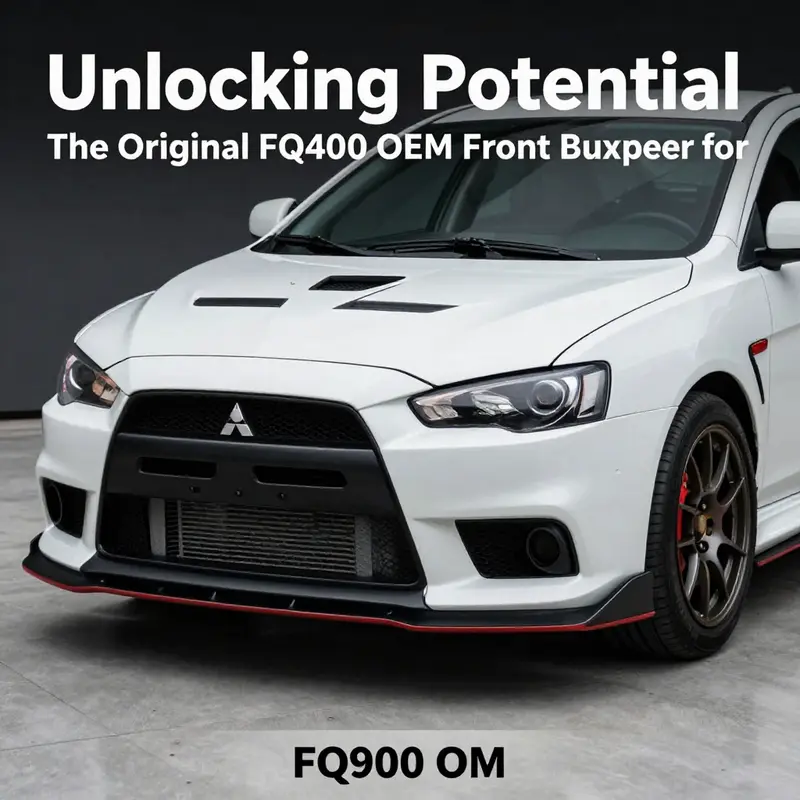

The Mitsubishi Lancer Evo X, particularly the FQ-400 model, is an iconic representation of performance and style in the automotive world. For business owners in the automotive repair and tuning industry, understanding the availability and specifications of the Original FQ400 OEM front bumper is crucial. This part not only enhances the vehicle’s aesthetic appeal but also maintains the integrity and performance expected from an OEM component. This article delves into the availability of the Original FQ400 front bumper, its specific features, compares it with aftermarket options, and provides a clear guide on purchasing this essential part. Each chapter aims to equip business owners with the knowledge needed to make informed decisions, ensuring customer satisfaction in high-performance automotive parts.

Chasing an Original FQ400 OEM Front Bumper for the Evo X: Availability, Reality and Practical Paths

Availability and Sourcing Realities for the FQ400 OEM Front Bumper

If you seek an authentic front bumper carrying the FQ400 designation for a Mitsubishi Lancer Evolution X, prepare for a patient, methodical approach. The FQ400 package was a limited, high-performance specification in some markets, and the specific bumper associated with it is not in regular production through the manufacturer. That absence from current production lines changes how the part is found, what condition you can expect, and how much you may pay.

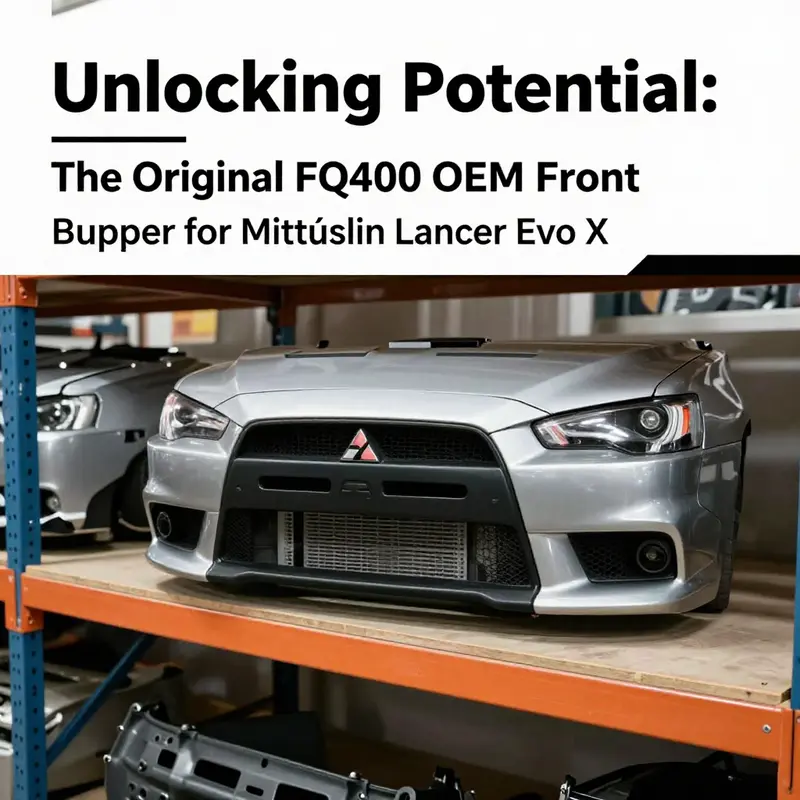

Because the OEM item is out of production, the only truly original pieces are salvaged, unused old stock, or previously fitted parts removed from donor cars. Each option has trade-offs. Salvaged parts are genuine but may show damage or prior repairs. Old stock may be flawless, but verification and provenance are harder. Used OEM bumpers can be expensive simply because supply is low and demand among enthusiasts remains steady.

Specialized salvage yards that focus on Japanese Domestic Market vehicles are the most likely source for a genuine bumper. These yards dismantle totaled or end-of-life cars and catalog parts for resale. When searching, prioritize yards that list part numbers or provide clear photographs. A visual inspection helps assess damage, previous repairs, and whether the mounting points and sensor holes match your vehicle. Expect to pay a premium for low-mileage or undamaged pieces. When a rare part becomes available, multiple buyers may compete.

Importing a used OEM bumper adds complexity. Shipping large body panels increases cost and the risk of damage. Customs handling can cause delays. When a salvage yard offers export, confirm packaging and insurance options. For international buyers, also check whether the bumper includes any ancillary parts, such as reinforcement supports, brackets, or grille pieces. Missing small parts frequently drive up installation costs.

Authenticity is not guaranteed by appearance alone. OEM bumpers carry specific part numbers and molding marks. When possible, request these identifiers from the seller. A part number check against manufacturer documentation or a reputable parts catalog confirms originality. Photos of the backside of the bumper are invaluable; they show mounting bosses, stampings, and other identifiers.

If a genuine FQ400 bumper proves too difficult to source, high-quality aftermarket replacements offer a pragmatic route. Modern aftermarket bumpers are designed to match the original shape closely. Many are produced from materials that provide acceptable durability and a factory-like fit. New aftermarket parts arrive ready to fit and often require less immediate repair work than a salvaged OEM piece.

Choosing an aftermarket replacement requires careful scrutiny. Look for suppliers who specify compatibility with your exact model year and chassis code. A legitimate listing will note fitment for the Evolution X platform and mention whether it is intended for sedan or wagon variants. Confirm whether the bumper includes provisions for any sensor cutouts, fog lamp openings, or mounting hardware your car requires. Some aftermarket bumpers are sold as shells only, while others include brackets.

Materials matter. Aftermarket bumpers commonly use injection-molded polypropylene or similar automotive plastics. These materials accept paint well and resist small impacts. They also flex more than older brittle components. However, fitment tolerances vary across manufacturers. A high-end aftermarket piece can save time and money when it installs without modification. Lower-cost aftermarket pieces sometimes need trimming, reinforcement, or bracket modification.

Installation and finish considerations apply equally to OEM and aftermarket parts. A bumper that mounts without stress preserves paint and body alignment. If the replacement requires welding or structural reinforcement, weigh the labor cost carefully. When purchasing a used OEM bumper, consider the cost of repairs, color-matching, and replacement of any attached components. OEM paint codes will help with a perfect match, but primer and refinishing remain necessary if the part has been repainted.

When authenticity is critical, the owner community and specialist forums are valuable. Enthusiast forums often document rare part sightings and provide practical advice on verifying authenticity. Members may post photos, part numbers, and seller contact details. Community trades can sometimes surface a genuine part before it reaches mainstream marketplaces. Use these networks to ask specific questions about mold codes and original trim features.

Detailed inspection tips help avoid costly mistakes. Ask for crisp, high-resolution photos of the bumper from multiple angles. Request close-ups of mounting tabs, grille interfaces, inner reinforcement areas, and any identification stamps. Verify that any integrated features, such as mesh inserts or fog lamp bezels, match the original design. If the seller cannot provide these photos, treat the listing with caution.

If you locate a convincing OEM piece, verify return policies and shipping protection. Large body panels are vulnerable to dinging in transit. Confirm who bears the cost of damage claims and whether the seller insures shipments. Some specialized sellers will only accept local pickup to avoid transit risk; plan accordingly if travel is required.

Budget expectations must reflect rarity. Genuine, well-preserved OEM bumpers command higher prices than standard replacements. Factor in the total cost of acquisition: the part price, shipping, import duties, finishing, and possible bracket or sensor replacement. In many cases, a new aftermarket bumper plus professional paint yields a lower overall cost and shorter lead time than chasing a scarce OEM piece.

If you decide to pursue an aftermarket route, select a supplier with clear fitment information and a reputation for quality. A well-made replacement will reduce installation time and avoid modification work. Some aftermarket options replicate the original design almost exactly. Others intentionally alter styling for a more aggressive look. Choose according to your goals—authentic restoration or visual upgrade.

For those who prioritize originality, carefully document the provenance of any OEM bumper you acquire. Keep photographs, seller invoices, export paperwork, and any correspondence that confirms part origin. This documentation adds resale value and serves as proof of authenticity when future buyers ask.

Be prepared for compromise. An exact OEM FQ400 bumper may surface, but it will likely require patience and flexibility. If a matching original is unobtainable, a high-quality aftermarket replacement can restore function and appearance. Use the community, specialized salvage yards, and reputable parts marketplaces to widen your search. Verify part numbers, inspect photos closely, and budget for finishing work.

When evaluating listings, a targeted checklist streamlines decisions: confirm part numbers; request detailed photos; verify included hardware; ask about export packaging and insurance; and confirm return terms. This checklist reduces risk and speeds the search.

To help your search, consult specialist inventory listings that focus on Evolution X parts. These places often list both used OEM and new replacement parts. A single detailed listing can reveal exact dimensions, mounting point compatibility, and any necessary supporting pieces. One such listing platform frequently carries both salvage OEM and new replacement bumpers, making it a helpful resource during a targeted search. See the CZ4A Lancer Evolution X front bumper (genuine) listing for reference if you want to compare visual cues and listing detail practices: https://mitsubishiautopartsshop.com/mitsubishi-cz4a-lancer-evolution-x-front-bumper-genuine/.

Finally, keep flexibility in your timeline. Rare parts appear sporadically. New aftermarket units are the fastest route to a complete, painted bumper. Salvaged OEM pieces satisfy authenticity but often require more time, higher cost, and logistical planning. Decide which attributes matter most—originality, cost, or speed—and align your search strategy accordingly.

For current listings and to widen your search internationally, check specialized parts exporters that list both used OEM and reproduction bumpers. These platforms permit filtering by chassis code and part condition, making them practical starting points for either route. For further exploration, see this parts marketplace for international options: https://www.partsinjapan.com/.

The Genuine Front Shield for the Lancer Evolution X: Authentic Fit, Quiet Power, and the Road to Real-World Performance

When builders and drivers seek a factory-grade front bumper for the Lancer Evolution X, they are often balancing three quiet demands: exact fit, uncompromised safety, and a look that signals track-ready intent without shouting. The story around the OEM front bumper for this platform unfolds like a careful negotiation between engineering integrity and the realities of the aftermarket marketplace. There is a tension between the clean, preserve-the-witness of factory engineering and the appetite for a more aggressive, track-inspired appearance. This chapter follows that tension not as a debate about fashion, but as a practical inquiry into what it means to source a genuine, factory-grade component for a modern high-performance sedan and how that choice shapes handling, cooling, sensor function, and long-term value.

The starting point, informed by hands-on discussions and official documentation, is the recognition that the concept of a factory front bumper exists within a broader catalog of genuine parts designed to integrate with the vehicle as it rolled off the assembly line. In real-world terms, OEM replacements are typically described as plug-and-play, intended to align with the vehicle’s structural rails, mounting points, and sensor arrays without requiring invasive modifications. Yet the research narrative also notes a common caveat in the field: while the OEM option guarantees compatibility with factory subsystems, it may not deliver the same visual impact or aggressive silhouette that many enthusiasts associate with high-performance variants. In other words, the OEM pathway emphasizes authenticity and reliability over bold exterior styling—an important distinction for buyers who aim to preserve warranty coverage and maintain factory calibration across the drivetrain and transmission controls.

From this vantage point, the genuine bumper for the Evolution X is presented not simply as a replacement part but as a meticulously engineered shield that preserves the car’s aerodynamic balance and cooling efficiency. Its design is described as seamlessly integrating with the car’s existing systems, including the sensors that perform crucial safety and performance roles, the lighting elements, and the body panels that define the vehicle’s proportions at speed. In practice, that means the bumper must align with the radiator’s intake geometry, the intercooler flow path, and the under-structure that anchors the front of the chassis. It also implies a maintenance of the vehicle’s crash structure, which plays a key role in occupant safety and, by extension, in insurance and warranty considerations. When a driver pivots toward an OEM bumper, the intention is not only to ride on a part that looks right but also to preserve a known interaction with the vehicle’s safety and performance systems.

The feature set of an original front bumper in this context is described as a package that optimizes aerodynamics while staying faithful to the car’s original engineering goals. A primary virtue highlighted in the research is fit and integration. The bumper is intended to snap into place with the factory mounting points, align precisely with the fender lines, and leave the factory gaps and tolerances intact. This precision matters because it reduces the risk of misalignment that can ripple through sensor accuracy, headlamp aim, and even hood alignment at the edges. The knock-on benefits include consistent paint coverage, predictable panel gaps, and minimal need for bodywork adjustments during installation. Designers and engineers who work on genuine parts are typically careful to preserve these interface details, because even minor deviations can affect air flow and cooling across the front of the car when the car operates at highway speeds or on a track.

Aerodynamics sits at the heart of the bumper’s purpose, and the OEM approach is to balance downforce with cooling efficiency. The Evolution X is a car built to perform under demanding conditions, where throttle, air flow, and heat management all interact. The genuine bumper’s geometry is described as optimized to compliment the vehicle’s existing aerodynamic profile, ensuring that downforce remains stable as speed climbs. This is not purely about speed; it is about predictable handling, brake cooling, and engine bay temperatures under sustained high-load conditions. The integrated air intakes are not mere styling cues. They channel air toward critical components, aiding engine cooling and intercooler efficiency, which matters when the car is pushed hard on a road course or spirited backroads session. The lower splitter, too, is designed to manage the flow of air as it exits beneath the front bumper, contributing to a balanced pressure distribution across the front end and reducing lift in ways that improve tire contact with the surface.

The Visual Language and Material Reality

Beyond the engineering calculations, the genuine bumper carries a visual language that mirrors the car’s high-performance lineage without sacrificing the discreet elegance that owners value for street use. The aesthetic is deliberately aggressive, signaling intent while staying true to the factory proportions. This is not a wholesale transformation of the vehicle’s face; it is, rather, a refinement that complements the sedan’s existing stance. The design choices—air intakes, lip geometry, and the way the bumper meets the grille and surrounding bodywork—coalesce into a front silhouette that communicates competence and precision at a glance. The end result is a front end that looks purposeful, ready for track duty, yet entirely maintainable in everyday street use. It is a reminder that performance can be expressed through engineering discipline as much as through dramatic styling cues.

In terms of materials and construction, the specifics are often guarded by the same expectations that surround other OEM components. The bumper is crafted to Mitsubishi’s exacting standards, meaning the materials are selected for compatibility with the car’s crash structure, thermal environment, and paint processes. While exact dimensions aren’t publicly enumerated in every source, the central claim is consistent: the OEM bumper is a high-quality part engineered to preserve structural integrity and provide a long service life when installed by qualified technicians. This is essential for customers who care about keeping the vehicle under warranty, maintaining consistent panel fitment, and avoiding the unpredictability that can accompany some aftermarket alternatives.

An important caveat emerges in the aftermarket landscape. The available literature and community discussions reveal a broad spectrum of options that aim to emulate the visual impact of the higher-performance variants. These alternatives range from replicas to brand-name aftermarket pieces that advertise aggressive styling and enhanced aerodynamics. The critical difference, however, lies not only in how they look but in how they fit and function. Aftermarket pieces can vary in their fitment with factory sensors and lighting, how they align with the hood and fenders, and how they influence air flow and cooling paths. The OEM route prioritizes compatibility and predictability, which matters for those who want a straightforward, warranty-friendly upgrade path rather than a bold but potentially inconsistent transformation.

From a practical maintenance and ownership perspective, choosing an OEM bumper supports consistent color matching, finish quality, and long-term compatibility with the car’s electronics. If the vehicle is still under warranty or under a service plan that relies on factory specifications, the OEM option minimizes the risk of inadvertent coverage gaps that could arise if a third-party part compromised a sensor calibration or a crash sensing system. The decision, then, is not purely about appearance. It is also about the confidence that the vehicle’s designers and engineers intended for the owner to enjoy a coherent, dependable performance envelope that aligns with the car’s original engineering intent.

For readers who want a concrete reference to a genuine bumper option, a dedicated page exists that discusses a front bumper for the Evolution X in the context of the CZ4A platform code. This resource emphasizes the practical aspects of sourcing a genuine bumper, including fitment compatibility with the Evolution X’s front-end architecture. The page offers a straightforward gateway to confirming availability, dealer support, and compatibility with the car’s sensor and lighting systems. To explore this option, you can follow the internal link embedded here: genuine Evo X front bumper (CZ4A) page.

The broader market context reinforces the value of careful sourcing. While aftermarket options can offer compelling aesthetics and sometimes modest cost savings, the OEM path tends to minimize risk—particularly for owners who rely on precise alignment with performance-related features such as intercooler routing, radiator cooling, and front-end crash structure. The OEM approach is a reminder that high-performance vehicles are engineered as integrated systems; a change in one part can echo through several subsystems. In this sense, the front bumper becomes more than a cosmetic piece. It is a component that helps sustain the car’s dynamic balance, cooling efficiency, and the reliability of its safety features under demanding conditions.

To those who are actively weighing the decision, it helps to ask a few practical questions. Does the part come with the same mounting points and hardware as the original? Will sensors, cameras, and lighting align without recalibration? Is the finish likely to match the rest of the body panels without extensive bodywork or repainting? Is the dealer or service network comfortable and familiar with installing this specific bumper in a way that preserves the vehicle’s warranty and service history? These are not trivial considerations. They are the kinds of checks that separate a smooth upgrade from an experience that invites misalignment, rattles, or misaligned optics.

In this context, one can also appreciate how the OEM bumper maps onto the car’s overall development philosophy. It embodies a design intent that values harmony between performance, safety, and durability. It speaks to a user who wants to preserve the vehicle’s provenance, maintain its engineering cohesion, and use a part that respects the car’s original chassis geometry. This is not a rejection of aftermarket creativity; it is a deliberate choice for owners who prefer a predictable, documented pathway to improvement. The fact that a genuine option exists—distinct from replicas—helps reaffirm the importance of sources that carry official parts branding, a network of authorized dealers, and a traceable parts history that can aid resale value and service continuity.

For readers who may still be weighing the pros and cons, the narrative remains grounded in practical realities. The OEM bumper’s appeal lies in its quiet confidence: it does not demand attention through extravagant lines or flamboyant gills; instead, it promises a front end that looks right because it is right. The resulting ownership experience can feel more cohesive, especially when the upgrade sits beside the original components that share the same engineering DNA. The decision, ultimately, should reflect a balance between desired aesthetics, confidence in fitment, and the practicalities of servicing and warranty protection.

External reference and further reading provide a broader lens on the landscape and official specifications. For an authoritative external source that surveys the official approaches to the Evolution X front-end components, see the external resource listed at the end of this chapter. This reference helps connect the practical considerations described here with the manufacturer’s perspective on parts and accessories that are designed to work together as a complete system.

External reference: https://www.mitsubishi-motors.com/en/vehicles/lancer-evolution-x/fq400.html

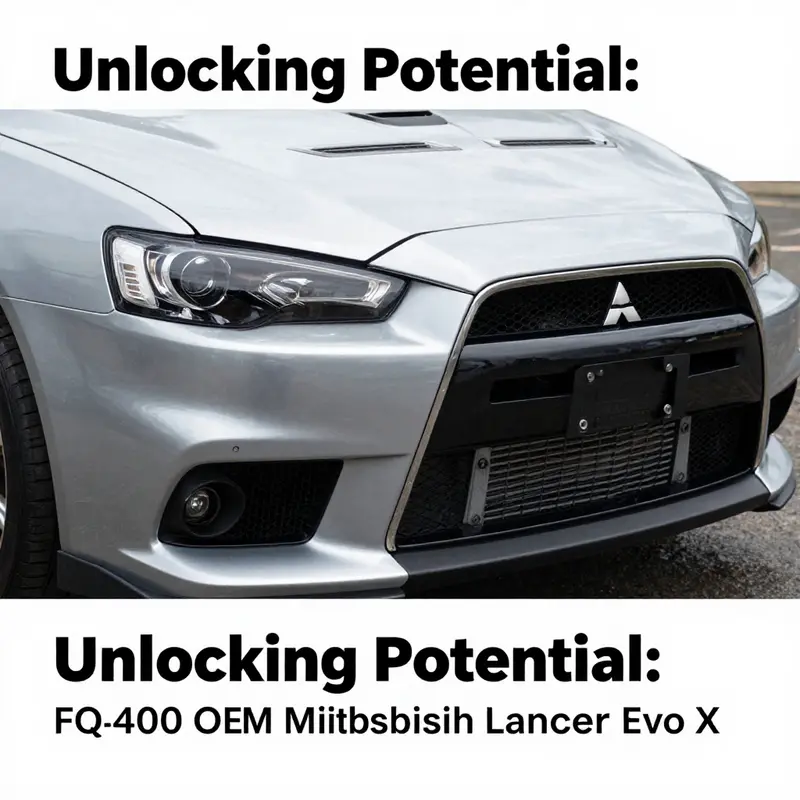

From Factory Subtlety to Aggressive Identity: Weighing the OEM FQ-400 and Aftermarket Front Bumpers for the Evo X

The front bumper is more than a protective cover; it is the defining line that separates a factory-minished silhouette from a statement on the road. When considering a front-end upgrade for the Mitsubishi Lancer Evolution X, especially the variant associated with the FQ-400 badge, the decision hinges on a balance between precision engineering, visual impact, and the daily realities of ownership. The Evo X has carved out a niche where performance engineering meets street presence, and the bumper, as the most visible interface with air, cooling, and the road, serves as a microcosm of that balance. In this chapter we explore the nuanced choice between preserving an OEM FQ-400 front bumper—carefully tuned to factory standards—and embracing aftermarket alternatives that promise a more radical presence without sacrificing too much of the car’s integrity. The discussion remains anchored in the Evo X’s architecture, recognizing that every front-end option interacts with cooling airflow, crash structure, and the quiet language of fitment that keeps panels aligned and warranty protections intact. While the evo lineage invites a dramatic visual transformation, the differences between OEM and aftermarket front bumpers are not merely aesthetic; they ripple through performance, durability, and long-term ownership experience.

The OEM FQ-400 front bumper, by design, embodies a philosophy of exactitude. It is engineered to fit the Evo X’s front fascia as delivered from the factory, aligning with the underlying crash structure, radiator support, and airflow ducts that the manufacturer calibrated during development. The plug-and-play nature of this component is not a mere convenience; it preserves the vehicle’s warranty envelope and structural safety considerations. When installed as a genuine part, the bumper slots into the existing mounting points without the need for cutting or reengineering, which means the integrity of the bumper reinforcements, impact-absorbing structures, and posture of the nose remains as the engineers intended. The aerodynamic profile is tuned to complement the factory undertray, the intercooler plumbing, and the cooling system’s ducting. In practice, this translates to predictable, consistent performance across the speed range the Evo X was designed to handle. Enthusiasts who prioritize reliability and factory coherence often regard the OEM option as the most trustworthy route to maintain a balanced chassis response, quieting concerns about distortion, misalignment, or unintended aerodynamic shifts that can accompany non-OEM assemblies.

Yet the OEM route carries a distinct aesthetic consequence. The FQ-400-branded bumper, within the framework of the Evo X’s silhouette, adheres to the original design language. It emphasizes precision lines, subtle contouring, and a restrained presence that respects the vehicle’s performance heritage. In the 시장, this manifested restraint often translates to a front end that communicates strength through form rather than overt aggression. For a owner who wants the car to blend in with the crowd or to preserve a more understated appearance, the OEM bumper delivers a clean, consistent look that remains faithful to the factory proportions. The trade-off, however, is clear: the visual drama offered by many aftermarket kits—think larger air intakes, bolder splitter geometries, and more aggressive canards—does not come standard with the OEM piece. If the objective is to retain a factory look with the assurance of genuine parts, the FQ-400 OEM bumper remains the anchor, a faithful steward of the Evo X’s original design intent.

On the other side of the spectrum lie aftermarket front bumpers, which alter not only the car’s face but, often, the car’s character. These kits embrace a design philosophy that prioritizes drama and performance-oriented styling. They frequently feature oversized lower grilles, wider mouth openings for enhanced cooling, pronounced splitter elements, and aggressive liplets that project the car’s stance toward the edge of the road. The visual transformation is significant enough to be instantly recognizable at a standstill and to leave a lasting impression in motion. The practical implications of such a design shift are equally important. Increased air intake size can, in some configurations, improve available cooling capacity for the engine and intercooler, a boon for track-focused drivers or cars that run higher boost pressures. However, with greater opening area comes the risk of unwanted air intrusion into the engine bay in certain weather conditions, potential turbulence at high speeds, and the need for careful alignment with the radiator, condenser, and intercooler ducts. The aerodynamic balance can require additional adjustments elsewhere in the car—such as revised underbody components, upgraded splitters, or changes to the front bumper’s mounting points—to ensure that the bumper does not depart from its intended behavior during cornering and braking.

Material choice and build philosophy further distinguish aftermarket bumpers from their OEM counterparts. OEM bumpers are typically molded from high-quality plastics selected for durability, impact resistance, and consistent production tolerances. The goal is a bumper that absorbs energy predictably and maintains structural integrity over thousands of kilometers of road use. Aftermarket bumpers span a broader spectrum of materials, from sturdy ABS plastics to carbon fiber composites and, in some cases, fiberglass. Each material brings its own set of advantages and trade-offs. ABS tends to offer a good mix of stiffness and impact resistance at a reasonable weight, making it a common choice for street-driven upgrades. Fiberglass, while lighter and moldable for complex shapes, can be more brittle under impact and may require careful prep and repair work after damage. Carbon fiber, while offering exceptional rigidity and an unmistakable premium aesthetic, commands a higher price and demands skilled installation and clearances to maintain fit and finish. Beyond material selection, the surface finish and texture level also influence durability and longevity. Carbon fiber and certain high-end resins can resist surface cracking and fading better under extended sun exposure, yet they may require meticulous care to preserve glossy finishes and avoid UV degradation.

From a performance perspective, aftermarket bumpers can meaningfully influence how air moves around the Evo X’s front end. A well-executed aftermarket design can improve intercooler efficiency by delivering more direct airflow to the radiator and intercooler cores, potentially reducing charge temperatures under sustained performance loads. An aggressive front end may also affect the pressure distribution at the car’s nose, altering lift characteristics at higher speeds. For performance-minded owners, the nuance is not merely about more air—it is about smarter air management. In this sense, some aftermarket kits are engineered with integrated vents, channels, and ducts that help route cooling air toward the engine bay and intercooler, sometimes in concert with splitter and canard configurations. The result can be a tangible drop in intake temperatures and a more stable operating envelope, provided the rest of the cooling system is aligned with the new airflow paths. On the other hand, a poorly designed aftermarket bumper can create turbulence, hamper airflow to critical components, or increase aerodynamic drag, which negates the potential gains and undermines stability at speed.

The installation experience itself is a practical frontier where OEM and aftermarket paths diverge. The OEM FQ-400 bumper offers a straightforward replacement: remove the old unit, bolt in the new one, and reattach any required sensors, grilles, or supports. This simplicity preserves alignment with the fenders, hood gap, and grille line, reducing the risk of rubbing against tires or interfering with the spray nozzles and bumper supports. Since it is designed to match the original mounting geometry, the likelihood of misalignment is minimized, which translates to less time in the shop and less chance of cosmetic gaps or inconsistent paint lines. Aftermarket bumpers, while attractive for their dramatic styling, often demand a careful pre-fit and sometimes minor modification to achieve perfect alignment. Installers may need to trim mounting tabs, adjust the bumper’s height, or adapt ancillary components like the radiator cover, headlight housings, or fog-light assemblies. Some owners choose to work with body shops that specialize in performance fitment to ensure the new bumper integrates seamlessly with the Evo X’s unique geometry. This process can involve not only mechanical alignment but also attention to the aesthetic continuity of the bumper with the hood, fenders, and front lip or splitter.

Another dimension to consider is the warranty and the long-term ownership implications. The OEM route tends to preserve warranty protections more reliably, especially when the bumper is installed using official channels or authorized service centers. The risk of warranty denial often correlates with non-OEM parts and non-standard installation practices—particularly if the bumper’s integration affects crash safety components or the vehicle’s airbag system timing in sensor-equipped fronts. By contrast, aftermarket bumpers, depending on the jurisdiction and the dealer’s policy, may introduce complexities when it comes to warranty coverage. Enthusiasts who drill into installation details, add new sensors, or alter the bumper’s mounting can create scenarios where coverage hinges on the compatibility and workmanship of the installer. This is not a universal rule, but it is a reality that requires upfront clarity with the dealer and a careful read of the vehicle’s warranty terms.

A practical way to approach the decision is to weigh what you value most in the Evo X: the assured, restrained elegance of a factory component or the bold, personalized identity that an aftermarket kit can deliver. For collectors or daily drivers who prize continuity with the car’s original build, the OEM FQ-400 bumper maintains that sense of integrity and predictability. For track-focused enthusiasts or those who want the Evo X to command attention with a pronounced stance, a high-quality aftermarket bumper can be a powerful differentiator—provided the buyer is prepared for careful selection, precise fitment work, and potential ancillary modifications.

Within this decision framework, it helps to view the choice as part of a broader strategy for the Evo X. The bumper does not exist in isolation; it interacts with the car’s cooling system, front-end aerodynamics, suspension geometry, wheels, and overall weight balance. A change in bumper geometry can influence how the vehicle carries its load through corners, how it responds to high-speed airflow, and even how the ECU interprets intake temperatures under certain conditions. For a street runner, the most important factor may be the bumper’s ability to maintain consistent performance in diverse weather and road conditions, while for a showroom or track-focused build, the emphasis shifts toward aggressive aesthetics, customizable color matching, and the integration of ancillary elements such as lip extensions, canards, or carbon-fiber splitters that augment the overall visual package.

Choosing between OEM authenticity and aftermarket drama is thus not a dichotomy that demands a single best answer; it is a dialogue about how you want the Evo X to exist in the traffic of modern automotive culture. For some owners, the path is to maintain a pristine factory appearance with the confidence that every component behaves as designed. For others, the path invites a sculptural statement—one that challenges the eye and redefines the front-end silhouette while pushing the car’s performance envelope in small, meaningful ways.

If authenticity remains a priority, the route to a genuine Evo X front bumper is straightforward: seek out official or authorized sources that guarantee OEM fitment, consistent paint, and adherence to the car’s engineering specifications. For those who crave the unmistakable, aggressively styled front-end, the market offers an array of aftermarket options designed to deliver dramatic visual impact and, in some cases, measurable cooling advantages. It is essential to approach any upgrade with a holistic mindset: verify compatibility with the Evo X’s existing sensors and lighting, assess the potential need for additional modifications, and engage a skilled installer who understands how to preserve the structural integrity and ride quality that define the Evo X experience.

For readers who want to explore a genuine Evo X front bumper option, see this source: genuine Evo X front bumper.

As you map out the path that best suits your Evo X, remember that the car’s identity is forged not just by a single component but by the careful orchestration of design, engineering, and the personal story you want to tell on every drive. The choice between OEM and aftermarket bumpers should align with your driving goals, your maintenance philosophy, and your willingness to invest in professional fitment and ongoing upkeep. When executed with care, either path can elevate the Evo X from a performance coupe to a strong statement of how you want to experience driving—whether you opt for the quiet confidence of factory precision or the bold certainty of a design-driven transformation.

External resource for further perspective: https://www.carscoops.com/2026/01/lancer-evo-x-aftermarket-bumper-guide/

How to Secure a Genuine FQ-400 OEM Front Bumper for a Lancer Evo X: Practical Steps and Pitfalls

Sourcing and Verification

Finding an original FQ-400 OEM front bumper for a Mitsubishi Lancer Evo X requires patience, method and attention to detail. The badge and styling that mark the FQ-400 are desirable, but the part you want must be a genuine factory item. That means it should fit without modification, integrate with lights and sensors, and match the vehicle’s engineering tolerances. Start by identifying the precise model year and spec of your Evo X. Small differences in model year trims, fog lamp provisions, or sensor options change the correct bumper part number. If your car has factory parking sensors or active cooling ducts, a visually similar bumper without those features will leave gaps or require retrofitting. Keep the car’s build details close at hand when you hunt for parts.

A reliable purchase begins with part number confirmation. The original bumper usually carries a stamped or stickered part number. That number is the quickest way to confirm authenticity. If you cannot inspect the original bumper, obtain the part number from the vehicle’s paperwork, service records, or a certified technician. When reviewing listings, compare the seller’s part number exactly with the number from your car. Even a single digit difference can mean a different sub-model or a non-compatible revision.

Authenticity goes beyond the part number. Genuine factory bumpers are made from specific materials and finished with factory paint processes. OEM finish tolerances, clip locations and mounting boss shapes are precise. Aftermarket replicas often get visual proportions correct but cut corners on the substrate material and clips. That can mean poor alignment, fastener breakage, and paint adhesion problems. Ask sellers for high-resolution photos of the mounting areas and inner surfaces. Look for manufacturer casting marks, consistent fitment tabs, and factory-style plugs for sensors and lamps. If a listing offers only stock studio photos, treat it as a red flag.

Price is an indicator but not proof. A significantly lower price may signal a replica or a damaged used part. That said, used genuine bumpers can be a bargain if properly inspected. Distinguish between legitimately lower-priced salvage parts and counterfeit copies. Request a written description of any damage and confirm whether the bumper has been professionally repaired. Repaired OEM parts can be fine when repairs are cleanly executed and structural mounting points are intact. Avoid listings that offer an “OEM look” bumper with unrealistically low shipping costs and no photographic proof of the inner panel details.

When buying online, prefer sellers that offer a clear returns policy and provide tracking. Verified marketplaces with seller ratings add another layer of protection. Still, verify the seller’s expertise with Evo parts. Specialty sellers and forums often reveal which vendors consistently supply correct OEM components. Forums and owner communities can also point you to local salvage yards that specialize in high-value parts. If you choose a salvage option, confirm that the bumper has not been stressed in a way that compromises critical mounting bosses or cooling duct inlets.

If the part is marketed as an “FQ-400” bumper, verify what that means. Many aftermarket vendors produce FQ-400–styled bumpers to mimic the aggressive look of that special edition. These parts can be a good choice for aesthetics but are not factory items. Ask if the bumper carries OEM part numbers and whether the seller can prove factory provenance. A factory original will often have a secondary label or engraving that ties it to the OEM supply chain. Conversely, aftermarket parts will lack those identifiers.

Shipping and packaging matter for large exterior parts. OEM bumpers are shipped with protective crating or heavy-duty packaging. Insist on a packaging description and photos before shipment. Damage during shipping can render a part unusable and make returns difficult. When arranging freight, verify insurance coverage and the carrier’s experience with automotive body parts. For international shipments, confirm customs documentation and potential duties ahead of time. That avoids surprises on delivery and saves you from accepting damage claims later.

Installation readiness is a useful metric. A genuine bumper should arrive with correct mounting hardware or a clear list of required fasteners. Some sellers include clips and screws; others assume the buyer will reuse the original hardware. Clarify what is included. If you plan to paint the bumper, factor in the need for factory-style priming and finish. OEM paint finishes often require specific surface prep to match factory sheen and color match. Consider professional color-matching rather than a quick workshop spray. A poor paint job ruins an otherwise perfect OEM part.

Warranty and documentation boost buyer confidence. New OEM replacement parts sometimes carry a limited parts warranty from the authorized dealer. Used OEM items generally do not have manufacturer warranties, but reputable sellers sometimes offer their own short guarantee. Ask for documentation that proves the item’s origin. Service invoices from a manufacturer dealer or dismantler provide traceable provenance. Keep all paperwork in case you need to assert warranty or return rights.

When possible, use local authorized dealers as the primary source. Dealerships can access factory parts catalogs and confirm compatibility by VIN. They may also provide installation guidance and warranty support. If a dealer does not show stock, ask them to source the bumper through official channels. Certified parts suppliers are another credible option. They strike a balance between price and authenticity, and they often have better return policies than private sellers.

Used part hunting benefits from careful inspection. If you can view the bumper in person, check for hidden damage. Look closely at inner reinforcement rails and clip mounting bosses. Confirm that sensor holes are intact and that light apertures align perfectly. Test bolt holes for signs of elongation or repair. Small cracks in mounting flanges indicate potential future failure under normal stress. Ask if the bumper was ever repainted. Repainted OEM parts are fine when done professionally. However, if repainting hides damage, the seller may be masking a serious issue.

Documentation of any prior repairs should be transparent. Ask for repair photos and a detailed description of materials used. Fiber reinforcement, plastic welding, or proper panel bonding are acceptable. Avoid bumpers that have sections replaced with different materials or improvised repairs. If you plan to resell the bumper later, full disclosure of repairs enhances buyer trust and avoids disputes.

Budget expectations should be realistic. Genuine OEM units cost more than common aftermarket shells. Factor in shipping, paint, and hardware. If the price differential between OEM and aftermarket is large, consider whether the added cost is justified for your use. For collectors or restoration projects, OEM originality adds value. For daily drivers where cost is the dominant factor, a high-quality aftermarket shell might be acceptable. Weigh installation complexity and the likelihood of needing electronic component integration when choosing.

Finally, keep community resources close. Owner forums and parts databases help verify part numbers and share seller reputations. A trusted community can often point to salvage sources or specialized vendors who reliably supply genuine parts. For a direct parts lookup and dealer contacts, consult the official parts catalog provided by the manufacturer. That resource remains the most authoritative source for part numbers, descriptions and dealer listings.

For a practical example of a reputable parts listing and to cross-check availability, see this genuine Evo X front bumper listing.

For direct verification and official parts catalog access, consult the manufacturer’s parts resource: https://www.mitsubishimotors.com/Parts/.

Final thoughts

The Original FQ400 OEM front bumper for the Mitsubishi Lancer Evo X stands as an invaluable asset for automotive professionals seeking to provide top-notch parts to their customers. Understanding its availability, features, and how it compares to aftermarket alternatives ensures that business owners can effectively meet clientele demands for performance and reliability. By following the purchasing guidelines outlined, professionals can confidently secure genuine OEM parts, enhancing customer loyalty and satisfaction. As the automotive market continues to evolve, knowledge of such key components remains essential for maintaining an edge in this competitive field.