Auto parts are the integral components that ensure a vehicle runs smoothly, safely, and comfortably. This guide delves into the essential elements comprising automotive engineering, types of auto parts, manufacturing processes, and their economic impact on the industry. Understanding these facets is crucial for business owners in navigating the competitive auto parts market.

Under the Hood: How Auto Parts Shape Performance, Safety, and Innovation

Auto parts are the assembled language of a vehicle. They define how a car moves, senses, responds, and endures. Far beyond simple replacement pieces, these components form integrated systems that determine performance, safety, comfort, and the long-term cost of ownership. Understanding what auto parts are requires looking at their roles, how they are made, and how they interact within modern vehicles.

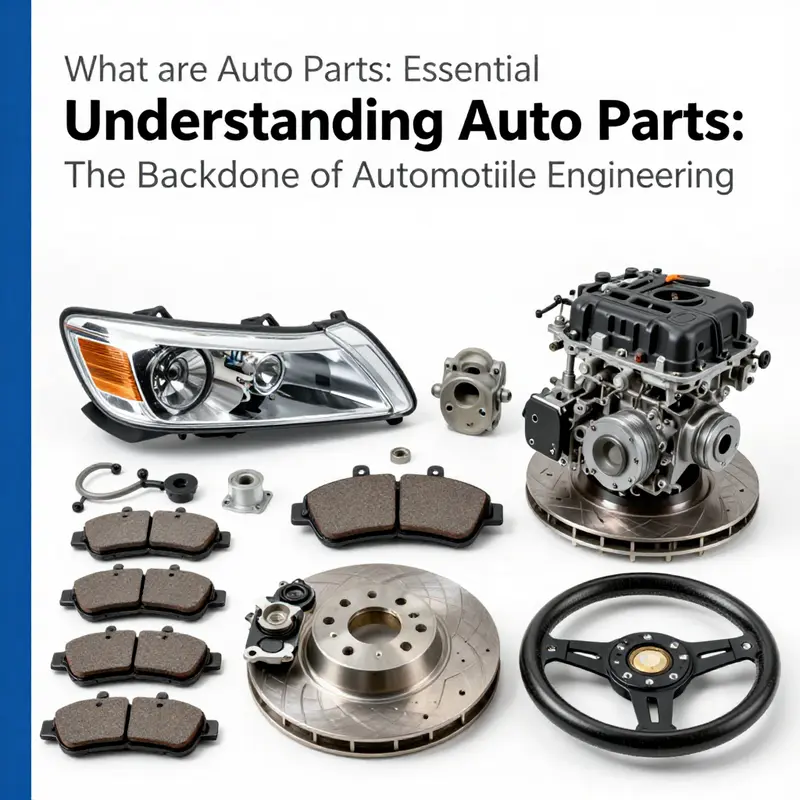

At a basic level, auto parts break down into functional groups: powertrain elements that create and transmit motion, chassis and suspension parts that govern handling, braking systems that ensure stopping power, electrical components that distribute energy, and body and trim pieces that protect and finish. Each group contains dozens to hundreds of discrete parts. For instance, powertrain assemblies include pistons, bearings, valves, gaskets, and sensors. Brake systems combine rotors, pads, calipers, hoses, and electronic controllers. These parts vary widely in size, material, and precision, but they share a common purpose: to meet engineering requirements for durability, safety, and performance.

Materials and manufacturing processes are central to how parts perform. Metals like steel and aluminum remain common for structural components because of their strength and predictable fatigue life. Advances in metallurgy and casting have produced lighter, stronger blocks and housings. Polymers and composites reduce weight and resist corrosion. Elastomers provide seals and vibration dampening. Surface treatments, such as plating and coating, extend life and resist wear. Precision machining, stamping, injection molding, and additive manufacturing shape parts to exact tolerances. Quality control at every stage ensures those tolerances are met. Parts that fail tolerance checks can reduce fuel efficiency or compromise safety.

Design standards and testing regimes bridge manufacturing to real-world use. Engineers specify parts to comply with industry regulations, performance benchmarks, and environmental limits. Components undergo fatigue testing, corrosion testing, and crash simulations. Electrical parts face electromagnetic compatibility trials. Brake components are validated for fade resistance and thermal cycling. High-volume manufacturers implement statistical process control to reduce variability. Smaller producers may use third-party certification to demonstrate compliance. Regardless of origin, a part’s specification establishes its expected behavior under stress, vibration, and temperature variations.

The market divides parts into original equipment and aftermarket categories. Original equipment parts are built to the specifications used during vehicle assembly. They match the form, fit, and function of the parts installed at the factory. Aftermarket parts are produced by third parties and range from economical replacements to high-performance upgrades. Some aftermarket options enhance durability, weight, or thermal performance. Others prioritize cost over longevity. The choice between these categories affects warranties, compatibility, and long-term reliability. In many cases, a well-specified aftermarket part provides equal function at lower cost. In others, the original design remains the safer choice due to unique tolerances or integration needs.

Integration is a growing theme in modern auto parts. Vehicles increasingly rely on sensors, cameras, and control modules. Parts now carry embedded intelligence. A headlamp may include adaptive lighting elements and sensors. A steering column houses angle sensors used by stability systems. Brake pads work with antilock braking controllers that monitor wheel speed and adjust hydraulic pressure. This integration means replacement parts must meet not just mechanical specifications but also electrical and communication standards. Misaligned or substandard parts can disrupt vehicle networks and trigger warning systems. Proper calibration during installation has become as important as the part itself.

Safety-critical components demand the highest scrutiny. Brakes, steering, suspension, and airbag-related parts directly impact occupant protection. Quality assurance for these items includes traceability, batch testing, and strict material control. Many suppliers maintain documented processes to ensure consistent material grades and heat treatments. Installation practices matter too. A correctly manufactured brake rotor can fail if mounted with improper clearance or torque. Technicians rely on service manuals, diagnostic tools, and torque specifications to preserve safety margins. Consumers and fleet managers must recognize that cost-cutting in these areas risks more than an early repair bill; it risks injury.

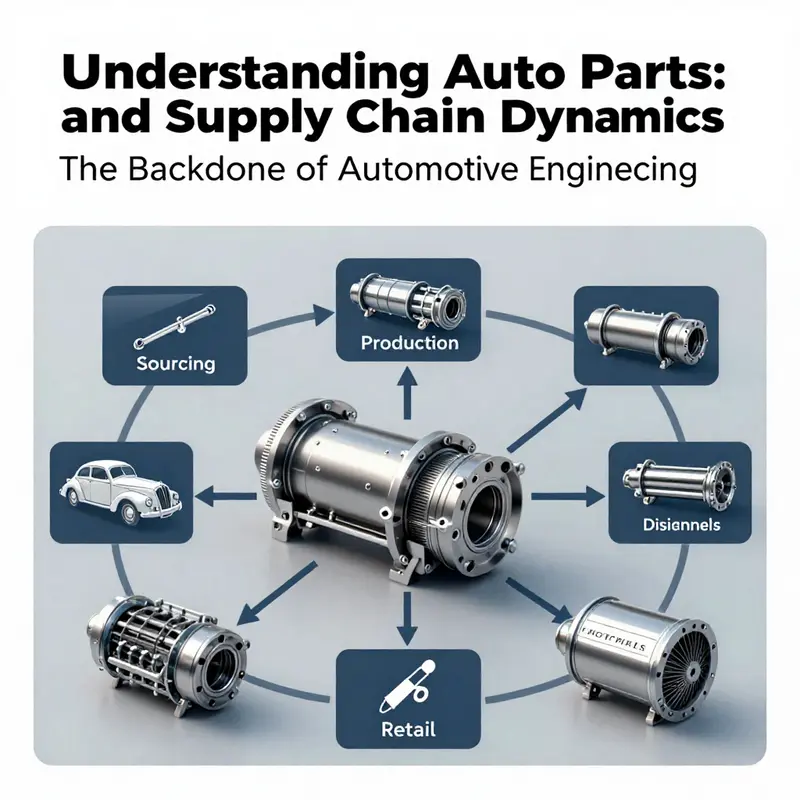

The supply chain behind auto parts is global and complex. Manufacturing clusters develop around skilled labor, raw material access, and engineering expertise. Distribution networks route parts from factories to warehouses and repair shops. Lead times, tariffs, and logistics costs affect availability and price. In some regions, local production dominates to support domestic assembly and exports. Trade flows shift as priorities change, such as a focus on electrification. For end users, supply chain issues explain why certain parts vary in price or why lead times differ across models. For repair professionals, sourcing reliable parts means balancing availability, compatibility, and proven supplier quality.

Maintenance and part selection influence longevity and total cost. Routine items like filters, belts, and brake pads follow predictable wear patterns. Replacing them at recommended intervals maintains performance and prevents secondary damage. More complex components, such as transmissions or electronic modules, present higher costs when they fail. Preventive replacement strategies help, but they require accurate diagnostics. Modern vehicles provide diagnostic codes and sensor data that guide decisions. Choosing parts that match specified tolerances and materials preserves the vehicle’s intended behavior and often reduces long-term expense.

Environmental considerations shape design and regulation. Regulations push for reduced emissions, improved fuel economy, and recyclability. Lightweighting through aluminum and composites reduces fuel consumption. Emissions control parts involve catalysts, sensors, and closed-loop systems. End-of-life strategies aim to recover metals and plastics. Remanufacturing—restoring a used component to like-new condition—conserves resources and reduces cost. It requires careful cleaning, inspection, and replacement of worn elements. Increasingly, manufacturers and suppliers track parts’ environmental footprints and offer recycling programs.

Technological change is redefining what an auto part can be. Advanced sensors, connectivity modules, and software-driven actuators transform passive pieces into active components. Over-the-air updates can change how a module behaves. As vehicles adopt driver-assistance features, components must meet stricter performance criteria. Calibration and software compatibility matter as much as mechanical fit. This shift places new demands on part certification and repair protocols. Technicians require updated training and tools to work on software-enabled components safely.

For consumers and technicians, reliable information and trusted suppliers are vital. Parts databases, vehicle identification number lookups, and detailed catalogs help identify correct items. Documentation on material grades, part revisions, and compatibility avoids costly errors. Reputable suppliers provide warranties and technical support. When choosing parts, prioritize those with clear traceability and documented testing. For complex systems, consider professional installation to maintain calibration and network integrity.

The evolution of auto parts continues to accelerate. Electrification introduces high-voltage components and battery modules with unique safety requirements. Software-defined functions allow updates and feature expansion. Additive manufacturing opens the door to rapid prototyping and on-demand parts production. These trends make parts more adaptable, but they also raise the bar for standards, certification, and training.

Within this landscape, everyday parts remain essential. A properly made filter protects an engine from abrasive particles. A correctly balanced wheel prevents premature bearing wear. A durable gasket keeps fluids contained. Attention to these details preserves vehicle health and performance. Understanding parts, their materials, and their system roles enables better maintenance, healthier budgets, and safer roads.

For readers who want practical examples of how interior components are assembled and cataloged, consult a detailed dashboard component reference available here: dashboard Evo 9. That resource illustrates how trim, instrumentation, and wiring integrate into a single module, and how fitment and part numbers guide replacement.

Manufacturers and suppliers publish technical resources that illustrate material composition, testing standards, and typical applications. These resources help repair centers and buyers match parts to vehicle systems. For deeper technical context on material composition and standards for modern connected vehicle parts, see this technical overview: https://www.zeekr.com/en/vehicle/zeekr-x/auto-parts.

As vehicles become more complex, the term “auto parts” will take on broader meaning. Parts will be mechanical, electrical, and virtual. The most effective approach to sourcing, installing, and maintaining them combines attention to specifications, respect for integration, and informed supplier selection. That approach keeps vehicles safe, efficient, and ready for the innovations yet to come.

null

null

null

null

null

null

Final thoughts

Understanding the diverse aspects of auto parts helps in making informed decisions for business success in the automotive industry. As components evolve with technology advances and market demands, staying updated on these dynamics is essential for capitalizing on opportunities and addressing challenges effectively.