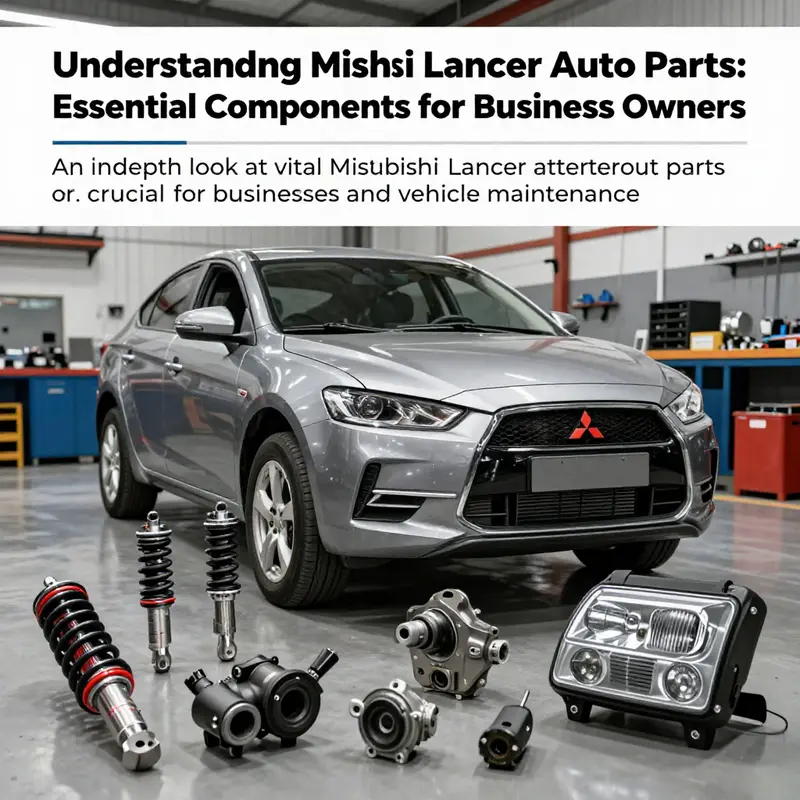

In the automotive sector, knowledge about aftermarket components is crucial for maintaining performance and reliability. For business owners dealing with Mitsubishi Lancer vehicles, understanding the variations in auto parts can significantly impact operations, servicing, and customer satisfaction. This article will delve into essential components specific to the Mitsubishi Lancer, particularly focusing on suspension system parts, stabilizer link bushings, as well as engine and drivetrain components. Each chapter will provide vital insights into these parts, their relevance, suppliers, and considerations needed for smooth operations in the automotive aftermarket.

Under the Skin of the Lancer: How Suspension and Core Drivetrain Parts Shape Handling, Comfort, and Reliability

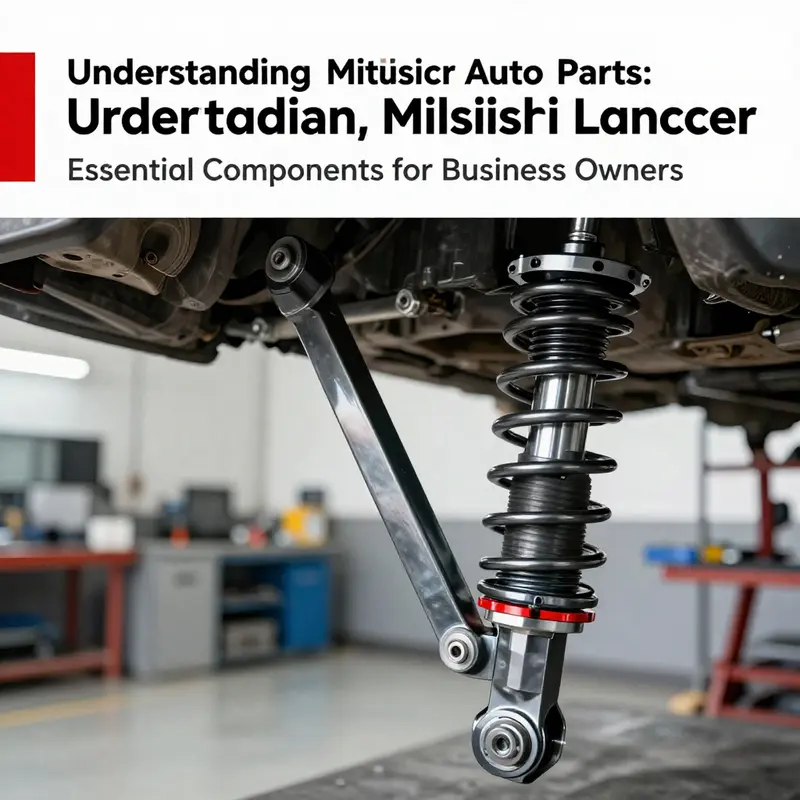

The Mitsubishi Lancer is more than a silhouette and a reputation for practical, approachable performance. Its character rests on a hidden network of parts that work in concert to translate road texture into steering feel, cornering poise, and everyday comfort. When you slide behind the wheel and press the accelerator, the chassis responds not just because of the suspension you can see, but because of a web of components that manage motion, dampen vibration, and keep the engine and transmission aligned with the road. In this chapter we move through that hidden network, focusing on the suspension family and the core elements that partner with it: engine mounts, drive-line attachments, and the small, often overlooked pieces that quietly maintain alignment and balance. This is not a catalog of parts, but a narrative about how these components shape the Lancer’s everyday behavior, from the almost imperceptible rebound after a pothole to the confident stability felt when exiting a high-speed bend. The reliability and feel of the Lancer hinge on precise geometry, robust joints, and materials designed to endure years of service. These are not glamorous pieces, but without them the smoothness, safety, and directional precision that owners value would vanish. Among the most visible, yet still behind-the-scenes, are the suspension components that control wheel motion and maintain the intended alignment under load. The upper control arm, working in concert with the wheel hub and steering knuckles, helps govern the camber angle and the wheel’s vertical movement as the car travels over irregularities. In a typical Lancer, this arm is designed to accommodate several generations, recognizing that chassis geometry evolves while the fundamental need remains: to keep the tire’s contact patch stable as the wheel climbs over a bump or dives under braking. The right front arm and the left front arm, each tailored for its position, are matched to the vehicle’s geometry so the wheel’s motion remains predictable. This predictability is the foundation for steering feel and grip. A well-tuned upper control arm contributes to even tire wear and a linear steering response, especially when the car is pressed through corners or stabilized after a rapid change in road texture. Although the specific part numbers vary with model year and trim, the function is constant: preserve geometry and maintain harmony between the wheel and the chassis. The complement to the upper control arms is the lower control arm and its associated bushings, which form the cradle for the wheel assembly. The lower arms carry substantial vertical and lateral forces, particularly when the car encounters dips, speed bumps, or aggressive cornering. The bushings, often made of rubber or a composite, cushion the contact between metal components and chassis while allowing a small amount of rotation and flex. Properly chosen bushings resist squeaks and wear, while still permitting the articulation required to absorb road irregularities without transmitting excessive harshness into the cabin. In the Lancer’s context, this pair of arms and their bushings work as a system; if one wears prematurely or becomes misaligned, toe and camber can drift, altering steering feel and tire contact. The result is a noticeable shift in how the car settles after cresting a rise or after a sudden braking event. Suspension links and their connections—the stabilizer links and their bushings—play a central role in reducing body roll and maintaining balance through corners. A stabilizer link translates trunk and chassis torsion into controlled, symmetric wheel movement, keeping the body from leaning excessively when the vehicle corners. The stabilizer bushing, often a simple elastomer or engineered polymer, isolates noise and vibration while resisting wear from repeated cycles of compression and extension. A robust stabilizer connection translates to steadier lines and quicker recovery in turn-entry and mid-corner throughputs, which is especially important in spirited driving or when the road surface is uneven. The design of these components recognizes the harsh realities of real roads: every bump, dip, and rut translates into a small torque that would otherwise disturb the chassis balance. The stabilization system, though not as dramatic as the engine or the transmission in terms of perceived drama, is essential to how the Lancer communicates with the driver. It is the difference between a car that simply goes forward and a car that threads a line through traffic with calm precision. While the suspension and stabilizer assemblies manage motion, the engine mounting bracket anchors the heart of the car in a way that matters as much to feel as to function. Engine mounts isolate engine vibration, reduce noise, and preserve the alignment between the engine and the transmission. A well-chosen mounting bracket helps the engine sit firmly in the engine bay while absorbing the shocks of torque transfer under acceleration and deceleration. When mounts wear or become brittle, vibration can travel more easily into the cabin and through the chassis, especially at idle or during rapid throttle changes. The Lancer’s powertrain stability depends on these brackets to keep the engine’s mass centered and tuned to respond in a linear fashion to driver input. A robust mount not only dampens vibration but also preserves the intended balance between engine torque and wheel torque, ensuring that power delivery remains predictable and the car remains controllable under a wide range of loads. In the realm of power delivery, the drivetrain’s heart, such as a 2.4-liter four-cylinder option often discussed in the Lancer ecosystem, can be swapped or refurbished to extend vehicle life or tailor performance without compromising the surrounding architecture. The engine itself is only part of the equation; the way it mounts, couples to the transmission, and interacts with the suspension geometry forms a holistic system. A fresh or refurbished engine option can provide renewed torque characteristics and throttle response, but the integration with engine mounts, transmission mounts, and subframe geometry is what makes the swap feasible and reliable. The price point for a rebuilt or refurbished engine reflects the value of this integration, but the larger payoff lies in the long-term reliability and the confidence it lends to daily use. In practice, owners pursuing such options weigh the cost against the improvements in drivability and return-to-service timelines. The mounting system, the brackets that support it, and the surrounding hardware become part of the conversation because they determine how the engine’s inertia and torque are absorbed and distributed through the chassis. The clutch assembly, including the clutch cover, is another fundamental piece of the drivetrain that interacts with the suspension and mounting systems in meaningful ways. The clutch cover is not merely a friction surface; it is a critical interface that translates pedal input into transmitted torque, and it must function reliably as the engine speed and load change. A well-matched clutch cover maintains smooth engagement, prevents judder, and supports consistent take-up in a way that complements the car’s suspension and steering dynamics. This is particularly important for drivers who frequently drive in heavy-traffic conditions or who push the car through aggressive driving scenarios where clutch performance can influence traction and balance. Beyond the core mechanical assemblies, the tail lamp assembly within the Lancer’s exterior lighting package contributes to the safe and predictable signaling of the vehicle. Tail lamps are designed for durability, often featuring sealed or water-resistant construction to withstand weather and car washing cycles. While not part of the suspension, the lamp cluster’s integrity is a quiet partner in safety, ensuring that signals are clear and consistent for following drivers. A reliable tail lamp assembly reduces the risk of misinterpretation by other road users in low-visibility conditions, which in turn supports stable driving behavior on crowded streets and highways alike. A well-maintained lighting system complements the chassis’s responsive handling by supporting safe lane changes, braking, and signaling, which reduces abrupt maneuvers and uneven load transfer that might otherwise stress suspension components. The steering system itself, which relies on the tie-rod ends to translate steering input into wheel movement, is another constant in the Lancer’s dynamic equation. The tie-rod end connects the steering rack to the knuckle and influences toe control, which is essential for precise directional response. Worn tie-rod ends can introduce play in the steering, causing the car to feel loose or imprecise as speeds rise or surfaces become uneven. With a modern Lancer, ISO and quality system certifications that underpin manufacturing processes provide confidence that these components meet consistent standards. The result is predictable steering behavior under a wide range of conditions and longer tire life due to more stable toe control. Shocks and dampers round out the core suspension package by controlling how fast the car recovers after a bump, how it responds to weight transfer during cornering, and how comfortable the ride remains across imperfect pavement. Hydraulic dampers paired with a resilient spring system absorb energy from road irregularities and help the chassis recover to its nominal stance quickly. The combination of shock absorbers and their mounting hardware ensures that the suspension arc remains within its intended geometry, preserving the alignment and the tire contact patch through varying road conditions. In the Lancer, a well-matched set of dampers and springs is not about stiffness alone; it is about controlled motion that translates into stability, grip, and confidence. Quality and reliability permeate every layer of these parts. The components that make up the Lancer’s chassis and drivetrain typically come with certifications and warranties designed to reassure buyers, whether they are performing routine maintenance or rebuilding the vehicle after wear or an unforeseen event. A common theme across manufacturer and supplier documentation is a balance between durability, serviceability, and performance. Warranty periods—often in the realm of one year or tens of thousands of kilometers—reflect the expectation that critical joints and mounts will endure typical driving cycles. This is not merely about preventing failure; it’s about preserving the integrative feel of the car over time. The end result is a Lancer that remains true to its intended handling and comfort across many miles. The procurement choices for these parts illuminate how owners, workshops, and fleets approach maintenance. Original equipment and aftermarket options exist, each with tradeoffs in fit, finish, and service life. Where OEM parts guarantee exact geometry and material compatibility, aftermarket options may offer cost savings or targeted performance attributes. Yet the most important criterion is the maintenance of geometry and tolerances that keep the suspension working as designed. Without careful selection, a vehicle may drift toward imprecise steering, increased tire wear, or a stiffer ride that amplifies road imperfections. For enthusiasts and daily drivers alike, the emphasis on proper mounting points, correct bushings, and correctly sized links ensures that the suspension communicates clearly with the tire and the road. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come. For readers seeking practical resources and real-world choices, it is helpful to understand how these parts are discussed and classified in the broader market. The suspension family comprises front and rear arms and links, each with variations to fit generations and trim levels. The bushings, a critical but often overlooked aspect, determine how much road texture is transmitted to the chassis, influencing both feel and noise. The stabilizer components manage roll dynamics, while the dampers and springs provide the essential decoupling and return-to-center behavior that keeps the car balanced during acceleration, braking, and cornering. When owners or repair shops evaluate options, they weigh the hardware’s compatibility with the vehicle’s geometry, the expected life under regional road conditions, and the availability of service and replacement parts. The Lancer’s design philosophy tends toward a balanced compromise: a chassis that is neither too stiff nor too soft, with parts that can survive ordinary road life while still delivering a satisfying sense of precision and control. In summary, the Lancer’s suspension and related drivetrain components form a cohesive system that defines how the car feels in the hand and communicates with the road. The upper and lower control arms and their bushings set the baseline for wheel articulation; the stabilizer assemblies, the engine mounting bracket, the engine and clutch hardware, the tail lamps, the tie rods, and the dampers together form a symphony of motion control. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. The practical reality is that these parts must be in good condition to deliver the intended Lancer experience. A small misalignment or a worn bushing can cascade into larger issues that degrade cornering stability and ride comfort. Routine inspection of control arms, bushings, stabilizer links, and mounts offers a straightforward path to preserving handling and comfort. A systematic approach to maintenance—checking for cracks in metal arms, play in joints, and wear in rubber components—helps ensure that the Lancer’s chassis remains faithful to its design intent. In practice, this means listening for unusual clunks in the wheel wells, feeling for changes in steering effort, and observing tire wear patterns that betray imbalances. When residents of a workshop identify and address such issues early, the likelihood of expensive repairs later drops significantly. To illustrate the breadth of options typically available to owners, consider the spectrum of parts that can be sourced for suspension and supporting components. You will find several variants of control arms, each engineered to fit a range of Lancer generations. These arms are paired with bushings tailored to resist wear while allowing the appropriate articulation. Stabilizer links and their bushings provide the necessary stiffness and damping to keep roll under control without transmitting harshness to the cabin. Engine mounting brackets are designed to absorb vibrations and torque, maintaining the engine’s position relative to the transmission and subframe. Engine and transmission mounts work together to preserve alignment and minimize noise transfer, making daily driving more comfortable. Then there are the other critical pieces—tie rods, shock absorbers, and the tail lamp and lighting system—that contribute to safety, visibility, and directional stability. Each component, while small in isolation, contributes to a larger picture of reliability and performance when it functions in harmony with its peers. The broader supplier ecosystem that supports the Lancer chassis reflects the practical needs of buyers around the world. Reputable manufacturers and distributors emphasize not only the quality of materials but also the consistency of manufacturing processes, with certifications that cover quality management, process control, and testing. This ecosystem makes it possible to source parts in various quantities—from single units for minor repairs to bulk orders for workshops or fleets—while maintaining a consistent standard of fit and function. For many owners, the choice between OEM and aftermarket parts hinges on availability, price, and the expected lifespan under specific driving conditions. In either case, the key is to ensure that the parts align with the vehicle’s designed geometry and tolerances, and that they integrate with the suspension, engine mounts, and steering system in a predictable and safe manner. As drivers and technicians, we understand that the Lancer’s satisfaction does not rest on a single element—no more than a song rests on a single note. It rests on the quality and harmony of many parts moving in concert. The driver experiences the result as precise steering, balanced weight transfer, and a ride that remains comfortable across a spectrum of surfaces. This holistic view helps explain why even seemingly minor components deserve attention during maintenance. A worn bushing or a loose tie rod end can alter handling characteristics enough to be noticeable to a trained eye or a seasoned driver. By focusing on the integrity of the suspension, the mounting systems, and the supporting driveline components, owners can preserve the Lancer’s intended feel and ensure reliable performance for years to come.

null

null

心脏与骨架:三菱蓝瑟发动机与传动系统零部件的全面解构

在任何一辆汽车的叙事里,发动机和传动系统往往被提及为最核心也最直观的“心脏与骨架”。对于三菱蓝瑟这一代代车型而言,发动机的内部精密与传动系统的协同工作共同塑造了其动力性、耐久性与驾乘体验的独特平衡。本章将以一个高层次、但不失细节的视角,梳理这两大系统所涵盖的关键零部件、它们在日常维护中的角色,以及在改装与维修市场中常见的供给与选择逻辑。整段论述力求以一个统一的叙事线索展开,避免碎片化的分段,确保读者在浏览时能感受到发动机“心跳”的韵律与传动“骨架”的支撑如何共同支撑起整车的动态与舒适。与此同时,本章也将把焦点从单纯的部件清单转向部件之间的关系,以及它们在不同年份、不同排量配置下的兼容性与替代性,帮助读者理解在维修、改装或批量采购时应如何把控核心要素。为了把理论与现实中的采购决策连接起来,我们还将简要提及一个内部资源,帮助读者获得更具体的替换部件示例;同时提供一个外部参考链接,帮助读者获取更广泛的市场信息。

发动机系统作为蓝瑟的“心脏”,其核心职责在于将燃烧产生的热能转化为可用动力,并通过润滑、冷却、燃油供给及点火等子系统维持这颗心脏的稳定运作。无论是新车状态的全新件,还是翻新件、原厂替代品,核心在于它们是否能在同一环境下提供一致的燃烧效率、响应速度与稳定性。为了理解这一机制,我们需要先从不同子系统的功能切入,逐步揭示每一个部件在整体中的角色。

一方面,进气与排气系统的组合控制着空气-燃油混合物的获取与排放的管理。空气进入发动机后,需经由节气门体、进气歧管及空气滤清器等部件将清洁空气以合适的压力和温度送入气缸。排气系统则通过消声器与排气管道将燃烧后的废气排出,同时配合氧传感器等监测元件实现排放控制与动力输出之间的平衡。定期清理节气门、清除积碳,能显著提升节气门的开启响应与进气流量的稳定性,从而改善燃油经济性与动力响应。

另一方面,燃油系统承担着把燃油以稳定且雾化的方式送入气缸的职责。喷油嘴、燃油滤清器、燃油泵等部件的质量与状态直接影响喷油压力、雾化效果以及燃烧的稳定性。高品质燃油滤清器在阻隔杂质进入喷油嘴方面发挥着关键作用;而燃油泵的供给能力则决定了引擎在不同转速下的持续性供油。对于长时间使用的车辆,定期检查燃油滤清器的外观与流量信号,是避免喷油嘴堵塞与燃烧异常的基本环节。

润滑与冷却系统共同保护发动机在高温、高压工作条件下的寿命与稳定性。机油滤清器、机油泵、油底壳等部件不仅维持润滑油路的清洁与连续性,更通过油温与油压的监控反应到发动机控制系统的调节策略。冷却系统的水泵、散热器以及冷却液的循环则保证发动机在持续工作时维持在安全温度区间。对发动机而言,机油的定期更换是核心保养之一,通常以保证润滑膜的完整性、减小摩擦与热积累为目标。与此同时,点火系统通过火花塞、点火线圈等部件确保燃烧过程的点火时序与燃烧稳定性。将这些子系统放在一起看,它们像一条错综复杂但稳定的管道网络,确保发动机在各种工况下都能保持清晰的转速响应、可控的扭矩输出以及可预测的热管理。

在传动系统方面,维护的焦点从发动机的“点火瞬间”逐步转向动力的传输、变速与驱动的整体协调。离合器系统作为手动车型的核心部件,承担着将发动机的动力逐步接入变速器的职责;而变速器系统则需要在不同齿轮之间平顺地切换,以匹配发动机的扭矩特性与驾驶员的需求。万向传动装置与传动轴、差速器等部件则在不同驱动形式下承担着将扭矩有效分配到各轮的任务,保证转弯时的稳定性与在不同路况下的牵引力表现。对许多驾车者而言,传动系统的性格往往在离合器的接合/分离、换挡的顺畅度以及行驶中的异响与振动中显现。因此,优质的传动部件不仅要在工作状态下传递稳定的扭矩,还需具备对振动与热负荷的抑制能力。发动机支架、变速器支架以及扭矩支撑臂等部件的橡胶-金属组合在减震方面发挥着不可忽视的作用,它们的衰退往往会让整车的传动舒适性和响应性下降。换言之,发动机心跳的稳定与传动骨架的坚韧,是驾驶者感知车辆“原始韵味”的两条主线。

进入实际采购与维护的视角,我们会发现市场上对于三菱蓝瑟发动机与传动系统的替代件、翻新件与新件的供给呈现出多元化的格局。这一格局的形成,既来自于不同车型年款对排量、缸数与驱动形式的差异,也来自于全球零部件供应链在质量管理、生产工艺与认证体系方面的共识与要求。常见的质量体系认证如ISO 9001、TS16949、SGS等,成为厂商在设计、制造与售后服务中追求的一致性标准。对于维修商与车主而言,选择具备这些认证的部件,往往意味着更高的一致性、更好的可追溯性及更稳定的售后保障。与此同时,许多供应商在包装与定制服务上也提供一定程度的灵活性,包括支持小批量采购、不同包装规格以及较长的保修期。这样的市场特征,使得无论是保养、修复还是轻度改装,车主都能在不牺牲可靠性的前提下,寻找到符合预算与性能取向的方案。

在深入探讨内部结构与功能关系时,我们也不得不面对一个现实:车型年代、发动机排量及驱动形式的不同,会让同一系统的部件在设计细节上存在差异。这种差异并非简单的“升级/降级”关系,而是基于功率输出、热管理、扭矩曲线与燃油经济性目标的工程取舍。因此,理解兼容性与替代性,成为每一个维修或改装决策中最重要的一步。这也是为何在实际操作中,车主与技师会强调“先确认车型的年份与发动机代码,再选择匹配的部件”的原则。这一原则的核心,是确保部件在物理尺寸、连接接口、密封件、工作温度范围和寿命周期等方面的匹配度达到最优。

为了提供一个更具体的导向,读者可以参考内部资源中的示例条目,这些条目往往以清晰的命名与结构,帮助专业人士快速定位到匹配的部件类别,并在需要时跳转到更具体的型号选择与替代选项。相关链接的使用有助于将理论认识转化为实际采购与装配的行动步骤。如下所示的一个示例链接,即是一个以部件类别为导向的内部资源入口: 4b11t-billet-block。通过该链接,读者可以看到与发动机结构相关的翻新或替换部件在网页中的展示方式、规格描述以及常见配套件的信息框架。这种信息组织方式有助于将“部件功能”与“装配需求”对齐,避免在实际购买时出现不必要的错配与返工。

回到更宏观的视角,综合上述系统的功能性与维护逻辑,我们可以把握一个总体的判断框架:在任何采购与维护决策中,优先考虑部件在physically compatible方面的匹配程度、在工况下的耐久性与热负荷适应性,以及在认证体系与质量保证上的可追溯性。通过这套框架,不仅能够提升车辆的驱动稳定性与操控性,还能在长期使用中降低故障率与维护成本。对于车主而言,这意味着在日常保养中能够用更少的时间和资金,维持更稳定的性能表现,并在需要加速、减速或转弯时获得更一致的响应与信心。对于技师与维修工坊来说,则是一个可落地的工作指引:先确认核心系统的实际工况,再在备件库中以兼容性、耐久性与价格三者之间的平衡点来进行选择。如此,发动机的“心跳”与传动的“骨架”将长期地、以可预测的方式共同支撑起整车的行驶品质。