The Mitsubishi Lancer Evolution X, known for its rally heritage and high performance, is powered by the remarkable 4B11T engine. This turbocharged inline-four engine not only sets the standard for sports sedans but also retains its integrity through advanced engineering. In the forthcoming chapters, we will dissect the key specifications that define the Evo X engine, examine its performance features that elevate driving experiences, highlight the importance of using genuine parts for maintenance, delve into the technological innovations that keep it ahead of the curve, and underscore the significance of proper maintenance to ensure longevity. These insights promise to enhance the understanding of this powerful engine for business owners interested in the automotive domain.

Pulse of the Rally: Inside the 4B11T Heart of the Lancer Evolution X

The Mitsubishi Lancer Evolution X sits at a precise intersection of rally heritage and modern automotive engineering. Its identity centers on the engine, the 4B11T, a compact 2.0-liter turbocharged inline-four that serves as more than a powerplant; it is the chassis’s rhythm, the metronome that keeps the car in harmony with its all‑wheel-drive chassis and adaptive dynamics. In the Evo X, the engine is not merely a power source but a tightly integrated system whose character shapes the way the car accelerates, handles, and survives the punishing demands of high-speed driving. Understanding this motor means tracing a lineage of design choices that balance power, response, durability, and efficiency in a package engineered for both road and rally-style exertion. The result is a purpose-built engine that thrives on revs, responds with immediacy, and remains trustworthy when the times get rough on a track or back road alike.

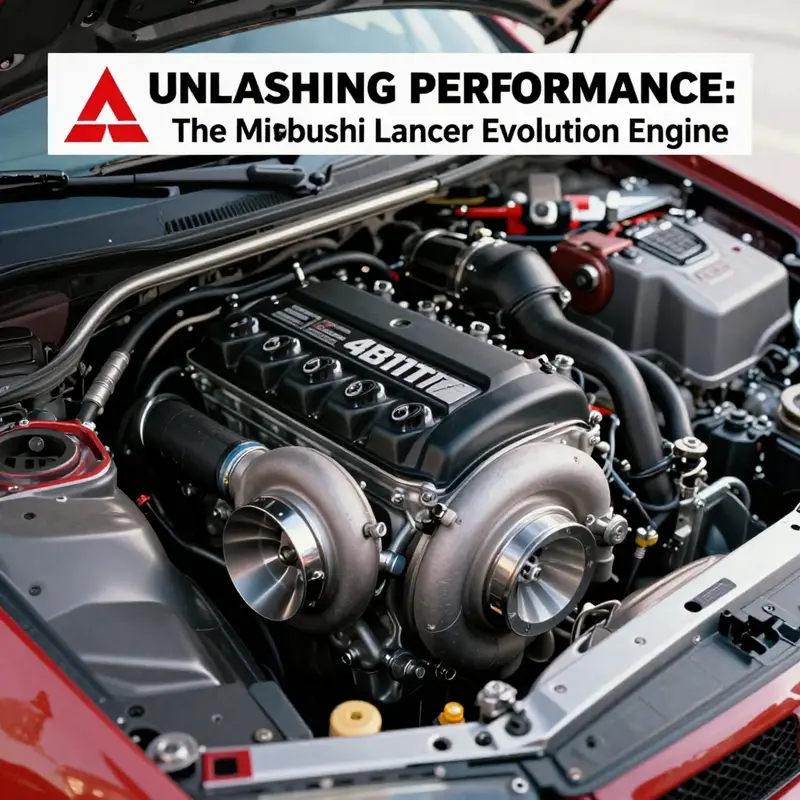

At its core, the 4B11T is a 2.0-liter, inline-four with double overhead cams and sixteen valves. The displacement—1998 cubic centimeters—belies the engine’s breadth of capability. The architecture favors a refined balance between light weight and rigidity: aluminum block and head materials help reduce unsprung mass and improve heat dispersion, which is crucial when the engine spends long periods at elevated temperatures under spirited driving. The decision to use an aluminum alloy for major structural components is more than a weight-saving measure; it is a deliberate strategy to maintain durability while the engine endures the thermal cycling and high cylinder pressures that come with turbocharged operation. The 16-valve DOHC layout, paired with Mitsubishi’s advanced valve timing control, ensures that the engine breathes efficiently across a wide rev range. This is not a one‑note powerplant; it is a flexible, adaptable unit designed to perform in slow-creaping daily drive and in high-strain track sessions alike.

Turbocharging defines the Evo X’s personality as much as its chassis does. While early interpretations of turbocharged four-cylinders often wrestle with lag and throttle sluggishness, the 4B11T is tuned to offer a robust, usable wall of torque from relatively low revs and a confident surge as the tachometer rises. In the Evolution X, Mitsubishi moves to a high-capacity, twin-scroll arrangement that pairs with the engine to deliver quicker throttle response and smoother boost delivery. The twin-scroll turbocharger design helps separate exhaust pulses from the two pairs of cylinders, reducing exhaust backpressure and minimizing lag. With a hardware pairing to an efficient intercooling system, the charge air remains cooler, denser, and responsive. The engine breathes through a direct injection system in later iterations, delivering precise fuel metering that complements the valvetrain and turbo architecture. This combination yields a broad, linear torque curve that makes the car feel eager and tractable, whether the throttle is planted full in a straight line or modulated through a tight cornering sequence.

In stock form, the Evo X’s engine produces power and torque figures that reflect its rally-bred intent. You’ll find roughly three hundred horsepower at about 6,500 rpm and a similar torque peak around 3,000 to 5,500 rpm, with the engine’s character leaning toward a strong mid-range that helps the car accelerate decisively from lower speeds and hold pace on longer straights. The torque curve in particular is a critical strength: the engine dishes out substantial usable torque within the mid-range, which translates into quick, satisfying acceleration without requiring the engine to be constantly spinning for propulsion. The compression ratio—pressed into turbocharged operation at about 9.5:1—reflects a careful compromise. It must be low enough to tolerate boost and prevent detonation at high boost pressures, yet high enough to maintain efficiency and broad air‑to‑fuel control under varying load conditions.

In service, the 4B11T’s performance is not merely a function of its own internals but of how those internals talk to the rest of the drivetrain. The Evo X is equipped with an advanced all‑wheel-drive system—S-AWC, or Super All‑Wheel Control—that integrates dynamic differential control and stability features to optimize traction and cornering stiffness. The engine and the transmission work in concert with these systems to deliver traction where it matters most, so the car can accelerate out of corners with confidence rather than spin away power into the pavement. The engine’s delivery, with a robust turbo response and a broad torque band, feeds directly into this dynamic handling environment, allowing the driver to exploit the Evo X’s grip without being overwhelmed by torque steer or abrupt throttle transitions. The bottom end is built for durability as well as speed: forged pistons and connecting rods, a reinforced crankshaft, and carefully engineered bearings all contribute to a motor that can tolerate sustained heat and high rotational stress. In short, the engine isn’t just strong; it is resilient, repeatable, and predictably so, providing a platform for shared control with the car’s electronics rather than fighting it.

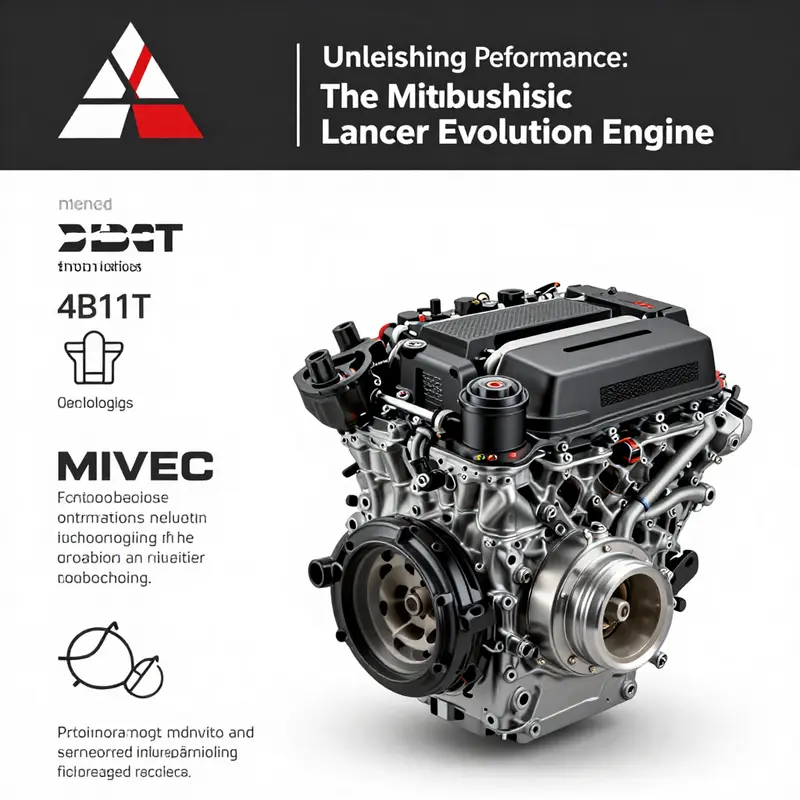

The valvetrain and timing are equally essential to the package. MIVEC, Mitsubishi’s valve timing control system, optimizes the engine’s breathing across the rev range. This technology tailors intake and exhaust timing to deliver stronger mid‑range torque while preserving high-end power. It is a quiet, almost invisible performer, smoothing throttle response and reducing valvefloat risks at high speeds. In practical terms, MIVEC means the engine makes instant responsiveness when you poke the throttle and keeps the engine pleasantly tractable at the end of a long straight or a data-rich, high‑speed corner. The result is an engine that can sustain quick accelerations, hold speed through corners, and return to a calm idle in traffic—all without the need for abrupt throttle corrections or sudden, violent surges.

Maintenance and durability are not afterthoughts with the 4B11T. The engine is designed to tolerate high operational temperatures and the stresses of a turbocharged environment. The cooling system, including a front-mounted intercooler, is positioned to maximize charge-air cooling under race-like conditions, while the oil cooling system helps manage lubrication under sustained high rpm. This is crucial because turbocharged engines rely heavily on lubrication and cooling to preserve bearings, pistons, and the rotating assembly from heat-induced wear. The design philosophy favors components sized for reliability under repeated, high-load cycles—components such as single, precise turbocharged boost pathways, robust gaskets and seals, and a strong timing mechanism that remains in sync across a wide rpm envelope. For a car that is often driven hard on twisty roads, track days, or rally stages, that emphasis on reliability translates into a machine that can run cool under load while still delivering the raw pace that enthusiasts expect.

From a builder’s perspective, the 4B11T is a capable foundation for both performance and durability. Its architecture supports a spectrum of upgrades, but there is a clear emphasis on choosing parts that respect factory tolerances and engineering intent. For enthusiasts seeking to rebuild or maintain the Evo X’s engine, sticking with high-quality, factory-grade components helps preserve the vehicle’s original character and its warranty integrity where applicable. The approach that many take involves ensuring components such as pistons, connecting rods, timing gear, and gaskets meet factory specifications or better, with attention to how these pieces interact at high rpm and boosted conditions. When upgrades are pursued, the goal is not simply more power but more consistent power within the engine’s torque band, enhanced reliability under heat, and predictable performance on the track or road. A practical route for those who want to preserve the engine’s core reliability while exploring performance potential is to consider OEM-level upgrades or verified factory-tested components that align with Mitsubishi’s design intent. In this context, even seemingly small choices—oil grade, intercooler efficiency, and fuel delivery precision—become meaningful levers that influence broad performance, efficiency, and endurance. For builders looking to deepen the engine’s capability while staying faithful to its roots, there is a documented path that includes options like a billet-block variant, which demonstrates how a modern, purpose-built block can reinforce the bottom end without altering the essential character of the original design. This path aligns with a philosophy of measured improvement rather than a wholesale departure from the engine’s intended behavior. In this sense, the 4B11T remains a paragon of how compact architecture can house serious performance and robust longevity when tuned and maintained within engineered limits. For those curious about the more specialized hardware, a dedicated path exists to explore components such as a billet block, which can be found through specific OEM-focused channels that offer high-precision replacements and upgrades. 4B11T billet block.

The engine’s story is inseparable from the Evo X’s broader engineering story. Beyond the hardware, the car’s firmware, transmission calibrations, and AWD control strategies shape how the engine’s power translates into on-road or on-track performance. The 4B11T’s torque availability, coupled with the twin-scroll turbo’s boost delivery, allows the S-AWC system to manage torque distribution and traction in ways that maximize cornering grip and line accuracy. The outcome is a high-performance sedan that behaves with a rally-bred instinct: eager at throttle, confident through corners, and precise in how it reemerges from each turn. The engine’s design supports this behavior by providing a smooth rise in boost with predictable throttle response, an attribute that is invaluable when the vehicle is pushed to the limits of grip and weight transfer. It is an engine that rewards skillful driving and careful tuning, as well as a willingness to do the work required to keep it healthy under sustained performance demand.

As the chapter closes on the engine’s core story, it becomes clear that the 4B11T is not a mere list of specs. It is a crafted proposition: a compact, high-revving, turbocharged heart that matches the Evo X’s chassis ambitions and rally heritage. Its aluminum construction, sophisticated valvetrain, and careful turbo design create a platform that responds with verve and remains credible after hours of punishing driving. The push to maintain reliability through OEM-grade components, alongside thoughtful engineering choices for heat management and fuel control, ensures that the engine can deliver the experience the Evo X promises—an experience defined by rapid acceleration, stable handling, and a working partnership with the car’s advanced stability systems rather than a one‑note sprint to peak horsepower. The result is a complete, coherent package: the engine and drivetrain working in tandem to produce a car that feels equally comfortable on a winding mountain road and a closed-road performance course. For readers who want to explore the deeper physics behind this engineering, a breadth of external technical literature—such as peer‑reviewed powertrain studies—offers a broader framework for understanding turbocharged engines and their control strategies. As a starting point, the automotive engineering community points to trusted resources such as SAE International for rigorous technical discourse. External reference: https://www.sae.org.

Rally-Bred Precision: The Performance DNA of the Lancer Evolution’s Turbocharged Powerplant

The Mitsubishi Lancer Evolution is built on a reputation for balancing extreme performance with reliable, repeatable handling. At the core of this reputation sits a turbocharged, 2.0-liter inline-four that has evolved through generations yet retained a coherent DNA: a compact, high-revving heart that responds with clarity to throttle input and a torque curve that delivers usable power across a broad RPM range. The engine that anchors the Evolution X represents a culmination of that heritage, yet to understand its current performance we must also consider the lineage that shaped it. Across the lineage, engineering decisions have consistently aimed at delivering rally-bred acceleration without compromising daily usability. The 4B11T engine at the center of the Evolution X embodies this philosophy through its displacement, its forced induction, and its attention to weight, heat management, and dynamic control. With a 2.0-liter displacement, a single turbocharger paired with an intercooler, and a modern valvetrain that blends speed with efficiency, the engine remains a precise instrument for a chassis that demands traction, balance, and feedback.

The 4B11T is a compact, all-aluminum design that reduces weight where it matters most: in the block and the head. Aluminum construction is more than a weight-saver; it contributes to heat dissipation and lowers the inertia of the moving parts, helping the engine respond more quickly to throttle inputs and to rev match with the rapid cadence the chassis demands. In stock form, power sits around the high 280s to 290 horsepower class and torque sits near 400 Newton-meters, but those numbers only tell part of the story. The real efficiency comes from how the engine manages air and fuel across the rev range. A single turbocharger with intercooling ensures that intake charge remains dense and consistent under sustained strain, which translates to robust midrange torque and a confident surge as the turbo spools into its sweet spot. In later iterations, direct injection complements this recipe by allowing more precise fuel placement and better combustion control, further sharpening throttle response and improving burn efficiency at load.

A fundamental facet of the Evolution X’s performance is how the engine coordinates with Mitsubishi’s all-wheel-drive architecture. The S-AWC system—Super All-Wheel Control—puts the engine’s power where traction exists and coordinates with active differentials and sophisticated stability control to maintain grip through corners and over uneven surfaces. This isn’t just about managing wheelspin; it’s about delivering a stable, predictable platform for aero-inspired corner entries. The synergy between the 4B11T’s torque delivery and the AWD system’s torque vectoring creates a dynamic where the car feels planted yet responsive, with the engine’s torque peaking in a way that the chassis can translate into linear acceleration rather than wheel slip. That harmony matters: it is the difference between a car that simply accelerates and a car that can pick a line through a corner and drive it with conviction.

The engine’s internals tell a similar story of purposeful robustness. Forged pistons and connecting rods, along with a stiff crankshaft, are the components you’d expect to see in a high-stress, high-response powerplant, but their — and the engine’s — true discipline lies in how those parts survive the repeated, demanding cycles of track and rally road. The block and the head’s aluminum casting further reduce mass, allowing the engine to rev with more immediacy and recover more quickly after peak power moments. MIVEC, Mitsubishi’s own variable timing strategy, is central to this balance. This system dynamically adjusts valve timing to optimize performance across both low-end torque and high-end power, smoothing throttle response and ensuring that combustion remains efficient across the full RPM spectrum. The effect is not a single spike in power, but a broad, usable, and controllable power band that makes the car feel both eager to accelerate and composed in mid-c corner exits.

Engineers did not stop at raw power figures. They aimed for repeatability and predictability, qualities essential to a car built for time attack, road rallies, and all-weather performance. The 4B11T’s control architecture, coupled with direct injection in later models, means fuel delivery can be fine-tuned in real time to match air density, boost, and engine temperature. This precision is particularly important in high-load scenarios, where a sustained rush of boost and precise fueling can otherwise push air-fuel ratios into lean or rich regimes that dull response or raise exhaust temperatures. In practice, that means the engine remains responsive through the entire rev band, with torque available when the driver wants it and a quick, linear delivery that helps the chassis stay in balance during aggressive maneuvers.

A decisive factor in the Evolution’s performance story is the engine’s compatibility with OEM parts designed specifically for it. Keeping genuine Original Equipment Manufacturer components within reach guarantees fit, tolerance, and reliability crafted to factory specifications. Pistons, rods, and the crankshaft are precision-forged to withstand the kind of peak cylinder pressures produced by turbocharged operation. Timing components are engineered to preserve synchronization under rapid accelerations, reducing the risk of valve floating or mis-timing that could threaten performance. Gaskets and seals are selected for high-temperature, high-pressure environments, resisting leaks that could degrade performance or reliability. In this sense, the OEM supply chain is not merely about replacements; it is about preserving the engine’s intended character as built. The careful balance between performance parts and reliability becomes even more visible when track use or repeated cold starts are considered, and it becomes a meaningful part of the ownership experience for enthusiasts who value predictable power delivery.

Beyond the specifics of the 4B11T, the Evolution’s performance story is also about how a driver interacts with the drivetrain. The Lancer’s chassis geometry, aerodynamics, and suspension tuning provide a receptive canvas for the engine’s output. The throttle mapping and boost control are set up to deliver immediate response, but not at the expense of stability. That combination—a turbocharged linearity in a modern chassis, with a drivetrain that can distribute torque where it matters most—defines the car’s edge. There is a clear thread that runs from the simplest gas pedal press to the most confident corner exit: a well-tuned powertrain that remains faithful to its rally roots while embracing the refinements of a modern performance car.

The lineage of the Evolution engine family helps illuminate this approach. The earlier generations relied on robust turbocharged designs with a focus on torque delivery and mechanical reliability. The Evolution VIII, for instance, featured a 2.0-liter turbocharged inline-four with a cast-iron block and an aluminum head paired with Mitsubishi’s MIVEC system. That combination—MIVEC’s variable timing, along with electronic controls for torque distribution and yaw moments—redefined throttle response and high-rpm power while maintaining the endurance required for prolonged track sessions. The MR variant gave drivers a 6-speed manual option, sharpening shift timing and reinforcing the practical link between engine behavior and the car’s overall dynamics. Electronic control systems such as the ACD and AYC further refined the driving experience, distributing torque between front and rear axles and managing yaw at speed. The result was a car that could be fed corner entries with confidence while keeping a predictable exit. In that sense, the Evolution family’s engine development is a study in progressive refinement: from robust, torque-rich setups to sophisticated, electronically managed powertrains that still speak the driver’s language with immediacy.

This narrative of growth finds its modern pinnacle in the 4B11T-equipped Evolution X. The shift to aluminum construction, combined with a modern turbocharging strategy and a refined valvetrain, translates the old rally discipline into a contemporary performance package. The direct injection approach in later models serves as a lever for efficiency without surrendering the immediate, throatier response that defines a turbocharged four’s character. The engine’s role is not to shout but to deliver measured, controllable power across the entire rev range, enabling the AWD system to place torque with precision through corners, over surfaces that would challenge a less cohesive setup. The result is a car that feels intuitive: you press the accelerator and the car delivers, but it does so with a stubborn clarity that invites the driver to explore the balance between grip and throttle.

For enthusiasts who seek the utmost connection to the engine, genuine components offer a pathway to preserve the character that makes the Evolution famous. Investing in OEM parts ensures that the engine remains within factory tolerances and maintains the warranty and reliability that are part of the vehicle’s long-term appeal. While aftermarket options exist, their gains may come at the cost of longevity or precise compatibility with the stock control strategy. In the context of a high-performance sedan that doubles as a track-ready machine, the choice between OEM and aftermarket becomes a negotiation between maximal peak power and consistent, repeatable performance over many miles and many sessions.

To anchor these ideas in concrete references, consider the engine block’s strength and the relationship between the block’s weight, the head’s architecture, and the turbocharged intake path. A link to a focused component discussion can illuminate how the 4B11T’s bolt-circle, bore, and stroke interact with forged internals and the aluminum chassis to form a cohesive performance system. For readers who want a direct reference to a component that embodies these engineering decisions, the dedicated page on the block highlights the weight considerations and the precision machining that keeps the engine sound under load. See more about the 4b11t-billet-block to understand how a strengthened bottom end can support increased boost and longer sessions on the track.

In sum, the Evolution engine lineage embodies a philosophy of performance that is both ambitious and disciplined. From the strategic use of MIVEC timing and torque management to the careful selection of materials and the integration with an advanced AWD system, the engine defines the driving character: immediate, predictable, and capable of sustaining extended performance with a calm reserve. The 4B11T in the Evolution X is not simply a power source; it is a meticulously tuned instrument whose design choices ripple through the entire vehicle, shaping how the car accelerates, how it pivots through corners, and how it communicates with the driver during every moment on the road or the road course. For enthusiasts, understanding this engine means appreciating the small choices—weight, heat, timing, and control—that culminate in a machine capable of rally-bred performance with modern-day reliability.

External resource for broader context and historical development: https://en.wikipedia.org/wiki/Mitsubishi_Evolution

Genuine Power, Proven Precision: Preserving the 4B11T Heart of the Mitsubishi Lancer Evolution Engine

The Mitsubishi Lancer Evolution has long stood as a benchmark for compact, turbocharged performance. In the Evolution X, the engine at the core is the 4B11T, a 2.0-liter inline-four that balances rally-bred torque with street credibility. This powerplant, with its single turbocharger, intercooler, and direct-injection capabilities in later iterations, is not just about peak numbers. It is about a bundled set of engineering choices that yield responsive throttle, linear power delivery, and reliability under demanding conditions. When you listen to the Evo X idle and hear the turbo spool, you are witnessing a carefully tuned symphony of components designed to maintain control and confidence, whether on a winding mountain road or a competitive track. The engine’s aluminum block and head reduce weight while improving heat management, a combination that makes the 4B11T both nimble and durable. The decision to pair this engine with Mitsubishi’s sophisticated all-wheel-drive system, notably the Super All-Wheel Control (S-AWC), further frames the Evo X as a vehicle that thrives on precision engineering at every corner and straight, rather than a mere collection of powerful parts stacked together. In this context, the topic of genuine parts becomes more than a matter of maintenance; it is a discussion about preserving the integrity of that integrated performance package over time.

At the level of core mechanics, the 4B11T is built to withstand stresses typical of high-performance driving. The engine’s displacement sits at 2.0 liters, with a 16-valve DOHC configuration, delivering power in a way that feels both immediate and dependable. The MIVEC system—a Mitsubishi Innovative Valve timing Electronic Control—manages cam timing to optimize airflow across the RPM band. This yields robust low-end torque for quick response and sustained high-end power for sustained high-speed runs. Understanding these features helps explain why genuine components matter so much. Precision timing, perfectly matched clearances, and controlled valve lift are not abstract concepts; they translate into practical driveability that enthusiasts feel on every drive. With this engine, the goal is not only to make power but to ensure that power can be accessed predictably and safely, whether the throttle is mashed in a rain-slick corner or held steady through a mid-range pull on a dry straight.

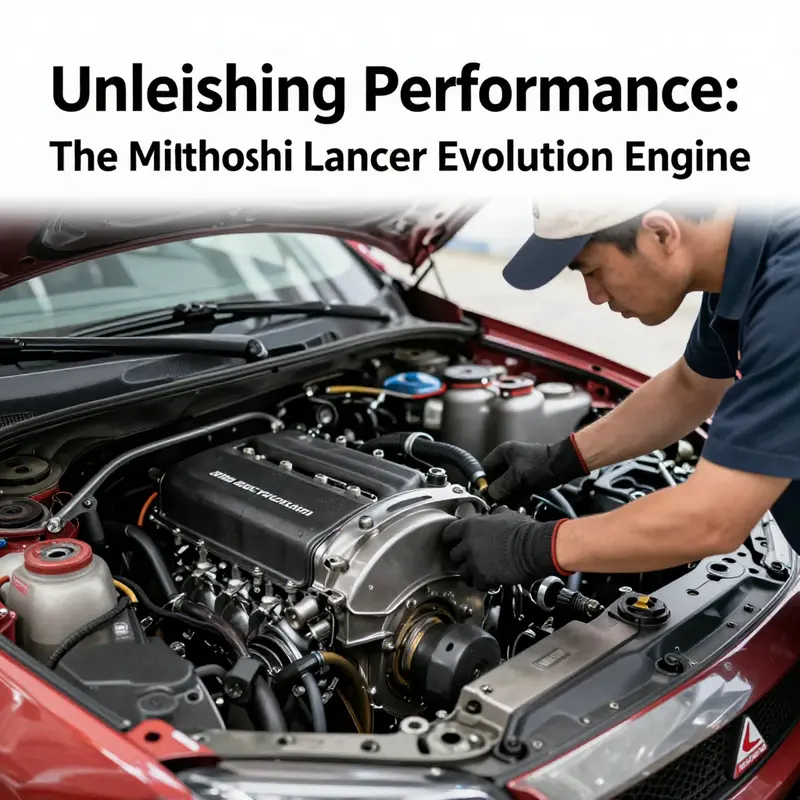

The role of OEM parts in sustaining that performance cannot be overstated. Genuine Original Equipment Manufacturer components are designed to meet exact factory specifications and tolerances. In a high-stress setup like the 4B11T, even minor deviations in dimensions or materials can cascade into reduced efficiency, heat buildup, or edge-case failures. Pistons and connecting rods, for instance, are precision-forged to withstand cylinder pressures that spike during peak boost. The timing components are engineered for precise synchronization, a critical factor for maintaining valve timing under rapid RPM changes. Gaskets and seals are formulated to endure both high temperatures and constant pressure differentials, preventing leaks that would otherwise erode performance or risk engine damage. The emphasis on exact fitment matters as much as raw material quality. OEM parts ensure that every bolt, every gasket groove, and every contact surface aligns with the engine’s original architecture. In other words, the 4B11T’s performance envelope rests on the assumption that every replacement part behaves as the factory intended.

From a practical standpoint, authentic parts offer more than peak performance. They contribute to safety, a crucial consideration in a car designed to exploit all-wheel torque and aggressive handling. The turbo system, intercooler, and related components operate under high boost pressures and temperatures. Genuine parts are tested to perform in those exact conditions, maintaining reliability where it counts most. When a turbocharger or intercooler is replaced with an off-spec unit, the risk is not merely reduced horsepower; it is the potential for boost fluctuations, heat soak, and delayed spool. Such dynamics can alter throttle response and even destabilize the chassis balance that the S-AWC system depends on. In a car like the Evo X, where traction management and differential control rely on precise timing and predictable drive forces, the risks of non-OEM parts extend beyond mechanical failure to a loss of confidence behind the wheel.

The conversation around OEM versus aftermarket parts in this context is not about denying performance gains; it is about recognizing how performance is earned and protected. Aftermarket solutions can offer beneficial gains in certain areas, yet they often come with altered tolerances and cooling needs that were not validated for the 4B11T’s exact pairing with S-AWC. The factory set of components is the result of an exhaustive calibration process that considers the engine, turbocharger, cooling system, electronic control strategies, and the drive system as a single, interacting entity. When any part is swapped for something outside that calibrated ecosystem, the ripple effects can travel through fuel maps, boost control, and torque distribution. This is especially true for a vehicle that was engineered to balance power with stability, a balance that the OEM suite preserves through matched performance envelopes.

A practical glance at genuine parts underscores their targeted role in longevity and reliability. For instance, a genuine engine assembly—such as those used in certain Evolution models—embodies a complete approach to reliability: compatible pistons and rings that seal under high cylinder pressures; timing kits engineered for precise camshaft choreography; gaskets and seals designed for sustained high-temperature operation; and engine mounts configured to dampen vibration while preserving the precise alignment needed for the turbo and the intake system. These components do not operate in isolation; they are part of an integrated engine bay where plumbing, control modules, and the turbo feed back into fuel delivery and ignition timing. In this integrated system, authentic parts help preserve factory-calibrated behavior and the predictable response that drivers expect from a rally-bred sedan.

The importance of verification cannot be overstated. Counterfeit or subpar parts can masquerade with a similar appearance, but they seldom deliver the same reliability or the same fit. Authenticity checks—looking for the Mitsubishi OEM logo, sourcing from authorized dealers, and verifying supplier legitimacy—protect both the mechanical integrity and the investment in the vehicle. In cars built around a performance ethos, the cost of a rushed or uncertain replacement is not just monetary; it is the potential erosion of the vehicle’s core character. Enthusiasts who pursue rebuilds or routine maintenance often encounter a straightforward truth: the engine’s long-term behavior tracks closely with the quality of its inputs. When the inputs are tuned to factory standards, the outputs tend to remain within expected boundaries, even after hundreds of thousands of miles of spirited driving.

To illustrate the practical value of OEM integrity, consider the idea of a complete, genuine component set during a rebuild. An Evo X owner contemplating a rebuild will find enormous value in opting for authentic parts that conform to the 4B11T’s original architecture. This approach supports not only performance fidelity but also warranty considerations and resale expectations. Replacements that preserve the project’s intent—engineered to meet the same standards as when the car left the factory—help maintain the vehicle’s value and its track-ready capability. The choice to use genuine parts is, in a broader sense, a commitment to the vehicle’s lifecycle: from initial purchase through potential motor rebuilds and beyond, a decision that corresponds with the meticulous nature of the Evo’s design language.

The connection between engine components and drivetrain behavior is not abstract. The 4B11T’s torque delivery, the turbo’s response, and the intercooler’s efficiency all rely on a chain of well-matched parts. The S-AWC system integrates actively controlled differentials and stability measures to manage this torque with finesse. When OEM components are installed, the calibration that binds engine performance to wheel control remains consistent with factory intent. In other words, using genuine parts helps the Evo X maintain its intended balance between agility and control, a balance that has defined the car’s reputation among enthusiasts and professional drivers alike. The upgrade path can be tempting, yet the most reliable route to sustained performance often runs through the OEM map—engineered to be precise, reliable, and coherent with the car’s broader performance architecture.

For those who seek to explore further, one concrete example of genuine, high-integrity engine components is the 4B11T billet block, a specialized part designed to endure the elevated stresses of performance driving. This component is described in detail on its dedicated OEM-focused page, reflecting the care that goes into maintaining the engine’s structural integrity under boost and high RPM. 4b11t-billet-block is a concise entry point to an ecosystem that emphasizes exact specifications, compatibility, and long-term resilience. The broader message remains clear: when the goal is to sustain peak engine performance across a lifetime of spirited driving, genuine parts are not a luxury but a foundational requirement that supports every mile of driving joy.

Authenticity extends beyond the engine bay and into the broader ownership experience. Maintaining a vehicle like the Evo X means safeguarding its value and preserving the character that attracted owners in the first place. OEM parts help ensure that the car continues to feel like a cohesive performance machine, not a patchwork of mismatched components. In the context of the 4B11T, that means a system where pistons, bearings, timing gears, fuel injectors, and the turbocharger all meet the same precise standards that defined the car at launch. The net effect is a car that remains eager to rev, delivers thrust with predictability, and retains the kind of chassis balance that makes it enjoyable to drive both on a road course and on a windy back road.

In closing, the subject of genuine parts for the Mitsubishi Lancer Evolution engine is not a narrow technical footnote. It is a central pillar in preserving the car’s performance identity. The 4B11T’s blend of turbocharged power, lightweight construction, and advanced valve timing hinges on components that fit and function exactly as intended. OEM parts deliver that fidelity, while helping protect safety, reliability, and vehicle value over time. Enthusiasts who prioritize long-term performance will find that the most meaningful upgrades and rebuilds begin with authenticity—an investment that keeps the Evo X aligned with its rally-bred heritage and its reputation as a benchmark in the modern high-performance sedan category. When you consider the engine as part of a holistic performance system, the benefits of genuine parts become self-evident: consistent power delivery, dependable operation under load, and a driving experience that remains true to the car’s original, uncompromising intent. For those who want to extend the life and glory of their Evo X, the route is clear: respect the factory specifications, verify authenticity, and lean into OEM components as the reliable foundation for all future performance endeavors. The engine, after all, is more than a sum of parts—it is the heart that makes the Evolution what it is, and genuine parts are the lifeblood that keeps that heart beating steady and strong for miles to come.

External resource for broader context: https://www.ebay.com/itm/144365799228

Rally-Bred Tech and Torque: Innovations in the Mitsubishi Lancer Evolution Engine

The Mitsubishi Lancer Evolution line has always treated its engine as more than a source of power; it is the core of a philosophy that blends rally-born aggression with refined engineering. Across generations, the engine room has served as a proving ground where small increases in displacement, breathing, and timing translate into measurable gains on the stage, on the road, and under the hood during a high-pressure pursuit of grip. This chapter traces the arc of those innovations, tying the history of the Evolution engine to the broader topic of its performance, reliability, and the intimate relationship between drivetrain and chassis work in one of the most storied platforms in modern performance driving. It is a narrative that moves from the early, forceful efficiency of the four-cylinder turbo era to the more advanced, tightly controlled heart of the modern Evo X, where engine design, materials science, and electronic control converge to shape a car that could, in many conditions, outdrive its rivals simply by keeping the power in the wheel tracks with precision and confidence.

The Evolution III marks a crucial inflection point in how Mitsubishi tailored its 2.0-liter turbocharged four for WRC-grade competition. This was a period when the goal was not merely to push more horsepower, but to craft an engine that could breathe cleanly at high altitude, respond crisply to throttled inputs, and sustain torque delivery across the demanding, varied surfaces of rally stages. The engine received an updated main configuration: a 2.0-liter turbocharged four, but with a higher compression ratio of 9.0:1, achieved through modified pistons that allowed a more aggressive compression in a package still cooled and managed for high-rpm operation. The turbocharger itself was larger, a TD05H-16G6-7 unit, which opened the door to stronger mid- and upper-range torque while reducing turbo lag and enabling more usable throttle response as the driver approached corners at speed. The result was a notable power step, with around 270 horsepower (273 PS) and about 31.5 kg·m (309 Nm) of torque. These gains were not just about peak figures; they refined the engine’s thrust curve to deliver faster throttle response and more linear power delivery, traits that translate directly into easier handling on loose surfaces where line and torque control dictate success.

A critical aspect of the Evolution III’s prowess lay in its drivetrain architecture. The S-AWC system—Super All-Wheel Control—continued to evolve from earlier models, representing a synthesis of active differentials, braking torque management, and stability control that created a more cohesive link between the engine’s delivery and the chassis’ ability to use it. The engine’s output was not merely sprayed into the front wheels; rather, torque could be dynamically distributed across axles and even across left and right wheels. This meant that the same power could be directed where the grip was the strongest, allowing the driver to chase speed through corners with a confidence that made the car feel more composed than the raw horsepower might suggest. The integration of the S-AWC system with engine management created a synergy that made the Evolution III a benchmark for handling precision, particularly on uneven rally surfaces where traction is a moving target and the car must adapt in real time to changing grip and geometry.

Even as the engine architecture pushed for more suspectless power, significant attention was paid to thermal efficiency and cooling. Rallying demands high-load operation for sustained periods, and the Evolution III introduced aerodynamic and cooling refinements that helped keep the engine and brakes within safe temperature windows. Front-end redesigns aimed at channeling air to the brakes, improving brake cooling under competitive conditions, while a broad aerodynamic package provided the necessary downforce to keep the car planted at speed. The rear wing, side skirts, and other aero enhancements were not cosmetic; they were integral to keeping the chassis stable as engine torque and wheel slip tested grip limits. A more efficient cooling strategy, paired with careful weight distribution and a robust cooling circuit, meant that the engine could sustain aggressive rev ranges without the overheating seen in lesser platforms. This blend of aerodynamics, cooling, and structural integrity created a platform in which the engine could perform predictably under rally-style duress, an essential characteristic if a race-tuned four-cylinder turbo is to endure a long-haul stage and still deliver reliable performance when the pressure is on.

Move forward a generation, and the evolution of the engine reaches a new phase with the Evo X and its 4B11T powerplant. This is a modern, high-stress engine designed to leverage weight savings, advanced materials, and a contemporary fuel strategy to extract performance without sacrificing endurance. The 4B11T is a 2.0-liter inline-four using a single turbocharger with an intercooler, producing horsepower in the neighborhood of 291 in stock form and torque near 295 lb-ft (400 Nm). The engine sits in an aluminum block and head, a choice that reduces overall weight and improves heat dissipation, a crucial factor in keeping high-rpm combustion consistent across long, hard sessions. The valvetrain employs Dual Overhead Camshaft architecture with 16 valves and benefits from Mitsubishi’s MIVEC technology, a variable valve timing system engineered to optimize performance across the RPM spectrum. The 4B11T’s breathing is enhanced further by the direct injection system that arrives in later Evo X models, enabling more precise fuel delivery and improved combustion efficiency at higher pressures. The combination of direct injection and robust turbocharging helps the engine maintain a strong torque curve while delivering a high peak output, all while maintaining a level of reliability consistent with Mitsubishi’s rally-bred ethos.

The 4B11T’s architecture is not merely about raw numbers; it is about the interplay between the engine, the chassis, and the all-wheel-drive system that defines the Evo X’s behavior. The aluminum block and head do more than save weight; they improve heat management and rigidity, both essential when the engine is operating near its limits on a track or on a rally stage. The timing and valve control provided by MIVEC allow the engine to make the most of the turbocharged air, especially as boost pressure climbs and exhaust scavenging needs to be efficient across a broad rev range. The result is a powerplant that feels very different from its predecessor in character: it is less peaky, more linear, and capable of delivering strong midrange torque that suits the car’s AWD dynamics. Even at the stock level, the Evo X engine is a mature composition of modern engineering practices, designed to deliver robust performance in a variety of driving conditions—from street driving to track work and the occasional demanding rally-cross event—without compromising on reliability and durability.

A thread woven through these engine developments is the repeated emphasis on keeping internal tolerances tight and components harmonized. When you consider the 4B11T’s path from conception to production, the emphasis on precise fitments becomes evident. Pistons, connecting rods, and the crankshaft must withstand significant pressures and temperature fluctuations while maintaining accurate timing and com pressure regulation. The OEM components, hardened to withstand the harsh environments of high-speed, high-boost operation, contribute to the overall reliability that enthusiasts expect from Evo models. The emphasis on factory-spec parts—those that are engineered to exact tolerances—makes a strong case for choosing genuine components when maintaining, rebuilding, or upgrading the engine. The aftermarket route offers performance potential, but reliability and warranty considerations often favor the OEM approach, especially when the goal is sustained performance in demanding conditions like track days or rally-inspired events. This philosophy of balancing performance gains with long-term durability remains a throughline from the Evolution III’s early innovations to the modern Evo X’s powertrain strategy.

For readers who crave a more granular look at engine internals and how they meet the stress of rally-grade driving, a dedicated exploration of the 4B11T’s structural elements can offer a deeper understanding of the underlying design logic. See the 4b11t-billet-block resource for a focused discussion of how engineers have optimized the engine’s core for high-strength operation and reduced weight, a topic that continues to resonate with enthusiasts who obsess over every gram of performance potential. This internal reference underscores how a modern, turbocharged engine can stay resilient under sustained high-load conditions while maintaining the kind of throttle response that makes a car feel alive at the limit.

Ultimately, the Evolution engine story is a story of careful compromises executed with a clear performance objective: to translate rally-derived engineering into a car that is both fast and controllable on public roads and demanding circuits. The evolution from the Evolution III’s tuned turbo and upgraded compression to the Evo X’s 4B11T, with its aluminum architecture, MIVEC, and direct injection, demonstrates how Mitsubishi’s engineers have balanced power, response, and reliability within a framework that also respects the car’s all-wheel-drive system. This cohesive integration across engine, electronics, torque management, and chassis dynamics is what gives the Lancer Evolution its distinctive character. It is a vehicle telling a story not just of horsepower, but of how a modern engine can work with a sophisticated drivetrain to deliver a compelling, scalable performance experience that can be as rewarding in everyday driving as it is on the test bench of a race track.

For those who want to dig deeper into the broader historical arc of this platform, a comprehensive external reference offers a broader look at the Evolution lineage and its engine technologies. You can explore the evolution of Mitsubishi’s Lancer Evolution through a reputable automotive publication that tracks how these engines have shaped the sport and the road alike: https://www.motortrend.com/cars/mitsubishi/lancer-evolution/

null

null

Final thoughts

Understanding the intricacies of the Mitsubishi Lancer Evolution engine allows business owners to appreciate the value of engineering excellence in automotive performance. From its high-powered specifications and innovative features to the critical need for genuine parts and regular maintenance, every aspect contributes to the longevity and reliability of this iconic sports sedan. Whether you’re involved in the automotive sector or simply an enthusiast, knowledge of the Evo X’s 4B11T engine emphasizes the importance of quality, performance, and proactive care in maintaining such a high-caliber vehicle.