Mitsubishi GTO, known for its formidable presence in the sports car arena, features headlights that are much more than mere functional components; they are integral to the vehicle’s character and performance. From its introduction with iconic pop-up headlights in the early 1990s to the modern fixed designs seen in later models, the evolution of the GTO’s headlights offers a fascinating glimpse into automotive design trends and technological advancements. This article delves into the complete journey of Mitsubishi GTO headlights, examining their evolution, replacement options, technological improvements, aesthetic impacts, and maintenance tips, all of which are crucial for business owners in the automotive industry. Understanding these aspects can enhance customer satisfaction and operational efficiency while reinforcing the critical role proper lighting plays in vehicle safety.

From Pop-Up to Fixed: Tracing the Evolution of Mitsubishi GTO Headlights

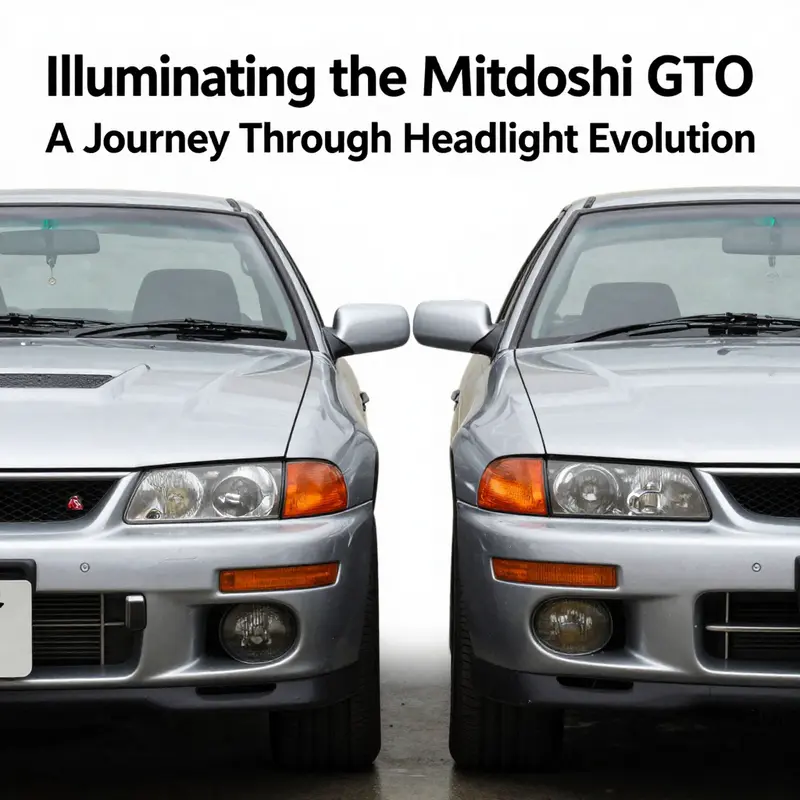

Headlights are more than simply a pair of lamps; they are a drawing of a car’s personality, a signaling system that communicates intent to the road, and a technology ledger that records the era’s priorities. In the case of the Mitsubishi GTO, known in North America as the 3000GT, the headlights chart a striking narrative of change. The early years trusted a pop-up mechanism that lent the car a low, sleek silhouette even when the lamps slept, and the later years embraced fixed, integrated units that spoke of modern reliability and evolving safety expectations. Reading this progression is like tracing a short, focused thread through the broader arc of automotive lighting technology, where design choices mirror shifting regulations, consumer tastes, and the push toward more capable illumination. The GTO’s headlight evolution becomes a compact case study in how a model can retain its core identity while adopting advances that improve performance, safety, and everyday usability.\n\nIn the dawn of the GTO’s life, the pop-up headlights dominated the street-scene. Between 1990 and 1993, the dual lamps sat within the front bumper, poised to rise with the flick of the switch. The moment they extended, a mechanical ballet began: housings unfolded, glass gleamed, and the car’s face acquired a signature expression that many enthusiasts still associate with the era’s Japanese GTs. When the lamps were off, the bodywork maintained a clean, uninterrupted line that suggested a paring down of frontal drag. That aerodynamic virtue, often cited alongside the dramatic visual effect of the rising lights, helped the car feel both futuristic and purposeful. The pop-up arrangement did more than entertain a crowd of observers; it reinforced the GTO’s identity as a car built for speed, precision, and a touch of theatrical flair. The added complexity—the motors, linkages, and seals that made those heads spring to life—also carried a cost: maintenance, potential points of failure, and the ongoing challenge of meeting evolving safety and reliability standards without sacrificing the clean look that defined the model.\n\nBy the early 1990s, however, a shift in priorities nudged the GTO toward a new design language. The 1993 mid-cycle refresh marked a decisive departure from the pop-up formula. Fixed, integrated headlights replaced the retractable units, and the front fascia acquired a more rugged, uninterrupted silhouette. The reasons for this change were pragmatic as much as stylistic. Safety regulations around headlight deployment and reliability concerns with the mechanical pop-up systems played a significant role. Fixed headlights eliminated several moving parts and potential failure points, offering improved structural integrity and easier weather sealing. From a consumer standpoint, the fixed design also signaled a more contemporary aesthetic. It projected a newer sense of sophistication—one aligned with broader automotive trends toward integrated lighting modules that could house more advanced technologies as they became available. The net effect was a more robust lighting system that could evolve with the car’s other technological upgrades, rather than keeping pace with a mechanism that tethered the car to a particular epoch of design.\n\nAs the GTO moved into the late 1990s, the second-generation refresh around 1998 delivered another layer of refinement. The headlights grew larger and more aggressively styled, harmonizing with the broader, muscular stance of the updated chassis and bodywork. This was not merely a cosmetic adjustment; the enlargement and angular shaping of the headlight housings opened new possibilities for light output and beam pattern design. The 3.2-liter V6 engine that powered later iterations contributed to a stronger performance narrative overall, and the headlight updates matched that momentum with a modern, more confident face. The fixed headlight configuration allowed Mitsubishi to incorporate more sophisticated optics, better reflectors, and the potential for enhanced lighting technology as it matured. The transformation underscored a broader truth about automotive lighting: once manufacturers moved away from mechanically driven headlamps, they could pursue more integrated, higher-performing solutions without being constrained by the quirks of a pop-up mechanism.\n\nThe narrative of the GTO’s headlights holds a quiet, enduring appeal for enthusiasts who regard the pop-up era with nostalgia. Those early units are remembered for their space-age charm and the almost ritual moment when they sprang to life, a small theater in the middle of a morning drive. Yet this sentiment sits alongside a practical recognition: the fixed headlights that followed offered greater reliability and better compatibility with rapid advances in lighting technology. The fixed units made it easier to seal against the elements, to integrate modern lighting elements, and to align with global standards that emphasized consistent performance, crash safety, and long-term maintenance. For owners today who seek to restore or upgrade their GTO’s lighting, the transition from pop-up to fixed is a reminder that authenticity and modern capability are not mutually exclusive. The core objective remains clear: to preserve visibility and safety while honoring the vehicle’s heritage.\n\nIn this context, modern enthusiasts often explore upgrades that align with current expectations for brightness, color temperature, and efficiency. Retrofitting with contemporary LED or HID solutions is a common path, but it is not a decision to be taken lightly. The fixed design reduces the risk of misalignment and water intrusion that can accompany aging mechanical pop-up assemblies, yet it also requires careful selection of compatible components. The challenge lies in maintaining the balance between performance and authenticity—the sense that the car still speaks in the same design language even as the lighting system speaks in a more modern dialect. This is where the broader ecosystem around classic GTO lighting becomes meaningful. Aftermarket options and OEM-compatible assemblies exist to support these transitions, with attention to seals, mounting points, and the electrical interfaces that feed the lamps. In every case, the goal is consistent and straightforward: safer nighttime illumination that respects the car’s original character.\n\nFor readers who want a tangible touchstone within the car’s lighting lineage, a deeper look into the range of headlight configurations from the 1995–1999 period can be instructive. A dedicated reference to the 95-99 Mitsubishi 3000GT SL VR4 clear headlights provides a window into how fixed designs could still offer clarity, depth, and a modern look while preserving a link to the era’s performance ethos. See the detailed overview here: 95-99 Mitsubishi 3000GT SL VR4 clear headlights. That resource highlights how the design language evolved around the headlights themselves, showing how the shape, glass, and internal optics contributed to a contemporary lighting package without betraying the car’s classic line.\n\nThe evolution of the GTO’s headlights ultimately mirrors a broader arc in automotive lighting. The move from pop-up to fixed reflects not only changing aesthetics but also a maturation of safety expectations and a shift toward more integrated, durable, and upgradeable systems. Today, the story continues with owners exploring how to preserve the vehicle’s distinctive look while embracing modern illumination technologies. The balance between nostalgia and progress is not a contradiction but a dialogue—one that respects the car’s original spirit while recognizing the practical demands of modern driving. As with many classic performance machines, the headlights are a small but telling chapter in a larger narrative about how design, engineering, and user experience evolve together over time, allowing the Mitsubishi GTO to remain legible on the road and in the imagination for years to come.\n\nFor those seeking a deeper technical dive into headlight materials, standards, and performance, a comprehensive external reference offers detailed guidance that complements the chapter’s narrative: https://www.mitsubishicarparts.com/fto-headlights-technical-guide. This resource extends the conversation beyond the GTO to illuminate how lighting components are specified, tested, and improved across related platforms, underscoring the shared engineering principles that underwrite both classic designs and modern innovations.

Beaming Across Eras: OEM versus Aftermarket Headlights for the Mitsubishi GTO (3000GT)

The Mitsubishi GTO, known in North America as the 3000GT, wears a headlight history that mirrors the car’s broader design arc: from the now-iconic pop-up units that gave the early cars a touch of theater, to the more restrained, modern fixed assemblies that followed the 1993 facelift. That evolution was not merely stylistic. It reflected evolving lighting technology, shifting regulations, and the changing tastes of drivers who wanted better illumination, longer life, and a look that could feel both classic and contemporary at once. When owners consider replacing or upgrading these headlights, they step into a choice between Original Equipment Manufacturer (OEM) units and a broad spectrum of aftermarket options. Each path promises distinct advantages and potential caveats, and the decision often hinges on what the owner values most: exact fit and factory authenticity, or broader styling and performance options at a different price point.

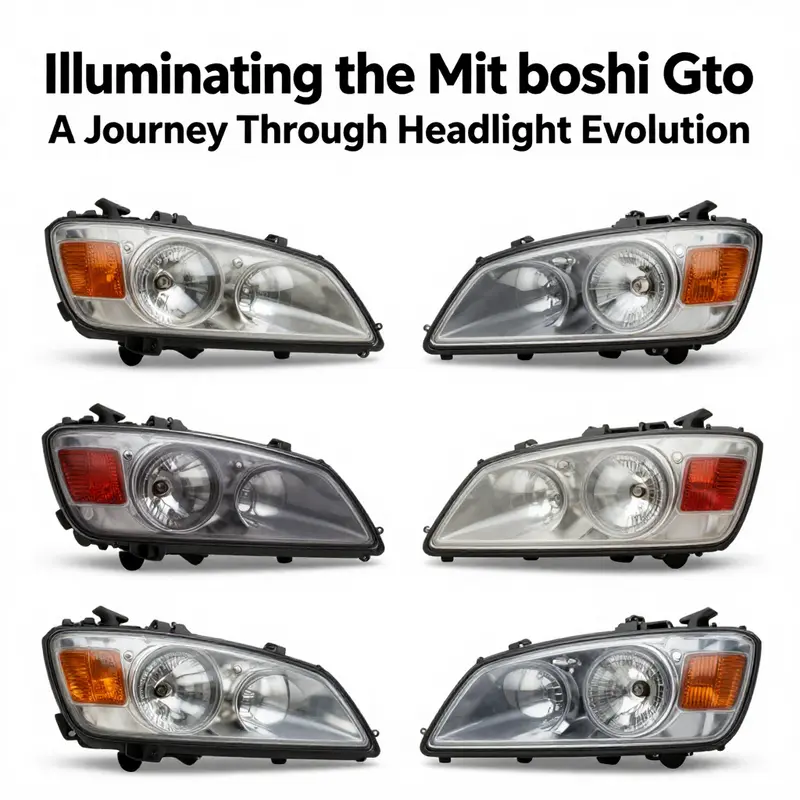

The GTO’s early lifespan is inseparable from its pop-up headlights. Those units defined a silhouette as much as the car’s sweeping lines did, giving the vehicle a level of aggression and sophistication that was, at the time, technologically impressive. But by the time the facelift rolled in during the mid-1990s, Mitsubishi—and the market at large—had begun to favor fixed headlamps. The reasons were practical as much as aesthetic: fixed headlights simplify manufacturing, improve aerodynamics, and provide a more reliable lighting experience in a world where reliability and nighttime visibility were becoming non-negotiable safety features. For current owners, that shift means that replacement parts for the GTO fall into two broad families: OEM units that reproduce the original look and performance as closely as possible, and aftermarket assemblies that broaden the spectrum of styling, brightness, and sometimes technology, at varying price points.

OEM headlights, by their very definition, come from the same manufacturers that supplied the original equipment. The benefits are clear in everyday use: a precise fit that aligns with factory mounting points, a color temperature and beam pattern that mirrors the car’s initial design, and an emphasis on safety compliance. An OEM assembly tends to be consistent from one unit to the next, which matters when you’re dealing with critical aspects such as seal integrity against moisture ingress and the regulation-driven requirements for beam patterns and luminance. The reliability story is reinforced by the manufacturing discipline that comes with OEM parts; they are designed, tested, and validated to meet the same standards as the parts that rolled off the line when the car was new. For owners who value preservation of original aesthetics—where the headlight’s shape, glow, and fitment matter for both resale and authenticity—OEM is consistently compelling.

On the other side of the spectrum lie aftermarket headlights. This category is vast, reflecting a broader trend in modern automotive lighting that emphasizes choices—especially as LED and HID technologies proliferate. Aftermarket options can deliver a wider array of looks, from crisp, bright white LED patterns that sharpen the GTO’s modern presence to smoked or clear finishes that alter the vehicle’s face without changing its silhouette. In many cases, aftermarket units come with enhanced features at lower price points than OEM, offering brighter illumination or advanced styling without the factory price tag. Yet that breadth comes with potential variability. Quality control across aftermarket brands can differ markedly, which means performance can range from excellent to disappointing. Some units may fail to meet regulatory standards in certain regions, and there is an ever-present risk of electrical interference if wiring, ballast, or igniters are not correctly matched to the vehicle’s electrical architecture.

A critical technical note about aftermarket headlights is the reality of retrofitting. Older models of the GTO, especially those transitioning from pop-up to fixed headlight configurations, sometimes require compatible ballast and igniter components when HID or LED retrofits are pursued. Without careful selection of these auxiliary parts, drivers can encounter flickering lights, sudden shutdowns, or erratic behavior that undermines both safety and reliability. The importance of compatibility extends beyond the light source itself. The beholder of the aftermarket option must verify that the new assembly can interface with the GTO’s electrical system, including connectors, wiring harnesses, and any vehicle-specific control modules that monitor headlight operation. In practice, this means doing thorough research into the chosen unit’s specifications, and ideally confirming fitment with a vehicle’s year range and trim level before purchase.

Within the aftermarket space, LED headlamps have become particularly popular for those pursuing a balance of cost, brightness, and contemporary aesthetics. LED units offer bright, white daylight illumination with energy efficiency and a longer lifespan than many traditional halogen or older HID implementations. They can enhance both visibility and the front-end appeal of the GTO, aligning with owners who want a more modern look without sacrificing the car’s classic lines. However, the precise benefits depend on the unit’s thermal management—good heat sinking and adequate cooling are essential to sustain performance—and on compliance with local lighting regulations. In some markets, regulators scrutinize color temperature and beam patterns as part of ongoing safety standards, so choosing a unit that explicitly adheres to regional rules is prudent. Even with LEDs, the installation needs attention to detail: proper sealing to prevent moisture, correct aiming to avoid glare for oncoming drivers, and, in certain cases, recalibration if a vehicle’s alignment data are stored by onboard systems.

The decision framework for a GTO owner then boils down to priorities. If authenticity and guaranteed compatibility are the aim, OEM headlights provide a straightforward path with predictable results. The trade-off is typically cost, as genuine OEM parts carry a higher price tag, and they may require careful sourcing given the car’s age and the specific trim. For enthusiasts who relish personalization, aftermarket headlights offer a canvas for expression. They enable a broader spectrum of finishes, a potential uptick in brightness or beam quality, and the opportunity to tailor the car’s face to a chosen look. The caveats, naturally, revolve around quality, checks for regulatory compliance, and the need for proper installation to ensure a safe, reliable result.

Whether one leans toward OEM reassurance or aftermarket versatility, the installation realities remain consistent. Most replacement kits assume a level of mechanical comfort for those performing the work themselves, although many owners opt for professional installation to protect the vehicle’s electrical systems and to guarantee alignment and sealing. The mounting points on the GTO are designed to accept standard assemblies, but the year-to-year differences introduced by the facelift can influence the exact match. This is where the practical strategy comes into play: verify compatibility not just by the year, but by the car’s specific trim and market. A used car’s previous repairs, rewiring, or condenser changes can alter the installation landscape, and a headlight replacement that seemed plug-and-play on paper can require adapters, new sealing gaskets, or harness modifications in practice.

For owners who want a concrete reference point when evaluating options, there is value in looking at OEM-era compatibility within the broader ecosystem of the GTO’s headlights. For instance, a maintenance-conscious buyer might explore an OEM-style option that preserves the factory look while offering updated lighting performance, minus the risk of misfit parts. At the same time, some owners discover value in blending approach: an aftermarket assembly that preserves the car’s original silhouette while adding a modern light source and a contemporary color temperature. The balance between cost, fit, and performance is a personal calculation that reflects how the owner uses the vehicle, the local climate, and how strictly the regional lighting rules are enforced.

As a practical note, consideration of an OEM path or an aftermarket path should include a check for compatibility guarantees. Many sellers emphasize compatibility with specific model years and configurations, which can provide a level of reassurance when purchasing from online marketplaces or specialist shops. If the goal is to keep the car as close to its original condition as possible, OEM remains the safer bet for maintaining factory aesthetics and alignment with safety standards. If the goal is to push the GTO’s styling forward or to improve nighttime visibility at a budget, the aftermarket segment opens the door to a wider spectrum of possibilities, provided the buyer invests time in vetting the source, reading reviews, and confirming that all regulatory and electrical considerations are addressed.

For readers who want a tangible stepping stone toward an OEM-style solution without the premium price, a notable option exists within the late-1990s GTO headlight family. An OEM-compatible choice is the 95-99 Mitsubishi 3000GT clear headlights. This path speaks to the desire for factory-fitment accuracy and clarity, while acknowledging that the car’s age may lead to trade-offs in price and availability. It’s a reminder that the replacement question is not simply about new versus old, but about what balance of authenticity, performance, and value best suits the owner’s relationship with a car that remains a defining chapter in Mitsubishi’s sports-car lineage.

External resources beyond the car’s own archives can help frame the decision more broadly. For those seeking a wider industry perspective on OEM versus aftermarket headlamps and how lighting technologies interact with safety and regulation, the following external resource offers detailed context and considerations: https://www.motor1.com/news/358749/mitsubishi-gto-headlights-oem-vs-aftermarket/

Ultimately, the path an owner chooses should harmonize with the GTO’s heritage while acknowledging contemporary needs. Whether the emphasis is on preserving the original look through OEM parts or embracing modern lighting technology via carefully chosen aftermarket units, the essential steps remain the same: confirm compatibility for the exact model year and trim, understand whether ballast and igniter components are required for HID or LED upgrades, ensure proper sealing and aim, and verify that the finished installation complies with local traffic regulations. When these elements line up, the headlights do more than illuminate the road; they complete a visual dialogue between a classic vehicle’s legacy and the present-day demands of safety, efficiency, and personal expression.

In the broader arc of the GTO’s evolution, headlights are a small but telling chapter—one that encapsulates how a car can retain its soul while embracing technological progress. The choice between OEM and aftermarket is not merely a shopping decision; it is a conversation about how a driver wants to experience the road, how a car’s face communicates identity, and how lighting can stitch together years of engineering into a single, coherent drive.

Shifting Lights, Stubborn Character: The Mitsubishi GTO Headlight Evolution, Visibility, and Safety

The silhouette of the Mitsubishi GTO, known in markets outside Japan as the 3000GT, has long carried a quiet claim to performance and personality. Its headlights do more than illuminate the road; they punctuate the car’s stance and signal a willingness to blend drama with precision. In the earliest years of production, the GTO wore a pair of pop-up headlights that rose and folded with a mechanical choreography as distinctive as the car’s turbocharged heartbeat. This configuration, familiar to enthusiasts, gave the GTO a certain theatrical aura. It also reflected the era’s preferences for crisp, compact lighting units that could vanish behind a smooth, uninterrupted front end when not needed. Yet the design also carried a practical cost: the weight of the mechanism, the risk of misalignment, and the potential for moisture or debris to compromise performance. The visual drama of pop-up lights was a defining feature of the 1990 to 1995 GTO, but it did not stay unchallenged. By the 1993 facelift, Mitsubishi began a careful pivot away from the pop-up paradigm toward fixed headlights that could better align with emerging consumer tastes and safety expectations.

That transition was more than aesthetic. It encapsulated a broader professional shift toward fixed, projector-style lighting systems and more integrated front-end design. The facelifted models presented a lower, broader glare line, and a cleaner face that could accommodate newer lighting technologies as they matured. The move toward fixed headlights reflected a broader industry trend—toward headlights that could be engineered for precise beam patterns, improved road illumination, and more straightforward maintenance. It was a shift born from both design momentum and safety considerations, as fixed assemblies can be easier to seal, align, and troubleshoot than mechanically complex pop-up units. The GTO’s evolution in this area mirrors a larger automotive narrative: the moment when safety, efficiency, and visual clarity began to converge in a single, stable headlight package.

From a lighting technology perspective, the early 1990s placed halogen lamps at the center of most performance cars, with reflectors and lenses shaping the beam to maximize road visibility while managing glare. High-Intensity Discharge (HID) systems and, later, Light Emitting Diode (LED) configurations were still taking shape in the broader market. For the GTO, exact specifications on the original hardware and the subsequent upgrades are not exhaustively documented in the available research. What is clear is that the shift from pop-up to fixed headlights coincided with a period in which manufacturers began to experiment more openly with light distribution, color temperature, and lens clarity. The driving logic behind these choices remains intuitive: the modern driver benefits from brighter, more uniform illumination and from optics that minimize stray light toward oncoming traffic. While the GTO’s historical data on headlight technology is not fully detailed, the general pattern speaks to a broader move toward safer, more predictable nighttime visibility.

As the decades progressed, aging front-end assemblies on classic sport cars became a natural concern for owners. The GTO is no exception. Lens yellowing, clouding, or pitting can dull the very effect that once promised sharp night-time performance. Condensation inside the housing, worn seals, or misaligned reflectors can degrade beam quality and may even reduce daytime running light effectiveness. Owners who want to preserve the car’s iconic look while improving function often weigh a careful refurbishment against a modern retrofit. Refurbishment can restore clarity to original lens surfaces and reestablish proper light output without altering the car’s character. On the other hand, retrofitting a fixed headlight system with modern LED or HID elements can offer substantial gains in brightness and color rendering. These choices underscore a central theme: modern illumination can honor heritage while raising the bar for safety on today’s roads. The balance, of course, lies in maintaining the GTO’s distinctive silhouette without crossing into a look that feels incongruent with the car’s era or its engineering lineage.

A crucial part of the conversation around headlight upgrades is the awareness that compatibility and beam pattern matter as much as brightness. The GTO’s chassis and geometry interact with the front-end lighting in ways that mandately emphasize correct alignment, proper cut-off lines, and consistent beam spread. Any upgrade must respect the vehicle’s mounting points, electrical load, and reflector geometry to avoid creating glare for other drivers or reducing illumination in critical zones like approaching lanes or unlit shoulders. In practice, this means that prospective changes—from restoring vintage units to introducing modern projectors—should be pursued with attention to the car’s original dimensions and the road safety implications. For those who want to pursue a period-correct appearance while benefiting from contemporary lighting technology, there are pathways that preserve the GTO’s visual identity while improving nighttime visibility. These avenues often involve carefully chosen component packages that fit within the car’s original silhouette and mounting footprints, ensuring the look remains faithful while the light output genuinely improves.

In discussing the GTO’s headlights, it is also useful to consider the broader ecosystem of parts and services that support classic forms. The maintenance and replacement market for older performance cars has grown increasingly sophisticated, with options ranging from faithfully reproduced OEM-style assemblies to more generalized aftermarket solutions designed to fit a variety of Japanese performance chassis. A careful buyer or restorer evaluates each choice for compatibility with year-specific headlights, bezel styles, and lens curvature. The careful alignment between the front fascia’s lines and the headlight housing—along with the quality of the seal and the reliability of the electrical connections—becomes part of the car’s overall reliability and daytime persona. In this context, genuine or OEM-like replacements can offer a straightforward path to restoring function, while more adventurous routes—like retrofits or stylized upgrades—can deliver heightened brightness and more modern color temperature while retaining the GTO’s aggressive stance. The key is to approach upgrades not as a gimmick but as a respectful evolution that honors the car’s original intent while enhancing safety and everyday practicality.

For readers seeking concrete, model-specific paths to replacement or upgrade, there exists a resource that addresses the 3000GT’s headlight options in a direct way. The compatibility and fitment of headlight assemblies for the late-1990s variants are documented in dedicated listings that emphasize accuracy and model-year specificity. When making a purchase, one should verify that the headlight unit matches the vehicle’s year, trim, and market. Paying attention to the details—such as the presence or absence of an adjustable beam mechanism and the configuration of the electrical connectors—avoids the common pitfall of buying a unit that looks right but performs poorly in practice. In addition, proper installation, including the alignment process, is essential to ensure the new headlights deliver their intended performance and do not introduce glare or misaligned lighting patterns. To assist with the practical side of this task, readers can consult the linked resource that targets the 1995–1999 range, which provides a concrete example of how to navigate compatibility concerns while preserving the car’s original look and feel. 95-99 Mitsubishi 3000GT SL/VR4 clear headlights.

From a safety standpoint, the narrative around headlight evolution in the GTO is not merely about brightness. It is about ensuring the beam is controlled, consistent, and appropriate for night driving. Fixed headlights inherently lean toward more predictable beam control, which translates into better visibility for the driver and less scatter toward oncoming traffic. This is a quiet but meaningful contribution to nighttime safety. The GTO’s transition from pop-ups to fixed assemblies thus stands at the intersection of style and practical safety. Even as enthusiasts celebrate the pop-up era for its theatrical charm, the modern perspective recognizes that reliable, well-behaved headlights are a foundational element of a performance car’s daily usability. In that light, the GTO’s headlight journey can be read as a microcosm of automotive lighting’s broader shift toward clarity, consistency, and safety as standard elements of the driving experience.

For readers who want to place this discussion within a wider context, a broader external resource on headlight technology and safety standards can provide useful background on how beam patterns, color temperature, and regulatory requirements have evolved over time. This contextual backdrop helps students of automotive history appreciate why the GTO’s headlights transitioned as they did, even if the exact specifications for every model variant are not exhaustively documented in one source. The essential point remains clear: the evolution of the GTO’s headlights reflects a broader commitment to safer, more effective night driving while preserving the car’s distinctive identity.

External resource: https://www.nhtsa.gov/equipment/lighting

null

null

Keeping the GTO’s Eyes Bright: A Practical Guide to Headlight Longevity and Performance

The Mitsubishi GTO, known to many as the 3000GT, wears its headlights like a signature. Their shape and character have shifted with every generation, from the bold pop-up lamps of the early 1990s to the more modern, fixed headlights that followed. The evolution wasn’t just about looks; it reflected advances in lighting technology and a growing emphasis on safety and practicality. As a result, maintaining the GTO’s headlights is not merely about keeping the car’s face intact. It is about preserving visibility, ensuring legal compliance, and protecting the carefully styled housing that defines the car’s nighttime presence. Proper care becomes a quiet performance upgrade, one that sustains the car’s historic visual impact while supporting reliable nighttime illumination. The following guidance draws on the practical realities of the GTO’s headlight design and the maintenance habits that keep them at their best throughout their life in the driveway or on the road. It also considers the realities of upgrading optics in an older system, where modern lighting technologies meet an aging electrical architecture.

Regular cleaning is the first line of defense against diminishing visibility. The headlight lenses on a GTO accumulate road grime, insects, and environmental residue that dull light output and obscure the beam pattern. A gentle automotive cleaner, soft cloth, and patience are enough to remove the everyday film. Avoid abrasive pads or strong solvents that might scratch or craze the lens surface. The lenses in these cars, especially those exposed to UV sunlight, can develop a subtle yellow cast over time. Keeping the surface clear not only improves brightness but preserves the aesthetic clarity that makes the GTO’s headlights instantly recognizable, whether you’re admiring them in a showroom retro scene or catching a glimpse of their reflection after sunset.

Beyond surface cleanliness, the integrity of the seals around the headlight assemblies deserves regular scrutiny. The seals act as a barrier against moisture, dust, and thermal cycling that can cause condensation inside the housing or premature corrosion of reflector surfaces. Periodic inspection is prudent because moisture intrusion can fog the lens from the inside or, worse, damage sensitive reflector coatings or electronic components tied to modern lighting options. If you notice fogging, dampness, or a soft, tacky feel around the gasket, replace the seal promptly or consult a professional who can reseal the assembly without disturbing the alignment. A compromised seal not only shortens the life of the lamp but also undermines nighttime safety by compromising beam consistency.

For owners contemplating a lighting upgrade, the discussion often centers on retrofitting with LED technology. LED headlights can deliver significantly brighter output and improved energy efficiency, a practical payoff for a car whose performance credentials emphasize nocturnal presence. The technical literature indicates that LED implementations for the GTO era frequently use a heatsink aluminum shell to manage thermal load, helping to extend the headlight’s life and maintain stable light output. Still, LED retrofits are not a plug-and-play proposition for older systems. They typically require compatible ballasts and igniters to function correctly. If those components are mismatched or improperly installed, flickering, dimming, or even wiring harness strain can result. Therefore any LED upgrade should be approached with careful attention to compatibility with the vehicle’s electrical system and the current headlight housing. The aim is to improve brightness and efficiency while preserving beam pattern and reliability, not merely to chase a whiter light.

Quality matters when swapping or upgrading parts, and the same principle applies to bulbs and replacement assemblies. Using OEM or high-quality aftermarket components helps maximize performance and longevity. Cheap, uncertified LEDs or mismatched bulbs can draw excessive current, shift the beam pattern, or fail prematurely in a way that creates new safety hazards. The GTO’s lighting system, especially in older generations, benefits from parts that meet or exceed the design specifications originally intended by the manufacturer. A careful selection process that prioritizes fit, reflector integrity, and electrical compatibility reduces the risk of nuisance failures while preserving the car’s distinctive nighttime look. It also aligns with the broader goal of longevity: a headlight that remains effective for many seasons rather than one that demands frequent replacement.

Temperature and thermal management are more than theoretical concerns in a vehicle that rivals modern sports cars in its penchant for performance. The operating temperature inside and around the headlight housing can influence both the lens material and the electronic components. Excessive heat can accelerate lens degradation and, over time, can erode reflector coatings or shorten the life of electronic modules connected to the lighting system. Maintaining proper airflow around the headlight assemblies is essential. That means keeping the area free from obstructions that could trap hot air or create a stagnant pocket behind the lens. It also means ensuring that the engine bay’s own heat and the headlight’s heat dissipation work in concert rather than at cross purposes. A simple practice is to verify that there is unimpeded ventilation near the headlight area when performing other service work, such as engine bay cleaning or radiator maintenance. Small steps, like removing debris that blocks cooling channels or opening a hood vent when conditions permit, can help keep temperatures at a level where lenses and electronics stay healthier longer.

A practical maintenance routine can be approached as a sequence of checks that evolve with the car’s age. Begin with a visual inspection whenever you wash the car. Look for signs of moisture in the housing or on the inside of the lens, as well as any cracks or loose trim around the bezel. If the seal looks damaged or softened, plan a replacement. Next, assess light output and beam pattern. A noticeable drop in brightness or a misaligned beam can indicate aging reflectors, degraded seal integrity, or a failing bulb or ballast in an LED retrofit. If you’re upgrading, test the new configuration in a controlled environment to confirm stable output without glare to oncoming traffic. A successful upgrade should produce a clean, crisp cutoff line that does not scatter light unpredictably.

Addressing these issues promptly is essential for safety as well as for preserving the vehicle’s look. Since the GTO has a storied appearance that can be as much about period authenticity as about performance, many owners seek period-correct optics when replacements are necessary. For those exploring replacement optics from the late-1990s era, one option is the 95-99 Mitsubishi 3000GT SL/VR-4 headlights with clear glass that matches the era’s styling cues while offering modern reliability. This kind of replacement preserves the original silhouette and maintains the signature glare pattern that enthusiasts expect from a classic GTO. Internal links can guide you to compatible assemblies that fit the 1995–1999 window and help ensure a seamless fit with the car’s body lines and mounting points. See the replacement options here: 95-99 Mitsubishi 3000GT SL/VR-4 headlights with clear glass.

Beyond replacement parts, maintenance also encompasses the electrical system that powers the headlights. The switchgear, wiring harness, and connector pins can accumulate corrosion or wear over the years, particularly if the seals have allowed moisture to contact metal surfaces. A corroded connection can increase resistance, reduce current delivery, and cause dimming or intermittent operation. Periodic inspection of connectors for signs of oxidation, hot spots, or loose fit is a prudent practice. If disposal or replacement is necessary, use corrosion-resistant contact materials and clean, to-spec connectors to maintain a solid electrical pathway. Regular inspection of the fuses and relay controls associated with the headlight circuit is also wise. A failing relay can mimic a burned-out bulb, complicating diagnosis and potentially masking a broader electrical issue.

Ownership of a GTO also involves understanding the broader guidance that came from the manufacturer’s manuals during the years these cars were on the road. While the modern reading of the manuals reflects a long history of development, the core messages remain relevant: keep optics sealed, ensure proper alignment, and protect the light sources from the heat and vibration of daily driving. The official manual for the 1994–1999 period provides specific recommendations about the assembly tolerances, mounting hardware, and service intervals that help avoid beam misalignment and water intrusion. Engaging with these resources can inform your maintenance plan without requiring you to dismantle the entire headlamp during routine service.

In practice, a balanced approach to headlight care for a GTO balances cleaning, sealing, and prudent upgrading with attention to electrical health and airflow. This approach preserves the car’s distinctive look and the essential function of the lights themselves. The maintenance choices you make—whether you stick with original optics, embrace a period-correct replacement, or move toward a carefully selected LED retrofit—should be guided by a desire to sustain both performance and appearance. The goal is not to chase novelty at the expense of reliability but to extend the life of the car’s most important nighttime feature while honoring its pedigree.

For readers who want to explore a broader range of replacement options and ensure precise compatibility with their model year, the headlight replacement question is part of a wider ecosystem of parts built around the 3000GT’s unique configuration. Platforms that offer OEM and high-quality aftermarket options can provide a pathway to restoring the headlights to their former glory or updating them to a more contemporary standard, all while preserving the car’s original silhouette. In all cases, verify fitment by year and trim level, confirm electrical compatibility, and consider professional installation for any complex upgrade.

External resource for further guidance on model-specific maintenance can be found at the official Mitsubishi manual for the 3000GT (1994–1999 model years) for those who want to dive deeper into the recommended service intervals and assembly tolerances: https://www.mitsubishi-motors.com/uk/owners/manuals/3000gt-1994-1999.html

Final thoughts

In summary, the headlights of the Mitsubishi GTO not only serve functional purposes but also embody a rich history of design and technological advancement. From the iconic pop-up headlights of the early models to the sophisticated fixed designs of later iterations, understanding this evolution is vital for business owners in the automotive industry. The insights into replacement options, technological upgrades, aesthetic significance, and maintenance emphasize the strategic importance of headlights in enhancing vehicle safety and appeal. Providing excellent headlight options ensures customer satisfaction and fosters loyalty in a competitive marketplace. Continuous learning about these aspects can empower automotive businesses to meet consumer needs more effectively and secure success in their ventures.