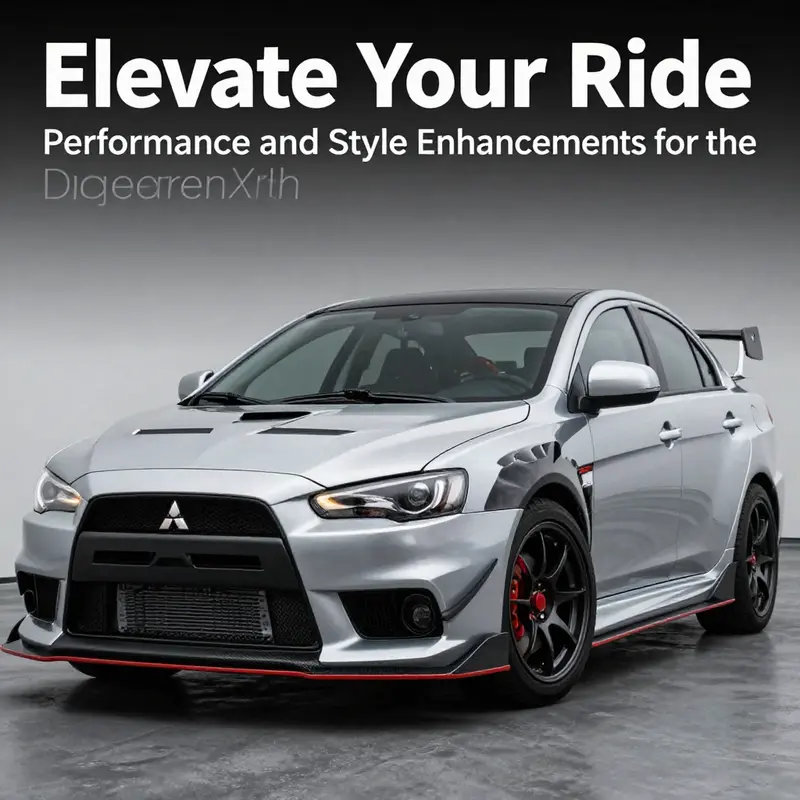

The Mitsubishi Lancer Evolution Evo X has forged its reputation as a performance icon among car enthusiasts and racers alike. For business owners in the custom car parts industry, understanding the nuances of body enhancements for this model can unlock new opportunities. This article delves into crucial components such as front and side body fenders for aesthetic upgrades and performance benefits, the role of carbon vents in enhancing engine performance, the critical nature of rear wings for stability, and key market trends influencing consumer choices in modifications. By exploring these aspects, businesses can better cater to the evolving needs of the aftermarket community.

Contours of Control: How Evo X Front and Side Fenders Redefine Grip, Heat Management, and Visual Dominance

The Mitsubishi Lancer Evolution X is a study in the marriage of form and function. Its chassis, suspension, and drivetrain were tuned to deliver a racer’s instinct with a streetable edge. Among the myriad upgrades enthusiasts pursue, the front and side body fenders stand out not as mere cosmetic flourishes but as deliberate, performance-oriented components. They redefine the vehicle’s silhouette while expanding the envelope of what the Evo X can do on a track or a winding road. In the context of a wider aero and weight-conscious build, these fenders become a fulcrum upon which handling, heat management, and visual impact pivot in unison. The Evo X’s front fenders, often paired with vent channels and integrated side vents, channel air with surgical precision. They work with the hood, bumper, and other aero pieces to orchestrate flow around the wheel arcs. The result is a front end that breathes more efficiently at speed, reducing pressure buildup near the radiator and the intercooler, while the splayed wheel openings accept wider tires that grip more aggressively. This is not a simple swap; it is a carefully chosen pivot point that can shift the balance between agility and rigidity as the speedometer climbs and the road narrows ahead. The history of this upgrade lies in the recognition that the Evo X’s performance budget benefits from a lighter, stiffer front-end structure. Real carbon fiber fenders, in particular, offer a meaningful reduction in unsprung mass compared with traditional materials. Lighter fenders reduce the inertia the suspension must work against during cornering, braking, and rapid steering transitions. Less mass at the wheel arches translates to crisper steering input, quicker turn-in, and a more direct connection to the road. Those who push the car to its limits on track or spirited canyon runs often discover that the early phase of a corner—where grip and steering feel are most sensitive—benefits from even minor reductions in weight and rotational inertia. The visual drama of carbon fiber fenders cannot be overstated, either. The weave pattern, the sharp edges around the wheel wells, and the precise lines that meet the body panels convey a sense of engineering discipline. It is the look of purpose, of a car that is built to be driven hard and to endure. The Evo X’s front fenders are commonly designed to accommodate wider wheels and tires, a fundamental enabler of enhanced grip and braking performance. When paired with a corresponding suspension system capable of handling added track width and altered geometry, broader fenders become part of a coherent strategy that maximizes cornering speed without sacrificing stability. The larger contact patch demands careful attention to braking systems; the added grip must be matched by more robust calipers, rotors, and lines that can sustain repeated high-load braking without fade. In this context, the fenders contribute to the overall aero package by preserving clean airflow around the tires, minimizing turbulence that could otherwise lift the nose or create unpredictable handling under high-G conditions. The goal is to maintain high-speed stability through the middle of a corner, where airflow separation around the wheels often tends to destabilize the front end. Carbon fiber fenders help keep the air attached to the body, smoothing pressure gradients and allowing the suspension to respond with greater fidelity.

Beyond performance, the fenders play a crucial role in engine bay cooling. The Evo X’s powerplant requires steady cooling and air management, particularly when additional heat loads come from widened intake ducts, larger intercoolers, or even forced induction. Side vents and strategically shaped openings on the fenders act as ducting conduits, guiding cooler air to critical components and diverting warmer air away from the engine bay. This air management supports both reliability and sustained performance during long sessions on the track. While the visual impact of carbon fiber is substantial, the material choice is not merely cosmetic. Carbon fiber’s high stiffness-to-weight ratio helps preserve panel integrity under dynamic loads and reduces the risk of flex under cornering, which can otherwise manifest as steering wheel play or subtle misalignment of fender edges against the wheel arch. The rigidity helps maintain accurate alignment with the rest of the aero kit, a factor that matters when air is expected to behave as a living thing at high speeds. The relationship between front fenders and side vents is not accidental. The Evo X’s fender area is a optical and aerodynamic conduit. The side vents, integrated into or placed near the fender, assist in evacuating heat from the front of the engine bay and can contribute to compressing the high-pressure zone that forms at the fender’s leading edge. When engineered together, the front fenders and side vents cooperate to reduce under-hood temperatures while mitigating lift generated by the nose under high-speed braking and cornering. The benefit is twofold: lower engine bay temperatures coupled with improved high-speed stability. In the most ambitious builds, the fenders are part of a broader widebody or semi-widebody approach, where the wheel arches are expanded to accommodate staggered, larger wheel and tire configurations. A wider stance demands careful alignment and a reconsideration of suspension geometry to prevent rubbing and to preserve suspension travel. The install process becomes an act of integration rather than a quick swap. Precision fitment matters, as misaligned fenders can create gaps that trap dirty air or allow water intrusion during rain rides. The best outcomes come from fenders that are tailored to the Evo X’s exact panel gaps and mounting points, with factory-like fit and finish that preserve the vehicle’s structural integrity and paint protection. When done correctly, the combined effect is a front-end that looks more aggressive and sits with a commanding presence, yet remains compliant with the vehicle’s geometry and handling characteristics. The aesthetic translation is not superficial. A carbon fiber front fender, whether finished in exposed weave or coated to a uniform color, communicates a message of disciplined performance. It signals that the owner is not simply chasing a look but pursuing a coherent, track-informed philosophy. The same logic applies to the carbon fiber side vents. They offer a visual cue of vented purpose while performing a practical function of the air that travels along the car’s flanks. The Evo X’s silhouette—the sharp line along the fender, the arch that widens toward the tire, the way the wing and trunk line up with the rear end—becomes more pronounced when these elements are integrated with a wider aero kit. The eye perceives a car that’s not merely lowered or dressed with glossy surfaces; it sees a machine whose lines have been tuned to improve aerodynamics and mechanical balance. In practical terms, the use of carbon fiber front fenders often aligns with a broader strategy of weight reduction without surrendering strength. The goal is to preserve rigidity and crashworthiness while trimming unsprung mass. Lighter fenders can contribute to quicker steering responses, sharper turn-in, and more precise feedback through the steering wheel. The suspension then becomes more predictable, with the tires’ grip translating to real-time feedback rather than being masked by mass and inertia. Installation is a critical step in achieving these outcomes. A professional, detail-oriented approach ensures wheel clearance remains ample, preventing rubbing at full suspension travel, especially when the suspension is lowered or when the offset of the wheels is adjusted. The process also includes rechecking the alignment to maintain correct toe and camber settings, which are essential when wheel arches are widened. Improper alignment can negate the gains achieved by stiffer fenders and can even introduce handling quirks that confuse the driver. It is also essential to consider street legality and daily usability. In some regions, modifications that pertest the fender line may require additional compliance or adjustments to avoid issues with fender coverage or headlight alignment. Road noise can be a byproduct of aggressive aero components if gaps exist between the fender, the door, and the body panels. Proper seals and careful finishing help maintain cabin quietness and prevent wind intrusion, particularly at highway speeds. The lifestyle implications of these changes cannot be overlooked. The Evo X remains an iconic platform because it invites owners to blend performance with personal expression. Carbon fiber front fenders and side vents contribute to that expression, offering a tactile sense of ownership over a vehicle that many enthusiasts consider a rolling tribute to the golden era of rally-inspired performance. Aesthetics and performance are not contradictory. When the fenders harmonize with the rest of the car’s modifications—wider wheels, high-performance brakes, a lightweight carbon trunk, and a purposeful carbon aero kit—the result is a coherent message. It says the car is built for the track and the street alike, a statement reinforced by the careful care given to alignment, fitment, and material selection. For readers who want a tangible sense of how to pair the Evo X’s front and side fenders with other elements of a performance build, there are options that emphasize compatibility and alignment with the car’s original geometry. A carefully chosen wide front fender set can be integrated with a matching set of vented side panels to create a visually extended stance that remains true to the Lancer’s lines. To explore a specific example of a wider, front-fender design that aligns with the Evo X’s dimensions, click the following internal link: wide front fenders for Evo X (Group A spec). This approach keeps the adaptation faithful to the Evo X’s geometry while offering the aggressive visual language and the necessary space for larger tires and brake assemblies. The overarching aim is to craft a front-end that communicates purpose at a glance: the car is wider, stiffer, cooler under load, and unmistakably tuned for performance. The fenders do more than cover the wheels; they help define the vehicle’s character. In a way, they embody the ethos of the Evo X—lightweight engineering married to aggressive aesthetics, where every panel is a part of the aerodynamic conversation and every line speaks of controlled, track-ready precision. As with any substantial modification, the careful selection of materials, the attention to fitment, and the integration with an equally capable cooling and suspension strategy will determine whether the change feels elective or indispensable. The Evo X chassis is sturdy, but it benefits from deliberate upgrades that respect its engineering heritage while expanding its potential. The front and side fenders, when chosen and installed with care, ensure that the car not only looks the part but also performs with greater confidence in high-speed contexts and aggressive cornering. External resource: https://www.alibaba.com/product-detail/Mitsubishi-Evo-Fenders-Enhance-Your-Vehicle-s-Style_1600724316382.html

Breathing Carbon: EVO X Front Vents, Fenders, and Wings as a Study in Cooling, Downforce, and Street Presence

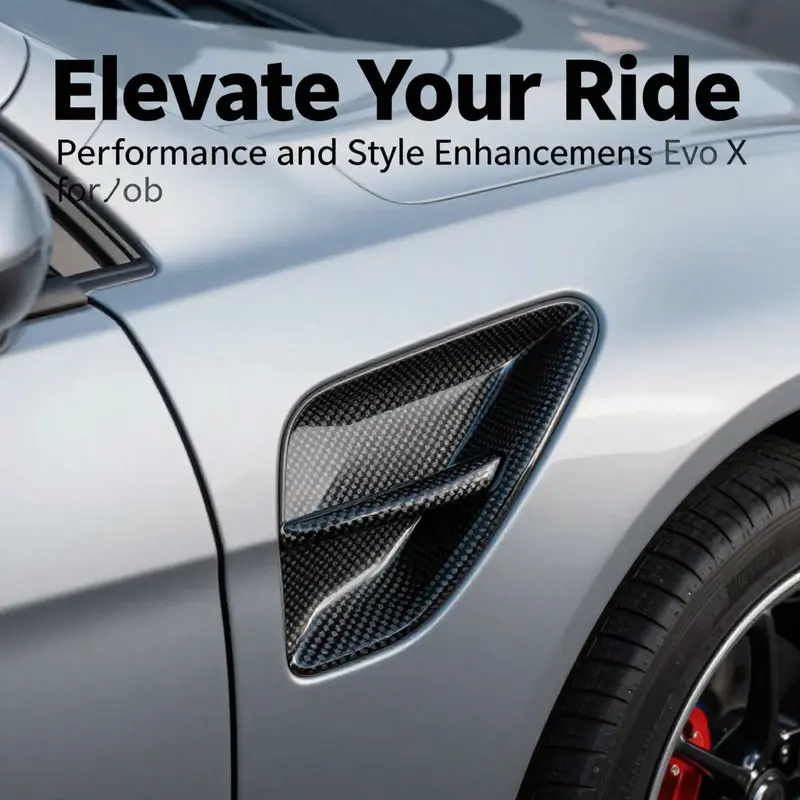

The Mitsubishi Lancer Evolution X sits at a crossroads where engineering ambition meets the aesthetic hunger of street enthusiasts. It is a car conceived for the track and then tuned for the road, where every contour and vent earns its keep not merely for style but for the precise management of heat, pressure, and flow. When you focus on the carbon vent applications, front fenders, and rear wing options in this chassis, you encounter a philosophy of performance that treats the body as a single aerodynamic instrument rather than a collection of add-ons. The EVO X’s forward stance already signals intent: the shark-nose intake, the cantilevered air channels, and the sculpted wheel arches work together to split and guide air with a purpose. Add genuine carbon fiber vents and fenders, and that purpose becomes more explicit. The material choice—carbon fiber—offers a practical payoff beyond the looks. It reduces mass, which at high speeds translates to less inertia and improved steering feel. It also raises stiffness, which translates into more responsive handling. Yet the benefits are not purely structural. In the hands of a careful tuner, carbon components become selective air management tools. They are designed to move air where it helps cooling and downforce most, while letting the rest pass with minimal resistance. In this sense, carbon venting on the EVO X is not a garnish. It is a strategic math problem solved with a light, rigid material that behaves well in the high-load, high-speed environment of a tuned sedan built for both road and circuit dynamics.

To appreciate how these elements function, it helps to imagine the car in motion across a披宽 summer highway or a damp, late-afternoon track session. The front fenders, when upgraded with venting, do more than frame the wheel opening. They are part of a carefully choreographed airflow system. Vent openings placed in the fenders serve a dual purpose. First, they relieve pressure that otherwise builds up around the wheel wells as the car accelerates. That pressure can push the front tires outward and toward the air, creating lift and reducing the precision of steering input at the limit. Secondly, the vents act as aspirators for the air that travels along the underside of the hood and into the engine bay. By capturing and directing this air, the front fender vents assist in stripping away heat from the brakes and the radiator area. The effect is twofold: cooler components under the hood and more stable dynamics at the front end. This is not about vanity cooling; it is about maintaining a consistent operating envelope for a car that is regularly ridden to the edge of its performance envelope. When you combine these fenders with the larger, more open hood vents that act as primary intake points, you create a path for cool air to reach the intercooler and engine bay with less resistance. The result is a more efficient cooling loop, lower engine temperatures, and a more predictable torque delivery during repeated hard runs.

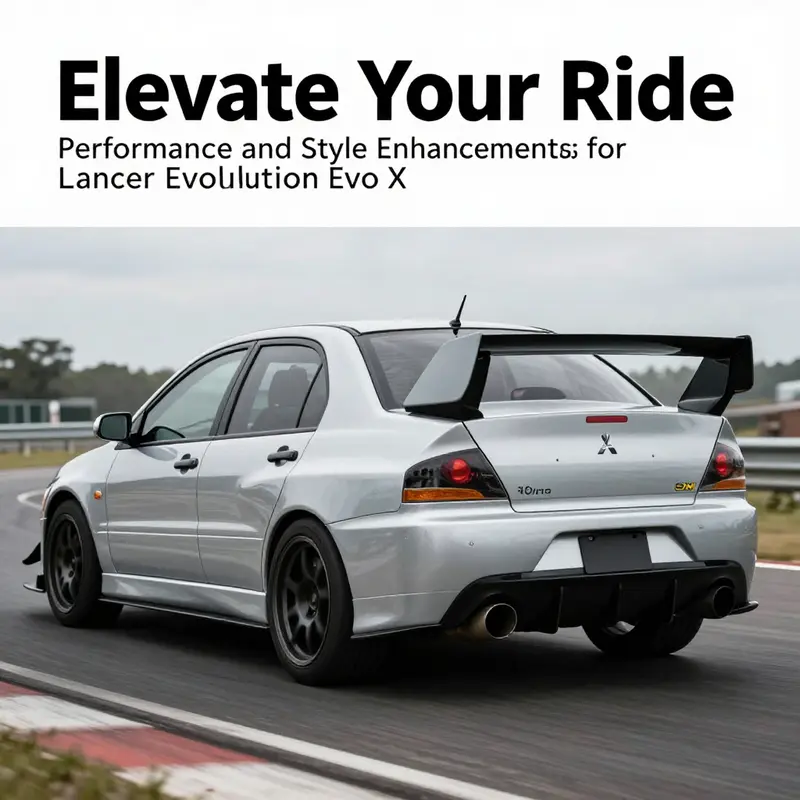

The rear half of the EVO X, too, benefits from carbon venting and a purpose-built rear wing. The rear wing is not a mere spoiler; it is a vital device for controlling the downforce distribution as air exits the car. In high-speed cornering, a well-integrated wing helps to push the rear tires down, increasing grip when the car transitions from straight-line speed to lateral load. The carbon weave of a properly chosen wing provides stiffness without unnecessary mass, enabling the wing to maintain its profile under the turbulent wake generated by the vehicle’s body. The diffuser, often a companion piece in a carbon aero kit, works in concert with the wing. As air exits the underbody, the diffuser guides it smoothly toward the trailing edge, reducing wake turbulence and helping to manage lift at the rear of the car. The synergy between diffuser and wing is subtle but critical: a stable rear end allows the driver to maintain confidence in corner entries at higher speeds and with more aggressive brake points. The car’s overall aerodynamic efficiency improves when these elements are harmonized rather than bolted on as separate adornments.

It is worth pausing on the role of the hood vents, which are among the most functional and visually striking elements in this aero narrative. The large openings in the hood are designed to draw cool air into the engine bay. This airflow not only feeds the intercooler more effectively but also facilitates the dispersion of hot air that would otherwise stagnate around the turbocharged four-cylinder. In a car that relies on forced induction and a high-boost setup, every degree of intercooler efficiency matters. Efficient cooling keeps intake air density higher and, consequently, improves combustion stability and throttle response. In this sense, the hood vents are a hardworking feature, transforming heat into performance rather than simply serving as a ventilated aesthetic. When carbon fiber is used for these elements, the promise of weight savings becomes real without compromising stiffness or heat resistance. A lighter front end plus better cooling is a formula for sharper steering, quicker turn-in, and more predictable throttle progression through the mid- to high-speed ranges.

The unification of cooling and aerodynamics in the EVO X’s carbon vent strategy also reveals an important design ethic: airflow is not wasted. In many modern performance cars, air is managed to reduce drag, which is important for top speed. In a tuned EVO X, however, the priority often shifts toward managing lift and heat as much as minimizing drag. The carbon venting system seeks a balance where airflow over the hood and around the fenders is directed to critical points—radiators, brakes, intercooler, and the underbody diffuser—while still creating the downforce necessary to sustain grip in corners at speed. It is a delicate balance. The car’s original geometry provides a starting point; the carbon upgrades modulate that geometry to create a more resilient dynamic posture at the limit. Enthusiasts who push their EVO X to track conditions quickly learn that the right vents and the right wing do not merely add a touch of racing DNA. They shape the feedback the driver receives through the steering wheel and the seat, giving more precise cues about airflow separation, tire grip, and brake cooling states. In practice, this means fewer surprise surges of lift, more linear brake bias, and a more coherent feel through fast sweepers. These are not mere upgrades; they are a new language for reading the car’s responses under high load.

The material choice of carbon fiber further enhances this language. Carbon’s stiffness-to-weight ratio means that the aero panels resist flex when exposed to the high-pressure zones they create. This stiffness helps preserve the intended airfoil shapes, maintaining clean separation lines over the wheel wells and along the body sides. Clean separation translates to smoother, more stable wake profiles behind the car, which in turn minimizes interference with the rear wing’s downforce contribution and the diffuser’s suction effect. The lightness of carbon fiber also reduces the unsprung mass of the front end, contributing to sharper suspension behavior and less inertia when changes in steering angle occur. In driving terms, that translates to crisper turn-in and a car that responds with immediacy to throttle modulation when exiting slow corners onto faster sections. The subjective impression is a car that feels more planted and aware of its aerodynamic skeleton, a sensation many drivers associate with a chassis that has been thoughtfully tuned rather than merely clipped with cosmetic carbon bits.

A crucial consideration in the EVO X’s carbon vent strategy is fitment and integrity. Carbon panels must be matched to the factory lines, including the headlight pockets, hood contours, and front bumper geometry. Poorly integrated vents can disrupt airflow or cause unwanted turbulence that negates any cooling or downforce gains. The best work remains faithful to the original design intent while maximizing performance—preserving the car’s clean silhouette while adding the technical capacity to manage heat and lift under stress. In this sense, the EVO X’s carbon vent applications demand more than just a good-looking install; they require a disciplined approach to aerodynamics, material science, and dynamic testing. Even so, the result is a vehicle that presents with a purposeful, aggressive stance yet remains manageable in daily driving. The car communicates its intent through a lowered, more resolved profile, a visual cue of its enhanced aero capability, and a sense that every contour has been pressed into service for speed rather than decoration.

The broader cultural context of this work among EVO X owners helps explain why the approach to venting and carbon aero is so persistent. There is a lineage of performance culture that values lightness, airflow efficiency, and the sensory feedback of a more responsive chassis. In a community where weight reduction and air management are pursued with a disciplined eye, the carbon vents and fenders become markers of a carve-out from standard production. They symbolize a willingness to calibrate a street car toward a track-ready balance. This mindset—combining engineering discipline with the visceral appeal of a tuned machine—drives the ongoing interest in carbon-based upgrades for this model. It is not merely about collecting parts. It is about constructing a coherent aerodynamic story where each vent, every slit, and the rear wing all contribute to a more articulate relationship between man and machine.

For readers who want to explore authentic paths to carbon improvements while preserving the car’s original character, there are genuine upgrade routes that maintain fitment and performance. Such choices emphasize real carbon fiber components rather than imitation materials, ensuring that the stiffness and heat resistance remain aligned with the car’s mechanical demands. The nature of carbon fiber—its layered construction and the ability to tailor weave orientation—makes it possible to design vents and grilles that respond predictably to different thermal loads and driving regimes. The driver benefits not only from the cooling and downforce gains but also from the consistency of feedback that carbon panels tend to provide. The result is a car that remains confident at high speeds, a vehicle whose front end communicates with clarity through the steering wheel about the airflow environment and its own physical state.

To illustrate how this philosophy translates into practical choices without becoming a catalog of specifics, consider the way a skilled fabricator approaches an EVO X shell. The front bumper, with integrated side vents, is treated as a single aerodynamic canvas rather than a set of separate add-ons. The fenders, reimagined with ventilation, are shaped to preserve the wheel arch’s structural integrity while allowing air to escape efficiently. The hood vents are positioned to align with cooler intake zones and to avoid siphoning away precious heat from the engine’s most critical components. The rear wing is tuned in concert with the diffuser to optimize the car’s wake, reducing drag where possible but prioritizing downforce where the car needs it most in mid- to high-speed corners. The car becomes a study in how the deliberate redistribution of air can improve both cooling and stability. This integrated view is what separates a thoughtful upgrade from a mere cosmetic modification.

If a reader is curious to see how these design ideas translate into actual parts without compromising the EVO X’s balance, a practical example lies in the way carbon fiber hoods and other shell components are documented in reference catalogs. The intent is to offer a path toward authentic, well-engineered upgrades that respect the car’s architecture while delivering measurable performance gains. A straightforward exploration of the project’s logic reveals a common thread: the car’s thermal and aerodynamic systems are not independent; they are interconnected. Improving one often improves the other, and carbon fiber serves as a vehicle to achieve these improvements without imposing an undue burden on weight or structural integrity. This principle underpins the ongoing interest in carbon venting and high-performance fender treatment among enthusiasts who want a street car that can actually handle extended sessions on a track, while still being practical for daily use.

For readers who want to explore further while keeping the experience grounded in authentic materials and proper fitment, there are accessible references that discuss the broader principles of carbon fiber aerodynamics and engine bay cooling in performance vehicles. A helpful way to connect with this topic in a tangible manner is to examine broader examples of carbon fiber components that support similar functions. For those curious about one concrete example of a carbon fiber upgrade, a product page dedicated to a carbon fiber hood and related components can offer useful context and imagery that clarifies how these parts integrate with the EVO X’s chassis geometry. You can learn more about how a carbon fiber hood and its air vents align with the car’s lines and cooling strategy by visiting a dedicated page that details this kind of upgrade. carbon-fiber bonnet hood page. This link provides a practical reference point for understanding the material choices, construction quality, and fitment considerations that underlie a successful carbon upgrade.

In sum, the EVO X’s carbon venting, front fenders, and rear wing represent more than a collection of performance parts. They embody a design ethos that treats airflow as a dynamic, usable resource. They illustrate how carbon fiber can deliver real-world gains in cooling efficiency and downforce, while preserving the car’s essential balance and street manners. The result is a vehicle that looks aggressively purposeful and feels precisely tuned to its aerodynamic duties. It is a car that invites a driver to engage more deeply with its flow, to respect the heat it generates, and to appreciate how careful engineering can translate the physics of air into something tangible behind the wheel. For the EVO X, carbon venting is not a fashion statement. It is a carefully measured response to the demands of speed, heat, and precision steering—an approach that quietly defines a modern performance machine on both road and raceway.

null

null

Aero, Weight, and Will: The Evo X Front, Fenders, and Wing as a Coherent Performance Narrative

The Mitsubishi Lancer Evolution X represents a rare moment in modern performance culture when engineering discipline and bold aesthetic intent converge around an agile, turbocharged four-banger and a chassis that invites specialization. In the Evo X modification market, the front end, the fenders, and the wing sit at the center of a holistic performance conversation. They are not merely cosmetic upgrades; they are aerodynamic instruments, weight-savers, and visual statements all at once. As enthusiasts move from simple bolt-on upgrades to integrated aero packages, the dialogue around front end components—fenders that reshape the car’s silhouette, vents that manage heat and flow, and wings that generate controllable downforce—becomes a narrative about how a capable street machine can translate track ambitions into real-world performance.

The front end of any high-performance car is a narrative in air. The Evo X, with its compact nose and mid-size wheel arch, presents an opportunity to sculpt the incoming airstream in ways that simultaneously reduce lift, stabilize flow, and give the driver a sense of direct feedback at the wheel. Real carbon fiber fenders, when used in conjunction with purposeful venting and lightweight mesh, do more than shave grams; they alter the boundary layer characteristics around the front corners, helping to keep the car planted as speeds climb and the air pressure changes around the bumper and undertray. When a driver approaches the car, the visual impact of carbon weave and sharply rendered lines communicates a readiness for the track, yet the true value lies in what those panels do when the car is already in motion. The fenders are a subtle but essential element in the Evo X’s aero toolkit, smoothing airflow around the wheels and reducing localized turbulence that can upset the balance of the chassis at high speed.

At the heart of these fenders lies a broader engineering aim: to manage heat and air through the engine bay and brakes without inviting excess drag. Side vents integrated into or mounted near the fender line act as miniature air-handling systems. They pull hot air away from the engine and turbocharged components, a critical function for a car that thrives on sustained performance rather than quick bursts of maximal horsepower alone. The presence of vents in the front fenders is also a signal to the eye that the vehicle’s aero package has been conceived with purpose, that its owner understands the trade-offs between stiffness, cooling, and drag. In practice, these vents contribute to a more stable engine bay temperature during hard driving and help maintain a more predictable pressure distribution across the front of the car. When the car is pushed through a series of high-speed corners, those small openings become part of a larger control system that keeps the Evo X from overheating and from introducing unwanted lift into the front axle.

The rear of the front fender line often draws a line of thought toward the wing, a signature feature of the Evo X’s performance identity. A rear wing—preferably crafted in lightweight carbon fiber and tuned to deliver downforce without excessive drag—anchors the aero balance. The wing works in concert with a carefully shaped front end and the overall underbody flow to keep the car glued to the road in high-speed sweepers and tight, late-apex corners alike. The synergy between the fender vents, the side air pathways, and the wing is where the Evo X’s track potential comes into clear focus. It is not simply the sum of parts; it is the orchestration of how air moves around, under, and above the body to generate stability rather than turbulence. The result is a car that communicates confidence to its driver—a chassis that responds with precise, linear behavior as torque rolls into the turbocharged four-cylinder and the tires seek grip on the tarmac.

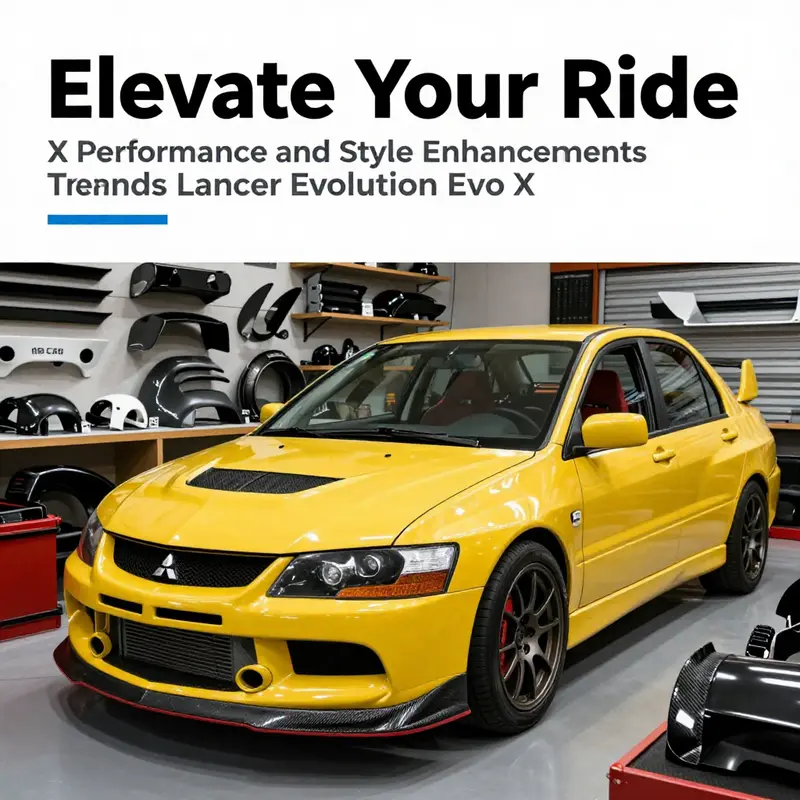

Behind the looks and the feel, there is a practical discipline: the Evo X modification market is increasingly driven by an integrated approach. Enthusiasts want aero that works in harmony with engine tuning, suspension settings, and a properly balanced chassis setup. The track-focused mindset drives people toward packages that optimize not just top speed, but cornering speed, entry and exit stability, and repeatability across sessions. Aerodynamic improvements must marry with handling, since a front end that reduces lift but increases stiffness in the wrong way can rob the driver of nuanced feedback through the steering wheel. A well-considered front fender and vent package, paired with a wing that provides measured downforce, allows the car to lean toward grip rather than buffeting in mid-corner gusts. The goal, in essence, is a cohesive system: air is steered, heat is shed, weight is shaved, and the driver experiences a chassis that communicates, almost telepathically, how much grip remains as tires heat and pressures change.

In the broader market narrative, this kind of integration also echoes a shift in consumer expectations. There is growing demand for holistic optimization, where aero upgrades are not stand-alone statements but components of a broader performance philosophy. Consumers increasingly seek packages that address aerodynamics, powertrain efficiency, and suspension harmony in a single, coherent vision. This shift mirrors the Evo X’s identity as an enthusiast’s platform—one that rewards thoughtful upgrades and iterative improvements over quick cosmetic changes. It is about creating a car that retains street usability while delivering track-ready behavior on weekends and at sanctioned events. The Evo X, with its compact footprint and balanced weight distribution, responds to this philosophy particularly well. Its potential is realized not just in horsepower figures but in the car’s ability to sustain high-speed stability, provide predictable turn-in, and return consistent lap times as parts are dialed in for specific tracks and conditions.

The conversation around these components inevitably touches on legality and practicality. Track necessities and street legality often contend with one another. A front fender vent or a carbon vent, while it can deliver cooling benefits and aerodynamic fine-tuning, also introduces considerations around noise, fender clearance, and local regulations. The Evo X owner must weigh the benefits of improved airflow and reduced lift against potential compliance challenges. In regions with strict inspections or noise limits, the choice of materials, the exact vent placement, and even the finish of carbon fiber can influence an inspection outcome. The willingness to navigate these considerations reflects a broader ethos among Evo X builders: performance should be achievable, durable, and sustainable within the owner’s intended use. This is not merely about chasing numbers; it is about crafting a vehicle that can be enjoyed on the street, then trusted on the track.

Aesthetic impact also matters, and it reinforces the market’s appetite for aggressive, purposeful design. Carbon fiber has become a visual shorthand for high performance. The weave, the gloss, and the contrast against a dark body speak to a discipline of weight-saving and stiffness. The front fenders, with integrated vents and a sculpted silhouette, contribute to a look that is consistent with a fight-tested racing heritage. The rear wing, when tuned with the same ethos, is not a flamboyant flourish but a measured extension of the Evo X’s aero narrative. The car’s stance changes with wider fenders and a lower, more aggressive ride height, signaling a readiness to compete while still offering a practical, street-driven experience. The driver and passenger feel a different relationship to the car; the vehicle’s lines read as a promise of precision engineering rather than a mere visual statement.

To ground the discussion in real-world practice, it helps to consider how a driver might approach building such a package. A well-conceived upgrade sequence begins with a clean assessment of the current aerodynamics and weight distribution. If the front end is a point of lift at speed, front fenders with vents begin to address that lift while assisting cooling and reducing belly flow toward the splitter. The side vents contribute to temperature management under the hood and can change how air travels along the flanks during acceleration. The wing then balances the front-end gains by adding downforce where it matters most, shaping the rearward airflow into a stable wake. Suspension choices follow, selecting coilovers or damper setups that preserve feel and adjustability while maintaining a predictable handling envelope. Alignments, camber settings, and tire choices all follow suit, tuned to the track or road profile the owner intends to chase. In time, the Evo X evolves into a singular, expressive machine: not just a car with a cool look, but a chassis that behaves with confidence at the limit.

Within this evolving dialogue, the Evo X community has formed a robust knowledge-transfer loop. Builders and drivers share data, compare notes about heat management, aero balance, and track performance. The narrative is not merely about possession of parts but about the journey toward a finely tuned machine that performs consistently. Even as the market embraces more complex packages, the emphasis remains on a harmonious integration where every piece serves the same purpose: delivering stable, repeatable performance while preserving driveability and temperament on public roads. In this sense, the Evo X becomes less about a single win and more about a durable, evolving capability—an automotive platform that rewards patient iteration and thoughtful engineering.

For readers exploring the Evo X modification landscape, it is valuable to consider a concrete path through the aerodynamic and structural choices without losing sight of the bigger picture. A practical approach to front-end improvements emphasizes compatibility with the rest of the build. The chosen fenders and vents should align with the vehicle’s overall width, tire selection, and brake package. The front fenders should accommodate the desire for a wider stance if the owner plans to run wider tires for better grip. A carbon vent strategy should consider how much additional cooling is required under track workloads and how it interacts with other cooling devices, such as the intercooler and radiator ducting. The wing must be tuned for the specific track profile, ensuring that downforce levels and drag penalties do not undermine straight-line speed or corner exit performance. All of these considerations highlight a broader truth: the Evo X’s modifications are most effective when treated as a cohesive aerodynamic and mechanical system rather than a series of isolated upgrades.

As the Evo X category continues to mature, the market trends outlined in research reflect a community that values engineered balance more than ever. Enthusiasts are drawn to products and concepts that promise track-credible performance while offering a reasonable compromise for street use. The appeal lies not only in the performance numbers but also in the clarity of purpose behind each modification. The front fenders, the vents, and the wing collectively tell a story of disciplined optimization—one that respects the original engineering while pushing it toward higher levels of precision. This story resonates with a growing audience that wants a car that feels alive at the limit, yet remains predictable, teachable, and fun to drive every day. The Evo X, in this sense, stands as a case study in how modern performance culture negotiates the space between speed, efficiency, and road manners, all anchored in a front end that learns to breathe, a body that sheds heat with intention, and a wing that rewards confident, composed driving. For readers who wish to dive deeper into the broader ecosystem of Evo X modifications, the community discussion and expert analyses available in independent outlets and specialized forums offer a steady stream of insight and real-world testing that enriches the understanding of how these parts work together in practice. External reference: https://www.speedhunters.com

Final thoughts

The Mitsubishi Lancer Evolution Evo X represents more than just a vehicle; it symbolizes a culture of performance and innovation. By offering front and side body fenders, carbon vents, and rear wings, businesses can tap into a passionate market hungry for both aesthetic enhancements and functional improvements. As aftermarket trends evolve, understanding consumer preferences and product applications will be crucial for staying competitive. Embracing these modifications enables car owners to elevate their performance vehicles while also offering businesses a pathway to connect with dedicated enthusiasts.