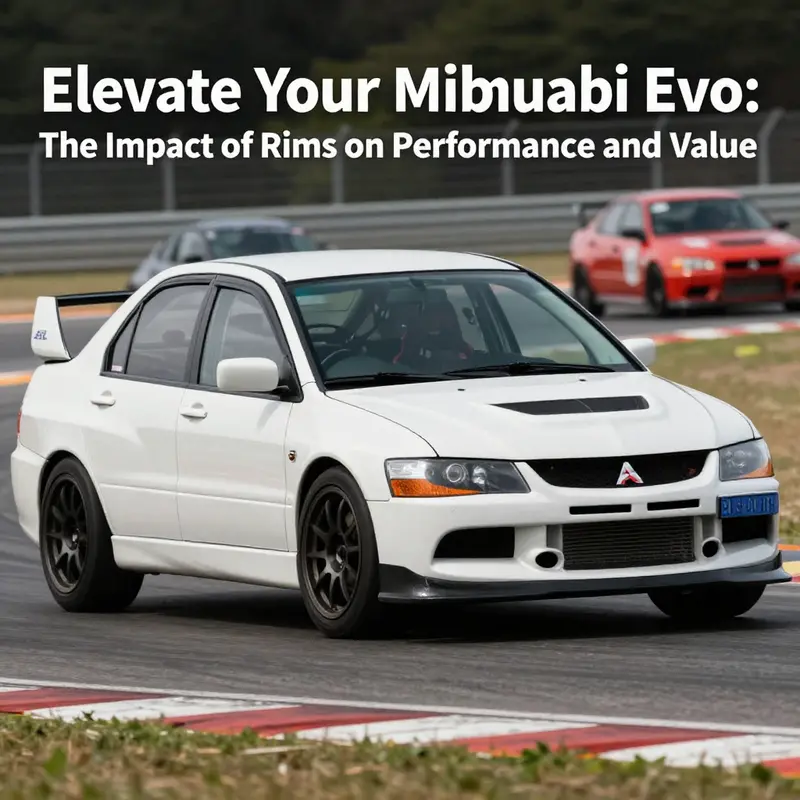

Mitsubishi Lancer Evolution, often referred to as EVO, is not just a car; it is a symbol of performance and engineering excellence. Rims form a vital part of this dynamic machine, affecting both its aesthetic appeal and functional capabilities. As business owners navigating the automotive aftermarket, understanding the nuances of EVO rims can position you to tap into a lucrative market that merges performance with style. This article delves into three critical aspects: the differences between forged and cast aluminum rims, the performance advantages of upgraded rims, and the historical and current market trends influencing their value. By the end, you will gain insights necessary for making informed decisions that align with customer demands and market dynamics.

Forged vs Cast Aluminum: The Wheel-Wise Upgrade Path for the Mitsubishi Evolution

Rims are more than a cosmetic upgrade on a Mitsubishi Evolution; they are a pivotal balance of strength, weight, heat management, and fitment that can redefine how the car feels on every corner, straightaway, and braking zone. When a builder considers upgrading the Evo’s wheels, two broad paths open up: forged aluminum rims and cast aluminum rims. Each path carries a distinct philosophy about performance, daily usability, and price. Reading the landscape of options without losing sight of the Evo’s core DNA—grit, speed, and relentless precision—helps a driver choose not just a wheel, but a chassis component that harmonizes with tires, brakes, and suspension. The Evo, after all, isn’t a mere street car; it’s a platform designed to attack tracks, rally stages, and winding canyon roads with a singular, rally-bred intent. That intent is best realized when the rims themselves serve the car’s dynamic demands, not just its visual aggression.

Forged aluminum rims emerge from a manufacturing process that begins with a solid billet of aluminum. Through a high-pressure forging stage, the metal’s grain structure is realigned, resulting in a wheel that is simultaneously stronger and lighter for a given design. The benefit is a reduction in unsprung mass, the portion of the car that directly influences how quickly the suspension can respond to pavement irregularities and how precisely the car can change direction during aggressive driving. On a sport-tuned Evo, even modest weight reductions in the wheel-tire-suspension triad translate into more immediate steering feedback, crisper throttle response, and sharper braking. That is the practical essence of forged rims: strength-to-weight superiority that translates into tangible on-road and on-track performance.

Performance-oriented Evo drivers often lean toward forged rims for several reasons beyond raw weight. The manufacturing alignment of the metal’s grain structure improves resistance to fatigue and impacts at high loads, a relevant factor when an Evo is pushed into tight hairpins, lap-bound straights, or track cornering sequences where heat and load cycles are repeated relentlessly. The result is a wheel that can endure the abuse of track sessions and spirited street use with a margin of durability that gives drivers confidence to push a little deeper into braking zones or faster through apexes. The tactile payoff is a car that rotates more easily, with reduced yaw inertia thanks to a lighter wheel system, enabling quicker mid-corner transitions and more precise line holding. When a driver is chasing lap times or simply enjoying a limit-driven drive, forged rims support a more responsive chassis and a more predictable handling balance, both of which are essential for exploiting a high-grip tire and tuned suspension.

Cost is the most immediate counterpoint to forged rims. The same grain-structure alignment that delivers strength and lightness comes at a premium, and forged wheels typically carry a higher price tag than their cast counterparts. For the dedicated track enthusiast or the professional racer who tracks miles and minutes as part of a program, the extra upfront expense is often justified by the longevity, reliability, and performance consistency forged rims provide under repeated heat cycles. For the street-focused Evo owner, the decision may hinge on how often the car is driven on dry pavement, how much the owner values feel and response, and whether the budget can accommodate a wheel package that optimizes performance without compromising everyday comfort.

Cast aluminum rims, by contrast, arise from pouring molten metal into a mold and allowing it to solidify in a designed shape. Cast rims are typically more cost-effective to produce, which translates into a lower price point for consumers. This affordability can be appealing for Evo owners who want a noticeable upgrade from stock wheels without venturing into the higher cost territory of forged alternatives. Cast rims also offer design flexibility; the molding process makes it easier to achieve intricate, aggressively styled wheel faces and unique spoke geometries that visually transform the Evo’s stance. For many owners, the aesthetic payoff—an eye-catching wheel design with distinctive depth, color accents, or concave profiles—pairs well with the daily-driver responsibility of a well-maintained Evo.

In terms of performance, cast wheels generally deliver a modest weight advantage over steel but remain heavier than forged aluminum wheels of comparable size and strength. The practical impact on handling is present but not as pronounced as with forged wheels. Cast rims still provide a meaningful upgrade over stock wheels, especially when paired with wider tires or lower offsets that improve contact patch and cornering grip. The texture of daily life with cast wheels is typically smoother in everyday conditions, as the design tolerances and material properties are well suited to regular road use. For enthusiasts who value a harmonious blend of price, appearance, and everyday performance, cast rims offer a compelling middle ground between stock equipment and high-end forging.

A critical thread running through both forged and cast options is how the wheel interacts with the Evo’s diverse performance demands. Heat management is a central consideration, particularly on track or spirited back-road sessions where braking forces are sustained and brake temperatures climb quickly. Deep-dish or multi-spoke designs, common in both forged and cast lines, are often chosen not just for their aggressive look but for improved heat dissipation. While the external appearance is important, the internal venting characteristics and spoke geometry influence how effectively the brake rotors shed heat. In this sense, the choice of rim is also a choice about how the car’s braking system remains consistent as temperatures rise—an essential factor in maintaining predictable stopping power and pedal feel during prolonged sessions.

Compatibility remains the practical gatekeeper for any Evo wheel upgrade. The Evolution platform commonly uses a 5×100 bolt pattern, with attention to offset and center bore to ensure proper fitment and clearance with brake calipers, suspension components, and the car’s hub. A wheel with the wrong offset can push tire contact patches outward or inward, altering steering feel and geometry in a way that reduces grip and increases wear. The center bore must align with the hub to avoid vibration or hub-centric offset issues, while a compatible TPMS (tire pressure monitoring system) setup ensures the car continues to monitor tire pressures effectively. For Evo owners, a wheel choice that respects these fitment constraints maintains safety and performance without compromising the car’s stability and steering precision.

The Evo’s visual identity is also a component of the wheel decision. A multi-spoke or deep-dish design can complement the car’s aggressive silhouette and rally-inspired lineage, contributing to a sense of immediacy and purpose when the car sits in the driveway or pulls into a paddock. The aesthetic impact is not trivial; wheels convey a message about intent and skill. Yet the most successful wheel choice balances form with function. Years of experience with the Evolution’s dynamic envelope show that the best wheel packaging is one that reduces unsprung weight, maximizes tire contact, and suits the driver’s handling style and track goals while preserving drivability on public roads.

In the aftermarket ecosystem, options proliferate for Evo rims tailored to performance or fashion alike. For those chasing ultimate track capability, forged rims with wider widths and lower offsets can unlock the potential of high-grip tires, improving traction and cornering stability on the limit. However, widening the wheel track and reducing offset can alter ride quality and suspension tuning, sometimes requiring changes to spring rates, dampers, or alignment settings to maintain an optimal balance. The interplay between wheel dimensions, tire choices, and suspension calibration is a reminder that a wheel upgrade is most effective when it is part of a holistic upgrade strategy rather than a single, isolated change.

Beyond performance, the Evo’s rims contribute to the vehicle’s resale value—an aspect that becomes especially meaningful for limited or highly sought-after generations. The ninth and tenth generations of the Evo have achieved a cult status among enthusiasts, and the market has shown that correct, well-maintained rims—whether original equipment or high-quality aftermarket options—retain strong appeal. Following the model’s discontinuation in 2023, demand for clean, compatible wheels has not waned. Buyers looking to restore or upgrade often place a premium on rims that fit the Evo’s exacting specifications. This dynamic underscores a broader truth in the performance car market: the value of a component is not just in its immediate performance benefits, but also in how well it preserves or enhances the vehicle’s overall desirability and market position.

For buyers and builders, sourcing plays a decisive role in achieving the intended outcome. Working with reputable suppliers who specialize in Evo-specific parts increases the likelihood of achieving proper fitment, reliable performance, and compatibility with systems such as TPMS and hubcaps. A trusted source will verify bolt pattern, offset, center bore, and brake clearance against the exact Evo model and wheel size in use. The right supplier also helps ensure that the wheels you choose are consistent with the car’s braking hardware and suspension geometry, minimizing the risk of interference or unintended changes in handling characteristics. In practical terms, this means confirming that a wheel build aligns with the Evo’s design language and mechanical realities, thereby preserving safety, performance, and the car’s characteristic dynamic response.

As with any meaningful modification, the choice between forged and cast rims invites a conversation about the owner’s priorities. If you prize peak performance, track reliability, and the long-term resilience of the wheel under repeated heat cycles, forged rims make a compelling case, especially when paired with a well-tuned suspension and high-grip tires. If, instead, your priorities lean toward cost efficiency, design variety, and a strong visual impact for daily driving, cast rims offer a satisfying upgrade that can still deliver meaningful handling improvements and a more engaging road presence. For most Evo owners, the sweet spot lies in a plan that uses the wheel as part of a broader upgrade strategy—tire choice, brake heat management, suspension tuning, and drivetrain reliability—so that the wheel and tire package performs predictably across a range of driving conditions.

The decision does not exist in isolation. It intertwines with how you drive, where you drive, and how you maintain the car over time. Track days, spirited canyon runs, and street cruising each place different demands on a wheel package. Forged rims, with their strength and low weight, can support aggressive driving sequences with reduced rotational inertia, enabling quicker steering and more precise brake modulation. Cast rims can still deliver substantial performance gains with careful tire selection and proper fitment, while providing an economical path to a refreshed look and improved handling. Either way, the Evo rewards a thoughtful approach that respects the car’s engineering fundamentals and the driver’s goals.

Among enthusiasts, the debate often touches on the practical realities of ownership. Forged wheels demand careful consideration of cost versus longevity, including potential maintenance and the possibility of curb damages that, while rare, carry different consequences for forged versus cast materials. Cast wheels, while generally more forgiving on a budget, can show cosmetic and structural vulnerabilities sooner if pushed beyond daily-use boundaries. The right approach recognizes that an Evo owner is not merely selecting a wheel shape; they are selecting a system that must endure high torque transfer, heat, and dynamic loads while preserving the charm of the Evo’s driving experience. In that sense, a wheel upgrade becomes a precise instrument—tuning not just grip and weight, but also heat management, steering response, and the car’s overall rhythm through a corner.

Internal links can guide readers toward deeper, non-promotional resources that illuminate the broader wheel trade. For those who want to examine a general industry perspective on forged versus cast wheels, a respected automotive publication offers a detailed comparison that helps contextualize the Evo-specific decision. As a practical starting point, consider exploring a dedicated analysis that contrasts the structural and performance differences between forged and cast wheels, including real-world considerations like durability, cost, and long-term value. This kind of resource can provide a sturdy framework for buyers weighing the tradeoffs inherent in any wheel upgrade while still keeping the focus on the Evo’s unique demands.

If you’re exploring options that extend beyond the purely technical and into the tangible, you might also consider how a wheel project fits into the broader ecosystem of Evo upgrades. A carefully chosen set of rims can be part of a holistic plan that includes upgraded brakes, improved cooling, and a tailored suspension tune. The result is a cohesive package where every component works in harmony to deliver the Evo’s signature blend of agility and grip. The thrill comes not from a single improvement but from how the wheel, tire, and chassis communicate with one another during aggressive driving. As you read about forged and cast rims, remember that the best choice for your Evo is the one that aligns with your intended use, your budget, and your willingness to invest in a complete, performance-focused driving experience.

To connect the discussion to real-world selection and options, consider a practical example of how a user might approach a wheel upgrade. Beginning with a mood board of the desired handling feel, the owner would evaluate the track or road-race intent, then select a wheel diameter and width that accommodate a specific tire model with the intended grip characteristics. In the forged path, the driver might opt for a lighter diameter with a low offset that widens the front track and improves turn-in. In the cast path, they could choose a design with a strong visual statement that still aligns with the Evo’s geometry and brake clearance. In both cases, careful attention to hub bore and TPMS compatibility ensures a seamless integration with the car’s electronic systems and sensors. The result is not just a sharper wheel, but a more cohesive driving experience that remains faithful to the Evo’s purpose and heritage.

As a closing thought, the decision between forged and cast rims is less a monopoly and more a spectrum. It depends on how aggressively you intend to drive, how much you value track-capable performance over daily practicality, and how much you’re willing to invest in a wheel system that lasts. For the Evo community, this spectrum is part of what makes the platform enduring and exciting. The right rims can enhance braking efficiency, reduce unsprung mass, improve steering response, and amplify the car’s visual presence—without compromising reliability or safety. In the end, the Evo’s wheel choice is a statement about how you want to connect with the road: as a precise, track-ready machine, or as a confidently striking road companion that still offers the thrill of high-performance dynamics. Either path, chosen with care, preserves the Evolution’s essence and keeps the drive as engaging as the legacy suggests.

Internal resource for related reading: brand-new original rims for Lancer sedans

External reference

For a broader perspective on forged versus cast wheels, see the detailed comparison in Car and Driver’s feature on forged vs. cast wheels, which discusses strength, weight, and cost considerations across mainstream automotive applications. https://www.caranddriver.com/features/a45879197/forged-vs-cast-wheels/

Unlocking Evo Potential: How the Right Rims Transform Handling, Braking, and Acceleration

How the Right Rims Change an Evo’s Dynamics

Choosing the right set of rims for a Mitsubishi Lancer Evolution is one of the most effective ways to improve dynamic performance without altering the engine. Wheels are more than just visual elements. They are functional parts of the drivetrain and suspension. The right rims change unsprung weight, rotational inertia, brake cooling, tire fitment, and the way the all-wheel-drive system transfers power. When you understand these interactions, you can make choices that sharpen steering, shorten stopping distances, and add usable traction where the Evo needs it most.

Lightweight rims reduce unsprung mass in direct and measurable ways. Unsprung mass includes everything not supported by the suspension—wheels, tires, brake components, and a few small fixtures. When that mass drops, the suspension reacts more quickly to bumps. Tires maintain better contact with the road. The Evo’s chassis and all-wheel-drive system benefit immediately; traction improves under acceleration and cornering becomes more composed. Many aftermarket alloys achieve these gains by using aluminum-magnesium blends, forging processes, or flow-forming techniques to deliver a strong wheel with less material. The result is crisper turn-in and more confidence entering corners at speed.

Rotational inertia is the other side of the coin. Wheels sit at the extreme edge of the drivetrain, so their mass has an outsized effect on acceleration and engine load. Lighter rims reduce rotational inertia, allowing the engine to accelerate the wheels with less effort. This yields quicker response from low and mid RPM, and can make shifts feel more energetic. On the road or track, that responsiveness translates to faster sprint times and a sharper, more engaged driving feel. For daily driving, the same change can also create modest fuel efficiency gains because less torque is consumed just to spin the wheels.

Brake performance and thermal management are tightly linked to wheel choice. Alloy rims conduct heat better than steel. When paired with open spoke designs, they help exhaust heat from brake rotors and calipers. During track sessions or spirited mountain runs, this cooling capacity reduces the onset of brake fade. Brake fade occurs when pad and fluid temperatures climb, degrading stopping performance. Wheels with sufficient clearance improve airflow to vented rotors and large calipers. Many high-performance rims feature multi-spoke layouts that balance structural rigidity and airflow. Choosing a design that directs ambient air to the brakes preserves brake performance over long, demanding runs.

Tire fitment and contact patch behavior are central to how an Evo grips the road. Wider rims allow wider tires and change the tire’s profile on the road. A properly matched tire-and-wheel combination increases the contact patch during cornering. The Evo’s all-wheel-drive system uses available grip at each wheel to vector torque and stabilize the car. Wider contact patches reduce slip under acceleration and enable higher cornering limits. However, width is not a free variable. An overly wide rim can deform a tire’s sidewall excessively, alter carcass stiffness, and produce unpredictable handling. The correct rim width and offset combination preserves the tire’s intended geometry while safely increasing usable grip.

Offset and backspacing determine track width and steering geometry. Lower offsets push the wheel outward, widening track and altering scrub radius. Increasing track width enhances lateral stability and gives the Evo a planted feel. But changes to scrub radius and steering geometry can increase steering effort and add torque steer on heavy throttle exits. Careful selection of offsets ensures the wheel clears calipers and does not contact suspension arms. It also ensures the tire sits correctly under the fender during full suspension travel. For the Evo lineup, typical bolt patterns and offsets are well documented, but aftermarket options often expand the feasible range. When you move beyond factory offsets, evaluate fender clearance, potential rubbing, and the need for minor body or suspension adjustments.

Construction method matters. Forged wheels often deliver the best strength-to-weight ratio. The forging process compresses a billet of metal into shape, aligning grain structure and improving fatigue resistance. Flow-formed wheels start as cast blanks that are spun and stretched to produce thinner, stronger barrels. Cast wheels are economical and can offer useful designs, but they usually weigh more than forged counterparts. Each construction method has trade-offs. Forged wheels handle hard track abuse and repeated weight loading better. Flow-formed wheels can approach forged characteristics at a lower cost, while cast wheels are a budget-friendly choice for street-focused builds where absolute weight savings are less critical.

Fitment specifics must be respected. Bolt pattern, center bore, load rating, and hub-centric fit are non-negotiable for safe operation. Many Evo models use a 5×100 bolt pattern, but wheel engineers and fitment guides vary across generations. The center bore must match the hub size or use proper hub-centric rings to avoid vibration. Load ratings should exceed the vehicle’s curb weight, considering potential track loads and passenger weight. True fitment goes beyond simply placing a wheel on studs. It ensures caliper clearance, suspension travel compatibility, and that the wheel does not contact control arms or bodywork during articulation. A correct fit is the foundation of both reliability and performance.

Balancing trade-offs is part of the decision. Wider rims and larger-diameter wheels look aggressive and can widen the tire choice pool, but they can also increase unsprung weight. Larger diameters can require lower-profile tires. Lower-profile tires stiffen ride quality and transmit more road input to the chassis. For drivers focused on track times, this trade-off is acceptable. For daily drivers prioritizing comfort, a careful compromise is necessary. The right match keeps ride quality reasonable while delivering tangible handling improvements.

Wheel weight distribution and proper balancing are often underestimated. Even a lightweight rim can have an uneven weight distribution that makes balancing difficult. A poorly balanced wheel creates vibrations, accelerates wear, and masks genuine chassis issues during testing. Precision balancing minimizes these problems and yields a neutral, predictable car at speed. When installing new rims, invest in dynamic balancing and road force balancing when possible. These procedures identify tire irregularities and wheel inconsistencies, producing the most stable behavior on highways and tracks alike.

Aero and rotational drag also play roles that are easy to overlook. Wheel design influences local airflow around the brake ducts and inner fenders. Some spoke patterns accelerate airflow into the brakes; others create turbulence that reduces cooling. Additionally, the wheel’s frontal area and design change aerodynamic drag. For top-speed runs or sustained high-speed driving, the drag penalty from an overly open or heavy wheel can be measurable. For most drivers, the handling and cooling benefits outweigh small aerodynamic impacts. However, when optimizing for lap time on high-speed circuits, consider both cooling and drag characteristics when choosing wheel profiles.

Interaction with the suspension is another critical point. Changing wheel geometry affects cornering roll, camber curves, and the suspension’s effective motion ratio. A wider wheel may change lateral load transfer characteristics, putting different stresses on sway bars and springs. That means you should reassess corner balancing and alignment after a rim upgrade. Proper alignment settings can exploit the rims’ benefits fully. Slight changes to toe, camber, and caster can sharpen turn-in and extend tire life. For Evo chassis tuned for high levels of grip, even small alignment changes can alter balance significantly.

Tire choice is inseparable from wheel selection. Performance tires must match the rim’s width and diameter to achieve correct sidewall behavior. Directional tread patterns and compound choices interact with rim width differently. For instance, a high-grip compound might benefit more from a slightly narrower rim that allows a fuller contact patch than a very wide rim that flattens the tire excessively. Staggered setups—different widths front and rear—can tune understeer and oversteer characteristics. For AWD E

vos, a balanced approach often yields the best traction across varying conditions.

Practical installation details round out performance gains. Use new or verified lug nuts and follow correct torque sequences. Ensure hub faces are clean and free of corrosion before mounting. Anti-seize on studs can ease future removal but must be used sparingly to avoid torque-reading errors. Check TPMS compatibility and recalibrate or replace sensors when necessary. After a fitment change, perform an immediate alignment and a wheel-torque check after the first 50 to 100 miles. These steps preserve safety and ensure that the dynamic gains translate to real-world driving.

Durability and longevity matter for drivers who push hard. Wheel fatigue, impacts with curbs, and repeated track loads can compromise structural integrity. Regular inspections for cracks, bends, and rim lip damage protect drivers and prevent catastrophic failures. Replace wheels that show evidence of stress or damage. High-quality wheels come with load and impact testing certifications. Consider these documents when selecting a wheel. They prove the wheel can withstand repeated stresses typical of spirited driving.

Aesthetic value ties directly to perceived performance and resale. A well-matched set of rims elevates the entire vehicle. For collectors and enthusiasts, original-style wheels or high-quality reproductions retain and sometimes increase value. The Evo’s enthusiast market values authenticity in certain cases. For those restoring or preparing a car for sale, consider OEM-inspired designs that remain true to the platform. For example, OEM-styled, high-quality R18 designs remain desirable among buyers of performance sedans. If you want to review an example of such an OEM-style wheel option, consider this listing for original BBS R18 rims for Lancer sedans.

Finally, think holistically. Rims are a critical node in a system of components. The best result comes when wheels, tires, suspension, brakes, and steering align to achieve a clear objective. If the goal is track dominance, favor forged, lightweight options with high-clearance designs for big brakes. If the goal is a sharper street car, balance weight savings with ride comfort and tire choice. If the goal is resale or preservation, prioritize period-correct or high-quality OEM-style wheels. Whatever the path, confirm fitment, respect load limits, and test carefully. That disciplined approach preserves the Evo’s character while unlocking meaningful performance gains.

For detailed technical guidance on rim specifications and best practices, refer to the technical upgrades and performance guide compiled by Evo specialists here: https://www.mitsubishievo.com/technical-upgrades/rims-performance

Rims in the Rally’s Wake: Tracing the Market Pulse of Mitsubishi Evo Wheels Across Generations

The market for Mitsubishi Lancer Evolution rims is a living map of a car’s evolving legend. As the Evolution matured—from its early, raw configurations to the high-tech, road- and track-ready machines of the later generations—the wheels that circled those brakes and carried the car’s weight shifted in tandem with the vehicle’s own identity. In the earliest EVOs, factory rims balanced resilience and performance, forged from alloy and tuned for demanding rally-style driving; 17-inch designs became symbols of capability. Over time, OEM packages carried provenance and authenticity, with well-documented mileage and service history boosting value in the secondary market. In 2026 genuine OEM rims from later generations, particularly the EVO X, can command premium when well preserved and fully documented, reflecting both engineering heritage and the car’s narrative. The market also recognizes compatible aftermarket options that offer lighter mass or wider tires, while mandating careful attention to bolt pattern, offset, center bore, brake clearance and suspension compatibility. Conditions, provenance, and original finishes increasingly influence price as collectors prize era-correct authenticity. Buyers should perform due diligence on fitment and history, while sellers benefit from clear documentation and careful presentation. Overall, rims remain a barometer of the EVO’s enduring influence, balancing nostalgia with modern performance expectations.

Final thoughts

Understanding the types of Mitsubishi Evo rims and their performance benefits is crucial for those in the aftermarket automotive sector. Not only do these components enhance the car’s aesthetics and performance capabilities, but they also play a significant role in the vehicle’s market value. As trends evolve, keeping abreast of both historical and current market data on Evo rims can equip you with the tools and knowledge necessary to meet customer expectations and capitalize on this niche market. Engaging with reputable suppliers and staying updated on performance advancements will ensure that you can offer the best to your clients.