The automotive landscape is marked by a crucial distinction: the choice between OEM (Original Equipment Manufacturer) auto parts and alternatives. For business owners in the automotive sector, understanding the significance of OEM parts is essential for maintaining quality, safety, and compliance in vehicle repairs and maintenance. As this guide unfolds, we will delve into what OEM auto parts are and their importance, explore how they differ from aftermarket parts, assess the economic implications of choosing OEM parts, and discuss the regulatory standards that govern their use. Each chapter will provide crucial insights that can enhance decision-making and reinforce the reliability of repair practices.

OEM Parts: Preserving Safety, Fit, and Value in Vehicle Repair

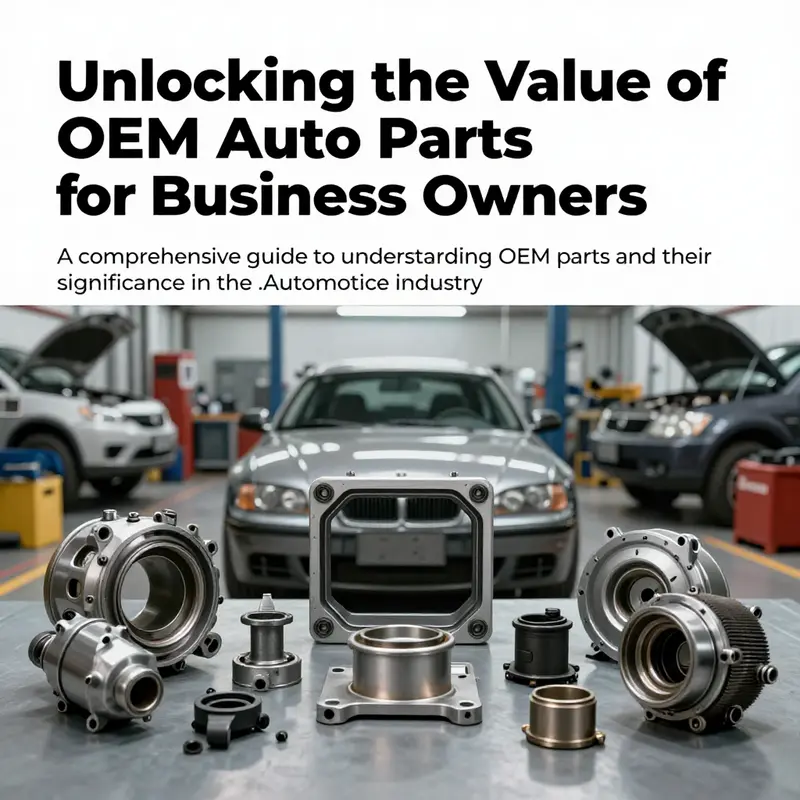

Original Equipment Manufacturer (OEM) parts are produced by the automaker’s trusted suppliers to the exact specifications used on the factory line. Using OEM parts helps preserve critical safety systems, maintenance histories, and the vehicle’s intended performance. OEM parts fit with the precise tolerances, mounting interfaces, and electronic connections required by modern vehicles, reducing the risk of NVH changes and warranty issues. While they can carry higher upfront costs, OEM parts often maintain resale value and regulatory compliance, particularly for safety-critical components such as airbags, braking hardware, and structural elements. The decision to use OEM versus aftermarket should consider the model year, warranty status, and the repair’s significance to safety and performance. In practice, many technicians start with OEM parts for essential or safety-related components and may opt for OE-equivalent options for non-critical systems when appropriate, always prioritizing alignment with the vehicle’s original design intent and the manufacturer’s service recommendations.

Fidelity, Fit, and Future: Navigating OEM Auto Parts in a World of Aftermarket Alternatives

Original Equipment Manufacturer parts, or OEM parts, are designed to meet the exact specifications of your vehicle and are typically the safest choice for critical systems. They fit precisely and maintain the vehicle’s warranty and insurance compatibility.

Aftermarket parts can offer cost savings and broader availability, but quality and fit can vary. Some aftermarket parts match OEM specifications and are produced by reputable suppliers, while others may compromise on material quality, testing, or compatibility. The decision often depends on the component, the vehicle’s age and warranty, and the owner’s priorities.

Key dimensions for decision include fitment, warranty coverage, performance, and long-term ownership costs. For safety-critical systems like brakes, steering, or airbags, OEM or OEM-equivalent parts are generally recommended, whereas for cosmetic or non-critical components, carefully chosen aftermarket parts may suffice.

To make an informed choice, consider: certified suppliers, documented testing results, clear warranty terms, and whether the repair requires software recalibration. A trusted technician can help verify compatibility and ensure that sensor alignment and calibration remain correct after replacement.

In summary, OEM parts offer predictability and warranty continuity, while aftermarket options provide flexibility and potential savings. A thoughtful approach balances safety, reliability, and total ownership costs.

Worth the Price? The Economic Landscape of OEM Auto Parts and What It Means for Owners, Shops, and Manufacturers

Original Equipment Manufacturer parts, or OEM parts, sit at a curious crossroads in the car world. They are the components that left the factory floor exactly as they were designed to be, and they return there when a repair is needed. The economic story of OEM parts is not simply about price tags. It is about the way a vehicle’s performance, safety, and long-term value are tied to the integrity of every component, and how that integrity is priced, delivered, and perceived by millions of drivers, repair technicians, and the companies that build, sell, and service cars. To understand the economics of OEM parts is to trace a chain that connects engineering standards with market dynamics, consumer behavior, and policy debates that shape everyday choices around maintenance and repair. In this sense, the topic becomes less about a single product category and more about a system in which design intent and economic incentives align or diverge, producing consequences that ripple through households, repair shops, and manufacturers alike.

At the heart of the OEM proposition is the assurance of compatibility. OEM parts are engineered to meet the exact specifications of a particular make and model, guaranteeing a precise fit and a predictable function. This precision matters because automotive systems are interdependent. A sensor calibrated for a specific control unit, a windshield that matches a unique curvature, or a brake pad that is harmonized with a brake system’s raw materials and heat tolerance all contribute to the vehicle’s overall safety and reliability. When these components are replaced with OEM parts, the risk of compatibility issues, warranty disputes, and unanticipated repairs tends to remain low. That is not to say aftermarket alternatives cannot meet or exceed OEM standards in many cases, but the difference often lies in the predictability of performance and the strength of warranty and service support that accompanies OEM parts. The economic implications of this predictability ripple through the lifecycle costs that owners weigh when they decide how to maintain their vehicles.

From a value perspective, OEM parts are frequently positioned as the premium option. Their higher upfront cost reflects the investment automakers and their authorized suppliers have made in maintaining strict production protocols, traceability, and testing that ties back to the vehicle’s original design intent. Consumers who prioritize safety margins, warranty protection, and long-term reliability often perceive this premium as well worth it. The logic is straightforward: when a part is designed and tested to the exact needs of the vehicle, the likelihood of a premature failure, a warranty claim denial, or an unsatisfactory repair outcome decreases. The payoff is fewer unexpected breakdowns, a smoother maintenance experience, and, in some cases, a higher resale value because the vehicle’s maintenance history aligns with the manufacturer’s standards. In this sense, OEM parts contribute to a kind of economic insurance policy—a hedge against the risk of misfit parts that could compromise performance or escalate costs down the line.

Yet the premium pricing of OEM parts cannot be understood in isolation from the channels through which they are sold and the agreements that govern their distribution. The economic reality is that OEM parts are often tied to authorized channels—franchised dealerships, certified service centers, and the automaker’s own parts network. These channels benefit from brand alignment, standardized pricing, and the ability to offer integrated service experiences that link parts with diagnostics, software updates, and warranty handling. The result is a pricing structure that reflects not only the cost of manufacture but also the value of a controlled ecosystem where service quality is correlated with the manufacturer’s reputation and warranty framework. When a part is sourced through these channels, price transparency tends to be guided by franchise economics—a model that emphasizes service consistency, long-term relationships, and aftercare that underpins trust between the consumer and the brand.

For many households, the decision to opt for OEM parts is a careful calculus of cost versus benefit. The upfront price difference between OEM and aftermarket parts can be substantial, sometimes several times higher. In the short term, a consumer might favor the lower sticker price of aftermarket options. However, the lifetime costs of ownership can tilt the balance in favor of OEM parts when the probability of component failure, warranty claims, and the need for repeated replacements is considered. The economics here are not just about a single repair but about the reliability of the entire system: an engine control module, a transmission part, or a braking component that is consistent with the vehicle’s original calibration can prevent cascading failures that would otherwise lead to more expensive fixes. In other words, the economic advantages of OEM parts are often realized not in the moment of purchase but in the months and years that follow, as maintenance becomes more predictable and the risk of costly repairs decreases.

The consumer’s long view on cost is also shaped by the concept of total cost of ownership. OEM parts can influence not only immediate repair bills but also insurance considerations, fuel efficiency impacts, and the potential for future maintenance needs to be staged in a way that minimizes downtime and the disruption to daily life. The precision of OEM components supports the broader engineering principle that a vehicle’s performance envelope is designed as a cohesive system. When a critical component aligns with that system’s specifications, the vehicle’s operability remains within expected tolerances, reducing the chance that ancillary parts must be replaced prematurely due to a mismatch. This creates a measurable economic benefit in terms of reliability, which, while not always captured in sticker price alone, contributes to a more favorable cost of ownership profile for many drivers.

The market dynamics around OEM parts also reflect supply chain realities and exclusive production arrangements. The premium price often mirrors the exclusivity of access, which can be a strategic choice by automakers and suppliers to ensure a controlled flow of components. Limited supply channels can maintain consistent quality and protect the brand’s performance narratives, but they can also constrain availability, especially during periods of high demand or vehicle model year transitions. When supply is restricted, the cost pressures on authorized service centers rise, and those costs are often passed along to consumers who require timely repairs. The flip side is that OEM availability can protect warranties and preserve the vehicle’s designed safety and performance thresholds, which many owners consider essential when repairing high-value or safety-critical systems.

The economic implications extend beyond individual end-users to independent repair shops and the broader aftermarket ecosystem. The exclusivity of OEM parts can present a barrier to entry for independent repairers, increasing the costs of repairs for customers who seek more affordable options. This dynamic supports a bifurcated market in which some owners accept higher prices for OEM parts and the associated service experience, while others pursue aftermarket parts that offer competitive prices and a growing diversity of technical solutions. The aftermarket sector has responded to this gap with an ever-expanding array of components that aim to replicate OEM performance at lower prices, including redesigned equivalents, remanufactured parts, and parts with varying levels of certification. The result is a competitive pressure that can drive overall market efficiency, quality improvements, and more transparent pricing, but it can also create confusion about what constitutes a “same as genuine” replacement and how warranty protections are handled when non-OEM parts are used. The evolving debate around reliability, warranties, and performance continues to shape repair shop practices and consumer expectations about what is acceptable in terms of part provenance.

Pricing strategies within the OEM ecosystem are nuanced. The premium pricing aligns with the certainty of fit and function, the alignment with the vehicle’s calibration, and the assurance of ongoing compatibility with diagnostics and software. Automakers and suppliers argue that this premium is justified by the maintenance of safety standards, the retention of performance characteristics, and the protection of brand integrity. Critics, however, point to the market power embedded in distribution networks and the potential for price discrimination that limits consumer choice. They argue that a more competitive environment—where aftermarket channels can access the same design data, quality controls, and testing protocols—could drive down costs and spur innovation in maintenance solutions. The tension between brand protection and consumer access is not a trivial policy concern; it is a distinctive feature of how modern automotive repair markets allocate risk, reward, and information.

A related economic thread concerns the reliability of supply and the risk of counterfeit or substandard components. Although OEM parts come with traceable provenance and standardized testing, the demand for vehicle maintenance inevitably invites counterfeit risks in any market segment that holds substantial repair costs. Consumers who unknowingly purchase counterfeit parts face potential safety and performance hazards, and repair shops risk warranty reversals or reputational damage. The economic consequence of counterfeits is not only the direct cost of poor quality but also the indirect costs of misdiagnosis, program recalibration, and the need for repeated replacements, which can erode trust in both OEM and aftermarket ecosystems. In this environment, the economic value of OEM parts as a safeguard for safety and reliability becomes a persuasive argument for many buyers, even when the initial price is higher.

Beyond the microeconomic decisions of individuals, the OEM parts economy interacts with public policy and consumer advocacy. Regulators and advocacy groups scrutinize practices that restrict access to essential components or that raise prices through opaque channels. This scrutiny reflects a broader concern with market concentration, transparency, and the fairness of pricing in the automotive supply chain. In some jurisdictions, policy initiatives emphasize the right to repair, encouraging or requiring access to diagnostic tools, service information, and, where appropriate, replacement parts at market-competitive prices. The economic impact of such policy considerations is real: it can alter the balance of bargaining power between manufacturers, independent repair shops, and consumers, potentially expanding options and dampening unnecessary price inflation. The ongoing dialogue between policy, market dynamics, and consumer choice is a defining feature of the OEM parts economy in the contemporary automotive landscape.

For readers seeking a broader lens on how the larger economy shapes the costs and choices around auto parts, official data from national statistics programs offer context about spending patterns, price movements, and the role of durable goods in household budgets. These macroeconomic perspectives help illuminate why OEM parts hold their current value position even as aftermarket options grow. They remind us that the price of a single replacement part is connected to a web of expectations about safety, performance, insurance, resale value, and the ability to maintain a vehicle in a state that reflects the original manufacturer’s design intent. In this interwoven system, the decision to buy OEM or aftermarket parts is rarely a narrowly financial one. It is a decision about risk, reliability, and the kind of driving life a person envisions for their vehicle over the years ahead.

The chapter of the story on OEM parts is not a simple tale of higher costs versus lower costs. It is a narrative about aligning engineering integrity with consumer expectations, about the leverage manufacturers hold over service ecosystems, and about the ways in which pricing reflects both technical necessity and strategic market management. It invites readers to weigh the tangible benefits—the protected warranty, the assurance of compatibility, the consistency of performance—against the economic realities of price, availability, and access. It also invites a closer look at how the aftermarket sector responds to these pressures, not as a mere substitute but as a complex system that can improve or undermine overall maintenance quality depending on how it evolves. As the market continues to diversify and as more data accumulate about long-term reliability and total ownership costs, the economics of OEM auto parts will continue to be a meaningful lens through which drivers, repair professionals, and policy makers understand the cost of keeping a car on the road.

In the end, the decision to choose OEM parts involves more than a price tag or a warranty brochure. It involves an assessment of risk, a belief in the longevity of the vehicle’s design concepts, and an appreciation for the broader ecosystem that sustains safe and reliable mobility. For some, that means investing in the assurance that comes with an OEM part; for others, it means embracing a broader spectrum of high-quality equivalents that can deliver similar outcomes at a different price point. The economy of OEM auto parts is, at its core, about balancing precision, protection, and value over time. It is a conversation that will continue to unfold as vehicles become more sophisticated, and as the incentives of manufacturers, consumers, and repair shops adjust in response to new technologies, pricing strategies, and regulatory expectations. This dynamic, evolving landscape is essential to understanding not just what OEM parts are, but why their costs matter—and what those costs say about how we maintain and value our vehicles in a modern economy.

External resource: For a broader view of how parts pricing fits into consumer spending and market dynamics, see the U.S. Bureau of Labor Statistics Consumer Expenditure Survey. https://www.bls.gov/cex/.

Internal link example: A practical example of OEM-like components available through authorized channels illustrates how design intent can be preserved in a repair. See a listing described as a brand-new original carbon-fiber hood listing for a vehicle model in the OEM context brand-new original carbon-fiber hood listing. This kind of listing helps demonstrate how manufacturers and authorized suppliers preserve fit, finish, and performance when replacing major exterior components.

How Regulatory Standards Shape OEM Auto Parts and Supplier Compliance

Operationalizing Standards: How Regulatory Requirements Define OEM Auto Parts and Supplier Practices

Original Equipment Manufacturer parts exist within a dense web of technical rules, legal mandates, and market expectations. It is not enough for a component to fit a bolt pattern or look like the original. OEM parts must meet documented performance profiles, pass defined tests, and carry traceable records from design through delivery. This chapter explains how regulatory standards shape those expectations, how suppliers organize to meet them, and what compliance means across product lifecycles.

Regulatory frameworks provide the structure that keeps vehicles safe, durable, and environmentally responsible. Quality systems such as ISO 9001 set the minimum expectations for consistent production and process control. Compliance to these systems forces suppliers to document procedures, track defects, and maintain corrective-action routines. For electrical and electronic modules, RoHS limits hazardous substances. For entry into European markets, certain components must bear the CE mark to demonstrate alignment with applicable directives. These standards serve two functions: they ensure minimum safety and create a common language for automakers and suppliers to specify requirements.

The modern compliance checklist goes beyond those foundational standards. Automotive-specific norms now govern systems that were once peripheral. Functional safety for electrical and programmable systems is codified under ISO 26262. This standard requires suppliers to assess hazards, allocate Automotive Safety Integrity Levels, and prove that systems meet safety goals through design, verification, and validation. As cars have become software-defined, cybersecurity standards emerged. Regulations such as UNECE Regulation No. 155 demand cybersecurity risk management for connected systems and call for lifecycle security planning. Environmental and sustainability requirements also intensify, pushing manufacturers to prove reduced emissions, responsible material sourcing, and robust end-of-life handling.

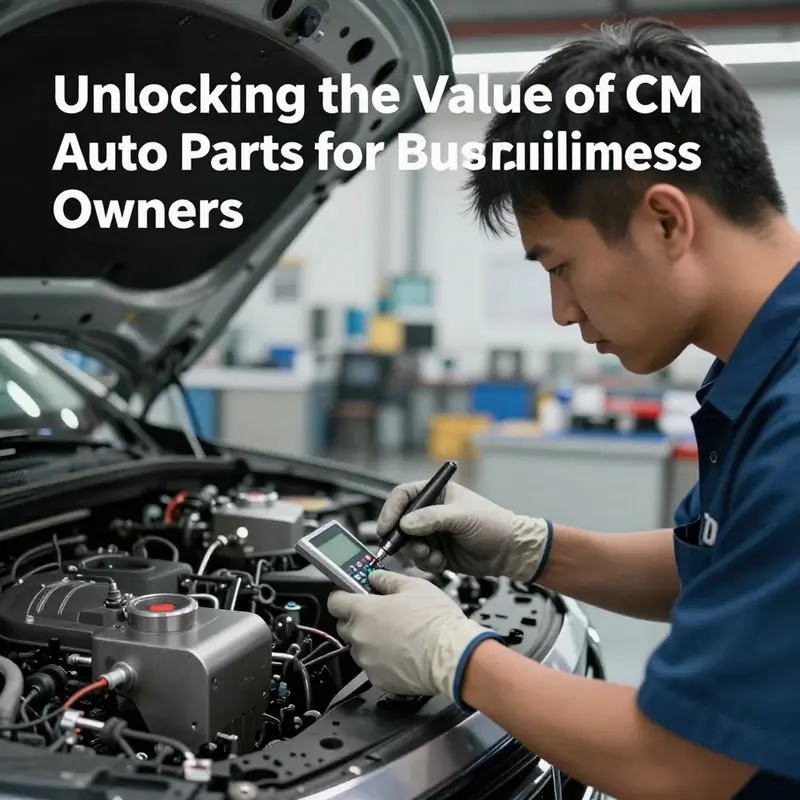

Compliance is therefore not a single checkbox. It is a continuous program spanning engineering, procurement, manufacturing, quality, legal, and aftersales. Suppliers must translate broad standards into concrete practices. During design, they create requirement matrices tying each component function to a normative requirement. During manufacturing, they instrument production lines for traceability, batch control, and statistical process control. During validation, they perform accelerated aging, vibration, thermal cycling, and electromagnetic compatibility tests. After delivery, they maintain complaint-handling systems, warranty records, and recall readiness plans. Integrating these activities demands management systems that link documents, test results, and corrective actions across the supplier enterprise.

Geography plays a role in how suppliers meet these demands. Industrial clusters concentrate engineering talent, tooling shops, and tiered supply networks. In regions known for heavy manufacturing density, suppliers enjoy proximity to tier-1 companies and logistics hubs. This proximity accelerates prototyping, shortens feedback loops, and enables lean production cycles. It also supports rapid compliance iteration: a supplier near major OEMs can quickly adjust processes to new normative requirements or to an automaker’s updated specification.

Third-party testing and certification bodies serve as compliance multipliers. Independent organizations provide audits, laboratory testing, and certification that reassure OEMs and regulators. These entities evaluate quality-management systems, perform product-level safety testing, and verify environmental claims. For many suppliers, passing such third-party audits is a de facto entry ticket to servicing global automakers. Their reports reduce the audit burden on OEMs and standardize what counts as demonstrated compliance.

Failing to meet standards carries real and immediate risks. Legal penalties for violating safety or environmental rules can be substantial. A flawed component can force a large-scale recall, creating direct financial cost and potential liability. Market access may also be revoked when regulators determine that a product does not meet required norms. Moreover, non-compliance damages a supplier’s reputation. In a market where long-term partnerships are key, reputation loss can shut off future contracts and shrink business opportunities.

Because the stakes are high, automakers embed compliance expectations into supplier contracts. These contracts require documented adherence to specific standards and often include rights to inspect, audit, or demand remediation. Suppliers must demonstrate capabilities not only in manufacturing but in cybersecurity, functional safety, and environmental governance. For instance, an automaker may require evidence of safety analyses for embedded software, or proof that a plastic component meets restricted-substance limits.

Operationalizing these requirements requires both governance and capability. Good governance clarifies roles for compliance: who tracks regulatory changes, who updates engineering requirements, and who manages audit responses. Capability comes from systems and skills. Suppliers invest in test labs or partner with accredited laboratories. They train engineers in functional-safety concepts and hire personnel skilled in cybersecurity threat modeling. They adopt product-lifecycle management and quality systems that centralize requirements and test evidence. These investments can be costly, but they reduce the risk of rework, product failure, and non-compliance.

Traceability is a recurring theme in compliance. Regulatory frameworks expect suppliers to show how a part was made, who performed key steps, and what test results led to acceptance. This requires data capture at every stage: material certificates from sub-suppliers, in-line inspection results, calibration records for equipment, and serialized production records. Digital tools make this feasible at scale. Manufacturing execution systems and cloud-based document control systems store and present evidence during audits. Traceability also supports targeted recalls. When a defect appears, accurate records enable a supplier and OEM to identify affected lots quickly and limit the scope of any remediation.

One practical intersection of compliance and OEM identity is the idea of “fit and function.” OEM parts must replicate the original dimensions, tolerances, and performance characteristics. But compliance adds layers: safety features such as adhesive bonding strength, curtain airbag deployment compatibility, and optical performance on glazing must all meet regulatory thresholds. A windshield replacement that matches dimensions but fails ballistic, optical, or defogging requirements could endanger occupants and trigger non-compliance. Thus, suppliers validate parts both to the OEM’s technical drawings and to relevant regulatory test methods.

Beyond product testing, labeling and documentation carry regulatory weight. Safety-critical parts require warning labels, installation instructions, and sometimes instructions for disposal. For electronic components, documentation must include information that supports functional-safety claims and cybersecurity mitigation measures. These documents follow the part through installation and service, ensuring that technicians have the information needed for safe repairs.

Compliance is not static. Regulations evolve with technology and societal priorities. Cyber threats change quickly, and regulators update expectations accordingly. Environmental targets grow stricter. Suppliers must therefore maintain programs for monitoring regulatory change and converting new rules into engineering and process requirements. This includes scenario planning for emerging standards, gap assessments, and staged investments in capability. A supplier that adapts proactively gains a competitive edge, while a slow mover risks losing business as automakers seek partners who can meet future requirements.

The economics of compliance matter. Meeting stricter standards increases unit costs through testing, certification, and process control. OEMs and suppliers negotiate who bears those costs. In many cases, OEMs require suppliers to absorb compliance investments as part of maintaining their supply agreements. For new technologies, cost-sharing agreements may appear. Transparent cost modeling and collaborative planning help both sides manage total lifecycle cost while meeting regulatory demands.

Finally, compliance shapes relationships across the extended supply chain. OEMs increasingly demand visibility into sub-suppliers. They want proof that raw materials meet environmental rules and that subcontracted machining operations conform to process controls. This pushes suppliers to manage not only their own compliance but that of their vendors. Supply-chain transparency programs, supplier audits, and contractual clauses ensure this alignment. In parallel, digital certificates and blockchain trials aim to reduce friction in showing compliance across multiple tiers.

Understanding regulatory standards and OEM compliance uncovers an important truth: compliance is an active engineering discipline. It requires design intent, rigorous verification, and clear governance. Parts that meet OEM specifications in form and function but skip compliance steps expose companies to risk. Conversely, suppliers that embed standards into their processes create reliable, auditable systems that automakers can trust.

For a concrete example of the way OEM identity and compliance intersect, consider a genuine OEM front bumper designed for a specific vehicle platform. That part must match crash energy management criteria, meet materials restrictions, and carry installation instructions aligned with the vehicle’s safety system. Suppliers producing these components must document material certificates, perform impact testing, and maintain traceable production lots. For an illustration of such a genuine replacement bumper and how OEM identity is preserved, see this example of a genuine CZ4A Lancer Evolution X front bumper available through an OEM parts outlet: https://mitsubishiautopartsshop.com/mitsubishi-cz4a-lancer-evolution-x-front-bumper-genuine/.

Standards bodies and testing organizations will continue to play a central role. They translate societal expectations into verifiable criteria. They run accredited labs and develop normative language that automakers and suppliers rely upon. Suppliers that partner with reputable testing and certification organizations benefit from standardized evidence and reduced audit cycles. This partnership model supports global market access and drives consistent quality across regions.

As vehicles grow more complex, the scope of compliance widens. Electronic control units, driver-assistance software, and connected services require new test regimes. Suppliers must plan for that complexity by building multidisciplinary teams, investing in validation infrastructure, and embedding compliance checks throughout product development. Doing so minimizes downstream surprises and supports a safe, sustainable automotive ecosystem.

For further technical guidance on automotive compliance and certification resources, consult the detailed offerings from a recognized testing and certification organization: https://www.ul.com/solutions/automotive-compliance-and-certification

Final thoughts

In summary, OEM auto parts represent the gold standard for vehicle manufacturers and repair shops alike, guaranteeing quality, safety, and compliance with regulatory standards. Understanding their importance, differentiating them from aftermarket alternatives, and recognizing their economic benefits arm business owners with crucial insights for making informed decisions that ensure customer satisfaction and vehicle reliability. As the automotive industry continues to evolve, embracing the value of OEM parts is not just smart—it’s essential for fostering long-term trust and success in the market.