Mitsubishi tail lights are more than just fixtures; they are essential components that enhance safety and vehicle aesthetics. In this comprehensive guide tailored for business owners, we will delve deeply into the functionality of Mitsubishi tail lights, discussing why they are vital not just for compliance but for visual appeal as well. We’ll examine the differences between Original Equipment Manufacturer (OEM) and aftermarket options, shedding light on the best investment for your fleet. Additionally, we will focus on the rising popularity of LED tail lights, outlining their myriad benefits, as well as considerations for installation and compatibility. Finally, we’ll explore the aesthetic variations—from Euro-style to smoked options—that can personalize your vehicles while improving functionality. Each chapter will provide insights crucial to making informed decisions that align with both safety and branding goals.

Beyond Brightness: How Mitsubishi Tail Lights Balance Safety, Signal Clarity, and Style

Tail lights are more than a rear glow on a vehicle; they are a system of communication and safety that works with other drivers to organize traffic, especially when visibility drops. For Mitsubishi models, from practical workhorses to sport-oriented hatchbacks, rear illumination is engineered to perform under a spectrum of conditions. In the dark, on rain-slick highways, or when mist folds into the air, tail lights must reliably mark the presence of the car, signal braking, and clearly indicate turning intentions. This is not merely about brightness; it is about consistency of light output, the speed at which the illumination responds, and the way the light signature informs other drivers. The tail light cluster is a small, tidy piece of the car that carries a heavy job: it preserves space on the bumper and roofline while delivering a signal that is understood instantly and without confusion. The elegance of a well-designed tail light lies not only in its ability to be seen but in how quickly it can be interpreted, helping to prevent rear-end collisions and miscommunications on the roadway.

In practice, tail lights perform three core functions that underpin road safety. The first is illumination—rear visibility so others can detect the vehicle’s position even when ambient light is scarce. The second is signaling—turn indicators and braking cues that convey intended actions to following drivers. The third is compliance—tail lights must conform to local regulations and standards that specify color, brightness, and reliability. Across Mitsubishi’s range, these functions are delivered through a blend of traditional and modern technologies, with design language that maintains brand identity while meeting evolving safety expectations. The shift toward more efficient and compact light sources has transformed how these signals are perceived. When a driver looks in the mirror and sees a precise, unambiguous brake glow or a cleanly staged sequential turn signal, there is an immediate cognitive cue that reduces reaction time. In conditions such as rain, fog, or snow, a bright, well-defined tail light is often the difference between a near-miss and a safe stop. The tail light, in short, is a cornerstone of the vehicle’s nighttime safety package, integrated seamlessly into the total silhouette and the rear bumper’s geometry.

Technologies within Mitsubishi tail lights have evolved to enhance what the eye perceives from behind the vehicle. LEDs have become the standard for many modern configurations because they can produce intensely bright beams with fast response times. The brightness is not merely about raw intensity; LEDs deliver a crisp, uniform output that remains legible at a variety of distances and angles. They can be arranged to form distinctive light signatures, including dynamic features such as sequential turn signals that trace a vivid arc when a driver signals a lane change. In addition, LED modules tend to generate less heat and consume less energy than traditional incandescent bulbs, contributing to overall efficiency and longevity. The payoff is longer life—often tens of thousands of hours in real-world use—reducing maintenance intervals and replacement costs. For vehicles that are used in rugged environments or subjected to long daily commutes, the durability and reliability of LED tail lights translate directly into fewer interruptions and more consistent safety signals.

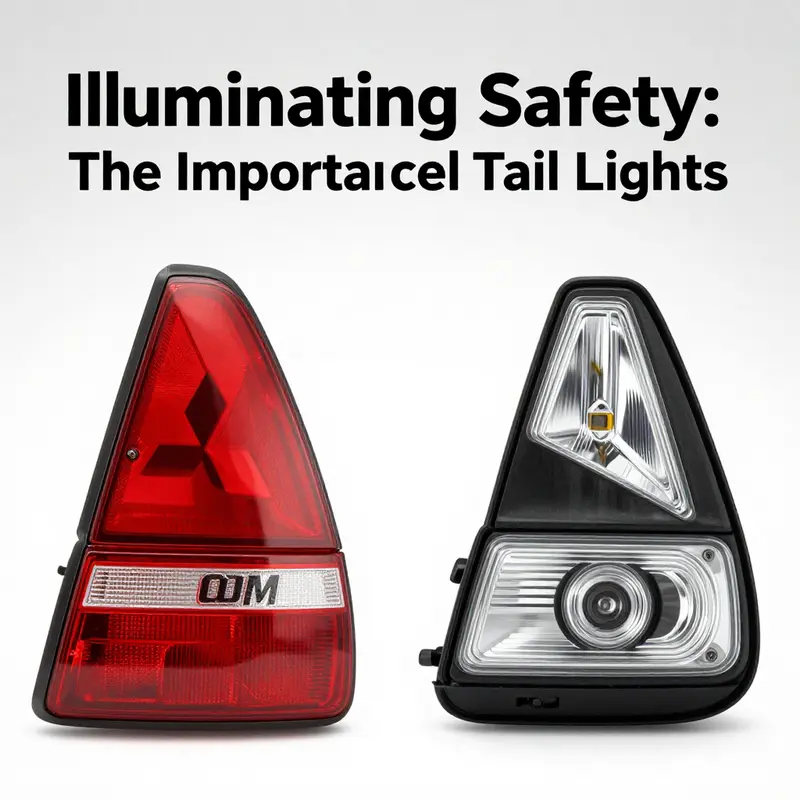

Yet not every owner is convinced that LEDs are the right choice for every application. Halogen tail lights, built around a tungsten filament within a quartz bulb and filled with halogen gas, offer a proven and affordable option. They deliver warm, familiar light and a straightforward replacement path that makes them attractive for budget-conscious buyers or for restorations that aim to preserve a period-correct look. Halogen systems, while reliable, do not match the brightness and energy efficiency of LED units, and their light output can degrade more quickly in harsh weather conditions. The slower response time of halogen signals can matter in high-speed traffic or in settings where milliseconds affect the perception of braking or turning. Still, their simplicity—the ease of replacement, the broad availability of parts, and a lower upfront price—keeps halogen tail lights relevant for many Mitsubishi vehicles, including older or more utilitarian models. In these contexts, a halogen configuration can be a sensible, economical choice that preserves the car’s original character while delivering dependable nighttime signaling.

An important aspect of tail-light design is the lens itself and how it interacts with the light source inside. Modern tail lights often feature integrated LED elements cast behind a colored or clear lens, with the housing designed to guide light through reflective surfaces that maximize visibility from different angles. The design must also account for weather extremes, from hot sun to cold rain, ensuring the seal against moisture remains intact for years. When the weather turns wet or snowy, the last thing a driver needs is a dim or uneven rear signal. The best tail-light assemblies are engineered to maintain a consistent light output, resisting moisture infiltration and maintaining color accuracy so that red signals remain universally recognizable. This is part of why OEM configurations have such appeal; they are engineered to Mitsubishi’s exacting standards, ensuring plug-and-play compatibility and predictable performance. The decision to opt for OEM versus aftermarket components is not merely about price; it is about the assurance that the tail-light system will behave as intended, preserving the intended brightness, color, and signaling pattern across a vehicle’s lifetime.

The market today also features a spectrum of style-oriented options that influence how a Mitsubishi’s rear end is perceived. Specialty styles such as Euro-inspired designs, clear lenses that reveal the internal lighting architecture, or smoked finishes that lend a more aggressive demeanor, can shift the car’s personality while preserving function. The combination of aesthetics and signaling clarity matters because drivers form visual expectations from a vehicle’s rear. A clean, well-defined brake signal communicates decisiveness, while a distinctive, modern tail-light signature can contribute to brand recognition and perceived quality. Even when the lighting serves primarily a safety function, the way it looks matters because it affects how other drivers read a vehicle’s intentions in a quick glance. A tail-light cluster that blends sharp geometry with bright, legible signals can harmonize the car’s overall design language with practical performance. For owners who crave customization, these design cues offer a way to retain Mitsubishi’s familiar profile while injecting a personal touch into the rear fascia.

From a practical standpoint, upgrading or replacing tail lights involves several considerations that extend beyond color and brightness. Compatibility with a vehicle’s electrical system—especially on newer models that rely on CANbus networks—may require resistors or error cancellers to prevent fault codes and electrical misbehavior. The potential for hiccups in signaling, such as flickering, warning messages, or rapid battery drain, underscores the importance of selecting parts that align with the car’s electrical architecture. For enthusiasts who want maximum brightness and the ability to program distinctive lighting signatures, LED tail-light assemblies can offer exciting possibilities, including dynamic braking or sequential indicators. However, the upfront cost and the need for careful matching to the vehicle’s electronics can be a drawback if a high-quality, plug-and-play solution is not chosen. Conversely, a budget-minded choice might favor halogen utilities, which, while simpler to integrate, do not deliver the same energy efficiency or longevity as LEDs. The point is that the best choice depends on how the owner uses the vehicle, what kind of driving they do most, and how much they value factors like reliability, resale value, and maintenance intervals.

The conversation around tail lights is also a conversation about maintenance and care. Sealing, moisture ingress, and the integrity of the lens seal are practical concerns that determine how long a tail-light assembly remains effective. Moisture inside the housing can fog or stain the lens, dulling the light and compromising legibility. Regular inspections for cracks, seal integrity, and moisture can help prevent the kind of performance degradation that reduces nighttime visibility. Cleaning should be done with care to avoid scratching the lens or degrading the seal, and any signs of moisture should prompt a closer look at gaskets and mounting hardware. For owners who pursue longevity and reliability, choosing a robust tail-light assembly becomes a matter of safeguarding a consistent light output over the life of the vehicle.

In the broader arc of Mitsubishi’s design philosophy, tail lights reflect a careful balance between form and function. They are not mere afterthoughts tucked away at the rear; they are integral components that influence safety performance and the vehicle’s perceived value. The ideal tail-light system respects the careful proportions of the car, remains legible in a range of lighting conditions, and offers a signal that is both quick to interpret and unmistakable. Whether the choice leans toward factory OEM units for exact fit and warranty compatibility, high-performance LEDs for maximum visibility, or cost-conscious halogens for restoration projects, the tail-light configuration is a statement that couples safety with style. It tells other drivers how the vehicle intends to move, and it does so with the quiet confidence that comes from precise engineering and thoughtful design.

For readers and buyers seeking a sense of the practical landscape, consider the value of OEM authenticity when upgrading or replacing tail lights. Factory-fit assemblies are designed to integrate with the vehicle’s circuits, meet safety testing standards, and maintain the vehicle’s resale value by preserving original specifications. In parallel, the allure of LED technology continues to grow as brightness, signal versatility, and energy efficiency advance. The choice between these paths is rarely purely about cost; it is about the alignment of vision with performance, longevity, and the road-tested reliability that comes with components designed for a particular vehicle family. It is also a reminder that the tail-light system is a dynamic part of the car’s ecosystem, capable of evolving with new lighting patterns, better materials, and smarter electronics while maintaining a clear line of sight for other road users.

In closing, the tail light cluster serves as a critical bridge between the driver and the surrounding traffic environment. It establishes visibility, communicates intent, and supports the vehicle’s overall aesthetic, but more importantly, it protects lives by providing clear, immediate signals in the moments when every second counts. The sophistication of modern Mitsubishi tail-light designs lies in their capacity to blend bright, fast-responding light sources with durable, lens-ed assemblies that endure weather, vibration, and daily use. The balance between safety and style is not merely a design concern; it is a functional mandate that ensures drivers and passengers stay safer on the road. The chapter’s reflection on the evolution from halogen to LED and the ongoing refinement of lens architecture highlights a broader truth: tail lights are a quiet, essential force in automotive safety, one that deserves thoughtful attention from buyers, owners, and enthusiasts who value clarity, reliability, and the clean lines of a well-lit rear end.

Choosing Mitsubishi Tail Lights: Weighing OEM Reliability Against Aftermarket Style and Performance

Understanding the decision between OEM and aftermarket tail lights for your Mitsubishi is about balancing reliability, cost, function, and style. Tail lights are far more than decorative pieces; they are primary safety devices that communicate braking, turning, and presence to other road users. For owners of models such as the Lancer, Evolution, Galant, Pajero / Montero, and L200, the choice affects appearance, electrical compatibility, inspection compliance, and resale value. This chapter walks through the trade-offs and real-world considerations, so you can select the right path for your priorities.

Start with what OEM means: these are units produced to the exact specifications set by the manufacturer or an authorized supplier. Fitment is precise, wiring harnesses match the factory connectors, and the lens, reflectors, and light output meet the design intent for the model. That translates into predictable performance, straightforward installation, and regulatory compliance. If your priority is maintaining the vehicle’s original character, ensuring warranty compliance, or avoiding after-sale inspection headaches, OEM tail lights are the safest option.

OEM units also bring peace of mind on longevity and performance. They use approved materials and manufacturing processes, so seals, gaskets, and plastics resist heat and UV degradation according to the original standard. That lowers the chance of moisture ingress, haze, or cracked housings in the long term. Factory parts are typically backed by a warranty that covers defects, which helps if an assembly fails prematurely. For buyers who plan to keep the vehicle long-term or sell it later with original parts intact, OEM often protects value.

However, OEM carries downsides. Cost is the most obvious. Factory assemblies are generally priced higher than many aftermarket alternatives. Design choices are limited to what was available from the factory, which can disappoint owners seeking a modern LED signature or a smoked lens look. If you want a contemporary light signature on an older Mitsubishi, OEM alone may not provide options.

Aftermarket tail lights address those gaps. Third-party manufacturers offer a wide palette of designs, from full-LED arrays and sequential turn patterns to clear, smoked, or Euro-style housings. Aftermarket units can transform the rear profile of a vehicle and often increase perceived value to buyers who prefer modern styling. Because many aftermarket lights use LEDs, they deliver brighter, quicker-responding illumination and lower power draw than typical incandescent setups.

That said, the aftermarket is a broad marketplace. Quality varies from exceptional to problematic. Premium aftermarket brands produce well-engineered assemblies with good fitment and reliable electronics. Lower-tier products may fit poorly or require modification. Beware of units that cause flicker, trigger dashboard warning lights, or produce uneven illumination. Some aftermarket LEDs draw less current, which can confuse the car’s monitoring system. To correct that, owners sometimes add resistors, load equalizers, or CANbus decoders—extra parts and labor that erode the initial cost savings.

When evaluating an aftermarket option, consider three technical dimensions: fit, seal, and circuitry. Fit affects how easily the assembly mounts and whether the trunk or tailgate closes without rubbing. A poor fit can allow water to enter the housing. Seal integrity prevents condensation that clouds lenses and reduces output. Circuitry quality determines whether the unit will handle voltage spikes, thermal cycling, and the vehicle’s multiplexed electronics. A well-built aftermarket light should include quality gaskets, properly secured connectors, and protective diodes or resistors where needed.

Style is where aftermarket tail lights truly shine. Clear housings, smoked lenses, and complex LED patterns let owners personalize their cars. Sequential turn signals add motion and improved noticeability. Integrated LED brake arrays can create a distinct light signature that stands out at night. Many enthusiasts use such upgrades to modernize older Mitsubishis or to give a custom finish to a tuned vehicle. If aesthetics are a major driver, the aftermarket will offer far more choices than OEM.

But modifications come with practical trade-offs. Aggressive smoked lenses reduce light transmission. That may be acceptable when bulbs are bright, but if the light output drops below legal thresholds you risk failing inspections or reducing safety. Some jurisdictions have strict rules about lens tint and light color. The safest route is to choose aftermarket units that state compliance with relevant standards and to test them on the vehicle before permanent installation.

A third path blends the benefits of both approaches: hybrid solutions. These use OEM housings or exact-fit shells combined with upgraded internal components—such as LED modules—that enhance performance while retaining factory fitment. Hybrids can give the cleaner installation and sealing of OEM parts with the brightness and longevity of LED technology. For owners who want a modern light signature without losing factory reliability, hybrids are an attractive compromise.

Cost vs. value is a recurring theme. Halogen-based replacements remain the most affordable for owners restoring classic models or maintaining a budget. Modern halogen assemblies burn brighter than old incandescent bulbs and are simple to replace. Yet they cannot match LED brightness, longevity, or energy efficiency. Over time, LEDs can reduce replacement frequency significantly, but they require a larger initial investment and, in some cases, electrical adaptation.

Installation complexity differs widely. OEM replacements are typically plug-and-play and can be installed with basic tools in a garage. Many aftermarket assemblies are also straightforward, but premium LED kits sometimes need additional wiring, mounting brackets, or adapters. If a unit requires resistors or a decoder, the job becomes a bit more advanced. Consider whether you will do the work yourself or rely on a professional. Labor, returns, and potential warranty work are part of the total cost picture.

Legal and inspection considerations deserve attention. Local regulations often dictate minimum light intensity, color, and visibility angles. Aftermarket lights that dramatically deviate from original specifications may fail vehicle inspections. Before purchasing, check local rules and verify that the lights are certified or clearly compliant with country-specific standards. Warranty and insurance are also factors—non-OEM modifications can impact coverage in some cases, so document purchases and consult policies if that concerns you.

Long-term maintenance considerations favor higher-quality units. LEDs last tens of thousands of hours, reducing the need for replacements. But when an LED assembly fails, it is usually replaced as a unit rather than repaired, which can be costly. OEM replacement parts can be pricey but are often stocked by dealers. Aftermarket replacements vary in availability. If you plan to keep the car for many years, think about sourcing and parts continuity.

Practical shopping tips: buy from reputable vendors, check return policies, and read installation notes. Look for assemblies that advertise corrosion-resistant connectors, proper gaskets, and multi-point mounting. Verify warranty length and what it covers. If choosing LED, ensure the unit includes proper heat management—heatsinks or thermal pads—to avoid premature failure. For plug-and-play ease, seek listings that specify compatibility with your model year and trim.

One useful resource for comparisons and fitment data is a detailed guide that compares OEM and aftermarket tail lights across real-world performance and user feedback. That resource can help you weigh options against your priorities and confirm compatibility before purchase: detailed comparison guide.

If you want to retain a factory look while upgrading performance, explore listings that match original housings but incorporate modern internals. For owners of performance-oriented models, there are authentic heritage options available from specialist sellers; for instance, listings for original JDM EVO taillight assemblies can be useful when authenticity matters, such as authentic-jdm-evo-9-mr-taillights.

Choosing the right tail light ultimately comes down to your priorities. If reliability, legal compliance, and seamless fitment matter most, OEM is the logical choice. If customization, brightness, and a contemporary look are your goals, a carefully chosen aftermarket or hybrid solution can deliver significant rewards. Take time to research fitment, read verified user reports, and confirm warranty coverage. With thoughtful selection, your Mitsubishi’s rear lighting can deliver improved safety, striking appearance, and durable performance without surprises.

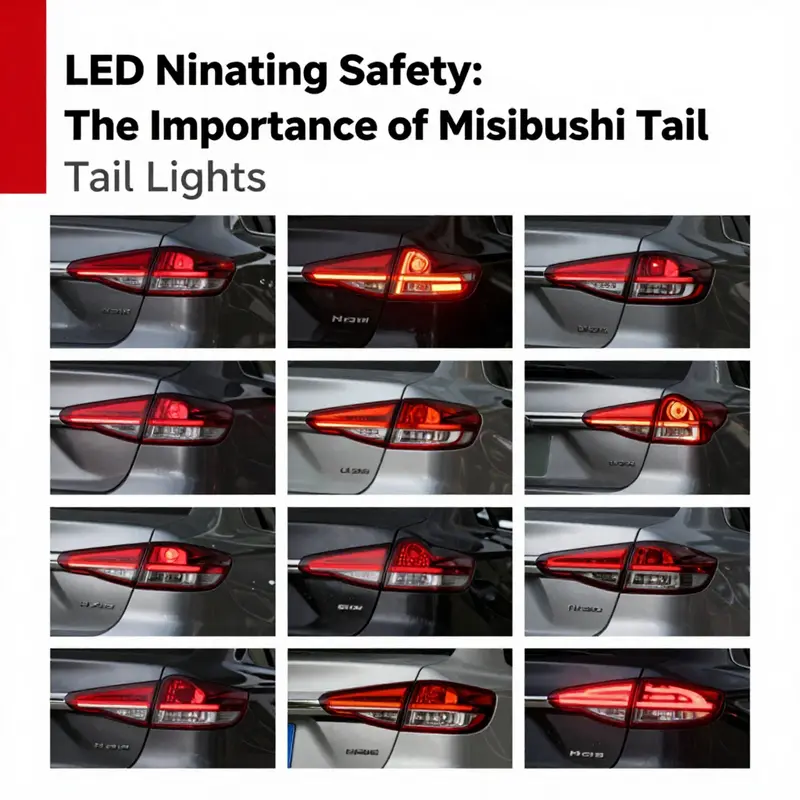

Illuminating the Road Ahead: LED Tail Lights for Mitsubishi—Bright Benefits, Real-World Considerations

LED tail lights have quietly shifted from a futuristic option to a practical standard for many Mitsubishi models. They are not just about a sharper silhouette or a cooler glow; they redefine how a vehicle communicates with the road at night. In the context of Mitsubishi’s broad lineup—from the compact Lancer family to the rugged L200 pickup and the versatile Montero Sport Pajero family—LED tails offer a blend of safety, efficiency, and style that aligns with modern driving realities. The shift toward LEDs reflects a deeper understanding that tail lights are as much about how other drivers perceive your vehicle as they are about your own visibility. When a driver approaches from behind on a dark highway, the brightness, timing, and clarity of those signals can influence reaction times and lane decisions more than many other upgrades. LEDs deliver a consistent, punchy presence that is detectable earlier and more reliably than traditional lighting, which translates into a tangible improvement in nighttime safety. The advantage is most evident in braking, where LED brake lamps illuminate with instantaneous intensity, signaling to following drivers that a stop is imminent. In adverse weather—rain, fog, or snow—the sharper edges and brighter output of LEDs help maintain a clear brake and tail light picture, reducing the chances of misinterpretation or delayed responses. This is not merely about visibility; it is about the cadence of information that a vehicle shares with its surroundings. The moment a driver taps the brake, the LED array responds with immediacy that can be the difference between a safe slowdown and a risky encounter in heavy traffic. The same immediacy applies to turn signals. Dynamic features, such as sequential signaling that sweeps from the inner to the outer edge or vice versa, provide a more legible cue to drivers behind. Even at a glance, those patterns convey intention with unmistakable clarity, which is especially valuable in dense urban settings where quick, low-amplitude driver hesitations can cascade into close calls. Beyond safety, LEDs carry a compelling economic argument rooted in longevity. Typical LED tail lights boast lifespans measured in tens of thousands of hours, often reaching or exceeding 50,000 hours with proper care. When you translate that into calendar years, the intervals between replacements can be many years apart, particularly for drivers who put modest annual mileage on their Mitsubishi. The reduced maintenance burden is not just about avoiding replacement bulbs; it also means fewer visits to the repair bay and less downtime for any tail-light related concerns. For long-term ownership, the energy efficiency of LED tail lights translates into a small but meaningful reduction in electrical load. While tail lights are not a vehicle’s primary power draw, the cumulative savings in energy use over the life of the vehicle can contribute to a smoother electrical system, especially on older models that may have a higher baseline parasitic draw. And yet, the practical appeal of LEDs extends into design psychology as well. A modern Mitsubishi communicates confidence and contemporary engineering through lighting. LED tails are a signature that immediately signals a vehicle’s alignment with current automotive design language. The aesthetic impact is subtler and more sophisticated than a simple brightness increase. They create clean, crisp silhouettes that complement the lines of the car, whether one is gazing at a sleek Lancer Evolution of a bygone era or a rugged L200 ready for work or a weekend adventure. The visual language of LEDs—glow uniformity, precise color temperature, and the potential for signature lighting patterns—lets owners tailor the vehicle’s presence to their personality. As much as LEDs deliver performance, they introduce a set of practical considerations that must be weighed before committing to a swap or upgrade. The first and most important is legality. Lighting regulations vary not only by country but by region within countries. Some jurisdictions govern color temperature, permissible brightness, flash patterns, and even the allowable width of a taillight assembly. In certain markets, aftermarket tail lights must meet specific standards to pass inspection or to remain street-legal. Owners considering an LED upgrade should verify that the target configuration complies with local rules. The potential consequences of noncompliance—fines, failed inspections, or the need to revert to stock lighting—can offset the initial appeal of a brighter signal. Compatibility is another central concern. LEDs are technologically sophisticated, and compatibility is more than a simple plug-and-play question. Vehicle electronics, including CAN buses that monitor electrical activity, may require resistors or error-cancelling devices to prevent problems such as dashboard warning lights, minor flicker, or codes in the body control module. This is particularly relevant for owners upgrading older Mitsubishi models that originally shipped with halogen or incandescent tail lights. A mismatch between the new LED assemblies and the vehicle’s electrical architecture can lead to flickering, rapid burnouts, or nuisance fault warnings. The best approach is to assess the product’s compatibility with the vehicle year, model, and any existing lighting control features. In some cases, a reputable supplier will provide guidance on required resistors, load regulators, or CANbus adapters; in others, it may be a matter of choosing a product engineered to work within a specific electrical profile. The spectrum of LED solutions is broad, and so is the price range. While the up-front cost of LEDs can be higher than traditional bulbs, the long-term value lies in the reduced replacement frequency and the potential for improved energy efficiency. It is worth considering the total cost of ownership rather than focusing solely on the purchase price. Quality varies widely in the aftermarket segment, and lower-cost units may compromise brightness uniformity, color consistency, or durability. In contrast, properly engineered LED tail lights from established manufacturers tend to deliver predictable light output, robust sealing against moisture and dust, and a warranty that provides some protection against early failures. This is not a universal guarantee, however, and buyers should seek out products from reputable sources that emphasize safety compliance and performance data. The question of aesthetics is not a trivial afterthought. Mitsubishi, like many brands, balances a vehicle’s performance with its visual language. LED tails, with their crisp light signature, can integrate more gracefully with the brand’s design philosophy than older lighting technology. The ability to tailor sequential patterns, dynamic brake signaling, or even hue accents within legal limits can offer a chance to personalize a vehicle’s appearance without sacrificing authenticity. For many Mitsubishi owners, the upgrade becomes a personal statement as much as a safety improvement. On the practical side, installation quality matters as much as the components themselves. A clean, professional installation ensures that seals remain watertight and that wiring is secured against vibration, heat, and road debris. Poor installation can lead to moisture ingress, which dulls brightness and shortens lifespan. When choosing a kit, consider whether it includes all necessary gaskets, mounting hardware, connectors, and instructions that align with the vehicle’s design. A well-executed upgrade preserves the factory look while introducing the benefits of modern lighting technology. In this context, OEM tail lights hold a distinct appeal. They offer a plug-and-play fit, tested safety compliance, and an assurance of compatibility with the vehicle’s electrical systems and warranty terms. For owners who prioritize authenticity or resale value, OEM components can be a prudent choice even if the initial cost is higher. Aftermarket options, when sourced from reputable suppliers, can deliver a similar level of reliability with the added advantage of design variety and potentially innovative lighting patterns. It is worth noting that the choice between OEM and aftermarket is not simply about cost or style. It is about the intended use of the vehicle, the owner’s willingness to manage installation considerations, and the importance placed on warranty and regulatory compliance. Beyond the technical and regulatory factors, maintenance remains a practical concern. LED tail lights generally demand less routine maintenance than halogen systems, but they are not maintenance-free. Moisture intrusion, degraded seals, or heat-related stress over time can alter light output. Routine checks after adverse weather or wash cycles help ensure continued performance. If a driver notices uneven brightness, flicker, or a delayed response when applying the brakes, it is wise to inspect the assembly for water intrusion or loose connections. A cautious approach—replacing suspect components with quality parts and verifying compatibility—helps safeguard safety without compromising visual appeal. The broader narrative around Mitsubishi tail light upgrades is anchored in realism. The brand’s models span a wide range of uses, from city commuting and family transport to rugged off-road or work-oriented duty. In every case, a tail light upgrade that emphasizes safety and reliability should harmonize with the vehicle’s original design language and performance capabilities. The Lancer’s compact precision, the Galant’s classic lines, the Montero Sport Pajero’s rugged character, the Shogun Pajero’s expedition-ready stance, and the L200’s practical utility all benefit from lighting that is consistent, legible, and enduring. The final calculus for any owner considering LED tail lights hinges on three pillars: legality, compatibility, and value. Legality ensures the upgrade remains within the bounds of local regulations and inspection standards. Compatibility ensures the electrical architecture, mounting points, and sealing systems cohere with the new tail light assemblies. Value captures the total ownership costs, including initial price, potential maintenance, and the experiential payoff of brighter, more informative signaling on the road. For enthusiasts who want to go beyond mere function, LEDs offer a canvas for subtle personalization—within lawful limits—to express a contemporary identity that resonates with the latest automotive styling trends. In practice, the best path forward is to approach an LED tail light upgrade as a carefully planned enhancement rather than a impulsive swap. A methodical approach begins with research into the specific model year of the Mitsubishi in question, followed by consultation with trusted sources about regulatory requirements and installation considerations. A reputable supplier can provide technical guidance on whether resistors or CANbus modules are necessary and, more importantly, can help identify products designed to deliver uniform brightness, color stability, and reliable sealing. For those who value a clean, factory-like upgrade with fewer questions about fit and warranty, OEM components remain a compelling option. For others who prize design variety, advanced signaling features, and potential long-term savings, a high-quality LED aftermarket tail light can be an attractive alternative when properly vetted. The overarching goal is not merely to brighten the night but to reinforce safety and clarity on every drive, no matter the journey. As the road ahead grows darker, the signal you send with your tail lights should be unmistakable, quick, and compliant with the rules that govern the roads we share. In the end, LED tail lights for Mitsubishi vehicles embody a convergence of safety science, design sensibility, and practical ownership considerations. They reflect a modern understanding that good lighting is an essential, continuous dialogue between a vehicle and its environment. This chapter has traversed the benefits—instant brightness, longevity, energy efficiency, and aesthetic refinement—while acknowledging the realities of legality, electrical compatibility, and total cost of ownership. For readers who are ready to explore further, a trusted external resource offers technical detail and safety-focused analysis that complements the considerations outlined here. External reading: https://www.mitsubishitaillight.com/led-tail-lights-mitsubishi-technical-details

Style and Signal: How Mitsubishi Tail Light Aesthetics Shape Identity and Safety

Style and Signal: How Mitsubishi Tail Light Aesthetics Shape Identity and Safety

Tail lights no longer exist only to mark a vehicle’s rear at night. For Mitsubishi models, they have become a design language. They express trim level, age, and owner intent. They also communicate critical information to other road users. This chapter traces how aesthetic variations in Mitsubishi tail lights balance style with function. It explores the major visual trends, the trade-offs buyers face, and practical considerations when personalizing a vehicle’s rear lighting.

Modern Mitsubishi designs embrace integrated lighting systems. Lenses sculpt with body lines. Light signatures form recognizable patterns. These patterns can be subtle rings, horizontal bars, or angular clusters that echo a model’s front-end geometry. Where older models used simple bulbs behind red plastic, new units use arrays of LEDs arranged to create consistent shapes. This shift from single-point illumination to distributed light sources changes how a car reads from a distance. A crisp LED pattern reads as modern and purposeful. A diffuse halogen glow reads as classic and familiar.

Among the most visible trends are sequential turn signals and dynamic braking effects. Sequential signaling uses multiple LEDs in a timed cascade to indicate direction. It offers a clear motion cue, improving perceptibility over a static blinking bulb. Dynamic brake lighting can ramp brightness or flash under emergency braking. These features increase reaction time for following drivers by presenting more salient visual cues. They also create a distinct visual identity for a vehicle at night. On models such as the Lancer Sportback and certain crossover trims, these effects have become part of the design brief rather than merely optional upgrades.

Beyond technological shifts, stylistic families have emerged. Euro-style tail lights favor minimalist forms, often with clear outer lenses and internal LED arrays. They aim for restrained elegance. Clear tail lights emphasize transparency and precision. Their polished housings reveal organized LED modules or reflective surfaces, producing a high-tech look. Smoked or blacked-out tail lights, in contrast, offer aggression. Tinted lenses mute red and amber tones during the day. At night, carefully engineered internal reflectors preserve visibility while maintaining a stealthy appearance in daylight. Chrome accents or layered elements still appear in many designs. They add perceived depth and catch ambient light, which enhances presence.

Halogen-based assemblies remain part of the palette, especially for restoration projects or budget builds. Their warm amber hues and traditional bulb glow suit older vehicle lines. They are inexpensive and broadly compatible. Many owners choose halogen for period-correct restorations where authenticity matters. However, the rising expectation for crisp LEDs means halogen units look dated beside newer units. For owners who prefer classic aesthetics, the choice becomes intentional rather than accidental.

Aftermarket options amplify stylistic variety. Some assemblies keep OEM fit and finish while altering internal layouts. Others rehouse lights in heavily modified shells that alter the vehicle’s perceived stance. Custom lens patterns, lens colors, and accent LEDs give owners tools to match their vehicle to a theme. But these choices involve trade-offs. Many aftermarket styles require careful selection to maintain legal compliance. Tinted lenses, for example, may reduce visible light output below regulatory thresholds. Other modifications can change bulb circuitry, causing errors on modern vehicles with monitoring systems. Owners should weigh aesthetic gain against compliance, reliability, and resale value.

OEM replacements continue to have strong appeal. They preserve factory appearance and fit without additional wiring changes. For owners focused on authenticity or who plan to sell, OEM units protect resale and simplify installation. They are designed to meet regulatory standards and to integrate with vehicle wiring and diagnostic systems. Yet they rarely push creative aesthetics. For buyers seeking a distinct look, the aftermarket provides more options, but at a cost in terms of fit, warranty, or electronics compatibility.

LED conversions are the most common performance-driven aesthetic upgrade. LEDs free designers from the constraints of filament geometry. They allow thin light bars, sharp edges, and precise cutoff lines. They also consume less power and last longer. The visual crispness of LEDs influences a vehicle’s perceived quality. However, not all LED products are equal. High-quality assemblies use well-engineered optics to avoid hotspots or uneven brightness. Poorly designed LEDs can look garish or create distracting glare for other drivers. On electrical systems with sophisticated monitoring, LEDs may trigger error codes. Solutions like resistors or CANbus adapters exist, but they add complexity and potential heat points.

Color temperature and hue factor into aesthetics as well. Traditional brake lights are deep red because that wavelength reads as urgent and is strongly regulated. LED technology allows slight tuning within the red spectrum. Cooler reds can read brighter, while warmer tones can feel richer and more classic. Turn signals also vary. Amber remains the most universally legible choice, but some designs blend amber and red elements to achieve a signature look. Choosing the right hue requires balancing distinctiveness with legibility. Visibility should remain the primary focus.

Material choices and finish quality also shape perception. Lenses crafted from high-grade polycarbonate resist yellowing over time. UV-resistant coatings preserve clarity. Internal reflectors with chrome-like finishes maintain brightness even when LEDs fail. Lower-cost assemblies may use cheaper plastics that haze quickly. Over time, even a well-styled unit can lose its aesthetic edge if materials degrade. Proper maintenance, including gentle polishing and UV protection treatments, extends both functionality and appearance.

Integration with bodywork is a subtle but crucial aspect. Tail lights that align with panel gaps and flow with the bumper and hatch lines look factory-fitted. Ill-fitting assemblies reveal cheap aftermarket origins, even if the light style itself is attractive. Designers often use light clusters to extend perceived vehicle width at night. Horizontal light bars or extended reflectors can make a compact car feel lower and broader. Conversely, vertical or stacked elements emphasize height and solidity, which suits SUVs and trucks.

Customization goes beyond the lens. Trim rings, bezels, and inner housings influence the perceived depth of a light. Blacked housings reduce perceived bulk and emphasize the illuminated elements. Chrome or polished accents boost perceived premium quality. Some owners choose accent LEDs within the housing to layer color and create depth. These design choices must account for heat management. LEDs produce concentrated heat at small points. Proper thermal pathways, heat sinks, and ventilation prolong life and performance.

Legal and safety considerations steer many styling choices. Regulations vary by market, defining minimum luminous intensity and acceptable lens colors. Tinted or smoked designs can inadvertently reduce output below legal levels. Sequential or dynamic features must still meet flash rate and intensity regulations to be compliant. Tampering with wiring for aesthetic flares can disable safety checks or airbags in rare electronic systems. Smart customization balances creative desires with compliance and safety.

Practical selection advice starts with clarity about goals. Are you seeking subtle modernization or a radical restyle? For subtle updates, OEM-style LED units maintain factory fit while improving performance. For bold change, Euro or smoked styles offer a distinct stance. When choosing, inspect materials, lens coatings, and internal reflectors. Verify thermal management for LED upgrades. Confirm compatibility with vehicle electronics and any diagnostic systems. Check whether resistors or adapters are required and whether those components are included. Seek sellers who provide clear fitment data for your model year and trim.

Installation quality matters. A professional installation avoids water ingress and misalignment. Proper sealing protects internal electronics and prevents fogging. Correctly routed wiring prevents chafing and connector strain. If color-matching is important, evaluate the whole rear ensemble. Replacing tail lights while leaving an older bumper or hatch may create visual mismatch. In some cases, swapping complementary parts—diffusers, trim rings, or bumper reflectors—creates a cohesive rear aesthetic.

Maintenance keeps aesthetics and function on point. Clean lenses with non-abrasive cleaners. Avoid harsh chemicals that strip UV coatings. Periodically check seals and vents. For LED arrays, monitor for dimming or flicker which indicates a failing driver or poor thermal performance. Address issues early to prevent moisture damage and electrical faults.

Finally, consider the long-term value. Customized tail lights may delight the owner but complicate resale. Keep original parts if you plan to return vehicle to stock. Where authenticity matters, OEM replacements retain market value. For enthusiasts who keep vehicles longer, high-quality aftermarket units deliver personalization and elevated performance. As lighting trends continue toward refined LED signatures, owners can shape their vehicle’s personality without sacrificing critical safety features.

For real-world options and current replacement styles, researching reputable suppliers helps. Explore assemblies that promise fitment for your model and year. One useful example of modern tail lamp offerings is a recent product page that lists contemporary replacement lamps suited to recent model years: https://www.alibaba.com/product-detail/2024-2025-Style-Tail-Lamps-for-Mitsubishi_1600738798187.html

For enthusiasts seeking period-correct or JDM-inspired options, there are many specialist resources focused on authentic designs. One relevant resource discusses authentic Evo taillight options for collectors and restorers: authentic JDM Evo 9 MR taillights. Use such resources to compare fit, finish, and compatibility with your vehicle.

When style and signal are treated together, tail lights become more than accessories. They become defining elements. Thoughtful choices enhance safety, maintain compliance, and create an unmistakable visual identity at the rear of the vehicle. Whether you favor OEM authenticity, subtle LED modernity, or bold smoked designs, the best approach balances aesthetics with dependable illumination and long-term durability.

Final thoughts

Investing in quality tail lights for your Mitsubishi vehicles is not just a matter of safety; it reflects on your brand and commitment to excellence. Understanding the functionality and importance of these components, distinguishing between OEM and aftermarket options, and exploring the advantages of LED technology equip you with the knowledge to make the best choices for your fleet. Furthermore, the aesthetic possibilities available through specialty styles provide a unique opportunity to enhance your vehicle’s appearance while maintaining functionality. By proactively considering these factors, you ensure that your vehicles are not only safe on the road but also represent your business with pride and professionalism.