The sequential gearbox has emerged as a pivotal upgrade for automotive enthusiasts seeking enhanced performance in their Mitsubishi EVO X models. With racing-grade solutions provided by KAPS, a respected Czech manufacturer, vehicle owners can significantly improve their transmission systems’ reliability and efficiency. This article delves into the transformative capabilities of KAPS sequential gearboxes, examining how these enhancements can elevate the driving experience for EVO X users. We will explore the performance benefits of sequential gear setups, highlight technical specifications that set KAPS apart, and discuss the evolving market trends in the aftermarket automotive sector concerning sequential gearboxes.

Shifts That Endure: A Deep Dive into KAPS’ EVO X Sequential Gearbox

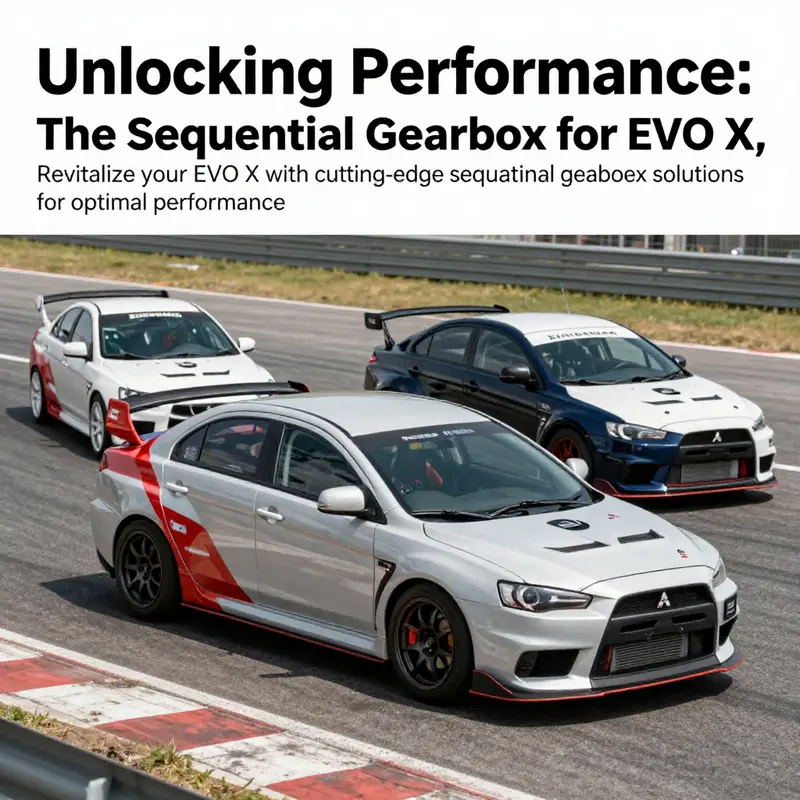

The Mitsubishi Lancer Evolution X lives at the intersection of raw torque, precise chassis balance, and the relentless pursuit of faster laps. In that space, the transmission is not merely a mechanism to move gears; it becomes a living partner that translates horsepower into momentum with every blistering shift. A well-tuned sequential gearbox can turn a skilled driver’s intent into a clean, repeatable line through a corner, a feat that standard manuals or DSG systems can struggle to sustain when the pressure is on and the clock is ticking. For teams and enthusiasts chasing reliability at high horsepower, a purpose-built, certified sequential solution offers more than faster shifts; it delivers consistency, durability, and an ability to push the EVO X beyond its stock envelope without sacrificing control.

KAPS distinguishes itself in this realm through a lineage that begins far from the modern race paddock. The company speaks to a heritage rooted in the design and manufacture of high-performance transmissions forged for demanding environments. That background informs every gearbox they produce for the EVO X, where racing-grade performance must stand up to the rigors of professional competition. The EVO X chassis is already a compact, well-balanced platform, but the stresses of high torque and rapid gear engagement test driveline parts in ways that are hard to prepare for with off-the-shelf components. The sequential gearbox that KAPS offers for the EVO X is not merely a replacement; it is an engineered upgrade that redefines how the car responds to driver input under race conditions. The emphasis is on reliability under load, but reliability does not come at the expense of precision. The transmission is designed to deliver crisp, unambiguous shifts with minimal time lost between gears, a combination that is essential when every tenth of a second matters.

What makes the KAPS EVO X solution especially compelling is the way it integrates racing-grade engineering with practical racing applications. The product line does not stop at the core sequential gearbox. Enthusiasts and teams benefit from a suite of reinforced components designed to work together, including reinforced gear kits and final drive components that are tuned for the kind of sustained, high-torque operation common in WRC- or Group N-spec competition. There is also attention to the differential side of the equation; adjustable center differential lock controllers provide tunable front-to-rear torque distribution that can be tuned to a specific circuit, surface, or weather condition. In the toughest environments, where traction and stability can mean the difference between a podium and a fall back, these elements help preserve drivetrain integrity while giving the driver more meaningful control over the car’s dynamic behavior.

The EVO X’s racing pedigree is reinforced by real-world validation. The same gearbox and kit combinations that see service in international events—such as rally stages and touring championships—must endure the brutal sequences of gear changes, the high-speed load shifts, and the abrupt accelerations that come with competitive driving. The durability demonstrated across such events is not incidental; it is earned through precision engineering and rigorous testing. The sequential gearbox is homologated, meaning it meets the requirements of legal motorsport competitions. This certification is more than a bureaucratic badge; it indicates a level of development that has been scrutinized for reliability, safety, and consistency under racing rules. For teams that rely on a predictable gearshift feel, the homologated nature of the solution reduces the risk that a non-certified modification could compromise competition eligibility or track side reliability.

An important facet of the KAPS EVO X package is its holistic approach to the drivetrain. Enthusiasts who adopt the sequential gearbox often look at the broader picture: how the transmission interacts with the clutch, the transfer case or center differential, the drive shafts, and even the cooling system that keeps the drivetrain within safe operating temperatures during a race or a long, high-speed session. The assurance of a coherent, race-adapted drivetrain is a significant advance over piecemeal upgrades that might address one aspect of performance but leave other weak links exposed to the same high-stress conditions. In practice, this means that the EVO X can exploit higher horsepower targets with more confidence, because the transmission architecture is designed to absorb and manage loads that would otherwise lead to gear whine, bearing wear, or inconsistent shift timing.

From the perspective of modification and competition strategy, the sequential gearbox represents a strategic choice rather than a quick upgrade. It is part of a broader discipline—the discipline of maintaining performance across a range of competitive scenarios. In addition to the core gearbox, KAPS offers a suite of related components that reinforce the drivetrain’s resilience under elevated power outputs. Final drive components can be tailored to the vehicle’s gearing strategy, ensuring that the engine’s torque curve remains compatible with the gear ratios selected for a given course. The adjustable center differential lock controller is a tool for dialing in traction, especially on slippery surfaces or in long endurance events where subtle changes in torque distribution can prevent tire slip and reduce heat buildup in the driveline. This is not about brute force; it is about controlled, repeatable performance.

The EVO X, with its aggressive styling, aggressive performance, and a chassis that responds to precise inputs, is a natural canvas for a high-performance sequential solution. What matters most in this context is not simply the speed of the shift itself but the manner in which the shift timing aligns with the engine’s torque release, the tires’ grip limits, and the driver’s intended line through a corner. The sequential gearbox is designed to deliver a shift feel that is crisp, unambiguous, and fast, while ensuring the drivetrain remains within safe operational limits long after the checkered flag has fallen or the rally stage has ended. In practice, drivers report that a well-tuned sequential setup enables them to repeat their corner exits with greater confidence, because each shift is predictable and stable rather than prone to unintended throttle cut or drivetrain disturbance.

For those considering the EVO X upgrade path, the integration of a sequential solution is often the centerpiece of a more extensive performance plan. The road from stock to race-grade transmission involves careful planning around the car’s overall balance, the driver’s style, and the event’s demands. The shift from a conventional manual or DSG-like system to a sequential gearbox changes the nature of the driver’s engagement with the car. The driver’s left foot is no longer the sole arbiter of timing; the upgraded system provides a direct, linear translation of the driver’s intent into wheel speed, allowing the driver to focus more on the apex geometry and throttle modulation rather than on clutch control and hand-measured rev matching. It also offers the potential for reduced wear on the clutch and related components, since the shift process is mechanically simpler and more controlled at high RPM and high torque.

In acknowledging how to approach such a transformation, it helps to consider practical pathways. A conversation with a reputable supplier often centers on compatibility with the EVO X’s existing architecture, the availability of certified components, and the support structure for installation and ongoing tuning. The narrative around these gear systems emphasizes that they are not generic aftermarket add-ons but purpose-built, race-proven transmissions designed to be integrated into the car’s overall performance architecture. This mindset resonates with teams competing on asphalt, gravel, and mixed surfaces alike, where reliability across varied conditions is critical to maintaining a competitive advantage. The transfer of knowledge from global motorsport events into club racing and street-legal track days is a hallmark of a mature, professional gearbox program. The same principles that enable a World Rally Championship car to survive the unrelenting demands of a long stage are, in essence, what makes the EVO X platform viable for serious competition and ambitious street builds alike.

To keep the narrative grounded in demonstrated capability, consider the practical details that accompany the EVO X sequential option. The package’s reliability and performance are not simply a matter of shifting speed. The internal geometry of gears, the stiffness of shafts, the efficiency of lubrication pathways, and the heat management strategy all contribute to a system that performs consistently under sustained load. In a championship environment, a gearbox must not only survive the heat and torque but do so with predictable engagement that a driver can rely on lap after lap. The KAPS EVO X option is engineered to meet that discipline, aligning with the demanding standards of professional racing while staying accessible to serious modification enthusiasts who value durability and repeatable performance.

For readers who want to bridge the gap between theory and practice, a tangible step toward a more integrated upgrade is to explore compatible components and cross-functional assemblies that can complement the gearbox system. For example, the EVO X half-cut components provide a practical pathway for integrating performance-focused sub-systems while maintaining alignment with the car’s existing powertrain architecture. This kind of component-level planning helps ensure that the upgrade is not just a bolt-on but a cohesive modification that preserves the vehicle’s intended balance and control characteristics. The path from concept to track-ready configuration is rarely a straight line, but with a robust set of compatible parts and the guidance of a knowledgeable supplier, it becomes a well-mapped route toward a more capable EVO X.

The broader implication of adopting a sequential gearbox for the EVO X is a more disciplined approach to power handling and driver confidence. The car’s behavior under throttle, cornering, and braking transitions becomes more predictable, enabling teams to push the package to higher performance thresholds without courting mechanical risk. What emerges is a vehicle that feels consistent across the grid, where the driver’s input translates into a clean, immediate response rather than a delayed or imperfect engagement that can upset rhythm. In this sense, the EVO X with a sequential transmission is less about chasing the latest trick and more about embracing a mature technology that respects the car’s chassis dynamics while elevating its capability under pressure.

As with any high-performance modification, context matters. A well-molerated upgrade hinges on professional alignment with the current race regulations, adherence to homologation requirements, and the availability of technical support throughout the lifecycle of the car. The most valuable narratives about these systems are not the marketing promises but the results logged on the clock. When a team can point to a long run of consistent shifts, reduced lap times, and improved reliability during critical stages, the value of the investment becomes clear. The EVO X then stands not just as a platform for speed but as an arena where engineering discipline meets driving precision.

In sum, the KAPS sequential gearbox solution for the EVO X embodies a philosophy that racers and serious modifiers have long pursued: make the powertrain behave as a coherent system, with the transmission acting as a dependable backbone that can sustain aggressive performance without surrendering control. The combination of a rigorously engineered gearbox, a set of reinforced drivetrain components, and a tunable differential control package creates a credible path to higher performance with measurable reliability. It is a pathway forged by racing experience, validated by competition, and made accessible to those who demand more from their EVO X without compromising safety, legality, or drivability. For anyone who wants to connect the concept of high-performance engineering to real-world racing discipline, this approach offers a clear articulation of how modern transmission systems can elevate an already spirited car into a consistently competitive machine.

Internal reference for readers seeking a deeper technical dive into the EVO X sequential option can be found at one of the site’s authoritative product pages, which lays out the core features, specifications, and installation considerations in a structured format. For a more general but authoritative external resource that captures the broader engineering philosophy behind these gear systems, the following reference provides a thorough overview of the technology and its application in the EVO X: https://www.kaps.cz/en/products/sequential-gearboxes/mitsubishi-lancer-evolution-x.

External reference: https://www.kaps.cz/en/products/sequential-gearboxes/mitsubishi-lancer-evolution-x

Shifting Power: How a Sequential Transmission Elevates a Rally-Ready, All-Wheel-Drive Precision

The act of changing gears can be the difference between a good lap and a great one, and nowhere is that truth more apparent than in the world of high-performance, all‑wheel‑drive road and track machines. A sequential transmission reframes the driver’s relationship with the powertrain. Rather than selecting a gear through a conventional H-pattern workflow, the operator engages a linear, up-or-down movement that delivers a measured, repeatable shift every time. In a context where every millisecond of shift time translates into precious hundredths of a second on the stopwatch, the sequential setup becomes less about novelty and more about reliability, consistency, and controlled power transfer under duress. For a track-focused, turbocharged performance sedan that routinely faces torque peaks well beyond its stock limits, upgrading to a race-grade sequential gearbox is less a tweak and more a fundamental recalibration of how the drivetrain responds to throttle input, engine speed, and the demands of traction on different surfaces and corners.

To understand why these transmissions matter, it helps to begin with the basics of how they operate and how that operation translates into tangible on-road and on-track benefits. A traditional manual gearbox relies on sync rings and gear teeth that must synchronize speeds before a clean mesh can occur. Even under ideal conditions, there is a limit to how quickly a driver can execute a shift, and that limit is set by the time it takes for the engine to align with a new gear and for the drivetrain to dampen any transient load. A sequential gearbox, by contrast, uses a single, linear shifting action—commonly up or down through the gear sequence—often driven by a short-throw lever or paddles. The change is direct, the engagement is consistent, and the shift time is dramatically reduced. The net effect is not merely quicker upshifts but more precise throttle staging and improved control during changes of load, such as exiting a corner while applying steady or rising torque.

The success of a sequential approach grows from the way the gearset itself is constructed and how it handles the stress of a boosted engine. In the racing context—where power figures routinely exceed those of most street cars—the gears are designed to resist the bending, twisting, and surface wear that come with high torque, heavy acceleration, and sustained lateral loads. The materials employed are typically high-grade alloy steels whose microstructure is refined through heat treatments engineered to boost strength, hardness, and wear resistance. The tooth profiles are optimized for dog-clutch engagement rather than the smoother meshing of synchronized gears, enabling rapid, decisive engagements that minimize torque interruption and drive-line lag. The result is a drivetrain that can deliver power to the wheels with minimal parasitic losses during upshifts and downshifts alike, preserving momentum when the driver needs it most.

In practice, this means a sequential system is not a single part but a carefully integrated package. The core gearbox houses the gear clusters and clutches or dog assemblies that perform the actual engagement. It is complemented by a finalized selection of components that tune how power is delivered across a range of conditions. Among these, the final drive gears—those tail gears that determine ratios closer to the wheels—are chosen to shape the car’s on-track behavior. A driver who wants rapid acceleration out of tight corners will favor shorter final-drive ratios; a higher-speed track profile, or a course with long straights, will push toward a taller ratio. The chassis must also accommodate a controllable differential system, with adjustable lock controllers that influence how traction is distributed across the driven axles under varying throttle states and cornering loads. In a competition-ready package, these controllers are tuned to interface with the driver’s inputs and the car’s stability systems, creating a seamless synergy between shift action, traction management, and the engine’s torque curve.

What makes the European racing-transmission landscape particularly interesting is the depth of experience found in firms that have evolved from utility-grade gears into specialized, purpose-built race transmissions. A prominent Czech-based outfitter, with roots tracing back to heavy-duty gear manufacturing for industrial and military applications, has become known for designing and producing sequential gearboxes tailored to rally and circuit racing. Their approach emphasizes reliability under duress, predictability in shift timing, and the ability to adapt gear sets to different power and track profiles. The gear blocks are engineered to withstand the elevated torque and high-speed demands of turbocharged engines, while the downstream components—such as final drives and differential locking solutions—provide tunable options that let teams and serious enthusiasts tailor the transmission to their specific driving style and course conditions. This philosophy—combining rugged gear construction with a modular approach to final-drive and differential management—maps cleanly onto the needs of a modern, high-performance, all-wheel-drive platform that is often run in competitive environments where reliability is as critical as speed.

Integral to this design philosophy is the awareness that a performance transmission is not a stand-alone unit but a key node in an entire driveline ecosystem. The engine’s torque output, the turbocharger response, and the inertia of auxiliary systems all influence how quickly and cleanly the gearbox can perform a shift, and how the power is then transmitted to the ground. In a turbocharged configuration, the engine’s peak torque is typically broad and intense, and the gearbox must manage that torque reliably through multiple heats cycles and high-speed shifts. The craftsmanship behind the gear sets emphasizes not only strength but also precision in tolerances, surface treatments, and the heat treatment processes that keep gear teeth from deforming or wearing under stress. The result is a system that offers not only reduced shift times but also a stable transfer of power with far less risk of a transitory hiccup that could upset the balance mid-corner or during a high-load exit.

On a practical level, an owner contemplating a shift to a sequential transmission should consider the broader implications for the drivetrain, suspension, and handling characteristics. A shorter, more immediate power transfer can alter how the car responds to throttle modulation and steering input in the critical moments after a corner. The effect on driveline stiffness and shock loading must be accounted for in the supporting components, including the clutching strategy, the transmission mounts, and the rear or front differential setup. If the engine is heavily modified—particularly with forced induction—the gearing strategy must be revisited. Shorter gear ratios may be ideal for sprint-style tracks or tight road-racing circuits, but they can pressure the engine and the cooling systems in ways that are not present with stock configurations. This underscores the need for a holistic approach to upgrading, one that aligns the gearbox with the engine’s torque profile, the track’s demands, and the driver’s preferred cadence.

Even as a sequential gearbox delivers tangible speed advantages, it is valuable to recognize the broader ecosystem of components that make it a practical upgrade. In a typical performance package, you’ll find a dedicated final-drive set tuned to the target power and track profile, paired with a central-differential lock controller that offers adjustable traction control in the sense of how aggressively the drivetrain distributes torque between wheels. The controller acts not unlike a smart brake that modulates torque delivery in real time, helping to stabilize corner exits under high power and to reduce the risk of wheelspin on uneven surfaces or when road grip is marginal. This harmonized ensemble—gears, final drives, and differential control—gives the driver the confidence to press the pedal earlier and with more precision, knowing the drivetrain will translate intent into propulsion in a predictable, repeatable manner.

The value proposition for enthusiasts seeking to push a four-wheel-drive performance sedan beyond its stock envelope is clear. A sequential gearbox, designed with racing in mind, can dramatically shorten shift times, which translates into improved engine braking control, more predictable acceleration through corners, and better time management across sections of a track where momentum is king. The gains in drivetrain efficiency—reductions in parasitic losses during shifts, more stable torque transfer, and cleaner engagement—increase the car’s ability to exploit engine power. When coupled with carefully selected gear sets, final-drive options, and differential-control strategies, the overall system becomes a more robust instrument for achieving consistent lap times even as the engine is pushed toward higher horsepower or tighter boost targets. This is not simply about faster shifts, but about a more coherent and disciplined powertrain behavior that the driver can rely on, corner after corner, lap after lap.

For readers who want a practical entry point into this upgrading path, one notable resource highlights the breadth of options available for modern sequential systems. It points to a lineage of parts that can be tailored to an individual car’s goals, with gear sets and supporting components designed to endure the kind of stress produced by a turbocharged engine while maintaining precise engagement during shifts. As with any major mechanical upgrade, the decision to move to a sequential gearbox should be framed by a careful assessment of the car’s torque targets, cooling capacity, and the wearing aspects of the transmission itself. It should also consider the installation context, including the suitability of the pedal feel (or paddle feel) and the integration with the car’s electronic control systems, which must be calibrated to coordinate shift timing with throttle and braking inputs.

From a narrative standpoint, the path toward a sequential gearbox for a rally- and circuit-ready sedan is a story of convergence: race-proven gear technology, an emphasis on durability under duress, and a design philosophy that privileges precise and repeatable engagement. The gear sets, the final-drive options, and the differential-tuning capabilities all work in concert to deliver a drivetrain that can withstand high torque and repeated heat cycles while still providing the driver with fast and predictable shifts. In this sense, the upgrade is less about a single piece of hardware and more about cultivating a system that behaves like an extension of the driver’s hands and feet, translating intention into controlled, efficient motion. The result is not merely a faster car, but a more capable partner on track days and a more confident platform for those who push a high-power four-wheel-drive sedan to its limits.

For readers seeking a concrete example of how this philosophy is embodied in practice, consider the detailed specifications and configurations that a well-established racing transmissions specialist outlines for competition vehicles. The company’s approach emphasizes durability and reliability at elevated torque levels, underscoring its capability to tailor gear sets for models in rally and circuit environments. In addition to the core gear package, the provider offers components that further tune the drivetrain, such as adaptable final-drive gears and adjustable differential-lock controls, which are essential for optimizing traction under varied surface conditions. This combination of robust gear design and configurable control hardware forms the backbone of a system that can be tuned to a specific track profile, engine torque curve, and driving style. The overarching point is simple: with a well-conceived sequential transmission, the car becomes more than the sum of its parts. It becomes a platform that rewards precise, deliberate inputs, and it is capable of delivering consistent, repeatable performance across a broad spectrum of competition scenarios.

To connect this discussion with practical resources, readers can explore detailed information on a full sequential gearbox package for a broad range of Evo-series platforms, which provides a direct pathway to understanding how gear ratios, final drive choices, and differential control work in concert. This resource emphasizes how a kit can be adapted to match the car’s torque profile and the track’s demands, ensuring the upgrade aligns with the driver’s goals and the team’s strategy. The page offers a clear lens into how gear sets and supporting components interact, and it may serve as a useful reference for those weighing the investment and the performance payoff of a sequential upgrade. For a closer look at that practical offering, see the linked specification page: Full sequential gearbox for Mitsubishi Evo 4-9 and X. While the specific configurations will vary by vehicle and competition category, the underlying principles described here apply across the board: quicker, more reliable shifts; stronger power transfer; and durable operation under high-load conditions. This cohesive approach to transmission design is what enables a modern, track-ready sedan to deliver consistent performance through a full spectrum of driving challenges.

In sum, the sequential transmission represents a fundamental shift in how a performance AWD sedan communicates with its driver and interprets the engine’s torque. Its promise lies in the blend of speed, control, and resilience—attributes that are essential when the goal is to extract maximum performance from a car that lives at the edge of its capabilities. By pairing a robust gearset with carefully selected final-drive options and differential control, a driver can maintain momentum through complex corners, manage traction with finesse, and push the envelope on track days with confidence that the drivetrain will respond as predicted. The upshot is a car that not only accelerates more aggressively but also feels more composed and predictable at the moment of power delivery. This is the essence of how a sequential gearbox can redefine what is possible with a rally- and circuit-ready, all-wheel-drive platform.

External reference: https://www.kaps.cz/en

How the EVO X Sequential Gearbox Works: Engineering, Integration, and Track-Proven Features

The transmission is the mechanical heart of any high-performance car, and the sequential gearbox option for the Evo X redefines what drivers can expect from shift speed, durability, and drivetrain integration. This chapter explores the engineering choices and features that make a sequential gearbox suitable for both competition and aggressive road use, how it differs from the factory alternatives, and what those differences mean for reliability, shift performance, and vehicle control.

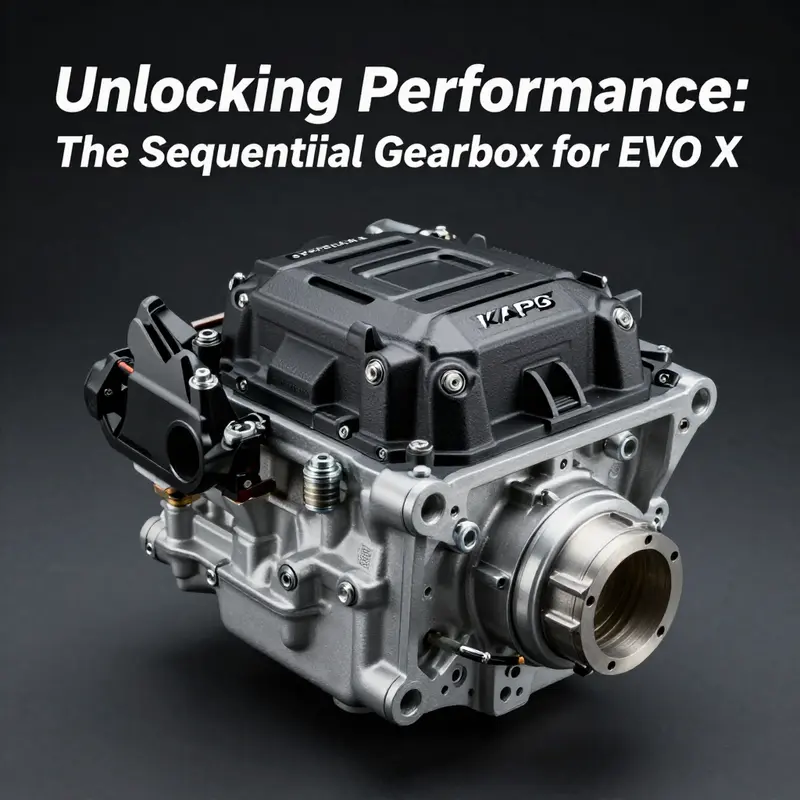

At the core, the Evo X platform offers multiple transmission philosophies from the factory: a traditional manual, and a dual-clutch unit that behaves like a sequential box. Both serve different driving priorities. The manual favors driver engagement. The dual-clutch provides nearly uninterrupted torque delivery with ultra-fast shifts. A purpose-built sequential gearbox, however, is a different engineering solution. It is optimized for repeatable, lightning-fast gear changes under high-load, high-rpm conditions. The mechanical design focuses on reducing shift times, increasing torque capacity, and simplifying actuation for race use.

A sequential gearbox replaces the traditional H-pattern selector with a dog-ring or straight-cut engagement mechanism that allows the next or previous gear to be selected in sequence. This setup eliminates the need to navigate between non-adjacent gears. The result is minimal shift interruption and a simplified, robust engagement method. In race-spec implementations, gearsets are often straight-cut to reduce axial loads and allow narrower gear faces. The trade-off is increased noise, which is insignificant in competition but notable on the street. Using dog engagement rather than synchromesh removes the wear-limited friction materials and enables instant lock-in of gears, which is critical for repeatable lap times.

Key mechanical features include hardened gear teeth, reinforced shafts, and upgraded bearings to handle elevated torque and shock loads. Manufacturers of competition gearsets apply specialized heat treatments and surface finishes to increase fatigue life. Gear ratios are selected to match the engine’s power curve and the intended use. Closer ratios keep the engine in the optimal power band during aggressive driving. This is why sequential conversions often come with a set of selectable ratio options, letting teams tune acceleration or top speed for specific tracks or stages.

Shift actuation is another defining element. Mechanical sequential boxes can be actuated via a lever, but modern race systems commonly use pneumatic or hydraulic actuators. These systems are tuned to deliver a specific shift stroke and force, ensuring consistent engagement regardless of driver input. Electronic shift-by-wire solutions layer precise timing and rev-matching into the actuation, coordinating throttle blips and clutch control. For the Evo X, integrating a sequential gearbox into the existing electronic architecture requires careful mapping so that traction and stability systems remain effective during shifts.

Integration with the vehicle’s all-wheel control systems is crucial. The Evo X platform benefits from an advanced AWD control suite that dynamically distributes torque front and rear and manipulates yaw through independent rear torque control. A sequential gearbox must coexist with these systems. That means shift strategies must avoid upsetting torque distribution at critical moments. Proper integration includes calibrating the engine management and drivetrain controllers to recognize the shift event. The aim is to prevent abrupt torque spikes or lapses that could trigger stability interventions or upset the vehicle’s balance under cornering loads.

Thermal management and lubrication are often overlooked but vital. High-performance sequential gearboxes run hotter than stock units. Oil must carry away heat, lubricate sliding and rolling contacts, and protect against micropitting. Race gear oils with anti-wear and extreme-pressure additives keep gear faces and dog rings protected under repeated shock loading. In many builds, an upgraded oil pump, external oil cooler, or dedicated gearbox oil circuit is added. These measures prolong component life and preserve consistent shift feel across a race distance.

Reliability is inseparable from component selection and assembly quality. A robust housing reduces flex under torque, maintaining precise gear alignment. Input and output shafts are typically uprated, sometimes to billet spec, to resist bending and torsional fatigue. Bearings are chosen for higher dynamic and static loads, and retaining methods are redesigned to prevent slippage or failure under race conditions. For anyone pushing the Evo X platform beyond stock power and duty cycles, a purpose-built sequential kit removes weak points inherent in road-focused gearboxes.

Shift ergonomics and driver feedback matter for both competitive and spirited driving. Sequential actuation provides a crisp, unmistakable shift feel. Paddle or lever systems can be tuned for travel and throw. Many setups allow manual mode in traffic, while offering full sequential mode in competition. Because dog engagement locks gears instantly, drivers experience almost no torque interruption. For circuits where momentum is critical, this immediacy translates to measurable time gains. On mixed-use cars, some builders add a rev-matching or auto-blip feature to smooth downshifts for street comfort while retaining race capability.

Performance metrics to watch when evaluating a sequential solution include torque capacity, shift time, weight impact, and gear spacing. Torque capacity should exceed the engine’s peak by a safe margin to account for transient spikes. Shift time varies with actuation method and tuning; pneumatic or hydraulic systems often achieve shifts measured in tens of milliseconds. Weight considerations are practical — some race gearboxes save weight through lighter materials and compact layout, improving response and handling. Gear spacing should align with the engine’s usable power band; very tight ratios improve acceleration, but may increase shift frequency and compromise top speed.

Installation and serviceability are part of the overall value proposition. A well-engineered kit will use modular components for easier replacement. Interchangeable gearsets simplify changing ratios between events. Clear service intervals and accessible inspection points reduce downtime. For cars intended for both track and street, a sequential gearbox must offer a realistic maintenance plan. Regular inspections of engagement dogs, selectors, bearings, and seals are essential. Service-friendly designs lower long-term ownership costs and make high-performance gear trains practical for dedicated enthusiasts.

Noise, vibration, and harshness (NVH) are different considerations between road and race builds. Straight-cut gears, dog engagement, and a stiffer housing will transmit more noise into the cabin. Engineers mitigate this with selective gearset choices, improved mounting isolation, and targeted sound-damping solutions. Many racers accept increased noise for performance. Street-oriented conversions often balance quieter helical gears with reinforced components to maintain durability while keeping NVH at acceptable levels.

Finally, the sequential gearbox plays a role in chassis setup and traction strategy. With near-instant shifts, drivers can keep the engine in the sweet spot more consistently, which changes how torque is delivered to the wheels. Suspension tuning, differential behavior, and tire selection must account for this altered torque profile. Brake-based techniques and throttle modulation also adapt to the sharper power delivery. The net result is a system-level improvement in lap times and responsiveness, provided the gearbox is matched to the rest of the drivetrain and electronics.

For those considering a conversion or upgrade, there are turnkey full-sequential options tailored for the Evo X lineage. These offerings typically include reinforced housings, race-derived dog rings, upgraded shafts, and an actuation system ready for competition. More details on available full sequential conversions can be found on a specialist listing for full sequential gearboxes for Evo models. Such solutions are engineered to balance durability, shift speed, and serviceability for both stage and circuit environments.

For a deeper look at factory transmission variants and comparative performance data, a reputable automotive resource provides comprehensive specifications and testing data on the Evo X’s transmission options. This serves as a useful technical companion when evaluating how a sequential gearbox will alter behavior, and what engineering trade-offs will be encountered in a conversion.

Overall, the sequential gearbox for the Evo X platform is not merely a faster shifter. It is a re-engineering of the drivetrain to prioritize durability under extreme loads, minimize shift interruption, and work in harmony with advanced torque-vectoring systems. When chosen and installed with attention to integration and service, a sequential gearbox transforms driving dynamics, providing a competitive edge and a purposeful, track-ready character.

How Sequential Gearboxes Redefined EVO X Performance and the Aftermarket Landscape

How sequential transmissions changed expectations for the EVO X platform

The conversation around sequential gearboxes and the EVO X is as much about engineering as it is about culture. Enthusiasts and teams began looking at sequential solutions because they solved precise, recurring problems: slow or imprecise shifts under race conditions, clutch and synchromesh wear at high torque, and the need for repeatable lap-to-lap performance. On a car originally built as a high-performance road-going all-wheel-drive platform, sequential transmissions offer a dramatic shift in capability. They turn the gearbox into a purpose-built component tuned for racing loads and rapid actuation.

This adoption has created a ripple effect across the aftermarket. Suppliers, fabricators, and race shops now prioritize driveline durability and modular designs. The market’s growth is driven partly by a steady stream of EVO X builds that push power and stress beyond stock tolerance. Owners upgrading engines or turbo systems routinely reach torque levels that expose the limitations of a factory gearbox. A sequential conversion becomes not only an option for quicker shifts but a necessary reinforcement for reliability at high output.

The European market has been particularly receptive. Racing heritage and a dense network of tarmac and gravel events encourage rapid technology transfer from professional to amateur competition. As teams demand gearboxes that deliver predictable shifts under extreme temperature and torque conditions, suppliers have responded with heavy-duty internals, improved lubrication circuits, and strengthened casings. This has pushed sequential boxes into a space once occupied only by specialist racing categories.

At the heart of the trend is a simple mechanical truth: sequential gearboxes offer faster, more deterministic gear changes than conventional manuals. That speed matters in competitive settings where half seconds are meaningful. But speed alone does not explain the broader market impact. These transmissions also change how drivers interact with the car. The removal of complex shift patterns reduces cognitive load. Drivers can concentrate on line, braking, and throttle control. For endurance events, this can lower fatigue and reduce human error. For sprint races, it improves consistency. Both outcomes increase the appeal of sequential swaps among serious EVO X owners.

Demand has encouraged suppliers to diversify offerings. Where once there were bespoke race-only boxes, manufacturers now create kits that balance track performance with serviceability. Modular designs allow teams to fit racing dog rings, straight-cut gears, or synchromesh clusters depending on regulations and budget. Heavy-duty variants include upgraded bearings, reinforced shafts, and enhanced cooling passages to handle the heat and torque that accompany modern power builds. Such diversity has a secondary effect: it reduces barriers to entry for amateur racers who can choose a package aligned with their goals.

The aftermarket ecosystem around EVO X sequential gearboxes extends beyond the gearbox itself. Upgraded differentials, robust axles, clutch systems calibrated for paddle or lever actuation, and standalone control electronics have risen in tandem. Specialists offer complete conversion packages that include mounting brackets, bellhousing adapters, and shift actuators. This holistic approach is important because a high-performance gearbox placed into a weak supporting system will only transfer the weak link elsewhere. The result is a more mature market where vendors think in systems rather than single parts.

Cost and accessibility remain critical dynamics. Sequential gearboxes carry a premium compared with upgraded stock kits. The upfront investment is significant, and it requires knowledgeable labor for installation and setup. Yet, when owners calculate total ownership for a competitive EVO X—factoring in downtime, repairs from gearbox failures, and lost race time—the value proposition shifts. Teams and privateers often justify the expense by measuring the gearbox as insurance against catastrophic transmission failure and as an enabling upgrade that unlocks consistent lap times.

Another market force is the parallel expansion of rebuild and service networks. Sequential gearboxes require periodic inspection and specialized maintenance. This need has spawned a service economy: gearbox rebuilders, dyno houses that perform gearset validation, and shops that calibrate paddle shift electronics. It is a two-way street. As more teams adopt sequential systems, more service providers invest in tooling and expertise, which in turn reduces lead times and service costs. Over several seasons, this can lower barriers for further adopters.

On the regulatory and motorsport side, homologation rules and class regulations influence platform choices. In some series, full sequential gearboxes are permitted, and teams can exploit this for competitive advantage. In other classes, regulations favor limited modifications to preserve parity. This environment creates clear market segmentation: one tier that moves aggressively towards full sequential conversions for maximum performance, and another that opts for reinforced stock gear kits to comply with class limits. Suppliers have adapted by offering both race-only sequential units and reinforced, class-compliant alternatives.

The EVO X community itself drives innovation through shared knowledge. Forums, build logs, and event debriefs accelerate learning curves. Builders report failure modes, recommend torque-management strategies, and document successful actuator calibrations. This communal knowledge reduces the risk of costly mistakes and smooths the integration process for newcomers. It also shapes product development, as vendors incorporate user feedback into next-generation designs.

Looking ahead, several technological and market trends will shape the landscape further. Additive manufacturing and precision machining reduce lead times for bespoke gearsets. Improved metallurgy and surface treatments increase gear life. Electronics, including more compact and deterministic shift actuators, make sequential systems easier to install and tune. These advances will broaden market access and gradually lower costs.

At the same time, broader automotive shifts will influence demand. Regulations and the move towards electrification will change how transmission systems are spec’d in factory cars. For now, the EVO X aftermarket remains grounded in internal-combustion performance, but the overarching trend toward hybridization and electric powertrains will prompt alternative approaches to rapid gear changes. In the near term, however, the EVO X platform will continue to be a niche where sequential gearboxes make practical and competitive sense.

For owners considering a sequential conversion, the decision is technical and strategic. It hinges on intended use, budget, and the level of commitment to maintenance. A full sequential install is not simply a speed upgrade; it is an investment in resilience and repeatable performance. Many teams treat the gearbox as the backbone of a race car. When configured properly, it unlocks the engine’s potential and stabilizes lap times.

The market impact of sequential gearboxes on the EVO X is therefore manifold. It elevates expectations for driveline durability. It reshapes the supply chain toward system-level thinking. It spawns a parallel service industry. And perhaps most importantly, it refines what drivers expect from their cars on track. Where enthusiasts once accepted compromise shifts and intermittent failures, they now demand solutions that deliver consistent mechanical behavior under extreme conditions.

Readers interested in conversion options and typical kit components can explore further details in a supplier listing that documents full sequential packages for the platform: full sequential gearbox for Mitsubishi Evo 4-9 and X.

For a wider market perspective and growth projections across sequential gearbox segments, industry research provides macro-level analysis and forecasts: https://www.grandviewresearch.com/industry-analysis/sequential-gearbox-market

Final thoughts

Upgrading to a sequential gearbox from KAPS offers substantial performance gains for the EVO X, making it a vital consideration for vehicle owners aiming for peak performance. As seen in our discussions on KAPS solutions, the performance enhancements, technical capabilities, and market dynamics reflect the ongoing evolution of automotive technology. By opting for reliable, high-performance components like the KAPS sequential gearbox, business owners can not only enhance their offerings but also contribute to the growing demand for specialized aftermarket solutions that characterize today’s racing and performance landscapes.