The Mitsubishi Lancer Evolution, an iconic name in the automotive world, garners respect not just for its powerful performance, but also for its legendary design features. One of the standout components that define the character of the Evo series is its rims. Originating with the EVO II, the factory rims have come to symbolize a perfect blend of performance and aesthetics, making them essential for enthusiasts and business owners alike. This article will delve deeply into the intricate world of Mitsubishi Lancer Evolution rims. Through a five-chapter analysis, we will explore the design elements and high-performance specifications of factory rims, the advanced materials and technology used, the burgeoning market choices and modification trends, the evolution of sizes and their implications, and finally, the cultural significance these rims carry in the automotive community. By understanding these facets, businesses can better appreciate consumer preferences and inform their product offerings accordingly.

轮圈的演化之声:原厂设计如何塑造Mitsubishi Lancer Evolution的操控与美学

(结束)

Rim Craft and the Evolution of Handling: The Material Science Behind Mitsubishi Lancer Evolution’s Lightweight Wheels

The Mitsubishi Lancer Evolution’s identity rests as much on what hides under its fenders as on what sits in the wheel wells. The rims are not merely cosmetic; they are a functional heartbeat that translates engineering intent into street-ready performance.

From the early Evo II era to the Final Edition, the wheel design tells a narrative of lightweighting, rigidity, and heat management, all tuned to the car’s demanding all-wheel-drive chassis. The five-spoke alloy silhouette emerged not as a fashion statement but as a practical embodiment of rally-derived engineering. This chapter charts how material selection, structural geometry, and evolving sizes converged to give the Evo its celebrated balance of quick steering, precise handling, and reliable grip under duress.

The lineage begins with a celebrated five-spoke alloy wheel lineage that echoed the wheel designs used in high-performance rally and circuit programs. The aim was clear: reduce unsprung mass without sacrificing structural integrity, thereby sharpening suspension response and steering feedback. In practice, this meant adopting a light yet rigid aluminum alloy and shaping it to resist the torsional and bending loads that rear-wheel and all-wheel drive dynamics impose during aggressive cornering and abrupt transitions. The five-spoke geometry also facilitated improved air flow and cooling around the brake assemblies, a feature that matters when a car repeatedly enters the apex at high speed and keeps braking hard into the turn. In this sense, the wheel becomes part of the cooling strategy, a small yet essential contributor to maintaining brake performance under load.

As the Evo evolved, so did the wheel program. The EVO II era, and its successors, pushed toward larger wheel sizes to accommodate higher performance tires and to provide more precise turn-in. The wheel diameter crept from the early, compact sizes toward 17 inches as a new normal for many iterations. This shift was not merely about fashion or the numbers on a spec sheet; it reflected a broader design conversation about unsprung mass versus rigidity and the dynamic balance between grip and rotation. Lighter wheels translate to lower inertia in the wheel assembly, allowing the suspension to respond more quickly to road surface irregularities and to change direction with less lag. The payoff is a more willing chassis, a more immediate steering feel, and a more confident sense of control when the throttle is applied through a corner and the car is loaded through the outside wheel.

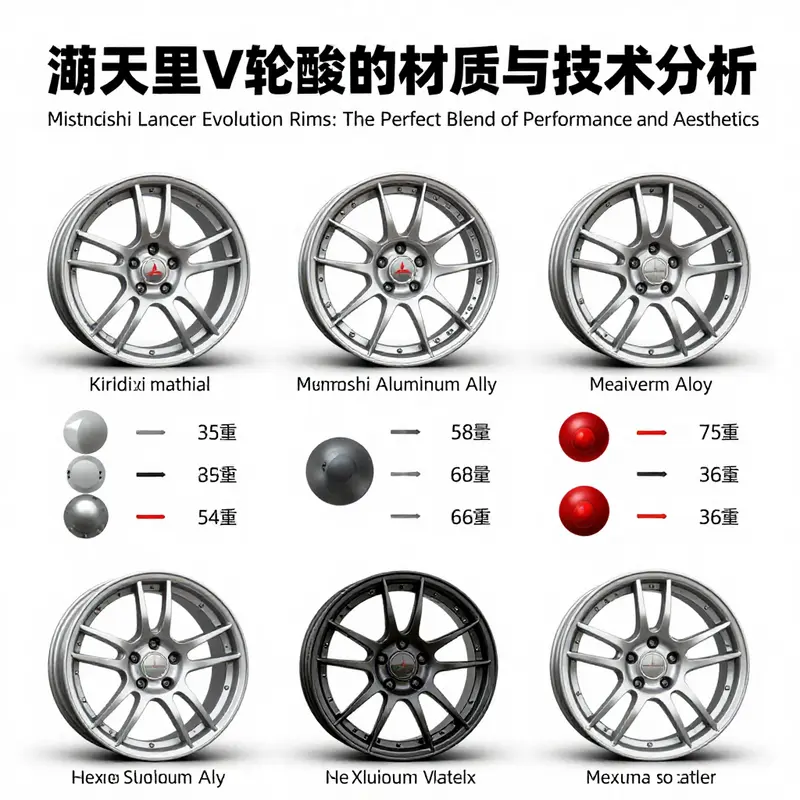

The question of material choice sits at the core of this performance equation. Across generations, the wheel program leaned heavily on high-strength aluminum alloys. The material choice supports two competing demands: low density to minimize inertial load, and high strength to withstand the shock and heat of aggressive driving. Forged alloys offered notable advantages in strength-to-weight ratios, enabling a reduction in weight without compromising rigidity. This is especially relevant in the context of the Evo’s aggressive aero and chassis dynamics, where every gram shaved from unsprung mass improves suspension articulation and brake response. At the same time, advanced casting and casting-forging hybrids allowed designers to tailor spoke thickness, hub connection geometry, and lip profiles to achieve desirable stiffness while maintaining durability during high-speed cornering.

Dimensionally, the Evo’s wheel program tracked the car’s performance envelope. Early models wore smaller wheels, paired with taller sidewalls that offered a forgiving ride and good compliance in street settings. As the chassis matured, the wheel diameter increased to 17 inches, a size that better accommodates wider, stickier tires and improved brake cooling. In higher-performance trims and later generations, optional larger sizes—up to 18 inches—became part of the portfolio. The move to larger wheels was not just about a more aggressive look; it signaled a more deliberate approach to maximizing straight-line acceleration, cornering grip, and steering precision. The additional diameter allows wider tread contact patches and lower profile tires that respond more crisply to steering input, while still preserving a balance with the suspension’s travel to prevent wheel tuck or tire rub in aggressive handling scenarios. The result is a more communicative vehicle—one that tells the driver precisely where the tire is gripping and where it will let go.

Rims as the Car’s Pulse: The Evolution and Market Rhythm of Mitsubishi Lancer Evolution Wheels

The Mitsubishi Lancer Evolution has long stood as a demonstration of how a car’s performance identity can be written in metal and rubber as much as in engine torque and chassis tuning. Among the elements that translate race-bred intent from the track to the street, the wheels play a crucial, almost percussion-like role. They are not merely finished disks that hold the tires; they are the unsung guardians of handling, brake cooling, and weight balance. From the earliest EVO iterations to the final generations, the wheel package has evolved in lockstep with the car’s ambition, morphing from simple rotating masses into finely tuned components that actively shape the car’s behavior under load. The story of the EVO’s rims is, in many ways, the story of the model’s ongoing pursuit of grip, precision, and a distinct visual cadence that signals a car built for speed rather than for showroom glare alone. The evolution of these rims also reveals a broader truth about performance cars: every millimeter of unsprung mass matters, every spoke pattern affects heat dissipation and aerodynamics, and every wheel diameter interacts with tire technology to redefine the balance between agility and stability on both the road and the track.

In the early phase of the evolution line, the wheel size and design were tightly aligned with the era’s emphasis on lightweight construction and mechanical simplicity. A classic pairing emerged in the EVO II era: a lighter aluminum wheel paired with a 15-inch diameter. The tires, around 205/60R15, worked with a wheel that emphasized quick responses and easy heat management. This pairing did not simply serve a cosmetic function; it was a deliberate choice to keep the car light on its feet, so steering could remain precise and the suspension could respond promptly to driver input. As the series progressed into the mid- to late-1990s, the wheel design took on a more race-inspired language. The five-spoke configuration that became a signature of the EVO lineage did more than look assertive on the fender; its geometry facilitated efficient brake cooling and provided a robust escape route for heat generated during aggressive cornering. The visual language of the wheel—strong lines, clean surfaces, and a compact footprint—became an immediate visual cue to performance enthusiasts. This is where the wheel design ceased to be merely utilitarian and became a badge of the car’s performance philosophy.

With EVO II’s lineage in mind, the subsequent generations began to push the wheel toward larger diameters to accommodate higher-performance tires and brake packages. By the time the EVO V and EVO VI entered the market, a trend toward 17-inch wheels had solidified. The increase in wheel diameter was not arbitrary; it matched an intent to court improved lateral grip, better high-speed stability, and more effective heat management across larger brake rotors. The shift also reflected a carefully orchestrated relationship with tire technology. A 17-inch wheel invites a lower-profile tire, which has a distinct effect on steering feel and feedback. Yet the move to larger wheels was not just about road feel. It was about creating a perimeter around the brake system that could endure higher thermal loads, particularly on track days when the EVO’s all-wheel-drive chassis was driven to its analytical limits. The wheel’s role in brake cooling is often underappreciated, but a properly designed wheel can channel air toward ventilated discs, maintain a stable temperature, and reduce brake fade during repeated hard stops.

As the Evolution line progressed toward its peak—across the late 2000s and beyond—the wheel architecture became a more deliberate statement about the car’s racing genes. The late-model iterations, including eighth- and ninth-generation variants, commonly featured 18-inch aluminum wheels as part of the standard or sport-oriented configurations. These wheels were not merely larger; they were engineered for rigidity and heat management, with designs that offered more aggressive brake clearances and stiffer spokes to reduce deflection under demanding driving. In some high-performance variants, a forged wheel option appeared, offering dramatic reductions in unsprung mass without compromising strength. The concept of a forged, high-rigidity wheel speaks directly to a driver’s desire for sharper steering responses, quicker suspension settling, and improved overall handling balance. Such a wheel is not a mere accessory but a weighted lever in the car’s dynamic system, capable of translating the driver’s hand movements into precise tire contact with the road surface.

In the broader market, the wheel conversation for the EVO has always carried a dual character: authenticity and possibility. For purists, the original or near-original wheel configurations carry a weight that goes beyond aesthetics; they encapsulate a period-correct interpretation of the car’s performance ethos. The classic five-spoke wheel—often associated with the EVO’s WRC-inspired image—serves as a touchstone for the brand’s racing heritage. Yet the market beyond the factory has responded with a vibrant spectrum of aftermarket options that reflect a modern appetite for customization and weight optimization. The aftermarket ecosystem is not merely about changing the wheel to look sportier; it is about building a cohesive package where each choice—material, weight, number of spokes, offset, and diameter—harmonizes with suspension geometry and tire construction. Forged wheels offer a path to markedly lower unsprung mass, which translates into more immediate suspension responsiveness. A lighter rim allows the suspension to react more quickly to pavement irregularities, while the tire can maintain a more consistent footprint under load, enhancing grip and steering precision in cornering.

The practicalities of tire and wheel pairing cannot be understated. A typical street-oriented EVO build might favor an 18-inch wheel paired with a high-performance, low-profile tire, such as a 245/40R18. The extra width increases the contact patch, improving straight-line grip and lateral traction, while the lower sidewall reduces the amount of tire flex during cornering. For track enthusiasts, some adjust the setup further toward wider tires with staggered offsets and careful attention to wheel width. The right combination of wheel width, offset, and tire profile is a delicate balance that aims to preserve the car’s balance and steering feel while still delivering the additional grip and braking performance demanded by track conditions. The aesthetics, meanwhile, follow the same principle: wheels that look as purposeful as they perform. Finishes, from gloss to matte and everything in between, have become a language of personalization as drivers seek to express their connection with the EVO’s performance lineage.

The story of EVO rims is also a story of heritage. The EVO’s wheel design became a visual shorthand for a car that fused rally legacy with modern engineering. The five-spoke lineage of the early generations takes on new life in later models through more intricate spoke patterns and more open heat management channels. The market’s evolution reflects that same tension between tradition and progress. OEM wheels maintain their resonance with the car’s original intent, preserving the JDM soul and the racing roots that many enthusiasts hold dear. But the aftermarket world expands the scope of what the EVO can be, allowing owners to sculpt the vehicle’s personality and performance profile to their own tastes and driving contexts. In this sense, wheels become more than a component; they become a statement about how the EVO is meant to be driven and enjoyed.

Across generations, a recurring theme emerges: the wheel is not an isolated choice but a keystone in the larger system of performance, handling, and driver feedback. The shift from lighter 15-inch designs to larger 17- and 18-inch configurations reflects an ongoing negotiation between weight, stiffness, heat management, and tire technology. It is a negotiation that has not ended with a single standard but rather continues through the market’s evolving choices. The result is a living ecosystem where OEM configurations intersect with a modular aftermarket culture, all seeking the same objective: to preserve the EVO’s essence while elevating its practical performance on street and track alike.

One practical thread in this story is how wheel choices interact with the EVO’s chassis and drivetrain architecture. The car’s sophisticated all-wheel-drive system, its multilink suspensions, and the varied power outputs across generations make successful wheel choices highly context-dependent. A wheel that reduces unsprung mass by a meaningful margin can improve handling precision and suspension travel, enabling the chassis to respond more crisply to steering input or braking forces. The wheel’s rigidity also affects the feedback path from the tire to the driver’s hands, shaping how quickly the driver can perceive changes in grip level and adjust the line through a corner. In other words, wheels pull their weight in both measurable performance terms and the intangible language of sensation. It is this combination—the measurable mass savings and the felt connection to the road—that has driven wheel choices across EVO generations and continues to guide enthusiasts as they consider upgrades.

For followers of the EVO’s storyline, the wheel is a natural starting point for an aggressive yet balanced performance build. It is where the heart of the car’s identity beats strongest: a blend of weight efficiency, heat management, structural rigidity, and a look that communicates intent even when the car is standing still. The market’s rhythm—OEM fidelity for purists, forged and high-rigidity options for speed-seekers, and aesthetic choices that reflect personal style—speaks to a community that treats wheel selection as part of a wider conversation about how to extract the most from a performance car while honoring its racing heritage. In this sense, the EVO’s rims are not a minor accessory but a fundamental instrument in the car’s ongoing dialogue between tradition and experimentation.

For readers curious about a practical, context-rich example of how OEM parts connect with performance-oriented wheels on the EVO X era, one internal resource illustrates how components are designed to coexist with a performance wheel program 08-15-mitsubishi-lancer-evolution-evo-x-hood-phantom-black-oem-u02.

External resource for further context on the EVO’s wheel and performance culture can be found in this contemporary automotive review, which details the IX GSR’s performance footprint and wheel-related considerations: https://www.autocar.co.uk/car-news/new-cars/mitsubishi-lancer-evolution-ix-gsr-review

Rim Size, Race Spirit: The Size Evolution of Mitsubishi Lancer Evolution Wheels and Its Grip on Performance

Wheels are more than accessories on a Lancer Evolution; they are the tangible link between the driver’s intent and the road. From the moment Mitsubishi’s engineers sketched the EVO lineage, the wheel design carried a compact philosophy: lighten where possible, strengthen where needed, and size up where it would translate into better grip, steadier cornering, and more precise feedback at the limit. This chapter traces how the Evolution’s rims grew from practical, road-oriented diameters to a more aggressive, resolute stance that matched the car’s shift from street performer to all-terrain racer. The change was not merely cosmetic; it reshaped handling, weight distribution, and how heat moved away from the brakes and through the wheel wells. It is a story of how a circle on a hub can steer the trajectory of a car’s character.

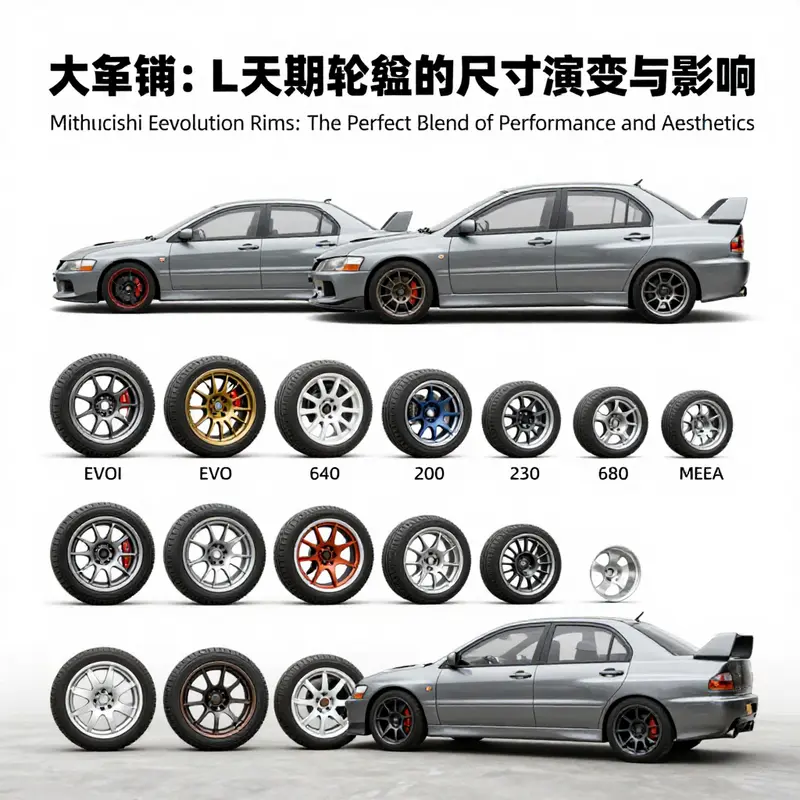

In the earliest incarnation, EVO I established a baseline that echoed its era: a 15-inch wheel paired with a 195/55R15 tire. The six-spoke design and the modest wheel diameter kept weight reasonable and response quick. This configuration favored nimble turn-in, an essential trait for a car that leaned on agile handling more than raw tire mass. Yet, as soon as engineers pushed it toward higher speeds and tighter apexes, the limits of that small wheel’s heat dissipation and torsional rigidity became apparent. The small hoop offered less surface area for heat to dissipate during aggressive braking and cornering. The brake temperatures rose faster, and the chassis relied more on suspension finesse to keep the car planted. In this early stage, the wheel was a compact lever of the EVO’s road manners—fast steering feel, crisp turn-in, and a dependency on chassis tuning to manage grip in demanding corners.

With EVO II, the wheel story took a decisive turn toward the wheel’s visual and functional identity. The EVO II maintained the 15-inch diameter but adopted a wheel design that would endure as a rally-tinged hallmark of the Evolution lineage: a five-spoke silhouette that delivered both strength and a clearer path for air to circulate around the brake components. The improvements in material quality and structure translated into better rigidity and heat management, a necessity as the car’s performance envelope stretched toward higher cornering loads. The same diameter could now support a more robust brake setup and a more efficient cooling path, and the deeper spokes allowed air to chase the rotor surface more effectively. This convergence—the iconic five-spoke aesthetic and the practical gains in stiffness and cooling—cemented EVO II’s wheel as more than a cosmetic cue; it was a tuned component aligned with the car’s race-bred DNA.

Yet the evolution did not stall at the aesthetic apex. By the mid-to-late 1990s, the brand found itself at the mercy of aerodynamic regulations that governed the WRC’s rules and the need for predictable, repeatable performance at speed. EVO VI, designed to comply with 1999 World Rally Championship aero restrictions, kept the wheel diameter at 15 inches while refining the wheel hub and spoke geometry to bolster stability in extreme banking and high-downforce conditions. The wheel’s purpose did not vanish; it adapted. The lighter, more robust wheel structure served the objective of maintaining a low unsprung weight and preserving a quick suspension response even as the bodywork demanded more from the chassis. The emphasis remained on how the wheel’s internal and external architecture could cooperate with the suspension and aero surfaces to deliver predictable behavior through long, demanding stints of cornering at speed. In this sense, the EVO VI era demonstrates that even when size cannot grow, the wheel can get smarter—better heat flow, sturdier rims, and reinforced mounting geometry that keep the car planted when the throttle is pushed toward the limit.

The most transformative leap arrives with EVO VII, when the wheel size finally grows and the performance narrative shifts decisively. The chassis team increases the diameter to 17 inches and pairs this larger hoop with a wider tire—225 or 235 mm, depending on the exact spec—and a 17-inch wheel that could accommodate a broader contact patch. The change is more than visual; it delivers a measurable improvement in grip, braking, and lateral stability. The larger wheel allows a bigger contact patch for the tire to press into the road, which translates into outstanding lateral grip and more confident braking performance as the vehicle slows from speed into tight corners. The added diameter also invites a significant shift in the vehicle’s overall dynamics: the wheel’s mass distribution changes how the car responds to steering input, and the increased wheel width helps guide the tire’s footprint across the pavement with more control. The result is a car that turns with more authority and can sustain aggressive lines through corners that would challenge a smaller-diameter setup.

With that leap in wheel size, the EVO VII also brings an almost perceptible jump in chassis rigidity. A 17-inch wheel, when paired with forged aluminum construction and a carefully tuned suspension, contributes to a stiffer overall structure. The increased rigidity improves steering precision and reduces the amount of flex that can dilute feedback at the steering wheel. It also enhances brake cooling because the larger wheel radiates heat more efficiently from the rotor area, aiding the brakes during repeated, high-speed stops. All these gains come with a caveat: the larger wheel adds unsprung weight, a factor that, if not managed, can blunt suspension responsiveness. Mitsubishi’s engineers addressed this through targeted suspension tuning. Revisions to spring rates, damper calibrations, and roll stiffness were essential to keep the car’s handling faithful to its roots while accommodating the heavier wheel and wider tire package. The car still needed to be light on its feet; the tire and wheel package just carried more of the load without sacrificing the precise, communicative feel that defined the EVO’s character.

The arc from 15 inches to 17 inches marks more than a dimensional change. It signifies a philosophical shift in how the Lancer Evolution balanced weight, stiffness, braking, and aero demands. The 15-inch era kept the car lean and line-focused, a reflection of the street-to-track ethos of the early EVOs. As the series matured, the larger 17-inch wheel became a symbol of its readiness to tackle higher-speed dynamics, more aggressive cornering, and the demanding surfaces of all-weather performance. The wheel design, moving from a simple, efficient layout to a more complex, structurally optimized form, mirrored the evolution in chassis engineering. It was a period when every component—tire, brake, suspension, and wheel—was tuned in concert to deliver a coherent performance package rather than a series of isolated improvements.

Everywhere in this evolution, the wheel’s form carried a legacy. The classic five-spoke silhouette that emerged with EVO II became a visual shorthand for the EVO’s racing pedigree and its willingness to push into the limits of grip and control. The lighter, forged construction choices in later generations, paired with larger diameters, reflected a broader trend in performance engineering: weight must come off where it hurts the most and where it makes the most difference to the car’s dynamic response. The wheel, in this sense, is a microcosm of the EVO’s broader engineering philosophy. It is where aesthetics meet engineering, where aerodynamics, heat management, and suspension geometry converge to define how the car feels when you push into a corner at the edge of adhesion.

Along the broader ecosystem of Lancer Evolution enthusiasts, the rim remains a focal point of personalization and performance. While OEM wheels accomplished the balance of lightness, rigidity, and cooling, the aftermarket offers a broader palette of forged aluminum designs, distinct spoke patterns, and wider diameters that continue the EVO’s performance tradition. For many fans and collectors, the original OZ-inspired or five-spoke heritage wheels are emblematic of a specific moment in time—the point at which the road-going performance car embraced rally-grade geometry and a design language that could be recognized at a glance. Yet, even with a strong preference for authenticity, the wheel remains a versatile front in the car’s character, capable of changing the way the Evolution behaves on a track or a back road.

To those who seek a bridge between the era-defining look of the early EVOs and the broader wheel choices available today, there are options that honor the same spirit. A practical way to explore this lineage is to look at aftermarket rims that maintain forged aluminum construction and a racing-inspired silhouette while offering modern tolerances and sizing. For example, there is a range of options available that echo the classic era’s spirit and provide a direct nod to the EVO’s wheel heritage. A related thread within the Lancer family keeps the conversation active through links to contemporary aftermarket rims that fit the Lancer’s platform, including models designed for older generations that share compatibility with certain EVO configurations. For a concrete example (and to explore how a classic wheel concept translates to modern Lancer models), see this collection of aftermarket rims associated with Lancer sedans, which preserves the same spirit of performance-focused design: brand-new-original-bbs-rims-set-of-4-r18-rims-for-lancer-sedans.

The story of the Evolution’s rims culminates in a simple truth: the wheel is an essential enabler of the car’s overall behavior. It is where the chassis meets the road, where aerodynamics meets brake cooling, and where weight distribution becomes a constant from corner to corner. The shift from 15-inch to 17-inch wheels marks a stage in which the Evolution embraced greater mechanical contact with the surface, stronger high-speed stability, and the confidence to drive in more aggressive conditions. This is not just about bigger wheels; it is about the translation of a racing mindset into a road car that could be driven to the limit and then back off with precision and control. In the end, the wheel’s size, its rigidity, and its ability to dissipate heat are all threads in the broader fabric of the Evo’s performance narrative. They tell a story of continuous refinement, a story that begins with a simple circle on a hub and ends with a machine that thrives on the edge of adhesion.

External resource for further context: https://www.mitsubishi-motors.com/jp/evolution/

Rims and Reverie: The Evolution of Lancer Evolution Wheels

Rims are more than metal and rubber; they form the interface between a car’s intention and the road. In the Lancer Evolution line, the wheels do not merely spin; they articulate the car’s character. Early EVOs used compact, light 15-inch wheels paired with performance tires, tightening steering, sharpening turn-in, and keeping unsprung mass in check. The design language was a functional extension of the chassis, where spoke geometry, brake clearance, and hub mounting all contributed to a feeling of precision on twisty roads. The five-spoke silhouette that emerged in those years became a badge of the EVO’s identity, signaling that performance and aesthetics could grow together without compromise.

Over the years the wheel diameter grew to 17 inches, offering better brake clearance, stiffer rotational inertia, and improved aero integration with wider fenders and tuned suspensions. The shift from 205/60R15 to 225/45ZR17 tires increased grip while preserving responsive handling. Lighter alloys reduced unsprung mass, a critical factor in how the car responds to road texture and steering input. The wheel design began to borrow cues from motorsport—weight reduction without sacrificing strength, heat dissipation for high-performance brakes, and a robust mounting interface for aggressive driving. The wheel became an extension of the chassis, a tangible link between engineering intent and road behavior.

Beyond measurements and materials, the wheel grew into a cultural symbol. The factory family of five spokes, and later more complex multi-spoke arrangements, carried a language of speed that read from a distance. In addition to aesthetics, the wheel balanced the car, helping lower inertia so the suspension could react more readily to road texture and cornering demands. As the EVO lineage evolved, so did its wheels, signaling shifts in tuning and aerodynamics while remaining faithful to a shared philosophy: performance as a dialogue between weight, stiffness, and form. For enthusiasts, rims are not just a cosmetic choice but a living part of the EVO story, a lens into how Mitsubishi fused endurance, speed, and style.

For readers curious about how wheel choices influence handling, braking, and culture, the EVO’s path from 15-inch roots to modern high-traction setups offers a concise arc of engineering and identity.

Final thoughts

In summary, the rims of the Mitsubishi Lancer Evolution represent much more than just functional components; they are a blend of aesthetic appeal, technological advancement, and cultural status. From their original design focused on performance to the diverse aftermarket options available today, it is clear that these rims are crucial not just for their practical benefits but also for their embodiment of automotive artistry and community identity. As the market continues to grow and evolve, understanding the significance of these components will empower businesses to align more closely with consumer desires and trends. Thus, it’s essential for entrepreneurs to keep an eye on the developments surrounding Mitsubishi Lancer Evolution rims, as they play a pivotal role in shaping both automotive culture and consumer preferences.