When it comes to the Mitsubishi Outlander 4 (2019–present), the front bumper plays a vital role in enhancing both safety and aesthetics for business owners who rely on this versatile SUV. Understanding the construction of these bumpers, the potential of aftermarket enhancements, and the distinctions between OEM and aftermarket options is crucial for making informed decisions. This article will delve into the sophisticated construction and materials of Outlander bumpers, explore exciting aftermarket possibilities to elevate performance, and guide you through reliable purchasing options to ensure you acquire the best components for your vehicle.

Guarding the Road: The Art and Science of Mitsubishi Outlander 4 Bumper Construction

The bumper is more than a protective shell on the Mitsubishi Outlander 4. It is the vehicle’s first line of defense in everyday encounters with the world—curbs, parking stops, and the occasional low-speed collision that can otherwise cascade into more costly repairs. In the fourth generation, spanning from 2019 onward, the bumper system embodies a philosophy that fuses safety engineering with weight efficiency and visual coherence. The result is a front end that looks integrated, feels sturdy to the touch, and performs predictably when it matters most. To understand the Outlander 4 bumper, one must see it as a layered system: an outer protective fascia, a structural core that absorbs energy, and the myriad integrated features that knit the bumper to the rest of the vehicle’s safety and comfort systems. This is not merely about a piece of plastic. It is about a carefully balanced architecture that must fit precisely, weather the elements, and align with sensors, lights, and hood mechanisms while keeping the vehicle agile enough to meet modern fuel economy and emissions targets.

The outer layer—what most drivers first notice—plays a crucial role in both aesthetics and energy management. Typically fashioned from high-impact thermoplastics or reinforced composites, this outer fascia is designed to be lightweight yet resilient. The material choices favor resistance to corrosion, UV exposure, and temperature swings, all of which are daily realities for an SUV that traverses city streets and backroads alike. The color and finish are often paint-mmatched to the body, so the bumper reads as a seamless part of the vehicle rather than a separate component. But the gloss of the surface is not its sole virtue. The outer skin is also tuned to manage minor cosmetic impacts, like brushing against a gate or a low-velocity collision with a shopping cart, while preserving the integrity of concealed fog lights, sensors, and the hood alignment system beneath.

Beneath that outer layer lies the backbone of the bumper—the center reinforcement and the energy-absorbing structure. Here the material choice shifts toward metals that can endure and dissipate energy efficiently. In many modern Outlander configurations, the center reinforcement bar is fabricated from steel, chosen for its high strength, stiffness, and predictable deformation characteristics in low-speed crashes. Steel’s rigidity helps maintain the alignment of the bumper and the attached components, and its ability to absorb impact through controlled plastic yielding reduces the risk of further damage to the vehicle’s core systems. In other designs and depending on the specific trim or market, aluminum can play a hybrid role: a lighter option that still offers sufficient strength to partly offset the weight added by the bumper’s outer skin and any integrated features. Aluminum’s lightweight nature contributes to overall fuel efficiency and handling, but engineers must weigh corrosion resistance, cost, and long-term durability when selecting it for a given vehicle specification.

The hook-up between the outer shell and the reinforcement is where innovation becomes particularly evident. A hybrid design—common in OEM and many aftermarket configurations—uses steel supports within a composite shell to achieve a measured balance between crash energy absorption and overall weight. This approach is especially important for the Outlander 4, where reducing unsprung weight and overall mass supports better acceleration, braking, and ride quality without compromising front-end safety. The bumper’s energy-absorbing zone is carefully engineered to deform in a predictable, gradual manner during a collision, which helps protect critical components behind the bumper cover, such as the radiator, fog lamps, and in some models the forward radar sensors. In this context, the bumper is not a single rigid plate but a controlled, energy-management system that behaves differently at various collision severities.

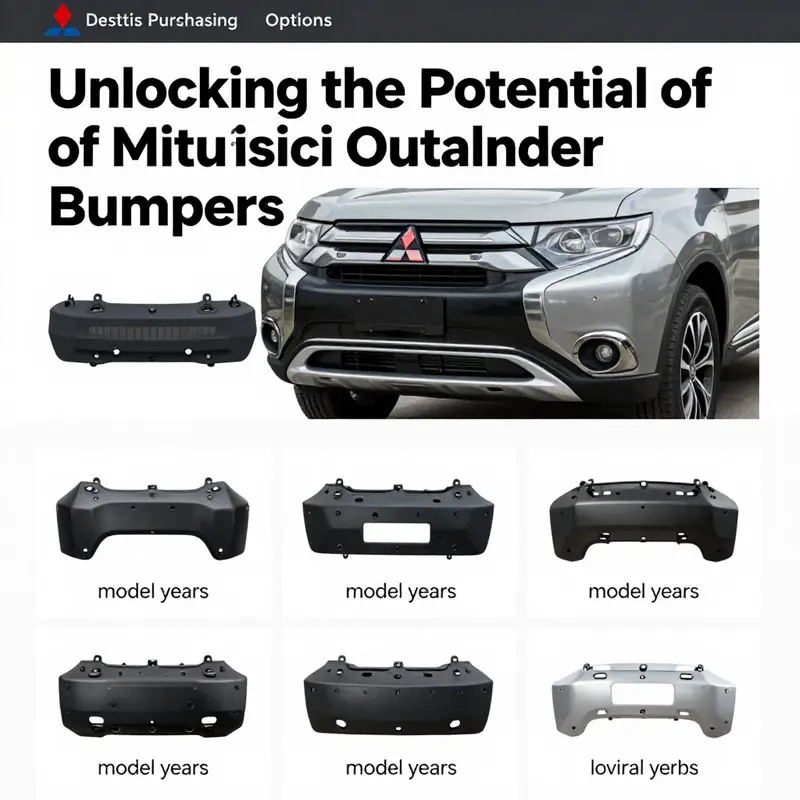

Compatibility and precision are central to the Outlander 4’s bumper story. The bumper parts are designed to fit specific model years and generation codes so that every feature—whether it is a fog light housing, a sensor recess, or a hood latch interface—lines up with factory tolerances. The design ensures that the hood sits properly, sensors recalibrate with minimal effort after replacement, and the grille blends with the surrounding body panels. This precision fit is why OEM bumpers tend to be the preferred option for safety-critical repairs or restorations after an accident. They are engineered to maintain the original performance envelope, compatibility with safety systems, and the integrity of warranty considerations. In practice, you will encounter a suite of components associated with the bumper: the bumper cover, the center reinforcement, the energy-absorbing elements, bumper brackets that secure the assembly to the chassis, and the small but essential hardware pieces that keep everything aligned and quiet during operation.

From a performance standpoint, the bumper is a guardian of the vehicle’s most delicate front-end systems. Fog lights, driver-assist sensors, and hood latch mechanisms often have dedicated housings that integrate into the bumper structure. The advance in sensor technology means the bumper must provide not only a protective cover but also a stable platform for sensors to function reliably in varied weather and road conditions. This integration is a reminder that the bumper is part of a larger safety ecosystem. Its geometry affects sensor field of view, the timing and calibration of assistive features, and even the way air flows over the vehicle’s surface—an aspect that touches on both cooling efficiency and aerodynamic stability at highway speeds. It is this confluence of mechanical fit, sensor compatibility, and aerodynamic behavior that elevates bumper construction from a simple enclosure to a sophisticated safety-and-performance module.

Of course, a modern Outlander 4 bumper is also a canvas for customization. For drivers seeking a more protective look or a sportier silhouette, aftermarket bumper covers and full body kits offer alternatives to the OEM aesthetic. A typical aftermarket approach may include features like a black gloss bumper cover with a center-grille panel, integrated side skirts, and even rear spoilers designed to influence airflow. The allure is obvious: enhanced visual aggressiveness and potential aerodynamic advantages such as reduced drag or increased downforce at higher speeds. Yet there are practical trade-offs to consider. Larger spoilers or aggressively styled kits can alter rear visibility and, if not installed with care, may introduce wind noise or adverse vibrations. The balance between enhanced appearance and potential functional drawbacks is a reminder that form must respond to function in bumper design. Careful selection, precise fitment, and professional installation become critical when adopting such modifications. OEM parts, by contrast, tend to preserve factory alignment, sensor synchronization, and warranty coverage, albeit at a higher cost.

Beyond the decision between OEM and aftermarket, another layer of consideration centers on the bumper’s brackets and mounting hardware. These components—often made from reinforced plastics or metal—anchor the bumper to the vehicle’s chassis and maintain consistent alignment under varying load and temperature conditions. The brackets must resist deformation, minimize noise due to vibration, and tolerate the heat cycling that is part of daily driving. It is easy to overlook these small metal and plastic anchors, but they are essential for maintaining that sense of solidity one expects when tapping the brake or steering through a corner. In the Outlander 4’s design language, these elements are sized and shaped to tolerate typical curb strikes and parking-lot scuffs while preserving the bumper’s alignment with the hood line and the vehicle’s front grille geometry.

From a maintenance perspective, the bumper requires periodic attention much like any other exterior component. The paint finish, for instance, should be inspected for chips that can let moisture penetrate toward the underlying metal, potentially initiating corrosion in steel reinforcement zones. Regular cleaning helps prevent the buildup of road salt and grime, which, if left unchecked, can accelerate wear over time. While the outer shell is designed to resist weathering, the joints and seams that join the bumper to adjacent body panels can collect dirt and become a source of squeaks or wind noise if neglected. During a collision repair, the process must carefully restore the bumper’s factory alignment parameters and ensure that the integrated sensors recalibrate properly. This is why many technicians recommend OEM replacement parts when safety-oriented repairs are needed. The goal is not merely to replace a cover but to restore the bumper’s full spectrum of functions, from visual coherence to sensor reliability and crash-energy management.

In sum, the Mitsubishi Outlander 4 bumper embodies a disciplined engineering approach. It is a multilayered system in which materials science, structural design, and sensory integration come together to protect occupants, preserve performance, and sustain style. The outer fascia provides impact-absorbing energy, the reinforcement and brackets provide a backbone that keeps the vehicle aligned, and the internal housings maintain the function of sensors and lights that many drivers now rely on daily. This is a chassis-level compromise, not a cosmetic add-on—a compact case study in how modern SUVs achieve safety and efficiency without sacrificing personality. For readers who want to see how this balance translates into real-world choices, the decision between OEM parts for guaranteed compatibility and aftermarket routes for customization remains a personal calculus, guided by how the vehicle will be used, how much weight can be afforded, and how much importance is placed on the seamless integration of safety features and aesthetics. For those interested in exploring a ready-made front bumper option that aligns with Outlander 4 specifications, the following resource offers a direct path to a compatible front bumper option: Mitsubishi Outlander 2019 front bumper.

As designers and engineers continue to refine bumper systems for new generations, the Outlander 4 stands as a snapshot of contemporary practice: a choreographed blend of steel and polymer, of precise fit and protective intent, of style that does not overwhelm substance. The bumper does not merely shield the vehicle; it communicates a philosophy of resilience and efficiency—an embodiment of how modern SUVs navigate both the urban landscape and the demands of dynamic driving. External references offer a broader view of the materials landscape, including how steel center reinforcements and corrosion-resistant treatments contribute to longevity in a bumper’s lifecycle. For readers seeking a deeper dive into a concrete steel-based reinforcement example, an external resource provides useful context: https://www.alibaba.com/product-detail/KOWZE-6400C432-Front-Bumper-Center_1600737317441.html?spm=a2700.18715353.0.0.1f5c5d3cZaHnLJ. While the specific product is a case study, the underlying principles—corrosion resistance, structural integrity, and energy absorption—resonate across the spectrum of bumper design and reflect the careful choices that go into the Outlander 4’s front-end architecture.

Front-End Finesse: Upgrading Mitsubishi Outlander Bumpers with Style, Safety, and Subtle Performance

The front bumper of a Mitsubishi Outlander is more than a cosmetic shield. In the current or recent generations, it functions as a carefully engineered barrier that blends energy absorption, aerodynamics, sensor compatibility, and the vehicle’s visual identity. The bumper assembly combines an outer cover crafted from high-impact plastic or a durable composite with an internal reinforcement structure that manages impact energy and protects critical components. This dual construction supports modern goals for lighter materials, improved crash performance, and better efficiency. Aluminum reinforcements have become common for strength with lower weight, aligning with SUV design priorities that balance protection and efficiency.

For owners exploring aftermarket options, upgrades range from subtle trim enhancements to more aggressive styling that must still respect the car’s safety architecture. The value of aftermarket parts extends beyond appearance: well-executed improvements can improve durability in daily driving, while maintaining or enhancing how the bumper interacts with sensing technologies and lighting. OEM bumpers are designed for precise fit and sensor harmony, and they often preserve factory warranty protections, especially after a collision or when exact replacement is needed to maintain alignment with safety systems. The discussion around OEM versus aftermarket centers on fitment reliability, long-term durability, and how choices affect warranty and serviceability.

On the aesthetic side, the Outlander’s front end offers opportunities to express personality without straying from the silhouette. Chrome trim or painted accents can add a premium touch, while overlays and toughened finishes should be weighed against wind noise, heat tolerance, and how they integrate with existing paint and chrome accents. Aggressive front splitters can sharpen the look and influence airflow, but overly low or poorly tuned pieces can cause bottom-out incidents or altered intake dynamics that affect cooling or engine performance. Thoughtful integration with the bumper’s structural elements and the overall aerodynamic package is essential.

A practical upgrade plan begins with fitment realism. OEM bumpers are matched to specific model years and generations, enabling straightforward installation and clean sensor alignment. Aftermarket options require careful verification of mounting points, reinforcement geometry, and sensor clearance. Verify compatibility with ADAS sensors and, when possible, seek professional installation to preserve factory tolerances and safety features.

For buyers, the best approach is to balance style, protection, and system compatibility. Styles might include trim accents, paint-matched surfaces, or overlays; protection can involve thicker inner reinforcements or energy-absorbing structures for low-speed impacts; and system compatibility means ensuring lights, cameras, and proximity sensors remain properly positioned and unobstructed. As with any thoughtful upgrade, the goal is to preserve or enhance safety feature performance while delivering the owner’s preferred look and feel.

Front-Line Choices: Navigating OEM and Aftermarket Bumpers on the Mitsubishi Outlander 4

The front bumper of the Mitsubishi Outlander, especially in the fourth generation that has defined recent model years since 2019, sits at a crossroads of safety, function, and style. It is not merely a cosmetic panel; it is a carefully engineered, safety-critical component that anchors sensors, lighting, and aerodynamic behavior while bearing the brunt of incidental contact on city streets and highways. When owners weigh their options between OEM (Original Equipment Manufacturer) bumpers and aftermarket alternatives, they embark on a decision that touches fitment, safety performance, cost, and long-term vehicle value. A thoughtful approach to this choice recognizes how the bumper interacts with the broader architecture of the Outlander—its lightweight ambitions, its driver-assistance systems, and the sometimes subtle but important differences in how the parts behave during a crash, a repair, or a routine maintenance cycle.

At the heart of the OEM versus aftermarket debate lies a simple truth: a bumper is more than a cover. The exterior shell is typically a high-impact plastic or composite designed to resist minor impacts and to present a paint-matched exterior that blends with the vehicle’s overall styling. Yet beneath that cover sits a reinforcement structure, most commonly constructed from aluminum or steel, that absorbs energy during a collision and helps protect more vulnerable components such as the engine bay, radiator, and suspension mountings. For modern Outlanders, weight reduction is a continuing priority to improve fuel efficiency and handling, which has steered engineers toward lighter yet strong metals like aluminum for certain bumper frame elements. The result is a system that must harmonize with safety tests, crash energy management, and a pristine factory appearance—an alignment that OEM bumpers are built to deliver.

From a usability standpoint, OEM bumpers are engineered to deliver a precise fit. Each bumper is designed for a specific model year and generation, meaning its contours, mounting points, and attachments line up with the surrounding panels, sensors, and closing panels without requiring extensive adjustments after installation. This precision is not only about aesthetics; it plays a critical role in aerodynamics, grill alignment, and the seamless operation of the front air dam and fog lighting system. When a bumper is properly fitted, gaps remain virtually invisible, and the vehicle’s overall silhouette maintains its intended airflow characteristics. In the context of the Outlander, where every millimeter of clearance and every alignment reference can influence sensor performance and hood sealing, that level of exactness is particularly valuable.

Paint-matching is another practical consideration that tilts the scale toward OEM components. When a new bumper is installed, color matching the vehicle’s paint finish ensures a uniform surface tone that resists weathering and sun fade differently across panels. OEM bumpers are typically finished in the same color code as the headlamps, grilles, and body sides, producing a cohesive, factory-like look that buyers often prize for resale value and long-term aesthetics. In contrast, aftermarket bumpers can offer a broader palette of finishes, sometimes with coatings that resemble the original but may require additional steps to achieve a perfect match. The trade-off is that achieving a seamless look with aftermarket options may demand more time, professional prep work, and, on some occasions, additional painting costs.

One of the most consequential differences between OEM and aftermarket options is how well each integrates with advanced driver-assistance systems (ADAS) and the sensory suite that modern Outlanders rely on. Front cameras, radar sensors, parking sensors, and lighting functionalities often connect through sensors integrated into the bumper structure itself. OEM bumpers, designed in tandem with the vehicle’s software and hardware, tend to preserve the intended geometry and sensor clearances that enable features such as adaptive cruise control and automatic emergency braking. Aftermarket bumpers, especially those marketed as universal fits, frequently require careful repositioning of sensors, recalibration of safety systems, and sometimes even alterations to the bumper reinforcements to maintain proper signal lines and field-of-view. The consequence can be not only a cosmetic mismatch but a drift in the very safety capabilities that modern Outlanders rely on every day.

Price is a practical driver in real-world decisions. OEM bumpers carry a premium, reflecting their targeted fit, verified crash-test performance, and seamless collaboration with the vehicle’s ADAS suite. They are often accompanied by part numbers that ensure compatibility with the exact generation’s bumper brackets, reinforcing, and mounting hardware, which may be plastic or metal and designed to resist vibration and noise. The brackets themselves are a crucial but sometimes overlooked component; they secure the bumper to the chassis and help maintain consistent alignment over years of operation. A rigid, well-positioned bumper bracket reduces edge gaps and mitigates noise from panel movement, contributing to a quieter ride as well as better energy management in a collision. For repair scenarios following a bump or a minor collision, OEM parts provide a straightforward path to restore factory geometry, maintaining warranty considerations and ensuring the vehicle remains within the intended safety envelope.

The aftermarket path opens a spectrum of possibilities. Aftermarket bumpers are often marketed as cost-efficient solutions and customized options, sometimes pushing the envelope with materials and styling that depart from the stock appearance. They can range from reinforced plastic to composite or even carbon-fiber variants, presenting opportunities to tailor the Outlander’s front-end attitude—more aggressive lines, a more rugged stance, or a streamlined profile intended to improve highway stability and reduce drag. In practice, the real-world benefits must be weighed against potential drawbacks. Some aftermarket bumpers are advertised as universal fit; however, fitment can vary widely depending on the exact trim, year, and regional manufacturing tolerances. Misalignments at the edges, gaps around the grille, and interference with fog lights or air dams are not merely cosmetic concerns; they can influence airflow, cooling efficiency, and sensor clearance.

The safety implications extend beyond touch-and-feel quality. Aftermarket bumpers may not meet the same stringent crash-test criteria as OEM parts, which can have downstream effects on occupant protection in a collision. This is not a universal claim about all aftermarket products but a caution that the tested performance, integration with reinforcement structures, and compatibility with the vehicle’s safety systems cannot always be assumed. The practical consequence is that some owners find aftermarket options to be compelling in the short term for looks or budget reasons, yet later seek OEM parts for post-accident repairs, warranty considerations, or when an exact factory fit becomes a priority for the overall integrity of the vehicle. In this light, the decision becomes less about “one size fits all” and more about aligning the bumper choice with the owner’s priorities—safety, warranty, resale value, and confidence in long-term performance.

Beyond the bumper cover itself, the ecosystem of components that accompany a front bumper remains essential to the Outlander’s performance. Bumper brackets, mounting hardware, and air-dam configurations all play their part in how the bumper behaves under load and how effectively it channels air around the engine bay. For the Outlander, a car designed to balance efficiency with practicality, preserving the designed airflow and cooling paths is not just about engine temperature; it’s aboutfuel economy and engine longevity over the lifespan of the vehicle. OEM configurations tend to preserve the original air-dam geometry, which supports stable highway aerodynamics, predictable fuel consumption, and reliable fog-light and sensor placements. Aftermarket configurations might alter these geometries, potentially changing how the front end interacts with wind at high speeds and how the bumper integrates with the surrounding body panels for a cohesive look.

For those attracted to the idea of an OEM pathway while still seeking information and options, a direct source of the genuine part is worth considering. The most straightforward way to ensure a precise fit and maintain factory integrity is to select a bumper designed specifically for the Outlander’s fourth-generation platform. Front bumper for Mitsubishi Outlander (19) represents a clear route to a bumper that aligns with the exact mounting points, bracket configurations, sensor placements, and hood alignment systems intended by Mitsubishi for that generation.

In evaluating costs, the decision often hinges on whether the owner values the peace of mind that comes with factory-level fit and safety versus the flexibility and potential styling customization of aftermarket solutions. OEM components often entail higher initial outlays and may require professional installation to accommodate sensors and lighting into the vehicle’s existing harnesses and control modules. Yet this investment can translate into smoother insurance claims after a collision, a more straightforward warranty pathway, and a confidence that the saddle and skids align with the chassis as originally designed. Aftermarket bumpers can offer substantial savings and the allure of unique looks or additional protective features like reinforced shells or skid-friendly profiles. The caveat remains that the fine points—the edge gaps, the gap-to-door alignment, the sensor housings, and even how the bumper sits against the hood—need attention to avoid a cascade of adjustments that undermine the intended benefits.

The discussion of fitment and safety is not merely about the bumper surface, but about how the entire front-end assembly behaves in real-world conditions. A well-fitted bumper, whether OEM or aftermarket, must work in harmony with the hood latching system, the grille, and the radiator shrouds. The paint process, scratch resistance, and UV stability of the bumper finish also matter because exposure at the front of the vehicle makes this component more susceptible to sun fading, stone chips, and road salt. In practice, the decision to opt for OEM or aftermarket bumpers often comes down to a calculation that includes the vehicle’s current condition, regional climate, driving style, and the owner’s comfort level with potential recalibrations of safety systems after installation. A careful, deliberate purchase that includes professional installation, sensor checks, and, where necessary, recalibration will help ensure that the chosen bumper delivers the right blend of protection, aesthetics, and reliability over the long term.

For the contemporary Outlander owner, the route to that outcome is increasingly straightforward when the philosophy behind the choice is understood. If the priority is flawless fitment, factory finish, and seamless integration with sensors and safety systems, OEM remains the strongest case. If the goal is to explore styling versatility, cost efficiency, and a broader spectrum of materials and finishes, aftermarket solutions offer a compelling path—provided that the buyer is ready to engage in careful measurement, potential customization, and professional installation. Either way, the bumper’s role as a guardian of the front end, a contributor to aerodynamics, and a contributor to the vehicle’s long-term value remains central. The Outlander’s fourth-generation design invites a measured approach to front-end parts that honors both the science of energy absorption and the art of presentation. A well-chosen bumper supports not only the moment of impact but the everyday experience of driving a vehicle whose looks, performance, and reliability are in alignment with the owner’s expectations.

In closing, the choice between OEM and aftermarket bumpers for the Mitsubishi Outlander 4 is less about a binary decision and more about a spectrum of trade-offs that reflect how much value a driver places on precise fit, safety integration, and factory continuity versus cost flexibility and personalization. The best path often starts with understanding the bumper’s dual roles: it is both protective shield and design element. It is a platform for sensors and lights, and it is a surface that endures a road’s weather and wear. For most owners who want to preserve the vehicle’s original character and safety guarantees, OEM remains the most reliable anchor. For those who want to tailor the vehicle’s appearance and potentially optimize certain performance aspects, a carefully chosen aftermarket option—installed with attention to sensor clearance and bracket integrity—can deliver a personalized edge without sacrificing essential safety. Whichever route is chosen, the key is a deliberate process that respects the Outlander’s engineering foundations and the practical realities of everyday driving.

External resource: a major online marketplace hosting genuine OEM bumpers provides a practical reference point for availability and compatibility when pursuing OEM paths. Genuine OEM bumpers offering verified compatibility and trusted seller ratings can be a useful part of the research process while ensuring alignment with factory standards.

Frontline Choices for the Mitsubishi Outlander Bumper: OEM, Aftermarket, and Supplier Perspectives (Gen 4)

The front bumper on a modern SUV is not merely decorative; it is a safety and engineering junction where crash energy management, design, and sensor integration come together. In the Mitsubishi Outlander Gen 4, introduced in 2019 and continuing today, the bumper assembly combines an outer cover with a structural reinforcement that may use aluminum or high-strength steel to absorb impact energy and preserve geometry. Weight management remains a priority, so aluminum alloys are common for front-end reinforcements to balance rigidity with mass, supporting efficiency and handling. The bumper is thus a composite of aesthetics, safety engineering, and durability, designed to perform when the moment of impact arrives and to maintain alignment across miles of driving. The visible finish and the protected subsystems work in concert with the vehicle’s ADAS to maintain sensor integrity and calibrated performance. When considering purchase options, OEM bumpers represent the gold standard for fit, function, and long-term reliability; they are engineered for the exact model year and generation, ensuring gaps, lines, and sensor mounts remain aligned. Paint-matched finishes flow from factory palettes, and the bumper preserves the safety system interfaces, including crash sensors and timing devices. The downsides are cost and the need for professional installation. The procurement path is VIN-specific and may rely on regional networks, which can extend downtime but helps preserve safety performance. The aftermarket route offers a broader range of styling and price points. A kit might include a bumper plus lower valance or side pieces, delivering value and a refreshed appearance, but fitment varies. Some kits replicate factory geometry and provide compatible mounting, while others require additional brackets or reinforcement work to preserve sensor alignment and hood closure. The risks include material tolerances, potential reductions in crash energy performance, and the need for sensor recalibration after installation. If the bumper is not dimensionally precise, cameras or radar modules can shift, affecting adaptive cruise, collision avoidance, or lane-keeping features. Recalibration costs and software updates can add time and expense. The supplier and quality assurance thread matters. Buyers should favor parts with documented compatibility notes, clear part numbers, traceability to manufacturing standards, and warranty coverage that mirrors factory levels. VIN-linked data and compatibility documentation reduce risk, particularly for ADAS safety features and warranty claims. Sourcing from less-regulated channels may save money but introduces uncertainty about fitment, corrosion resistance, and reinforcement fitment. Practical steps: verify model-year compatibility, confirm hardware and brackets are included, check for any required recalibration steps, and gather documentation mapping the part to the VIN. Insist on a complete bill of materials for aftermarket kits, including reinforcement components, and seek warranty coverage or post-purchase support. If pursuing aftermarket, choose suppliers who can demonstrate traceability to manufacturing standards and provide clear compatibility notes and service support. The result is a risk-managed plan that preserves safety while allowing for stylistic personalization. In practice, OEM remains the most predictable path for perfect fit and preserved warranty, while a carefully chosen aftermarket kit can offer styling variety and cost savings if fitment, sensor integration, and the included hardware are validated before purchase. Regardless of path, ensure reinforcement brackets are included and correctly installed to maintain alignment and crash performance over the vehicle’s life.

Final thoughts

Understanding the intricacies of Mitsubishi Outlander bumpers empowers business owners to make informed choices regarding safety and aesthetics. The construction materials play a crucial role in meeting safety standards and providing durability, while aftermarket options allow for personal customization and performance enhancements. Choosing between OEM and aftermarket parts has significant implications for fitment and warranty services but also offers opportunities for cost management. Lastly, accessing reliable purchasing platforms ensures that business owners can find exactly what they need for their Outlander. By investing time in understanding these components, owners can enhance both the vehicle’s functionality and aesthetic appeal, thereby ensuring a lasting investment that meets their professional needs.