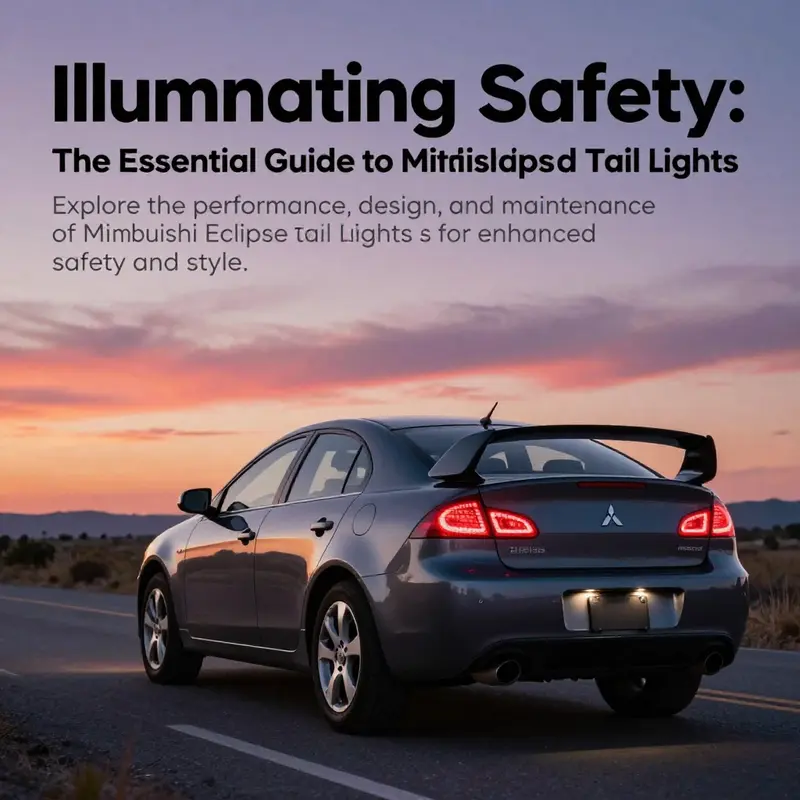

Tail lights are not just a functional aspect of a vehicle; they play a crucial role in ensuring safety and enhancing aesthetics. For Mitsubishi Eclipse owners, understanding the importance of tail lights can significantly impact both safety on the road and the overall visual appeal of their vehicle. This guide delves into the various components and designs of Mitsubishi Eclipse tail lights, beginning with the advantages and compliance of genuine OEM options in terms of performance and safety. Following that, we will explore aftermarket alternatives, comparing their value and fitment with OEM parts. The third chapter will highlight technological advancements integrated into tail light designs, showcasing how these innovations contribute to improved visibility and aesthetics. Finally, we will cover the essential maintenance practices and replacement procedures necessary to keep tail lights functioning properly, ensuring continued safety and compliance. Each chapter aims to provide business owners with insightful information that underlines the importance of investing in quality tail light solutions for their Mitsubishi Eclipse.

OEM Precision, Nighttime Clarity: The Genuine Mitsubishi Eclipse Tail Light as a Safety-First Upgrade

Tail lights are more than decorative accents on a Mitsubishi Eclipse; they are a critical fusion of safety, reliability, and modern design. The tail light assembly is a carefully engineered system that must endure a range of weather conditions, road debris, and the constant demands of daily driving, while also presenting a cohesive visual signature that complements the vehicle’s lines. When a driver taps the brake, when a car behind signals a lane change, or when twilight deepens into night, the lighting system becomes a clear, unambiguous communicator. In this sense, genuine Eclipse tail lights are more than lamps; they are safety instruments that carry a manufacturer’s precise expectations for performance, durability, and legal compliance. The third brake light, or CHMSL, sits above the main assemblies as a federally regulated enhancement to rear visibility, reinforcing the message that braking is happening even when the lower lights are shaded by the vehicle ahead. All of these elements work together to reduce the risk of rear-end collisions and to improve flow in traffic, especially in urban settings where stop-and-go conditions are common and every fraction of a second counts.

Genuine Mitsubishi Eclipse tail lights embody a design philosophy that ties form to function. The technology inside these factory-original assemblies often relies on high‑intensity LED elements—integrated directly into the cover design rather than added as a separate bulb cluster. This integration yields several advantages. First, LEDs provide brighter, more consistent illumination with better visibility across a range of weather and lighting conditions. The uniform glow helps drivers behind you gauge your intentions more quickly, which is particularly important during hurried city braking or when morning fog dulls distant cues. Second, LED technology responds with speed. Brake lights illuminate almost instantaneously, delivering a crisp cue that others can react to in time, reducing the likelihood of abrupt, last-second braking by following drivers. Third, LEDs offer precise, sharply defined turn signals. The ability to cue lane changes with clear, rapid flashes improves predictability on crowded roads and highways alike.

The engineering behind OEM tail lights also emphasizes longevity and resilience. For Eclipse models, including variants such as the Eclipse Cross, the OEM assemblies are built to meet stringent quality standards and to withstand the rigors of real-world driving. The materials are chosen to resist weather-induced fading, UV exposure, and impact damage, ensuring the tail lights maintain their appearance and function over many miles. The result is not only a factory-original look but a level of durability that aftermarket components often struggle to guarantee. In many regions, OEM parts are manufactured under recognized ISO certification protocols and subjected to testing that seeks to replicate years of use under diverse conditions. This meticulous quality assurance translates to a reliable warranty framework and a built‑in confidence for owners who want to protect their investment while preserving the vehicle’s intended aesthetics.

The technology inside these genuine assemblies can also accommodate modern lighting expectations without crossing regulatory lines. Some lighting systems are designed to offer additional effects—such as sequential turn signals or dynamic braking patterns—within the constraints of traffic laws and safety standards. When implemented properly, these features provide a more sophisticated appearance while sending clear signals to surrounding traffic. The careful balance between stylistic enhancement and steadfast safety is a hallmark of OEM design, and it is this balance that makes genuine tail lights a preferred choice for many Eclipse owners seeking a factory-original look with upgraded performance.

Choosing between OEM genuine parts and aftermarket alternatives is more than a matter of sticker price. Genuine Eclipse tail light assemblies deliver a level of fitment precision that is difficult to match when substituting third-party components. The electrical interfaces, mounting points, and sealing surfaces are designed to integrate seamlessly with the vehicle’s wiring harness, gaskets, and body panels. This seamless fit reduces the risk of moisture intrusion, misalignment, or electrical faults that can arise from poorly matched parts. A factory-original tail light typically comes with warranty coverage and a documented lineage that reassures owners about consistency of performance across model years and production runs. In contrast, aftermarket options often present cost advantages but may require additional wiring work, supplemental adapters, or custom fittings to achieve a reliable seal and correct alignment. The trade-off between upfront savings and long-term reliability is a central consideration for Eclipse owners who value both safety and appearance.

To maximize the asset value of a genuine tail light while maintaining an authentic look, owners should consider the installation and maintenance implications as well. Proper installation is essential to preserve seal integrity, ensure correct alignment with the rear body panels, and maintain the intended beam pattern. Even when the parts are OEM, minor adjustments during installation can influence how the light disperses across the license plate region, the edge of the trunk lid, and the surrounding reflectivity of the vehicle. A professional installation or a careful home installation using the vehicle’s service manual helps ensure that the tail light’s electrical connectors engage fully and that the gasket remains flush against the body, preventing water ingress and corrosion. Routine maintenance includes cleaning the lens to prevent buildup of dirt and road film that can dull the brightness of LED elements and obscure signal clarity. Although LED modules tend to resist classic bulb blackening, the lens surface and housing must remain clear for maximum efficiency and visibility over time.

The Eclipse’s tail light system is not an isolated aesthetic detail; it is a core safety feature that interacts with the vehicle’s braking system, signaling logic, and even its homologation status for road use. When a driver presses the brake, the intensity and color output are designed to convey immediate and unmistakable intent to following drivers. When the turn signal is engaged, the timing and consistency of the flash provide reliable cues to other motorists about upcoming lane changes. And when the vehicle decelerates without braking—such as when a driver eases off the accelerator—subtle lighting cues can help emphasize the vehicle’s deceleration to the traffic behind, reinforcing the overall rhythm of traffic flow. In environments that demand quick reactions, such as city street driving or congested highways, these capabilities contribute to safer, more predictable road behavior. The genuine tail light assembly thus serves as both a protective device and a stylistic element, harmonizing the Eclipse’s exterior language with a commitment to driver and pedestrian safety.

From a practical standpoint, owners who want to preserve the original look while upgrading performance may find that OEM tail light covers and assemblies offer a durable, dependable pathway to enhanced visibility and lasting aesthetics. The design language—the lines, the lens curvature, and the subtle reflections within the housing—works with the Eclipse’s overall silhouette, ensuring that even minor changes in lighting do not disrupt the vehicle’s visual balance. When replacement or upgrade is necessary, consulting the official parts catalog or an authorized dealership ensures correct compatibility, accurate part numbers, and the proper wiring configurations. The goal is not merely to replace a light but to reaffirm the reliability of the safety systems that accompany every drive. For those who value precise fitment and verified applications, following official channels provides peace of mind that the chosen tail light component will perform as intended under a wide range of driving conditions.

In the broader landscape of vehicle personalization, it is worth noting that owners who are also considering complementary upgrades can integrate inspired design choices with a focus on practicality. For instance, when upgrading wheels or other exterior components, it remains important to verify compatibility with the Eclipse’s lighting and bodywork, ensuring that new parts do not interfere with the tail light’s light dispersion or mounting geometry. A practical example of this approach can be found in community-focused guides to wheel compatibility for the Eclipse, which discuss how to coordinate wheel size, offset, and spoke design with the vehicle’s overall aesthetics and electrical layout. See more on wheel compatibility here: 17 rims fit mitsubishi eclipse wheels 2018-2023.

Ultimately, the genuine Mitsubishi Eclipse tail light represents a thoughtful equilibrium of safety, durability, and refined design. It is engineered to meet exacting OEM standards, designed to maintain a factory-original appearance, and tested to withstand the realities of daily driving. For owners who prioritize reliability, warranty protection, and regulatory compliance, OEM tail lights provide confidence that the vehicle’s rear signaling remains clear, consistent, and legally compliant across its lifespan. The choice to invest in genuine parts is a decision to protect both safety performance and aesthetic integrity, ensuring that the Eclipse continues to communicate with other road users as its designers intended. For those seeking further technical details and part applications, consult the official Mitsubishi parts catalog and trusted suppliers.

External reference: For detailed technical data and official part applications, visit the Mitsubishi parts catalog and related resources at https://www.mitsubishiparts.com. This repository of OEM information supports precise fitment and informed decision-making when upgrading or replacing tail light assemblies on the Eclipse family.

null

null

Illuminating Evolution: Advances in Mitsubishi Eclipse Tail Light Design

The tail light assembly on a Mitsubishi Eclipse serves as more than a signaling device; it is a statement of engineering intent and a barometer for modern automotive lighting. Over successive model years, the Eclipse has mirrored a broader industry shift toward lights that blend safety-critical performance with distinctive styling. In this chapter, we trace how tail light design has matured from simple illumination to a carefully engineered system that reinforces visibility, efficiency, and personality on the road. The orchestration of light in these assemblies—how it is produced, directed, and perceived—illustrates a broader move in vehicle design toward integrated, intelligent lighting that supports both the driver and the aesthetics of the car as a whole. The discussion here pulls together the technical implications of LED adoption, safety improvements, dynamic signaling, durability under diverse climates, and the tradeoffs between OEM fidelity and aftermarket customization. It also points to how these developments connect with the broader ecosystem of parts catalogs, regulatory standards, and the evolving language of automotive design.

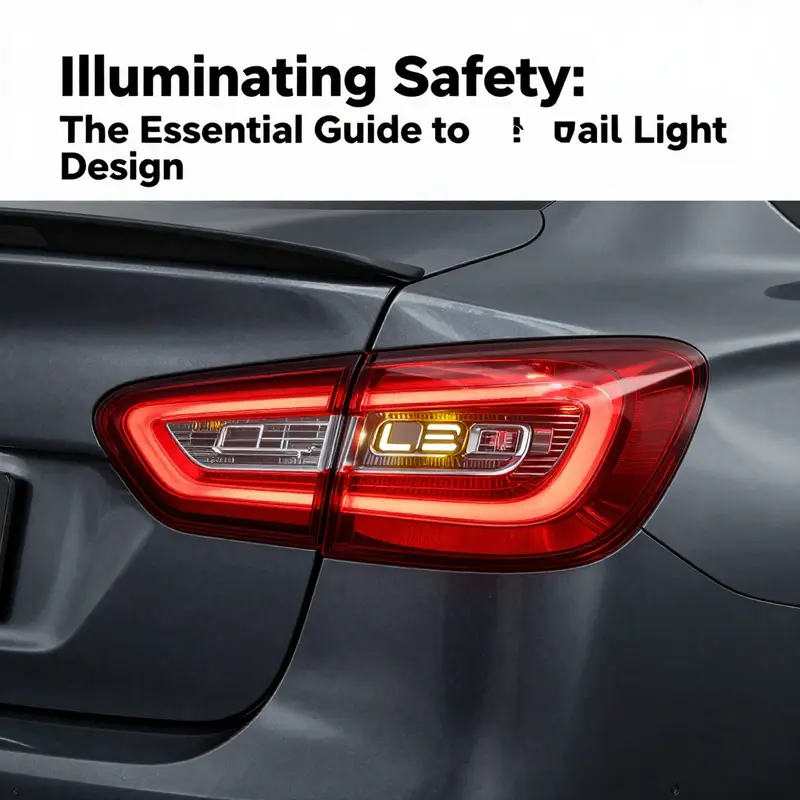

Central to the Eclipse’s evolution is the shift from traditional incandescent bulbs to LED technology. LEDs illuminate with speed and precision, delivering brighter output at lower energy costs. The advantages are not merely about brightness; they translate into faster response times for following drivers and improved perception during braking and signaling in complex traffic. The instantaneous rise and fall of an LED segment provide a more legible signal for other road users, which is crucial in urban stop-and-go conditions where milliseconds matter. In terms of energy efficiency, LEDs draw less current for the same perceived brightness, reducing load on the electrical system and contributing to the vehicle’s overall efficiency footprint. In practice, this means tail lights that respond almost instantly when the driver activates either the taillight or the brake function, enhancing road safety without requiring additional power draw. The underlying electronics—driver ICs, current regulation, thermal management—are designed to keep performance stable across a wide range of temperatures, which is essential for a vehicle that experiences hot summers and cold winters across diverse markets.

From a safety perspective, the bright, uniform illumination of modern Eclipse tail lights has a direct impact on visibility bands behind the car. A tail light that maintains consistent luminance across the lens helps reduce the likelihood of misinterpretation by drivers in rear-end situations. The third brake light, often integrated into the tail assembly, serves as a supplemental alert that reinforces braking intensity when the vehicle decelerates rapidly. While the CHMSL (center high mount stop lamp) designation varies by jurisdiction, the intent remains consistent: a higher, clearly visible signal that amplifies braking cues for drivers who may be following at longer distances or in vehicles with higher seating positions. Advances in lens design and housing materials further support this visibility by reducing light scattering and optimizing the spread pattern. The durability of the light’s performance under moisture, dust, and temperature swings is equally important, as the last thing a driver needs is a dim or inconsistent signal during a rainstorm or highway wind storm. This is where the choice of housing materials and sealing technologies plays a critical role in long-term reliability.

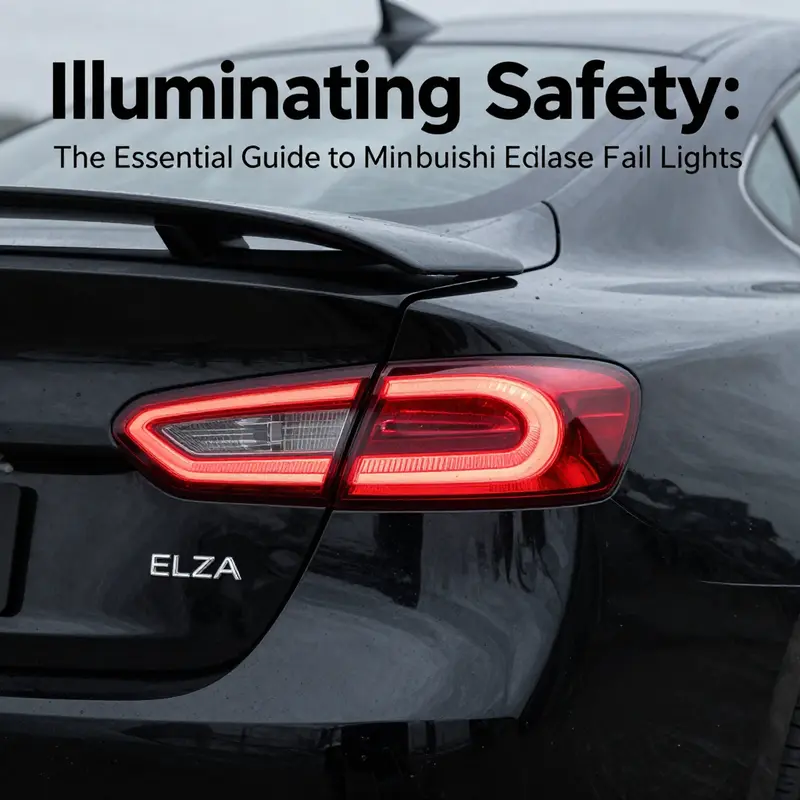

The Eclipse tail light suite also embraces dynamic lighting features that have become a hallmark of contemporary design. Sequential turn signals, for example, choreograph a rising wave of light along the lens at the moment a turn is indicated. This not only looks striking but also communicates intent more clearly to surrounding traffic, potentially reducing the risk of misinterpretation in busy traffic environments. When the brake is applied, some versions incorporate a diagnostic lighting cue or a shifting intensity pattern that intensifies communication with drivers behind. These effects require tightly integrated control software and precise LED positioning to ensure the sequence remains legible at various viewing angles and weather conditions. The aesthetic payoff is more than superficial; it signals modernity and performance without compromising legibility or safety. The visual language created by these sequences has become part of the Eclipse’s identity, melding form with function in a way that resonates with a wide audience of enthusiasts and everyday drivers alike.

The physical build of the tail light assembly supports these functional ambitions through durable materials and robust weather protection. The housing is engineered to withstand moisture ingress, thermal cycling, UV exposure, and road grime, all while maintaining optical clarity. Weather-resistant gaskets and well-sealed lens interfaces mitigate fogging and the gradual loss of brightness that can accompany aging lenses. Lens polymers are chosen for their clarity and resistance to yellowing, ensuring that the actual color and brightness of the light remain consistent over time. This is essential for safety, as dimming or discoloration can reduce the readability of signals in adverse conditions. Manufacturing quality here matters as much as the electronics; a well-sealed unit preserves performance, maintains consistent light output, and upholds regulatory compliance across the car’s lifespan.

Aesthetics play a nontrivial role in tail light design, even as the primary function remains safety-first. Designers sculpt the tail light shape to harmonize with the Eclipse’s rear silhouette, using the lamp’s outline as a punctuation mark that completes the vehicle’s lines. The light cleanse, cut lines, and internal geometry work together to create a signature glow that makes the car instantly recognizable at night. The color quality, beam pattern, and even the way light refracts within a multi-segment arrangement contribute to a sense of depth and sophistication. This synthesis of form and function is why tail lights are often perceived as a core element of a vehicle’s brand language, not merely as a utilitarian accessory. In this sense, advancements in tail light design reflect a broader trend where lighting becomes a primary design element that reinforces identity while maintaining an uncompromised commitment to safety.

Owners who pursue a factory-original look with upgraded performance often weigh two broad paths: genuine OEM tail light assemblies and carefully chosen aftermarket options. OEM parts tend to guarantee proper fitment, sustained performance, and adherence to safety regulations, factors that simplify maintenance and preserve resale value. Aftermarket solutions, by contrast, can offer cost advantages and opportunities for customization, such as discrete lens tones, updated internal reflectors, or distinct light patterns. However, such upgrades may require more involved wiring work, compatibility checks with the vehicle’s onboard controllers, and verification that the altered lighting still complies with regional lighting regulations. In all cases, the guidance of official parts catalogs or trusted suppliers remains a prudent compass. The aim is to maintain the integrity of the Eclipse’s signaling system while embracing any design or efficiency improvements that do not compromise safety.

For readers who want to explore authentic, carefully curated options that balance OEM fidelity with practical upgrade potential, there is a dedicated pathway that highlights carefully selected tail light configurations. This resource provides a reliable overview of how authentic and OEM-aligned choices can preserve fitment and regulatory compliance while offering some leeway for personal preference in lighting patterns. This approach aligns with the broader goal of keeping signaling predictable and legible in all driving environments. It also avoids the pitfalls of mismatched dimensions or unintended electrical strain, which can arise when adopting parts that do not align with the vehicle’s original design intent. The Eclipse tail light system thus becomes a case study in how modern lighting design negotiates the tension between innovation, safety, and the authentic look that owners often seek to maintain over time.

From a sourcing perspective, the conversation around tail light technology inevitably touches the practicalities of part selection and installation. Buyers are encouraged to consult official parts catalogs or trusted automotive suppliers to confirm compatibility with their model year and trim. This due diligence helps ensure that the chosen assembly, connector geometry, and mounting hardware align with the vehicle’s electrical system and regulatory constraints. The aim is not merely to install brighter lights but to retain the stability of the vehicle’s signaling architecture, maintain seamless operation with existing fuses and controllers, and preserve the long-term reliability that owners expect from modern lighting systems. In short, the Eclipse’s tail lights exemplify how contemporary automotive lighting can harmonize high performance with dependable, user-friendly maintenance experiences.

For readers who wish to delve into a practical example of authentic tail light options within the same ecosystem, a dedicated page offers insights into how seemingly small choices—such as lens clarity, internal reflector geometry, and the presence of a distinct light sequencing pattern—can cumulatively alter the vehicle’s nighttime presence without deviating from safety norms. This approach helps convey that tail light design is not a series of isolated improvements but a cohesive strategy that binds safety, efficiency, and style into a unified visual language. The result is a tail light system that remains legible and compliant while advancing the Eclipse’s modern aesthetic, a balance that will continue to orient future updates as the technology and regulations evolve.

External resource for broader context and technical specifications can be found on the official vehicle manufacturer site, which provides detailed information about lighting standards, regulatory expectations, and the technology underpinning modern Eclipse lighting systems. Access to these technical details supports a deeper understanding of how the tail light evolves in concert with other lighting elements and vehicle electronics over successive generations. External reference: https://www.mitsubishimotors.com

Preserving Signal and Style: A Deep Dive into Maintaining and Replacing Mitsubishi Eclipse Tail Light Components

The tail light cluster on a Mitsubishi Eclipse is more than a signaling device. It is a claim on safety and a touch of personality, blending function with a design cue that can set the tone for the whole rear end of the car. When designed and maintained properly, tail lights illuminate decisively in low light, respond promptly to braking, and present a clean, cohesive silhouette that complements the vehicle’s lines. In practice, the tail light assembly endures a lot: road grit, temperature swings, moisture intrusion, and the occasional misjudged parking maneuver. These factors can take a toll on lenses, seals, bulbs, and the wiring harness that ties the illumination system to the car’s electrical brain. A careful, regular eye for these components helps preserve visibility for drivers behind, reduces the risk of rear-end incidents, and keeps the Eclipse looking intentional rather than neglected. In other words, tail light maintenance is a quiet, ongoing act of stewardship that upholds safety and style in equal measure.

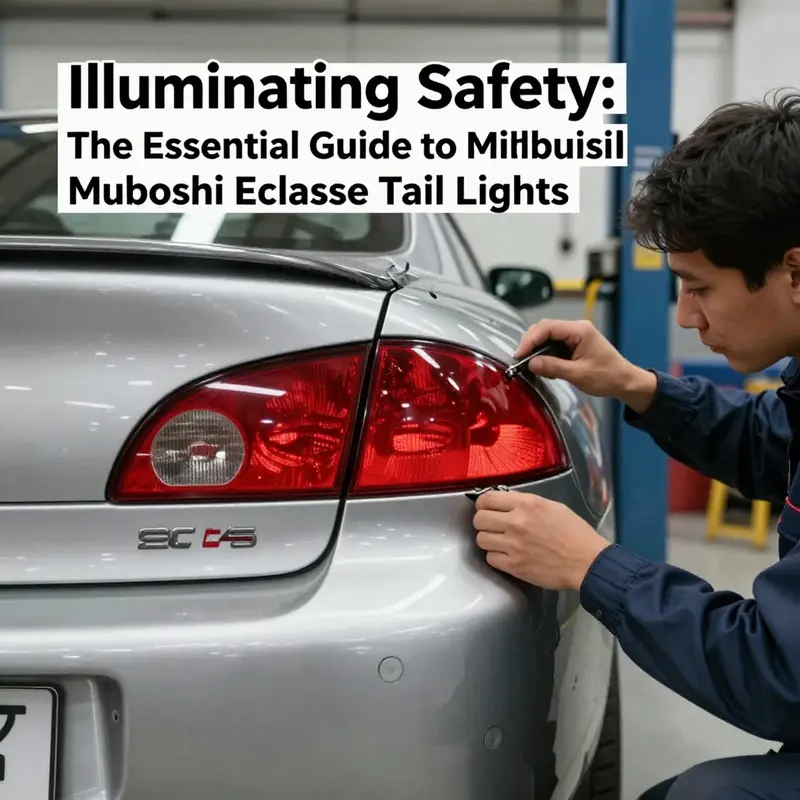

Regular inspection is the first discipline every Eclipse owner should practice. The lenses should be clear and free of cracks or pitting, because even minor damage can scatter light and reduce brightness. Condensation inside the lens housing is a telling sign that seals are aging or compromised. Moisture can corrode contacts and degrade both performance and reliability. A simple visual check, done in a well-lit space, can reveal fogging that would otherwise go unnoticed on a dim street. The exterior lens surface should be cleaned with care, using a mild cleaner that won’t degrade the plastic or strip protective coatings. Gentle scrubbing along the edges and any gaskets can prevent the buildup that invites moisture to linger behind the seal. A quick test of the operation—lights, brake lights, and turn signals—confirms that the circuit is intact and that the lighting is evenly bright across the entire spread of the lens.

Beyond the lenses, the electrical heart of the tail light deserves equal attention. Wiring harnesses run along the trunk or rear body to feed power to each lamp unit. Over time, insulation can wear, connectors can loosen, and harnesses can become brittle from temperature exposure. A dedicated inspection should look for frayed wires, loose connectors, or any signs of corrosion at ground points. When a tail light fails to ignite with the expected brightness, the culprit is not always the bulb alone; a degraded connector or a compromised ground can cast a shadow over the entire system. In practical terms, this means owners should carry out a tactile check of the harnesses behind the interior trim, listening for loose pins when panels are pried away for inspection. While this sounds meticulous, it is a small investment in safety that pays dividends in night driving and inclement weather conditions when visibility matters most.

When replacement becomes necessary, a set of practical pathways opens up, each with its own balance of fit, performance, and cost. OEM tail light assemblies—the original equipment—are the most straightforward choice for many owners who want factory-original look and exact fit. These units are designed to align with the car’s electrical system, seal against the elements, and comply with safety standards. The advantage is predictable performance and durability, because OEM parts are engineered to the same specifications that rolled off the assembly line. Yet availability can become a limiting factor for older models, and the price tag may be higher than aftermarket alternatives. For some Eclipse owners, the assurance of precise fit and long-term reliability justifies the premium, particularly when the vehicle’s value and vibrancy depend on a seamless, factory-present rear end.

LED tail light replacements offer another compelling route, one that mirrors broader shifts in automotive lighting toward brightness, efficiency, and functional design. Upgrading to LEDs can yield faster response times, more efficient energy use, and a sharper, more contemporary appearance. The advantages extend beyond mere aesthetics: the longer lifespan of LED elements translates into less frequent bulb changes and more consistent performance over time. However, LED kits require careful attention to compatibility with the Eclipse’s original electrical setup. Some aftermarket LED assemblies can trigger CAN bus warnings, flicker, or glare if they aren’t designed for the vehicle’s electronics. To avoid these issues, buyers should select high-quality LED kits made specifically for the Eclipse, and be prepared for essential steps such as integrating resistors or CANbus error cancellers if the kit requires it. In short, an LED upgrade can be a meaningful improvement, but it demands thoughtful selection and precise installation.

For those who want to preserve the look and feel of the stock design while still achieving a contrast with modern tech, aftermarket or replica tail light assemblies present a budget-conscious option. These units can mimic the factory design and deliver a distinctive presence at a lower upfront cost. Yet the trade-off is real: build quality can vary widely among third-party manufacturers, and sealing, lens material, or bulb configurations may not meet the same standards as OEM parts. The risk of premature fogging, mismatched light patterns, or misalignment is nontrivial if the unit isn’t properly engineered for the Eclipse’s dimensions. The prudent approach here is to verify compatibility by model year and trim, read independent reviews for reliability and installation ease, and plan for careful inspection after installation to ensure the light pattern is correct and the seal is intact.

No matter which replacement path is chosen, the installation sequence is a constant, and doing it correctly matters as much as selecting the right component. The basic steps include safely disconnecting the battery to prevent any electrical mishaps, removing the interior trim panel that hides the taillight mounting hardware, detaching the wiring harness with attention to retaining clips and connectors, and finally securing the new assembly with the correct fasteners and torques. A methodical approach helps prevent damage to nearby panels, gaskets, or paint, and it reduces the chance of later reworks caused by a loose or misaligned unit. A well-documented repair guide can be a valuable companion during this process, offering clear, step-by-step instructions with photos and troubleshooting tips. While the guide referenced here is external to this chapter’s immediate resources, it serves as a practical reminder that DIY maintenance benefits from reliable, detailed references when approaching a task that intersects electrical safety and cosmetic precision.

In the broader context of maintenance, the third brake light (CHMSL) deserves particular emphasis. Mounted higher and more centralized, this light contributes a critical layer of visibility during braking, especially in dense traffic and in stop-and-go environments. Law and regulations in many regions mandate a functioning CHMSL, and failing to maintain it can carry regulatory consequences as well as safety risks. Keeping the CHMSL in good working order—checking bulb integrity, lens clarity, and the seal around the unit—ensures that the Eclipse communicates braking intent clearly to following drivers. In a vehicle whose tail lights carry both a signal and a design statement, neglecting any part of the system diminishes the whole package and can undermine both safety and curb appeal.

Of course, every maintenance decision benefits from alignment with the car’s overall design language and engineering. For those who prefer factory-like coherence, it can be useful to reference adjacent body components when planning a lighting upgrade. A genuine OEM approach to the Eclipse tail light path is not just about the lamp itself; it is about how the rear assembly relates to nearby parts, such as the deck lid, trunk seal, and surrounding panels. In this spirit, one might explore cross-references that share a design philosophy and a common lineage of fitment. For example, a page detailing a specific Eclipse body component—such as the 2006-2012 Mitsubishi Eclipse Monster GT style carbon fiber hood—can serve as a helpful cross-reference for fitment cues and design cues that influence overall rear aesthetics and alignment with the taillight housing. This is a practical reminder that maintaining an Eclipse means considering the whole car, not just a single lighting unit. See the related component page here: 2006-2012-mitsubishi-eclipse-monster-gt-style-carbon-fiber-hood.

Finally, always anchor maintenance decisions in trustworthy sources and official specifications. Replacement parts should be verified against the vehicle’s exact model year and trim level, and buyers should consult official catalogs or trusted suppliers to confirm compatibility and electrical requirements. Aligning part choice with the vehicle’s electrical architecture helps prevent compatibility issues that can manifest as flicker, misalignment, or reduced illumination. When in doubt, prioritize reliability and safety: a correctly installed OEM unit may cost more up front, but it reduces the risk of warranty problems or electrical faults later on. Conversely, if an upgrade is desired for improved brightness and sharper signaling, opt for products that are designed for the Eclipse, and prepare for a careful integration process that respects CANbus considerations and proper heat management for LED modules. In all cases, thorough inspection after installation—checking seal integrity, light output, and correct operation across all indicators—will help ensure the tail light system remains a durable, dependable component of the vehicle.

The discipline of tail light maintenance, at its core, embodies the same careful attention drivers bring to every other vital system in the car. It is a reminder that safety is not a single act but a continuous practice—one that preserves the subtle balance between function, form, and the trust that others place in the vehicle’s signals. As the Eclipse continues to navigate nights and weather with composure, a well-maintained tail light assembly ensures that its presence on the road remains legible, reliable, and visually coherent with the sleek lines of its design. That ongoing commitment to care—engaging with lenses, harnesses, and housings, choosing the right replacement path, and following through with thoughtful installation—translates into a safer drive for everyone who shares the road and into a richer ownership experience for the enthusiast who keeps faith with the car’s lineage and its evolving lighting narrative.

External reference: https://www.ifixit.com/Guide/Mitsubishi+Eclipse+Tail+Light+Replacement/34567

Final thoughts

Mitsubishi Eclipse tail lights play a vital role in enhancing both the safety and visual appeal of the vehicle. From the reliability of genuine OEM parts, which ensure compliance with safety standards, to the cost-effective nature of aftermarket options, understanding the available choices is crucial. Additionally, as technology progresses, the design and functionality of tail lights become more sophisticated, offering improved visibility and customizable features with energy-efficient designs. Regular maintenance and timely replacement of these components safeguard against accidents while maintaining the vehicle’s aesthetic appeal. For business owners, investing in quality tail lights is not only a matter of compliance but also a commitment to safety and style on the road. This comprehensive understanding will help optimize vehicle functionality and ensure that both owners and others on the road stay safe.