构会在保持核心安全理念的前提下,提供不同的模块化选项。例如,在城市配送和高密度交通环境中,前照设计更偏向于紧凑与高效;在需要夜间作业或偏远地区救援的情境下,前后灯具、警示灯及额外的防护措施成为可选的强化配置。更有意义的是,某些特殊用途的车型,如消防、救援或高效物流版本,会将保险杠设计得更高,以确保在狭窄的城市街巷或地下结构中也能保持前部的通过性与耐用性。这样的设计体现了保险杠不再只是“碰撞后的防护”,而是一个为任务定制的工作平台。

从材料与工艺角度看,多功能保险杠的性能取决于材料选择、加工精度与组装工艺之间的协同。轻质但高强的聚合物复合材料被广泛应用于外壳部分,以减轻整车重量、提升燃油经济性,同时通过表面处理和防腐涂层提升耐久性。内部支撑梁通常选用高强度钢或铝合金,通过一体成型的工艺实现刚性与柔性的兼容,使保险杠在关键区域具有更高的吸能能力。对于边角区域、连接点和嵌入式传感器的安装孔,制造工艺需要极高的公差控制,以避免因安装误差影响传感器的视场和保护壳的完整性。正因如此,原厂件在设计阶段便将传感器的等待位、走线通道、以及机械联接的承载点纳入考量,确保每一个零部件在后续组合时保持一致的性能标准。这也解释了为什么维修与更换时,优先考虑原厂件而非简单的替代品,因为原厂件在材质、涂层、以及与整车系统的接口方面,具有更高的可靠性与一致性。

在维修、维护与升级方面,保险杠的设计也强调维护便利性与长期成本的控制。可拆卸的外覆壳、快速释放的螺栓及模块化的结构,使得在需要更换或更新传感器、灯具及保护件时,维修工作能够快速完成。这种“更少停工、更高可用性”的理念,对以车队运营为核心的企业用户尤为重要。在设计阶段,工程师们也考虑了未来可能的升级路径,例如在现有前部传感系统中增加摄像头替代件或替换成更高分辨率的传感器,而不需要对大面积壳体进行改动。这样的 foresight 意味着保险杠不仅满足当前法规和安全标准,还为未来的技术迭代留出余量。与此同时,外观层面的美学与品牌语言也在保险杠的三段式设计、线条处理和灯具轮廓中得到体现,使其成为车身整体视觉重量与情感表达的一部分。

在与车身其他部件的协同方面,保险杠与车门、引擎盖、翼子板等部件的接口设计至关重要。车身面板的平整度、涂层一致性、以及与铰链、密封条的协同工作,直接影响到防水、防尘与防腐效果。从更宏观的角度看,保险杠的设计需要考虑到整个车身的结构强度分布与碰撞能量的传递路径。一个优化的保险杠能够在低速碰撞中吸收足够的能量,保护关键部件,如灯组、进气口和散热器格栅,同时避免将冲击力传递到框架与乘员舱。这种能量管理的优化不仅提升了安全性,还对整车的维修成本和后续保值产生积极影响。

对于行业从业者与车友社群而言,理解多功能保险杠的价值,也意味着在日常改装与个性化定制时,能够在“美观”与“实用”之间做出更明智的选择。改装时常见的方向包括提升保护性、改进底盘接近角、增加专用的防护板以及在不破坏ADAS功能前提下对灯光系统进行升级。但重要的是,这类改装应遵循制造商的接口规范,保持原厂件级的兼容性,以确保安全与性能不被轻易妥协。若需要了解不同车型在前后保险杠设计上的差异,参考相关车型的官方说明与零件页,能够帮助理解模块化如何在实际生产中落地,并帮助车主在二手市场上辨识保养状况与潜在的维护成本。你可以查看2016 Mitsubishi Lancer front and rear bumpers页面了解一体式保险杠设计在不同车型中的应用要点,从而更好地理解Canter 这类轻型商用车在功能集成方面的独特价值。

参照上述分析,Canter 的多功能保险杠并非孤立的部件,而是一个与传感、照明、空气动力学和车身结构紧密耦合的系统。它的成功,在于对安全性、实用性与美学的综合权衡,以及对不同工作场景的前瞻性适配。这种设计语言不仅提升了驾驶员对环境的感知和反应能力,也为未来的车载系统升级打开了空间。对于行业观察者而言,这是一种值得借鉴的集成思考:将安全技术前置于外部壳体的更高效能量管理中,让每一次碰撞都以最小的代价转化为可控的修复与维护成本。对于车主而言,则是一种长期的消费体验优化——在保持强大保护性的同时,确保日常运营的稳定与舒适。

如需进一步了解官方的车型技术细节与原厂零件信息,可访问官方渠道获取最新资料。外部参考资源: https://www.mitsubishi-fuso.com/

Final thoughts

Mitsubishi body parts are not merely functional components; they are critical elements that ensure safety, enhance performance, and contribute to the aesthetic appeal of vehicles. By understanding the protection offered by bumpers, the advanced materials used in body panels, and the multifunctional capabilities in models like the Mitsubishi Fuso, business owners can make informed decisions that will not only benefit their operations but also enhance customer satisfaction. Investing in quality body parts is essential for sustaining vehicle integrity, performance, and safety in the competitive automotive market.