The Mitsubishi Lancer Evolution X is not just a car; it’s a legacy of performance and engineering excellence. One of the crucial components that contributes to its iconic design and functionality is the hood. For business owners in the automotive sector, understanding the intricacies of OEM hoods for the Lancer Evo X is essential. This article delves into the composition and quality standards of OEM hoods, outlines their advantages, presents potential limitations, and explores market availability and pricing. Each chapter builds upon the previous one to provide a comprehensive overview that empowers business owners, ensuring they can make informed decisions when it comes time to offer OEM hood replacements to clients.

The OEM Hood Advantage: Fit, Finish, and Long-Term Value for the Lancer Evolution X

When replacing the hood on the Lancer Evolution X, most owners weigh aesthetics against fit and long-term reliability. The hood is more than a cosmetic panel; it anchors weather sealing, sensor alignment, and the car’s front-end geometry. An OEM hood is manufactured to the exact factory specifications, ensuring precise mounting point alignment, uniform edge gaps, and compatibility with the existing paint system. This makes installation straightforward, preserves the factory silhouette, and maintains the Evo X’s aerodynamic balance.

Materials and finish matter. OEM hoods for the Evo X are typically stamped from galvanized steel with corrosion resistance designed for a wide range of climates. The standard fabrication steps—controlled thickness, proper forming, a primer layer, and a factory-applied topcoat—help anchor durability, resist stone chips, and deliver color and gloss that age consistently with the rest of the bodywork.

Reliability and safety are central to the OEM choice. The hood must align with the latch, sensors, and drainage paths without substantial adjustment. When sensors monitor hood position or rain sealing, predictable tolerances prevent false readings and misalignment. Factory controls ensure the hood leaves the plant within spec, helping to preserve warranty coverage and dealer support.

Value and resale considerations. While OEM parts can carry a higher upfront cost, they contribute to resale value through accurate paint matching, consistent finish, and uninterrupted warranty compatibility. For many owners, the long-run benefits of factory-backed fit and service access outweigh the initial price premium.

Bottom line: for drivers who prioritize authenticity, reliable performance, and straightforward maintenance, the OEM hood represents the safest and most predictable choice. It upholds the Evo X design intent—fit, finish, and function—without the trade-offs that can accompany certain aftermarket alternatives.

Preserving Original Rhythm: The Durable Case for an OEM Hood on the Lancer Evo X

When a car carries the kinetic personality of a tuned engine and a chassis tuned for cornering precision, the hood is more than a sheet of metal. It is a statement of how the vehicle perceives itself and how the owner intends to preserve that identity. For the Lancer Evolution X, a model whose reputation hinges as much on its massaged aerodynamics as on its intercooler chatter, choosing an OEM hood is more than a maintenance decision. It is a deliberate design choice that reinforces the car’s factory balance, fit, and long-term reliability. The appeal rests not just in a perfect gap or a factory-applied color, but in the way an OEM hood supports the creature comforts of ownership: a seamless fit with existing hardware, predictable performance, and a warranty-backed peace of mind that aftermarket alternatives rarely match. In a world where a hood can be a visual centerpiece, the OEM option offers a quiet certainty that the Evo X’s lines will remain true to the day it rolled off the showroom floor, and that its underlying engineering will continue to be accessible, serviceable, and safely integrated with the vehicle’s broader system design.

At its core, the core advantage of an OEM hood is fitment. The Evo X was engineered with mounting points, latch systems, hinge geometry, and panel gaps that were carefully calibrated to deliver a particular front-end silhouette and aerodynamic profile. When a hood is sourced from the same manufacturing lineage as the original, those relationships stay intact. There is no need to guess about bolt locations or to improvise around altered mounting points. The OEM hood slides into place with a precision that reflects the engineering discipline Mitsubishi applied during the vehicle’s initial development. This exact fit translates into seamless bodywork around the hood edges, consistent panel alignment, and a front fascia that closes with the same tactile feel a seasoned owner expects from a factory-new panel. That reliability is not merely cosmetic; it reduces the risk of rattles, wind noise, and misalignment that can creep in when non-OEM parts are forced to play catch-up with the rest of the car’s geometry.

Color and finish sit at the intersection of aesthetics and practicality. OEM hoods, produced by Mitsubishi or its licensed suppliers, come pre-painted to match the factory color. This feature is not simply a convenience; it is a crucial component of the vehicle’s overall surface harmony. A factory-matched hood eliminates the often expensive and time-consuming paint-matching process, which can escalate costs when color variations arise from environmental exposure, painting variations, or suboptimal color mixing. The result is a surface that looks intentionally uniform across the entire front end, preserving the Evo X’s line and the subtle interplay of light on its contours. For many owners, this means avoiding the visual disturbance that can occur when a mismatched shade sits awkwardly next to the surrounding panels, and it means avoiding the cost and risk of repainting the entire front end just to restore visual cohesion.

Beyond fit and finish, OEM hoods carry the intangible but meaningful value of compatibility with factory mounting points. When the hood is built to factory specifications, it aligns with the same hinges, latch assemblies, and under-hood hardware that the vehicle originally used. This compatibility simplifies installation and preserves the integrity of the vehicle’s warranty and dealer-service avenues. The knock-on effect is a smoother service experience. Maintenance intervals, inspections, and potential recalls connected to the hood structure remain straightforward under the umbrella of dealer networks and official guidance. In a vehicle as performance-focused as the Evo X, where every component bears on how quickly and safely you can transition from street to track-inspired performance, this level of predictability matters.

On the safety and performance front, OEM hoods meet the standards that governed the Evo X’s initial design. They are tested to meet the original engineering criteria, including crash-safety considerations, impact resistance, and their interaction with the vehicle’s aerodynamics under a range of driving conditions. The hood’s stiffness, the integrity of its skin, and the way it behaves under wind load all contribute to the car’s overall performance envelope. An OEM hood is designed to cooperate with the hood latch, the struts, and the engine-compartment layout in a manner consistent with factory testing. This results in a predictable closing force, reliable latch engagement, and consistent hood alignment after countless opening and closing cycles. Those small, often overlooked details accumulate into a more confident ownership experience, especially when rainy days, highway speeds, or spirited canyon runs demand quick, repeatable access to the engine bay without the added worry of misalignment or misfit.

Weight is one of those pragmatic realities owners weigh when considering a hood. OEM hoods tend to be heavier than some aftermarket alternatives because they adhere to factory materials and thickness specifications designed to uphold rigidity and safety standards. The Evo X itself was engineered with a certain mass distribution in mind, and a factory-reproduced hood aligns with that mass distribution; it reinforces predictable feedback through the steering and chassis at the limit, rather than chasing a potential weight reduction at the expense of structural integrity. For drivers who prefer a balanced, reliable platform that performs consistently across a full spectrum of driving contexts, that trade-off often feels worthwhile. The assurance that the hood will respond in a known way when cooling demand and air pressure shift across a corner is a quiet but lasting benefit that takes on greater significance the longer one holds onto the car.

Durability and reliability form another important axis of consideration. OEM hoods are built to Mitsubishi’s quality and safety standards, and they often come with warranty support and dealer-service backing. This is not merely about having a repair option if something goes wrong; it is about confidence in the car’s long-term value. The Evo X is a car that can command strong resale interest in part because it preserves that sense of factory authenticity when maintained with factory-referenced parts. A factory hood reduces the sense of an “assembled from pieces” impression that can accompany heavily modified or aftermarket-focused builds. It preserves the car’s narrative arc—the story of a vehicle designed to perform at high levels, with every part contributing to a coherent performance envelope. For owners who want to protect that narrative as their car ages, the OEM hood offers a straightforward path to maintain the authenticity of the original design without needing to chase a bespoke, potentially less durable safety solution.

However, the choice to go with an OEM hood is not without its considerations. For some Evo X enthusiasts who chase weight savings or a more aggressive aesthetic, aftermarket alternatives offer a wide range of materials, shapes, and styling cues. Carbon-fiber hoods, lighter alloys, or hood designs with aggressive scoops can contribute to a perceived performance advantage or a bold street presence. Yet these gains can come with trade-offs—cost, certification, impact on warranty, and potential mismatch with the rest of the car’s structural suite. The OEM path prioritizes authenticity and reliability over the thrill of a head-turning alteration. It is a deliberate decision to preserve the car’s factory balance, its long-term serviceability, and the confidence that a standing warranty or dealer support will cover the vehicle should any issue arise.

Buying decisions for an Evo X hood often hinge on miles, climate, and how the car is used. A hood that has endured sun, rain, and road salt will have faced the same environmental challenges as the rest of the vehicle. OEM options provide a controlled path for maintenance and restoration, especially in regions where dealer networks emphasize original parts for safety and compliance. New or used OEM hoods can be found for the 2008–2015 Evo X, with conditions ranging from showroom-new to lightly used. The choice between new and used may come down to budget, the availability of paint-matched finishes, and the owner’s willingness to accept potential micro-damage from prior use. Regardless of condition, a genuine OEM hood holds its value better than many aftermarket alternatives when the goal is long-term reliability and an unbroken visual lineage from showroom to today.

For readers weighing the practicalities of replacement, it helps to view the OEM hood as part of a broader ownership strategy. The hood interacts with cooling ducts, the radiator support, and the engine bay harnesses in ways that influence service accessibility. A factory-reinforced hood will not obscure important inspection points, nor will it necessitate re-engineered accessories or re-routed wiring in order to fit properly. This predictability is especially valuable for owners who drive their Evo X every day and still owe a piece of ownership to the car’s original design philosophy. The decision to pursue an OEM hood can thus be framed as a choice to keep the car’s identity intact while simplifying maintenance and safeguarding resale value. In a model where performance and practicality must walk a careful line, preserving that balance just makes sense.

For those who prioritize a visually seamless presentation without compromising the vehicle’s core values, the OEM option provides a compelling path. The aesthetic benefit is immediate—a front-end that looks as cohesive as when first driven off the lot. The functional benefits, meanwhile, remain consistent with the car’s engineering heritage. The hood closes with familiar confidence, the paint matches alongside the rest of the body, and the installation aligns with the factory blueprint. In short, the OEM hood is not merely a part; it is a continuation of the Evo X’s original design intent, offering a straightforward route to sustained reliability, easier maintenance, and preserved value over time. Those who choose this route often discover that they’re not choosing a mere replacement, but a steadfast ally in maintaining the car’s authentic, uncompromised character.

For readers who want to explore specific options, one practical route is to consider genuine OEM Evo X hood offerings that align with the vehicle’s color and trim. This can be particularly relevant if a color-matched restoration is a priority or if dealer support and warranty coverage are strong considerations. When evaluating options, look for clear alignment with factory mounting points, verified color-matching capabilities, and documented compatibility with the Evo X’s hood latch and hinge system. In doing so, owners can preserve the Evo X’s careful proportional balance and the car’s faithful performance profile without sacrificing peace of mind. If you are curious about a factory-accurate option that aligns with the Evo X’s original look, you can explore the specific OEM Evo X hood offering here: OEM Evo X hood (phantom black, U02).

Ultimately, the choice to invest in an OEM hood is a statement about how a car owner views the Evo X’s design language and long-term reliability. It is a decision grounded in exact fit, factory color fidelity, and compatibility with the car’s established mounting points. It is a decision that accepts some trade-offs in weight and styling diversity in exchange for confidence, serviceability, and resale value. In the context of a vehicle whose handling, turbocharged response, and all-wheel-drive system reward consistent, predictable behavior, the OEM hood becomes more than a piece of hardware. It becomes a quiet guarantor that the Evolution’s front-end geometry will remain aligned with the rest of the car’s engineering intent. For enthusiasts who value these attributes, the OEM hood offers a straightforward path to maintain the Evo X’s factory rhythm while continuing to enjoy the vehicle’s performance-centric personality. For those readers seeking an authoritative source on official guidelines and specifications, the official manufacturer page remains a solid reference for how Mitsubishi envisions the Evo X in its own design language. Further official specifications can be found here: https://www.mitsubishi-motors.com/vehicles/lancer-evolution/x.html.

When Factory Fit Meets Real-World Limits: Understanding OEM Hoods for the Lancer Evo X

When Factory Fit Meets Real-World Limits: Understanding OEM Hoods for the Lancer Evo X

An OEM hood for the Lancer Evo X carries a clear promise: exact fit, factory finish, and engineering matched to the rest of the vehicle. That promise is valuable. Still, it comes with trade-offs that affect owners differently depending on goals and driving habits. This chapter looks closely at those trade-offs. It unpacks the practical limitations of factory hoods, explains why they matter to owners and drivers, and offers a framework for balancing authenticity against performance, appearance, and long-term ownership costs.

The most immediate limitation people notice is material and durability. Factory hoods are almost always stamped from relatively thin gauge steel. That choice reflects original design priorities: cost control, crash performance, and consistent manufacturing. Thin steel is easy to form into complex shapes and to weld into assembly lines. But it dents more readily than thicker steel or composite alternatives. Small parking-lot dings and minor road debris strikes leave visible impressions. Paint chips expose bare metal quickly, and if moisture and road salts reach those spots, corrosion can begin beneath the paint. Left unaddressed, a small chip can grow into rust, then into a bigger patch that requires cutting, welding, and repainting. For drivers who park outdoors or in crowded urban environments, the increased susceptibility to dents and chips is a real maintenance consideration.

Weight is another practical constraint. An OEM steel hood is heavier than many aftermarket options. Performance-focused owners often look to reduce mass high on the vehicle to improve handling and steering response. Replacing the factory hood with a lighter material can lower the center of gravity and improve yaw characteristics. With the factory hood retained, those marginal gains are harder to realize. A heavy hood also affects how the bonnet behaves when opened and closed, and it places additional cyclical loads on the hinges and latch. Over many years, that added weight may accelerate wear in hinge assemblies. For drivers content with street use and daily comfort, the extra weight usually has negligible impact. For track-focused owners, though, every kilogram counts.

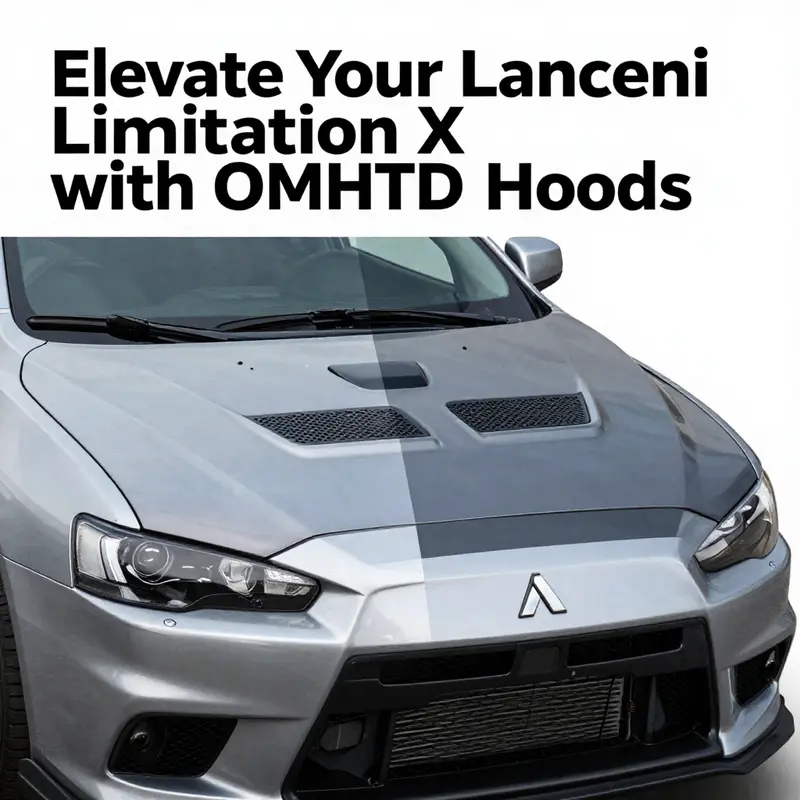

Closely tied to material and weight are the limitations in performance and visual upgrades. OEM hoods are engineered to meet the original vehicle’s aerodynamic, airflow, and pedestrian-safety requirements. They do not include functional or stylistic enhancements such as integrated vents, scoops, or aggressive contours that redirect airflow for brake cooling or engine bay ventilation. Aftermarket hoods often introduce large vents, ram-air inlets, or cowl designs that actively alter under-hood temperatures and aerodynamic balance. By contrast, a factory hood preserves the stock airflow profile and engine bay thermal behavior. For some owners, that is preferable. For others, it limits the potential for meaningful cooling upgrades, especially when other engine and cooling mods are present.

Styling options are likewise constrained. An OEM hood generally offers only factory colors and finishes, along with the possibility of repainting to match a bespoke color. It rarely allows for the dramatic visual choices found in the aftermarket: exposed carbon fiber weaves, matte finishes, or sculpted vent arrays. Owners seeking to stand out visually may find the OEM look too conservative. At the same time, that conservative look preserves the car’s original lines. That preservation is a benefit when originality is important for shows, registrations, or resale.

Fitment compatibility is a double-edged sword. The factory hood fits perfectly to existing mounting points, latch systems, and bonnet alignment tolerances. That precision eliminates the need for bodywork or gap-filling adjustments. It also ensures compatibility with factory safety systems and hood-related sensors where present. However, this same fit can make integrating aftermarket components more challenging. If you want to add aftermarket vents or modify the hood to improve airflow, the factory hood’s thin steel makes cutting and reinforcing necessary. Reinforcement requires careful welding and structural work to maintain rigidity and safety. Aftermarket hoods are often sold with pre-cut vents or are built from materials that tolerate more aggressive modification without losing structural integrity.

Repairability and long-term cost form another critical angle. OEM replacement panels are straightforward to repair. Body shops can source matching parts and color codes easily, and repairs typically restore the vehicle to near-factory appearance. But repairs to thin steel can be frequent and recurring if the car sees daily exposure to hazards. Conversely, composite or thicker aftermarket hoods may resist small impacts better but often require different repair processes and materials. For instance, bonded carbon fiber repairs need specialist skills. The choice between easier conventional repairs and potentially fewer repairs but more complex procedures becomes a practical budget decision.

Warranty and dealer support represent a real advantage for OEM parts. Most factory hoods come with warranty coverage and predictable quality assurance. If a part fails due to manufacturing reasons, dealer support simplifies replacement and inspection. That advantage translates into lower anxiety for many owners. The trade-off is that warranty-backed parts adhere strictly to original specifications. They do not offer factory-backed performance enhancements. Owners looking to improve track performance or to run modified engines will not find factory options that meaningfully change weight, cooling, or airflow.

Corrosion behavior deserves focused attention. The factory hood’s paint system and anti-corrosion treatments match the vehicle’s original assembly standards. When maintained properly, they provide long life. Yet, because steered design emphasizes thin metal, a breach in the protective finish can lead to faster rusting than with thicker metals or certain composites. Regular inspection and prompt touch-up of chips become non-negotiable habits for owners who want to keep the OEM hood in top condition.

Ownership goals determine how limiting these factors feel. If you value originality, easy repairs, warranty coverage, and predictable resale value, an OEM hood aligns well with those priorities. If you target lap-time improvements, aggressive styling, or significant weight reduction, the OEM hood becomes a limiting factor. Many owners find a middle ground: retain the factory hood initially for insurance and resale reasons, then move to an aftermarket option later when a car becomes a dedicated track or show vehicle.

There are practical strategies to mitigate OEM limitations without abandoning factory parts. One is proactive maintenance: frequent inspections, paint correction, and touch-up work greatly reduce corrosion risk. Simple protective steps, such as applying a clear film to vulnerable leading edges and parking with cover or shelter, extend longevity. Another is selective reinforcement. If modification is necessary, work with a reputable body shop to reinforce cut areas correctly. Reinforcement restores stiffness and preserves crash behavior when venting or scooping the hood.

For owners who want improved thermal management while keeping the factory hood, targeted cooling upgrades elsewhere can compensate. Upgrading intercooler plumbing, improving radiator efficiency, or adding ducting under the bumper can reduce the need to alter the hood for airflow. These choices keep the car visually and structurally stock while addressing thermal limitations.

Finally, consider resale and documentation. An OEM hood carries weight in the used market. Buyers who value originality often pay premiums for cars with factory panels and color. If resale value matters, keeping an OEM hood in good condition, or replacing it with an OEM part after damage, makes financial sense. When modifications occur, keep records and receipts. Proper documentation for any aftermarket hood or reinforcement work reduces buyer uncertainty.

If you need a quick reference, remember three truths. One: OEM hoods deliver fit and finish unmatched by most aftermarket panels. Two: they sacrifice weight savings and aggressive venting. Three: careful maintenance and strategic upgrades can reduce their practical limitations while preserving authenticity.

For owners researching replacement options, a factory hood remains the right choice for many. If you prioritize authenticity, warranty support, and straightforward repairs, it checks the right boxes. If you prioritize track performance or unique styling, the limitations documented here explain why many owners look beyond the factory bonnet. For a direct example of an OEM hood option and its factory finish, see this OEM Evo X hood listing (08–15 Phantom Black).

Balancing authenticity and ambition is central to any decision about the hood. This chapter unpacks the trade-offs so you can weigh them against your own priorities. Choose based on how you drive, how long you keep cars, and whether maintenance simplicity or performance gains guide your choices.

Under the OEM Hood: Navigating Availability, Fit, and Value for the Lancer Evo X

When a carmaker designs a hood, it is not just a piece of metal. It is a carefully engineered component that contributes to the vehicle’s aerodynamics, safety, and visual harmony. For the Lancer Evolution X, an OEM hood represents more than a replacement part. It is the closest thing to a factory reassembly, a guarantee that every mounting point, hinge, hood latch interface, and contour will align with the fenders and the cowl. In a market crowded with aftermarket options and gray-market alternatives, OEM hoods stand out for drivers who prize authenticity, warranty coverage, and a finish that matches the original factory paint. In practical terms, this means a precise fit that minimizes the time and guesswork required to reinstall, plus the assurance that the hood meets Mitsubishi’s safety and structural standards. Yet this exactness comes with tradeoffs. OEM hoods are typically crafted from thin gauge steel, which, in comparison to some lighter aftermarket rivals, can feel heavier and, if subjected to careless handling or parking lot incidents, more prone to dents or paint chipping. The reality is that OEM equality in fit does not automatically translate into lighter weight or enhanced performance; the door to weight savings is often closed by the factory’s materials choice and safety margins. Owners who value the factory look and the confidence of dealer-backed service must weigh these realities against the benefits of a true factory replication. From a market perspective, the availability of OEM hoods for the Lancer Evo X has grown more complex as global supply chains and licensing arrangements shape how parts move from the factory to the driveway. OEM hoods are still sourced through licensed suppliers and manufacturers who adhere to Mitsubishi’s original specifications, ensuring a seamless integration with the vehicle’s bodywork. The result is a finish that can be paint-matched to the car’s original color, a crucial factor for anyone repairing a damaged panel without altering the aesthetic continuum of the vehicle. In theory, this should make OEM hoods straightforward replacements for anyone who wants the look and function of a factory assembly. In practice, the market reveals a more nuanced picture, especially for owners outside the dealership network or those repairing older Evo Xs that have accumulated miles and miles of parking-lot door dings. As of early 2026, the landscape is shaped by a mix of procurement channels and regional availability. Several suppliers on international platforms include OEM-compatible hoods listed for the Evo X, often at prices that reflect bulk manufacturing efficiencies and the overhead savings of large-volume sellers. Price, as one would expect, is a function of several variables: whether the hood is a new factory part or a certified-used replacement, the integrity of the paint finish and warranty backing, the stated thickness of the steel, and the logistics costs tied to shipping and handling. Buyers frequently encounter a spectrum where the cost premium for OEM fit and finish sits above generic aftermarket options, but the additional value comes in the form of guaranteed compatibility with factory mounting points and a factory-developed shaping that prevents gaps or misalignments that can otherwise plague imperfect replacements. In practical terms, this means a buyer can expect better predictability of the install outcome when choosing OEM—a critical factor for owners who are balancing downtime, repaint costs, and potential re-qualification of body panels after a collision repair. Among the channels driving availability, direct factory replacements and authorized dealership networks remain the most dependable avenues for true OEM hoods. They offer the peace of mind that the part has not been altered or compromised by third-party fabrication. However, these channels can also entail longer lead times and higher price tags, especially for Evo Xs produced within a certain window or for models with limited remaining new-old-stock. For those who are open to non-dealer avenues, the market has seen an uptick in listings from licensed suppliers who claim to reproduce OEM-grade hoods that conform to Mitsubishi’s specifications, sometimes with paint-ready finishes or primer-ready surfaces for dealers to complete the color-match. These options can present a compelling balance of fit and cost, particularly for independent repair shops or enthusiasts who need a reliable, factory-accurate component but without the overhead of a boutique dealer network. The key, as ever, is verification: confirming part numbers, validating compatibility with the hood latch and hinges, and ensuring that the replacement aligns with the Evo X’s documented body tolerances. For buyers navigating the tug-of-war between authenticity and price, the existence of OEM-compatible offerings on international wholesale platforms adds a layer of accessibility that meets varying budgets and timelines. For example, a vendor portal may describe: “Mitsubishi Lancer Evo X hood” alternatives with negotiable pricing and relatively low minimum order quantities, signaling that even workshops or individual hobbyists can secure a genuine-like part without the burden of a massive purchase. Yet, the phrase “OEM-compatible” can be a reminder that not all listings guarantee the same level of fidelity as a factory-new hood. The critical distinction lies in the source and the warranty: true OEM hoods sourced directly from Mitsubishi or its authorized distributors typically come with the strongest assurance of grade and support, while aftermarket or non-authorized reproductions may deliver similar fitment at a cost but with variance in paint matching, thickness, and long-term durability. These dynamics underscore the practical reality that OEM is not a monolith; it is a spectrum of options that require careful due diligence. For those who want to see concrete options and confirm current stock, the market messages suggest reaching out to verified suppliers directly through established wholesale platforms and contacting authorized Mitsubishi dealerships when possible. The path to the right hood often begins with a precise specification check: year range, hatch or sedan variant, and the exact hood design used on the Evo X in your region. It also helps to confirm whether the hood comes with ancillary hardware, such as the latch assembly, weather seals, or decorative trim pieces, all of which must align with the mounting points on the car. The advantage of OEM is not just the panel itself but the ecosystem that supports it after installation: dealer service, potential warranty coverage, and the assurance that the hood’s structural behavior—how it compresses in a low-speed impact or how it resists torsional flex at highway speeds—matches the factory’s tested standards. These facets matter when the car is not simply a showpiece but a daily driver with spirited performance expectations. To illustrate the current market reality without venturing into speculative pricing, consider how a true OEM hood is positioned relative to non-OEM choices. OEM hoods tend to be heavier, as mentioned, and their finish is designed to endure repaint cycles that maintain the original color and gloss depth. Some Evo X owners value this consistency because it minimizes the risk of mismatched hues that can occur when aftermarket finishes are applied to non-OEM forms. Others prioritize the reassurance of a genuine part that will retain compatibility with the hood’s sensors, if any, and with the vehicle’s safety-related integrations, such as alignment with the hood latch safety interlock system. For those who are renovating a vehicle that has sustained damage to the engine bay side, replacing the hood with a genuine component can simplify insurance assessments and streamline the repair process, reinforcing the vehicle’s value at resale. In this sense, OEM hoods deliver not just a cosmetic match but a holistic alignment with the car’s built-in systems and the expectations of buyers who equate authenticity with long-term reliability. A practical route to finding the right component is to pursue direct inquiries through established channels or to explore paint-ready solutions that can be completed by a reputable body shop with the right color code. When authenticity takes precedence over the incremental gains of lighter weight or bold styling, OEM remains the most reliable choice. For those curious about the wider market context, industry signals show a robust secondary market for OEM-style parts, including hoods that aim to replicate factory fit and finish while offering quicker access through international suppliers. In evaluating options, it helps to compare not just the sticker price but the value proposition: fitment certainty, paint compatibility, warranty terms, and delivery timelines. These considerations often determine whether an OEM replacement ends up being a prudent investment or a prolonged chase for the perfect match. This is where the decision becomes less about a single component and more about the broader implications for maintenance, aesthetics, and the vehicle’s overall ownership experience. For readers seeking a concrete touchpoint within the broader ecosystem, an internal reference can illuminate a path toward a factory-accurate replacement that aligns with the Evo X’s design language. See the dedicated Evo X hood option that showcases phantom-black OEM styling and the authenticity that comes with a true factory lineage: Mitsubishi Lancer Evolution Evo X Hood Phantom Black OEM U02. This example highlights how paint-matched finishes and exacting form can translate into a seamless repair experience, minimizing the guesswork that often accompanies panel replacement. It also serves as a reminder that while aftermarket alternatives can offer value, the OEM path remains a well-trodden route for those who want a straightforward, warranty-backed restoration to factory condition. In sum, the decision to pursue an OEM hood for the Evo X rests on a balance of fit integrity, paint match, and long-term support against the realities of weight, cost, and lead times. The market landscape as of early 2026 confirms that true OEM hoods are accessible, albeit through channels that require verification and patience. For owners who prize the seamless integration of factory engineering, and for shops that rely on predictable repair outcomes, OEM hoods remain a compelling choice. Those who value aggressive weight reduction or bespoke styling might still lean toward aftermarket variants, but even here most buyers will acknowledge that nothing quite duplicates the confidence that comes from a hood that was designed, manufactured, and validated to the exacting standards of the original factory program. As the Evo X continues to age gracefully, the OEM hood stands as a testament to a simple, enduring principle: when form, fit, and function are aligned, the drive—whether daily or aspirational—stays true. External market insights and supplier dynamics provide a broader backdrop to this narrative. For a snapshot of current pricing and supplier activity in the OEM-style space, industry observers reference wholesale platforms that aggregate parts pools, sometimes listing OEM-compatible hoods with negotiable terms and modest MOQs, signaling accessibility for independent repair shops or individual buyers. These signals reinforce the core takeaway: OEM remains a stable, if sometimes pricier, route for a factory-accurate restoration. For readers seeking a more direct view of the market’s breadth and price movement, see the wholesale marketplace resource: https://www.goldsupplier.com

Final thoughts

In summary, OEM hoods for the Mitsubishi Lancer Evolution X stand as an essential investment for business owners aiming to provide authentic, high-quality replacement options. Their precise fit, adherence to manufacturing standards, and warranty support underscore their value for clients seeking reliability and aesthetic authenticity. However, potential drawbacks such as weight and durability compared to aftermarket options should also be considered. By understanding the market availability and pricing strategies, businesses can successfully cater to the needs of Lancer Evo X owners. Ultimately, offering OEM hoods is not just about parts; it’s about maintaining the legacy and performance this iconic vehicle represents.