For many business owners, dealing with vehicle maintenance can be a time-consuming task, especially when the elusive Check Engine light illuminates your dashboard. This warning signal is not merely an inconvenience; it indicates that your vehicle’s electronic control system has detected a problem that requires attention. Understanding the implications of this light and how to respond appropriately is critical for maintaining your fleet’s efficiency and performance. In the chapters that follow, we’ll first explore what the Check Engine light signifies specifically in the context of Advance Auto Parts. Next, we’ll detail the common diagnostic steps you can take at their locations. Finally, we’ll evaluate the essential role Advance Auto Parts plays in resolving these issues, making vehicle maintenance smoother for business owners.

Decoding the Check Engine Light: A Practical Guide to Diagnosis and Safe Driving

The Check Engine light, often called the Malfunction Indicator Light or MIL, is more than a simple dashboard ornament. It is the vehicle’s early warning system, programmed to alert you that the electronic control system has detected a fault somewhere in the engine, emissions, or fuel management network. When the light comes on, it does not announce a single failed part; rather, it signals that the onboard computer has identified a condition that could affect performance, efficiency, and emissions. In most cases, the light glows yellow rather than flashing red, a distinction that matters for how you respond. A steady glow usually means a fault has been detected but is not immediately dangerous, while a flashing MIL signals a potentially severe condition that could damage the catalytic converter or other components if the car is driven aggressively. Understanding this nuance is the first step toward a measured, effective response rather than a hasty, costly guess.

Beyond the color and the moment of activation, the Check Engine light is really a breadcrumb trail left by a complex network of sensors and actuators. Modern vehicles rely on a web of systems—the oxygen sensors monitoring exhaust gas composition, the mass airflow sensor measuring the amount of air entering the engine, the throttle position sensor, the fuel delivery system, and the ignition system, to name a few. Each sensor feeds data to the engine control unit, the car’s electronic brain. When that data shows a deviation from expected values, the ECU stores a diagnostic trouble code and illuminates the MIL. The range of potential triggers is broad. A loose gas cap, a common and easily overlooked culprit, can be enough to trigger a code if fuel vapors escape or the system detects pressure irregularities. A failing oxygen sensor can degrade fuel economy and raise emissions; a dirty air filter or a clogged intake can starve the engine of air, reducing performance and prompting a fault code. Worn spark plugs or ignition coils can cause misfires, leading to poor combustion and elevated pollutant output. A dirty or faulty mass airflow sensor, or problems with the EGR valve and catalytic converter, can also set the light ablaze. The array of possibilities means a code is not a verdict but a direction; it points you toward the system that needs attention, while the finer diagnosis reveals the exact component in need of repair.

A helpful way to think about the MIL is to imagine it as a caretaker rather than a judge. It does not demand immediate replacement of parts in every case. Rather, it asks for a diagnostic check to confirm whether the fault is temporary, such as a sensor reading that will normalize after driving for a short period, or whether an actual component has failed or is failing under certain conditions. This distinction is essential for prudent decision making. If the light has just appeared, there are practical, low-stakes steps you can take before heading to a shop. For instance, first check the gas cap. A loose or damaged cap is a surprisingly frequent trigger for the MIL because vapor leaks affect the system’s pressure readings. Tighten the cap fully and monitor the light over the next few driving cycles. If the light persists or returns after a few days of normal driving, it is time to move to the next step: a diagnostic scan using an OBD-II reader.

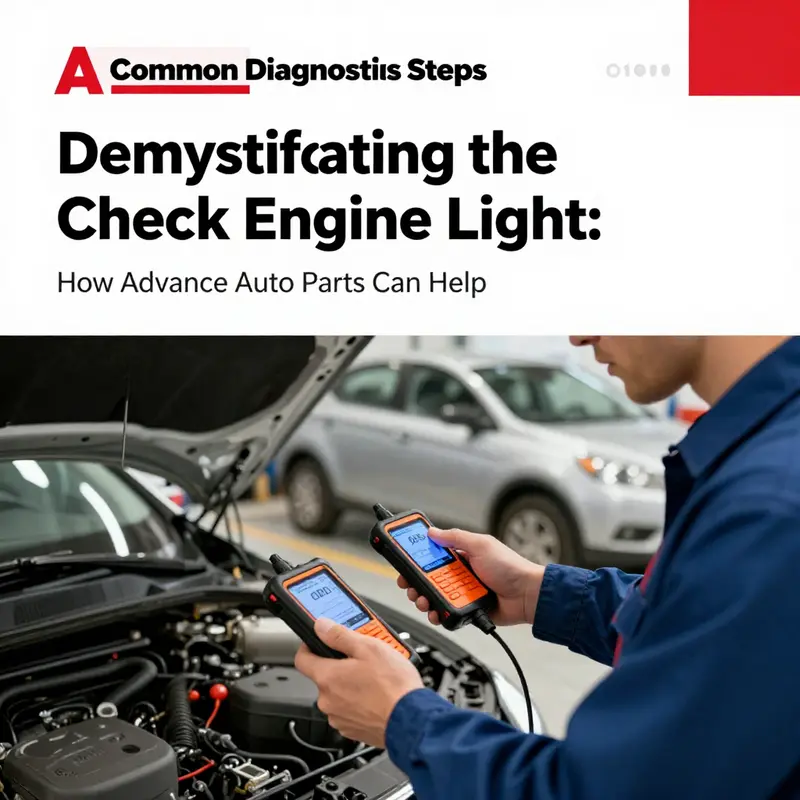

The reason a scan tool is so valuable is that it translates the MIL’s warning into concrete information about the fault’s origin. An OBD-II scanner can retrieve diagnostic trouble codes, or DTCs, that describe the system and, in many cases, the approximate sensor or device involved. The codes themselves are keys, not locks. They tell you which subsystem is involved and often hint at the likely culprits. A single code might indicate a specific sensor circuit, such as a malfunctioning oxygen sensor, while multiple codes can reveal related issues that emerge when one part’s behavior affects another. Interpreting these codes accurately requires a blend of knowledge, experience, and, ideally, proactive consultation with a trained technician when the interpretation reaches a gray area. For the do‑it‑yourself enthusiast, a trusted parts retailer’s guides and diagnostic tools can be invaluable, but they also remind us that some problems demand professional attention.

Interpreting the codes is not simply about memorizing a list of alphanumeric tags. It is about understanding how the system works and what common failure modes look like in practice. Some codes are generic and apply across many makes and models; others are more specific to a manufacturer and can require additional testing to differentiate a failing sensor from a wiring fault or a software quirk. A classic example is a code that points to the evaporative emissions system, which governs fuel vapor handling. A loose gas cap might trigger a P0457 or a related code, but it can also be a symptom of a larger leak or a faulty purge valve. Similarly, a misfire code like P0300 can indicate multiple cylinders misfiring or a handful of cylinders that misfire under load. In any case, the diagnostic path begins with the code and then follows a professional’s methodical testing: inspecting wiring, connectors, sensor housings, and related actuators, and evaluating the sequence of operation in the air intake and fuel delivery systems.

The pace of modern diagnostics underscores why a careful, patient approach often yields the best long-term result. Jumping straight to a DIY replacement based solely on a single code is a common pitfall. While it is true that some codes—such as a loose gas cap—are simple to confirm and fix, others require careful testing to avoid replacing the wrong part. For example, an error in the oxygen sensor circuit can be caused by a failing sensor, but it can also result from exhaust leaks, vacuum leaks, or issues upstream that skew readings. A replacement without identifying the root cause can fail to resolve the problem and may even create new ones if the wrong part is installed in the wrong position. That is why many shops emphasize the importance of validating codes with a thorough diagnostic procedure before committing to repairs. The aim is not to add expense but to prevent it by ensuring the fix directly addresses the fault’s origin, not a symptom that coincidentally accompanies it.

When the MIL lights up, the choice of next steps often comes down to a balance between urgency, risk, and cost. A steady MIL invites a measured approach. Start with the low-hanging fruit: verify the gas cap, inspect for obvious vacuum leaks, and replace inexpensive items like dirty air filters or worn spark plugs if they are due for service. If those steps do not clear the fault, or if the light returns after a few days of driving, it is prudent to move to diagnostic testing. A diagnostic scan is a relatively affordable first step that can save money in the long run by avoiding unnecessary part replacements. The information gleaned from the codes can be shared with a trusted mechanic to guide further tests, or, for the more technically inclined, used in conjunction with service manuals and reputable repair guides to perform a more comprehensive assessment. In either case, patience is a virtue because it reduces the chances of introducing new issues or overlooking a more serious fault.

An essential caveat accompanies the pursuit of a fix: the road to a repaired car is not paved with guesswork. Certain problems, particularly those that affect engine timing, ignition, or fuel delivery under load, can rapidly lead to more serious damage if neglected. A misfire that is allowed to persist, for example, can heat up the catalytic converter, degrade emissions performance, and invite costly repairs. This is especially true when the MIL is accompanied by performance symptoms such as stuttering, hesitation, or a noticeable drop in power. In these circumstances, the prudent course is to minimize driving, especially at highway speeds or under heavy load, and to arrange a professional diagnostic session as soon as possible. The goal is to obtain a precise, actionable diagnosis that leads to a targeted repair rather than a trial-and-error replacement strategy that can dilute the value of the repair and extend the downtime without guaranteeing a fix.

From the perspective of the car owner, the value of a good diagnostic approach is twofold. First, it protects the vehicle’s performance and fuel efficiency, ensuring the engine runs optimally and emissions remain within acceptable limits. Second, it preserves future reliability by addressing issues before they escalate into expensive components or safety hazards. The practical truth is that a well-executed diagnostic plan matter of factly pays for itself by preventing cascading failures—think catalytic converter damage, excessive fuel consumption, or degraded acceleration—scenarios no one wants to face at the worst possible moment. Because diagnostic tools and the knowledge to interpret them are widely available, a responsible owner can often begin with self-checks and then seek professional help when the data point in a clear direction, or when the situation becomes too intricate to navigate safely at home.

Of course, there is a place for the responsible DIYer in this process too. Many drivers find it empowering to learn how to read codes and perform basic maintenance, such as replacing a sensor or cleaning a dirty mass airflow sensor with the correct procedures and the right tools. What remains crucial is restraint and humility: if a proposed fix would require disassembling crucial engine components without the proper training or torque specifications, it is wise to defer to a professional. Replacing a part without confirming the fault can result in unnecessary costs and, in the worst case, new faults that did not exist before. A reputable parts retailer can be a valuable ally here, offering guidance on compatible parts, service manuals, and safe, tested procedures for common maintenance tasks. They can also point customers toward reliable diagnostic tools that make it possible to retrieve and interpret codes without guesswork, provided the user understands the limits of home diagnostics and knows when to seek expert help.

As the diagnostic journey unfolds, it is helpful to frame the experience as a learning process. The MIL is not an adversary; it is a signal that the vehicle’s software is tracking performance and emissions, and it invites you to take corrective action before the problem becomes a safety or cost liability. A clear plan—confirm the gas cap, scan for DTCs, interpret the results with a trained eye, and pursue targeted repairs—keeps the process efficient and reduces the risk that a minor issue becomes a major expense. Even when the solution is as straightforward as tightening a gas cap, this approach remains valuable: quick wins build confidence and demonstrate to drivers that being proactive with vehicle maintenance is a practical habit, not a chore.

In summary, the Check Engine light is a practical, information-rich signal rather than a single fix. It offers a map of the vehicle’s systems and their current states, guiding you to a diagnosis that can preserve performance, fuel economy, and emissions compliance. A steady MIL invites routine checks and a measured diagnostic process. A flashing MIL demands immediate attention and a conservative approach to driving. Either way, the path to resolution starts with an accessibly priced scan, followed by careful interpretation, precise testing, and repairs aligned with the fault’s root cause. With the right tools, reliable information, and a sensible plan, you can navigate the MIL’s warnings with confidence, protect your investment, and keep your vehicle running smoothly for miles to come.

External resource for further reading: For a concise overview of what the MIL means and what to do, see Autocar’s guide on the check engine light. Autocar UK guide on the check engine light.

null

null

From Signal to Solution: The Practical Role of a Parts Retailer in Check Engine Light Resolution

When the yellow Check Engine Light flickers on the dashboard, it does more than grab attention. It starts a small, practical investigation in the mind of every driver. The light is not a verdict but a notice from the vehicle’s onboard computer. It signals that something in the engine, exhaust, or emission control system has fallen out of spec enough to trigger a diagnostic warning. In the days when owners could ignore it and still drive, the light might have meant little beyond an annoyance. Today, that same light is a gateway to real clarity about a car’s health and a pathway to cost‑effective repair. This is where a modern auto parts retailer shows its value beyond shelves and checkout lanes. The retailer becomes a partner in understanding, diagnosing, and resolving the issue behind the warning lamp. That partnership rests on three pillars: accessible diagnostic tools, a broad, reliable parts inventory, and guidance that helps a driver move from diagnosis to repair with confidence.

The diagnostic landscape begins with a basic truth: the Check Engine Light is triggered by the vehicle’s computer, which monitors emissions, fuel delivery, ignition, sensors, and many other subsystems. When the computer detects a fault, it stores a diagnostic trouble code, or DTC, and illuminates the MIL. The DTC is a clue, not a final answer. It points to a system or component that needs attention, but it rarely tells you precisely what to replace or repair. A common misstep is to treat the light as a single problem, when in fact it might be a loose gas cap, a clogged air filter, or a misfire in one cylinder. A driver who starts with the simplest possible fix can save money and time, especially if the issue is something minor. Yet the same light can also mask more serious problems like an aging catalytic converter or faulty fuel delivery that, if ignored, will worsen and become more expensive to repair.

This is precisely why a well‑rounded auto parts retailer takes a different stance from a simple storefront. The right retailer understands that catching the root cause early matters as much as offering the right replacement parts. To begin, the retailer provides access to diagnostic tools capable of turning a vague MIL into actionable data. A modern OBD‑II scanner is central to this effort. Readily available at many stores, these scanners read the DTCs stored in the vehicle’s computer and often translate them into plain‑language explanations. They don’t replace the need for professional diagnosis when the fault is tied to high‑risk components, but they do give drivers a solid starting point. With the codes in hand, a driver can decide whether to pursue a quick, inexpensive fix or to seek more extensive service. The value here is not merely the tool itself but the guidance around how to interpret the results. The retailer’s staff, trained to understand the nuance behind common codes, can help interpret what the codes mean in practical terms for a given make and model, helping to avoid guesswork and wasted trips.

Beyond this, there is the practical matter of matching the right parts to the right problem. The classic advantage of a large auto parts retailer is breadth. A catalog that includes oxygen sensors, mass airflow sensors, ignition components, fuel delivery parts, and catalytic converter elements provides a safety net. When a DTC points toward a sensor or a fuel system component, the driver can pursue the fix with a clear plan. The knowledge that the part is compatible with the vehicle is as important as the part’s function. This is where the retailer’s digital tools shine. A well‑designed online search system lets a customer filter by year, make, model, or even VIN, ensuring that the chosen part fits the vehicle precisely. A vehicle VIN search can be essential for European, Asian, or domestic cars with subtle engineering differences that influence compatibility. The same digital system often includes a Vehicle Garage feature that lets a driver save multiple vehicles, making it faster and easier to switch between cars when the same home workshop is maintaining a small fleet or a family of cars.

Equally vital is the organization of DIY resources. The roadside code reader is only the first step. The next is guidance that translates a code into a practical repair plan. High‑quality retailers often provide a library of how‑to content that walks a driver through common CEL fixes. Step‑by‑step repair guides, diagnostic tutorials, and video demonstrations can demystify tasks that would otherwise require professional service. For those who prefer a hands‑on approach, these resources are gold, letting the owner become better informed and more capable, without pretending that every fix is trivial. The result is a healthier-starting point for home repair that still respects the limits of one’s skill and safety considerations.

Another critical benefit comes from the retailer’s in‑store and digital services designed to streamline the repair journey. The ability to reserve parts online for same‑day pickup can transform a potentially disruptive repair into a quick, predictable process. This convenience matters when the Check Engine Light appears during a busy weekday or just before a planned trip. In many locations, free battery testing and basic installation services are offered, which helps confirm the scope of the problem and reduce the risk of missteps in repairs that involve circulation around the engine bay. And in certain cases, complementary diagnostic checks help verify the initial assessment before any work begins. Even if the root issue lies with a sensor or a small component, verifying the diagnosis before purchasing parts protects the budget and prevents unnecessary replacements.

The decision to pursue a repair based on a DTC and a MIL is not always straightforward. Some codes signal easy fixes, while others require professional diagnostic work that involves more sophisticated equipment or a closer inspection of the engine’s mechanical condition. Here, the retailer’s role overlaps with the technician’s expertise in a meaningful way. A customer can start with a diagnostic reading, gather the list of possible culprits, and use the retailer’s inventory to assemble a targeted repair plan. If the issue is a loose gas cap, the fix is quick and inexpensive; if the issue is a faulty oxygen sensor or a failing ignition coil, the part replacement carries more complexity but remains manageable with careful following of guides or with the help of a trained mechanic. An informed approach that uses a calibrated mix of DIY tools and professional insight minimizes risk and reduces the chance of chasing the wrong problem. In other words, the retailer helps translate data into actionable steps, and in doing so lowers both the emotional and financial costs of dealing with the Check Engine Light.

This kind of assistance also matters for emissions and fuel efficiency—two areas where the MIL can have a meaningful impact on running costs and environmental compliance. The underlying idea is simple: fix the actual fault quickly, keep combustion efficient, and avoid cascading damage that could affect emissions control devices such as the catalytic converter. A worn spark plug or a dirty mass airflow sensor can degrade fuel economy and power, but these issues are often addressed with a straightforward part replacement once correctly identified. In contrast, a faulty catalytic converter or a damaged exhaust system demands prompt attention because of both regulatory and safety considerations. A retailer that offers a robust selection of exhaust and emissions components, along with clear guidance about fit and installation, becomes a reliable ally in staying compliant and keeping the engine performing as designed.

No discussion of the Check Engine Light would be complete without acknowledging the limits of DIY. While a parts retailer can equip a driver with diagnostic tools, high‑quality parts, and educational resources, the mechanical or electronic fault behind the warning often requires professional judgment. Some faults involve complex electronics, high‑voltage systems, or precision tolerances that demand specialized tools and training. The retailer’s best practice is to emphasize safety and responsibility. They provide the means to identify likely causes, offer the right parts, and advise when a professional technician should take over to complete the repair. This approach protects the vehicle, the driver, and the wallet. It also reinforces the idea that the Check Engine Light is a serious warning, not an invitation to gamble with a car’s reliability or emissions status.

As drivers move from diagnosis toward repair, the retailer’s value becomes more tangible. The journey begins with the diagnostic code, which narrows the field of potential causes. It continues with the careful selection of parts that fit the vehicle and address the identified faults. It ends with either a guided DIY repair, a well‑planned professional service, or a combination of both, depending on the situation. Importantly, the retailer bridges the gap between information and action. It provides the educational context needed to understand what the maintenance entails, the parts necessary to perform it, and the practical steps to execute the repair efficiently. In this way, the retailer’s role evolves from a simple supplier to a trusted partner who can help maintain performance, reduce waste, and protect against the sudden cost of unexpected breakdowns.

A durable, dependable repair path also requires awareness of when parts replacement should be avoided. For example, replacing multiple components without confirming the root cause can lead to wasted money, especially if the original fault lies elsewhere in the system. The retailer’s diagnostic tools and guidance help balance confidence with restraint. They remind drivers to focus on the most likely causes first, to verify with a readout after each fix, and to consider professional follow‑up if the issue persists. This disciplined approach is especially valuable for drivers who depend on their vehicles for daily commuting or critical work duties. The Check Engine Light, then, becomes less a source of anxiety and more a signal that a careful, data‑driven process is underway. The end result is a car that runs better, uses fuel more efficiently, and remains in good standing with emissions requirements—all achievable with the right tools, information, and part choices supplied through a thoughtful retailer ecosystem.

In sum, the Check Engine Light is a practical invitation to understand a vehicle more deeply. A capable auto parts retailer supports that understanding by offering diagnostic access, a carefully curated inventory of replacement parts tied to common CEL triggers, and a suite of educational resources that empower drivers to act with confidence. The retailer’s role is not to pretend to fix the fault directly but to equip the driver with the means to diagnose accurately, source the correct components, and manage the repair process in a way that protects both safety and value. When the MIL lights up, the smart route is to engage with the retailer as a partner who can help translate warning codes into a clear, affordable, and reliable repair plan. The goal is straightforward: restore engine health, improve efficiency, and ensure the vehicle remains compliant with emissions standards while minimizing downtime and disruption to daily life.

For readers pursuing a deeper understanding of the Check Engine Light and structured steps to take, the Autocar UK guidance offers a helpful external reference that complements the practical, retailer‑driven approach described here. Autocar: Check Engine Light – What it Means and What to Do.

Final thoughts

Understanding the Check Engine light and how Advance Auto Parts can assist in diagnosing issues is essential for business owners looking to maintain their vehicles effectively. By utilizing tools like the OBD-II scanner and the expertise of technicians, you can address potential problems before they escalate. This proactive maintenance approach ensures that your fleet remains in top condition, minimizing downtime and maximizing your investment. Equip yourself with the knowledge and resources available at Advance Auto Parts to keep your vehicles running smoothly and efficiently.