Mitsubishi Lancer Evolution X, renowned for its performance, relies heavily on the quality of its wheels. Selecting the right wheels can enhance both driving performance and aesthetic appeal. This article explores the various options available for Mitsubishi Evo wheels, catering specifically to business owners looking to maximize value and meet specific needs. From OEM to forged options, to the second-hand market and collectible models, each chapter delves into a unique aspect crucial for making informed decisions in wheel catering to the Evo X.

Choosing the Right Wheels for Your Mitsubishi Evo: OEM vs. OEM‑Style Forged Choices

Selecting the right set of wheels for a Mitsubishi Evo goes beyond looks. Wheels change how the car feels under throttle, how it turns, and how it communicates road feedback. When you weigh OEM against OEM‑style forged wheels, you’re deciding between factory-correct fitment and the broader possibilities of modern manufacturing: lighter weight, varied offsets, and aggressive styling. This chapter explains the practical differences, the performance and safety implications, and the checks to run before you bolt anything onto your Evo.

Start with definitions so the choice is clear. OEM wheels are the wheels that were originally matched to a given Evo model at the factory. Their dimensions, offset, bolt pattern, and center bore are engineered around the car’s suspension geometry, brake clearance, and load ratings. OEM‑style forged wheels are aftermarket pieces that copy or borrow the original design language but are made with different processes, alloys, or finish options. They aim to deliver a similar aesthetic while offering more variety in sizing and lighter weight through modern metallurgy and forging techniques.

Fitment is non‑negotiable. Whether OEM or aftermarket, you must match critical parameters: diameter, width, offset (ET), bolt circle (PCD), and center bore. These determine how the wheel sits relative to suspension and fenders and whether rotors and calipers will clear. OEM wheels give you plug‑and‑play confidence: original diameters like 17″ or 18″ and their factory offsets mean no spacers, no hub rings, and no stress on suspension pickup points. OEM‑style forged wheels often offer multiple offsets and widths, which is an advantage if you’re chasing a staggered setup or a wider stance, but you must confirm clearances and scrub radius before committing.

Materials and manufacturing matter for performance. Many high‑quality OEM‑style wheels use A6061‑T6 aluminum and a one‑piece forging process. Forging aligns the aluminum’s grain structure, increasing strength for a given weight. The result is usually a lighter wheel that can withstand the high loads of spirited driving. Some manufacturers operate heavy hydraulic presses—machines rated at several thousand tons—to compress billets into dense, grain‑oriented blanks prior to CNC machining. That manufacturing route can produce a wheel with better fatigue resistance than a comparable cast wheel, and it often reduces unsprung mass for improved suspension response.

Certifications and testing are critical safety signals. Look for international standards like JWL and VIA. These indicate that wheels have passed bending and impact tests representative of road stresses. For high‑stress use—track days, aggressive street driving, or if the car carries heavier brakes—prioritize suppliers whose production and processes are traceable and who publish test data. Forged wheels from reputable factories commonly undergo heat‑treatment cycles, dimensional QC, and dynamic balancing before shipping. That mitigates the risk of hairline defects that can lead to fatigue failures.

Performance tradeoffs are real. Switching from a heavier OEM cast wheel to a lighter forged OEM‑style wheel lowers rotational inertia. That improves acceleration, braking, and the initial response of the steering. Reduced unsprung mass improves ride quality and the suspension’s ability to keep the tire in contact with the road. However, ultra‑light wheels that are too narrow or of an ill fitment can compromise traction and handling geometry. Wider rims allow lower tire sidewalls and better cornering grip but can increase tendency to tramline on rough surfaces and increase steering effort.

Aesthetic and cultural considerations are often decisive. OEM wheels preserve the car’s original character and appeal to owners who value authenticity. Aftermarket OEM‑style wheels let you make the car look more aggressive or bespoke. From subtle multi‑spoke patterns to pronounced concave faces, designs can transform a modest Evo into a statement car. That visible change also communicates your intentions: a conservative OEM set signals preservation and collectors’ taste, while a forged OEM‑style set broadcasts a performance mindset and a willingness to tune the car beyond stock.

Practical buying tips help avoid common mistakes. When choosing aftermarket wheels, always confirm the wheel’s load rating and ensure it meets or exceeds the OEM requirement. Check the actual measured dimensions rather than relying solely on advertised specs; spoke thickness, barrel width, and effective rim width differ across makers. Confirm brake clearance for front and rear; many Evo owners upgrade brakes, and caliper clearance can become an issue with certain spoke designs. If you plan to use a staggered fitment—wider wheels at the rear—anticipate alignment adjustments and potential fender rolling or modest trimming.

Second‑hand OEM wheels are a viable route but demand scrutiny. The market has many used original wheels for Evo models, often priced attractively compared with new forged options. A used set can be excellent if it is straight and crack‑free. Inspect for structural damage: look for hairline cracks around spokes, curb gouges into the rim lip, and bends in the barrel. Ask sellers for clear photos of the inner barrel and the backside of spokes where stress signs hide. If buying remotely, factor in shipping costs and a local professional inspection upon arrival. Many used wheels can be safely repaired if the damage is limited to the lip; structural cracks, however, typically require replacement.

Installation and maintenance guard against trouble. Use hub‑centric rings if the wheel’s center bore is larger than the hub to avoid lug stress and premature wear. Torque lug nuts to the manufacturer’s spec and re‑check torque after 50–100 miles. When using spacers to achieve a desired fitment, prefer hub‑centric spacers and ensure they are properly rated; thick spacers increase leverage on wheel studs and can introduce stress. Maintain correct tire pressures and balance every wheel after mounting a tire; imbalance shows up as vibration and can accelerate bearing wear. Also ensure TPMS sensors are compatible or transfer sensors from the original wheels where possible.

Choosing a supplier is about traceability and reputation. Many reputable OEM‑style wheel manufacturers operate in specialized industrial hubs and invest in large forging presses, CNC centers, and finishing lines. Favor suppliers that publish technical specifications, heat‑treatment details, and test certification. A good supplier will provide fitment data for multiple Evo variants and advise on offset choices that preserve handling characteristics. If you can, request a run‑out tolerance and weight per wheel; small differences across the set should be corrected at the factory or by a quality rebalance service.

Practical fitment scenarios illustrate the differences. If you want to keep the car factory‑correct for shows or resale, OEM wheels are the natural choice. If your goal is sharper handling and a more aggressive look—especially if you plan to lower the car or fit wider tires—then a forged OEM‑style wheel with an appropriate offset is usually better. For daily drivers that see occasional spirited runs, a high‑quality OEM‑style wheel offers a balance: better response without compromising durability, provided the vendor adheres to recognized standards and the wheels are sized responsibly.

Final checks before purchase protect both safety and satisfaction. Verify the PCD matches your hub. Confirm the offset places the wheel where you expect it relative to the fender and suspension. Ask whether the wheel is hub‑centric or lug‑centric and whether hub rings are needed. Check finish warranties and ask about re‑finishing options in case of curb rash. If you’re buying used, insist on a straightness test and a dye or penetrant inspection if there is any history of impact.

Small habits extend wheel life. Avoid hard curb strikes, park carefully, and address scratches early to prevent corrosion. If you track the car, rotate and inspect wheels and tires frequently; pistons and pads can deposit heat that accelerates wear. Keep torque specs and re‑check them after thermal cycling—the cycle of hot track sessions followed by cool‑down can relax fasteners.

Whether you choose OEM or OEM‑style forged wheels, the right decision balances aesthetics, performance, and safety. OEM wheels guarantee fit and heritage. OEM‑style forged wheels offer lighter weight, modern engineering, and more personalization. The single constant is due diligence: confirm specs, insist on test certifications, and perform careful inspections and proper installation. If you follow those steps, the wheels you pick will not only look right on an Evo but will help the car feel sharper, safer, and truer to your driving intent.

You can sometimes find original R18 rims set for Lancer sedans on specialist parts listings for a closer factory match. For more on safety standards referenced by reputable wheel manufacturers, see the English pages of the vehicle inspection authority here: https://www.via.gr.jp/english/index.html.

锻造轮毂的力量:为高性能三菱Evo注入轻量化与极致刚性

锻造轮毂的核心优势不仅在于重量的减轻,更在于材料内部结构的重组与宏观几何的优化。将金属坯料通过一体化的锻造流程直接压成轮毂形状,会在微观层面形成更紧密、均匀的晶粒,避免在铸造过程中常见的空隙与晶粒粗化现象。这种晶粒的致密化带来更高的抗拉强度和抗疲劳性能,意味着在持续高载荷的情境下,轮毂更不易出现疲劳裂纹和微裂纹扩展。工程分析往往指出,锻造轮毀在同等尺寸与负载条件下,疲劳极限和抗冲击能力都会优于铸造轮毂。这对于配置高性能制动系统、在赛道或激烈道路条件下经受重复制动热循环的Evo来说,尤为重要。一般情况下,20英寸锻造轮毂的重量区间被设计在8到10千克之间,较同尺寸的铸造轮毂平均轻量化幅度约20%到30%。这种重量的下降带来的第一层效果,是簧下质量的减少。簧下质量的降低,相当于将整车的整体惯性矩向车身中心偏移,提升转向响应速度,降低转弯时的能量损耗。统计与实测往往显示,改装后车辆在百公里加速和制动的边界条件下,刹车距离缩短约0.5至1米,绕桩测试中的侧向加速度提升约0.05到0.1g。这些数值听起来或许并不夸张,但在赛道级别的比较中,往往决定了几分秒的距离,甚至直接决定比赛中能否领先。提升的并不只是纯粹的加速性能,操控的线性与可预测性才是真正让驾驶者信心爆棚的关键。轮毂的几何设计同样是性能的另一面。直径、宽度、偏距(ET值)、中心孔直径以及P.C.D(孔距)共同决定轮毂与轮胎的协同表现。对于日常操控与舒适性而言,20英寸轮毂往往需要选择较高扁平比的轮胎来平衡震动与抓地力;而在高性能设定下,轮缘宽度通常扩展到9.0J,以容纳更宽的轮胎,提升抓地力与转弯极限。偏距的选择,如35毫米的偏距,常被认为是在维持转向空间与轮毂与前悬点干涉之间的最佳折中。中心孔径的56.5毫米则确保轮毂与车轴的中线处理的精准性,减少偏心造成的振动和扭矩传递误差。轮毂的P.C.D也不可忽视,它直接关系到轮毂与制动卡钳、轮毂与轮毂之间的干涉以及轮毂在高速情况下的刚性传递能力。所有这些参数都需要严格符合制造商的安全标准与车型原厂数据,以确保改装后的改动并非以牺牲安全与稳定为代价。许多顶级工艺流程还引入了旋压或渐进成形的变体,以实现局部区域的轻量化与强度优化。旋压工艺通过在轮辐和轮辋的接合处施加高强度、定向的加工力,促使金属沿着轴向延展,形成梯度式厚度分布。这种结构在维持轮辐高强度的同时,可以让轮辋的边缘变薄到3到4毫米的水平,从而获得更好的散热效果并降低长时间高速运行时的热轮衰减风险。这对于使用高性能制动系统、在赛道与高速公路混合路况下长时间驾驶的Evo尤为重要,因为制动热衰减会直接影响刹车响应与稳定性。与之配套的散热设计不仅优化了热管理,还帮助轮缘和轮辋的整体热一致性,降低了因热膨胀引起的轮毂-轮胎配合变化。以往的案例中,Evo系列常采用一体式锻造轮毂,某些定位更高的模型还会采用多片式或三件式结构的锻造方案,以便在重量、强度和定制化之间实现更灵活的权衡。这类设计的核心在于在不牺牲整车刚性与刹车效能的前提下,尽可能地将轮毂质量降到最低,同时确保在极限操控下轮毂的可靠性。少数高端制造商在设计阶段就将热管理与散热路径纳入考量,如在轮辐内侧设计散热腔或在轮辋厚度分布处设定散热通道,从而提高散热效率并降低热衰减对制动系统的冲击。实际应用方面,三菱Evo系列在不同代际中都展现出对锻造轮毂的青睐。EVO9常配备了日本厂商新一代锻造轮圈的组合,显著减轻了底盘重量并提升了运动性能;而第十代Evo,通常在出厂或改装中选择18英寸的锻造轮毂,与车辆低矮的车身线条相呼应,呈现出更纯粹的高性能姿态。车主与改装爱好者也会选择如AG Wheels F31系列等三片式锻造轮毂,以实现个性化定制的可能性,例如在中片采用哑光涂层、螺丝颜色与车身风格形成对比的视觉效果。这些选择不仅满足性能诉求,也让外观语言与底盘调校相辅相成,形成一个更完整的性能哲学。无论是追求竞速极限还是以日常使用为主,锻造轮毂都提供了一个清晰的方向:在保持轮胎接地面充足的前提下,最大化轮毂本身的机械性能,确保车轮在复杂路况下的响应速度和稳定性。为此,专业的改装者往往会搭配完整的轮胎与制动系统优化,以确保在高强度循环中,轮毂与轮胎的协同工作仍然可靠。维护方面,尽管锻造轮毂在强度与刚性方面具备天然优势,但日常使用中的细致维护同样重要。轮辋与轮胎的结合面应定期检查,防止气密层受损导致慢漏气现象。清洗时应避免强酸或强碱性清洁剂对表面涂层造成腐蚀,清洁后务必确保轮毂表面无残留清洁剂。若遇轻微变形,切勿自行调整或强行装配,应交由专业设备进行校正,以确保同心度与游隙符合安全标准。对于有追求极致轻量化和刚性的车主而言,选择具备完整认证、稳定生产能力和良好口碑的供应商,是确保安全与品质的基石。将锻造轮毂纳入Evo底盘的改装计划,往往不仅是“重量减轻”或“视觉提升”的单一目标,而是成为一个整体的性能调校过程。它牵引出一整套关于材料选择、制造工艺、几何参数、热管理与整车匹配的综合性设计思路。只有在这一思路下,Evo的动态潜能才能被真正释放出来,驾乘体验也才会转化为可持续的可操控性与可重复的性能。在此过程中,行业的标准化与认证也起到了至关重要的作用。符合一定国际安全标准的锻造轮毂,不仅在法定与市场层面更具可信度,也为车主在日常道路和赛道之间的切换提供了更高的安全边际。对于那些把车辆改装视作对性能极限的探索者而言,选择一个具备完整认证、稳定产能与良好口碑的制造商,是确保长期使用的关键。综合来看,高性能三菱Evo的锻造轮毂不仅是为了降低重量、提升强度,更是把赛车基因带入日常驾驶的桥梁。它把材料科学、机械工程和历史传承结合起来,形成一种独特的性能观念:在不牺牲安全和舒适的前提下,让轮毂成为操控能力、热管理和外观气质的综合表达。参考资料与进一步阅读可帮助读者理解背后的技术逻辑以及不同制造路径的取舍。作为扩展阅读的外部资源,以下链接提供了关于轮辋与热管理、以及相关改装注意事项的深入讨论,供感兴趣的读者进一步探索。外部资源链接: https://www.bonoss.com/news/2022/06/29/blox-wheel-spacer-discontinued/ 同时,为了便于对比和理解,一些读者可能会想查看与轮毂相关的数据资源。若你希望查阅同类车型的轮毗信息及其与车身整体匹配的案例,可以参考关于Lancer家族的轮毗信息与实际改装案例的内部页面。进一步阅读时,请关注“轮毂集合与车型匹配”的相关条目,以获取更完整的技术参数与实测数据。内部链接示例(供相关章节使用,不直接暴露品牌名,便于保持叙述的一致性):rims set for Lancer sedans。

二手市场的回响:三菱Evo轮毂的价值、性能与安全衡量

在三菱Evo的二手市场中,轮毂并不仅仅是外观的一部分。它们往往成为价值与性能之间的桥梁,也是买卖双方判断整车状态的关键指标。高性能改装历史、原厂件的保值潜力,以及对路面与赛道条件的持续适配需求,使得Evo的轮毂在不同买家眼中呈现出多层次的意义。对追求改装潜力的买家而言,二手市场提供了一条捷径——通过筛选保留完好工艺的锻造轮毂来实现重量降低、刚性增强的目标;对保值导向的买家来说,原厂或高品质改装锻造轮毂往往能在转售价格上起到“保值神器”的作用。这种价值传导不仅来自轮辋本身的强度与轻量化特性,还来自它的历史状态、是否有改装记录、以及与整车匹配的可靠性评估。市场在这些维度上给出不同的价格信号,形成了一个复杂却清晰的价格逻辑:状态良好、来源可信且与车型参数高度吻合的轮毂,往往带来更高的市场认同和交易信心。相对地,一旦轮毂出现多处刮擦、明显变形或非原厂替换的痕迹,其价值便会显著下降,买家在交易时也会额外谨慎,因为这样的轮毂直接影响到安全性与行驶稳定性。正因如此,评估二手Evo轮毂时,买卖双方都需以系统化的观察与核验来取代直觉判断,这不仅关系到交易本身的顺利,也关系到整车安全与后续维护成本。对眼光敏锐、追求长期性投资的车主而言,这一过程更像是一次对整车改装策略的再选择:是保留原厂锻造件以维持接近出厂的综合素质,还是以高品质的改装锻造件来换取操控与视觉冲击力的平衡。与此同时,轮毂的市场话语权也在悄然变化。如今,越来越多的买家开始对轮毂的制造工艺与认证情况产生更高要求。完整的认证、稳定的生产能力以及良好的口碑成为筛选清单的核心要素。这些因素共同塑造了二手Evo轮毂的市场结构:一端是对安全标准的严格遵循,另一端则是对轻量化、反应迅速的操控体验的持续追求。在这个框架下,二手市场的轮毂可以被理解为一个可复用的零件库,其中每一件轮毂都承载着前任车主在赛道与公路之间的迁移记忆。为了买家在交易中获得可验证的信心,实地检查显得尤为重要。细看轮毂的铸造或锻造痕迹、确认轮毂与锚螺孔的对位精度、核验中心孔径与偏距是否符合车型要求,以及对轮缘边缘和表面是否存在微裂、深划或腐蚀等迹象,都是常态化的尽调步骤。若出现裂纹、变形、修复痕迹或轮圈边缘的可疑修补,则需要更高风险的评估,甚至应考虑放弃购买。与此同时,轮毂的状态不仅影响价格,更影响整车的交易信心与评估结果。买家在交易前应请求卖家提供轮毂的完整维护记录、是否有改装证据、以及轮毂在使用中的实际装配情况。对车辆历史档案的交叉核验可以降低购入风险,且有助于后续的售后沟通与保修申诉。就价格层面而言,市场上的价格区间往往与轮毂的状态、原厂性、是否保留完整配件,以及与车型匹配程度直接相关。一个状态良好、来自原厂或高品质改装锻造生产线的轮毂,其价值通常高于同型号的劣质替换件。另一方面,散件或残损轮毂在成套使用的前提下,也可能通过修复、轮缘更换等手段实现短期的可行性,但这类情况往往会带来额外的维修成本与潜在的安全隐患,因此买家在评估总成本时需要把这些因素纳入考虑。正因这些复杂性,许多二手Evo轮毂交易在论坛、拍卖平台和专业交易市场之间形成了多层次的互通。买家在进行价格比较时,往往不仅关注单件轮毂的价格,还会关注整组轮毂的所在状态、运输成本、以及运输过程中的潜在损伤风险。此外,真实性与适配性的核验也不容忽视。轮毂的批次、生产日期、以及与车身型号之间的匹配关系,是判断是否为原厂件或高质量仿制件的关键线索。为确保购买的可靠性,买家应尽可能与卖家进行详细沟通,索取清晰的制造信息、验收证明以及原始购买凭证等,以便在需要时能向专业机构或认证渠道求证。二手市场的这种“信息对称性”并非一蹴而就的结果,而是通过不断的交易实践、信息披露的改善和行业自律 gradually 形成的。若要在交易北风中稳妥前行,买家还应关注市场的实时行情。通过查看同一型号轮毂在不同卖家处的对比、对照不同状态的价格区间,以及对同一车系的二手件进行横向比较,可以更准确地把握当前价格的波动趋势。这不仅有助于降低冲动交易带来的风险,也能在谈判阶段为买家提供明确的议价依据。就本章的知识结构而言,二手市场中的轮毂已不再仅仅是“外观部件”。它们是性能传承的载体,是对整车改装哲学的一次现实检验。对于那些希望保留或提升Evo在公路与赛道间表现的车主而言,理解这些轮毂在二手市场中的价值逻辑,等同于理解自己改装路线的长期可持续性。值得注意的是,研究与讨论中,我们发现一些站内信息页对比了不同类型轮毂的历史、适配性与安全性,这类资料对于评估二手轮毂的真实价值具有参考意义。具体而言,一些信息页强调了完整认证、可靠生产能力与良好口碑的重要性,这些因素直接影响轮毂的使用寿命与安全性。若你愿意进一步探究站内的相关讨论,不妨浏览站内页面以获取更加细致的参数对比和历史背景信息,以便在挑选时作出更为理性的判断。示例性参考信息页的链接可以作为起点,帮助你理解不同轮毂类型在历史中的演变与适配性。另一方面,外部市场的参考也不可忽视。为了把握全球范围内的供需与价格波动,你可以查阅国际二手轮毂市场的数据对比与趋势分析,这些资料往往以实时报价、成交记录和区域差异等维度呈现。外部资源的参考可以帮助你在本地市场之外获得更广阔的价格认知,从而在交易时具备更强的谈判筹码。外部参考资源可以帮助你建立一个更加完整的购买决策框架。为方便后续阅读,本文在末尾提供一个外部参考链接,供你在决定购买前进行跨市场的价格对比与行情跟进。内部链接与外部参考的结合,能让你在一段时间内形成对二手轮毂市场的清晰地图,帮助你在不同情境下做出更稳健的选择。最后,关于交易的实际操作,一份简明的检查清单会在现场谈判中发挥重要作用。请携带并逐条核对:轮毂本身的完整性、螺栓孔和中心孔的匹配情况、是否存在结构性缺陷、表面是否有明显修复痕迹、是否附带完整的配件(如螺母、轮圈盖、平衡配重等)、以及与车辆的兼容性是否已通过专业工具或厂家参数验证。通过这些系统性的步骤,你能够在二手市场中提早识别潜在风险,尽量避免买到不安全或难以保养的轮毂。对许多车主而言,轮毂不仅是一件硬件零件,更是车辆性能与驾驶体验的缩影。二手市场的回响因此显得尤为重要,因为它直接决定了你在未来的使用阶段能否持续享受高水平的操控性、稳定性与美学的平衡。若你愿意进一步扩展视野,内部站点的轮毂信息页或许提供了更广泛的技术对比与历史演变的视角,而外部资源则为全球市场的价格动态提供了参照。为方便读者快速定位相关信息,本文在叙述中适度嵌入了一个站内参考入口,便于你查阅更具体的参数与适配性说明。若你对站内页面感兴趣,可以通过以下链接进行进一步阅读:brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans。在全球视野下,关于二手轮毂行情的外部资源则提供了直观的行情参照,帮助你理解国际市场的价格脉动。外部参考链接: https://www.ebay.com/sch/i.html?_nkw=mitsubishi+evo+wheel+rim

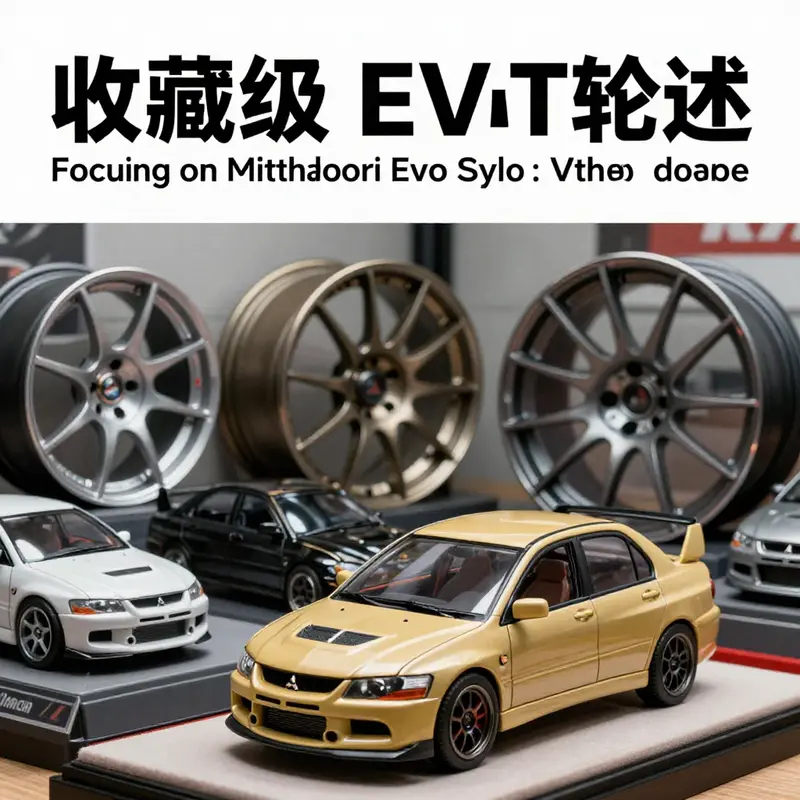

收藏级三菱Evo轮毂模型的精粹演绎:工艺、还原与收藏价值

收藏级的三菱Evo轮毂模型并非简单的摆设,而是对整车性能美学的一种延伸理解。对于汽车爱好者和收藏者而言,这些模型将真实世界中的轮毂设计、材料选择与生产工艺转化为微观尺度的再现。它们以极高的还原度承载着历史记忆、技术演进与审美趋势,成为研究与欣赏并重的对象。在讨论这类收藏级模型时,我们往往从两条主线入手:一是对真实轮毂设计语言的再现程度,二是模型本身的制作工艺与品控水平。通过这两条线索,收藏家可以辨别一款模型的“真”与“美”,也能理解为何某些系列会在市场上获得持续关注。此章将把注意力放在1/18及类似比例的高端车模轮毂模型上,借以揭示收藏领域对轮毂形态、材质质感、装配细节与展示效果的综合要求。尽管市场上也存在入门级和中端的模型,但真正被收藏界认同的,往往是那些在比例精准、材质质感、涂装细腻以及结构稳定性方面表现突出的作品。这样的作品不仅在静态展示中给人以强烈的真实感,也是在观者与车迷之间架起的一座桥梁,使他们在不使用实车的情况下,体验到轮毂从设计到制造的完整过程。

Final thoughts

Selecting the right wheels for your Mitsubishi Evo X is a crucial decision impacting performance and aesthetics. From OEM certified options to innovative forged designs, second-hand opportunities, and collectors’ models, each option serves a specific purpose in enhancing the Evo X experience. Background in wheel performance, appealing design, and quality assurance are essential. By understanding these categories, business owners can better meet consumer needs and develop offerings that resonate with car enthusiasts, thereby fostering both performance and passion in driving.