As advanced gear transmission systems gain prominence, business owners are increasingly interested in understanding the price dynamics of XShift gearboxes. This systematic exploration unravels the complexities surrounding XShift gearbox pricing, comparing it to other automatic systems, evaluating technological influences, and examining market demand trends. Each chapter offers insights into the variability of costs based on features and configurations, and culminates with best practices for obtaining accurate price information, empowering business owners to make informed purchasing decisions.

Beyond the Sticker: Unraveling XShift Gearbox Pricing in a World of Smart Automatics

Pricing is not just a number on a price tag. With XShift gearboxes, the sticker price sits at the end of a longer value chain that starts with engineering, materials, software, integration, and ongoing support. Public price data for such systems are rare, but several patterns emerge. Premium hardware is paired with sophisticated software, frequent updates, and a service ecosystem that adds value beyond the metal and gears. To grasp what buyers should expect, it helps to look at total cost of ownership rather than headline price. The first layer is hardware configuration: actuation technology, gear ratios, torque limits, and the build quality of sensors and control modules. Different configurations can produce markedly different upfront costs, even within the same family, because the surrounding software and service packages vary as well.

Software is the second major driver. Modern automatics are as much software platforms as mechanical assemblies. Licensing, updates, and remote diagnostics shape the ongoing cost, and features like predictive control or OTA calibrations often come with periodic charges. These software components influence maintenance strategies and uptime as much as the initial sticker.

Integration with the vehicle and with fleet operations is the third layer. The gearbox coordinates with engine control units, braking, traction control, and driver assistance features, creating engineering requirements that add to the price but also unlock efficiency, reliability, and real time data for maintenance planning. In fleets, the value of integration can outweigh upfront costs over the life of the asset.

Market and procurement dynamics further shape pricing. Operators of different sizes may see different configurations, lead times, and discounts. Volume purchases, bundled service packages, and extended warranties are standard levers that shift the discussion from a one time payment to a total cost of ownership. A direct price quote will still reflect regional conditions, installation charges, and training requirements.

For buyers seeking concrete guidance, the recommended approach is to request quotes that compare hardware tiers, software access levels, and maintenance bundles, then evaluate not just the upfront delta but the expected annual operating costs. The absence of public pricing should not deter a rigorous, structured inquiry that aligns technical capability with financial planning and lifecycle value.

In sum, the price of XShift gearboxes embodies trade offs between hardware sophistication, software intelligence, integration depth, and after sales service. The final package should deliver reliability and lifecycle efficiency, not just a lower sticker price.

How Advanced Technology Shapes the Price and Value of XShift Gearboxes

Advanced electronic controls, precision machining, and embedded software have redefined what a gearbox does. For XShift-style automated manual transmissions, these technologies drive both capability and cost. Understanding how each element influences price helps fleet managers, technicians, and buyers make informed choices. This chapter walks through the technical drivers of cost, the economic trade-offs buyers face, and practical strategies to assess value over the lifetime of a gearbox.

The first and most visible factor is the software and control architecture. Modern gearboxes depend on real-time processing of vehicle speed, engine torque, load, and terrain. That requires robust control units running complex algorithms. Designing, validating, and producing such controllers adds to the bill of materials and to development expenses. The software itself must be tuned across dozens of use cases, so engineering hours and long validation cycles are embedded in the price. Manufacturers also package features like adaptive learning, predictive shift planning, and driver-assist integration. Each feature increases development and testing time, and those costs are reflected in the unit price.

High-quality sensors and electronics follow directly from that control architecture. Accurate speed, position, pressure, and temperature feedback are essential for reliable shifts and safe operation. Premium sensors, shielding, and wiring harnesses cost more than basic mechanical components. Sensors must withstand vibration, heat, and contamination for many thousands of hours. Manufacturers who prioritize longevity and fault tolerance select components with higher ratings. That choice improves durability, but it raises manufacturing costs and the retail price.

Mechanical precision is another major price driver. Automated manual transmissions require fine tolerances in gearsets, synchronized shafts, and actuators. Precision grinding, ion-nitriding, tight assembly tolerances, and specialized lubricants increase production cost. Hydraulic or electro-hydraulic actuation systems further add to complexity. These subsystems need pumps, valves, reservoirs, seals, and robust plumbing. Designing hydraulic circuits that deliver consistent, repeatable actuation in harsh conditions demands materials and testing that are more costly than simpler mechanical linkages.

Materials selection matters in two ways: performance and longevity. Premium alloys, surface treatments, and wear-resistant coatings reduce failure rates and extend service intervals. Those treatments increase raw material and processing costs. When a gearbox is intended for heavy-duty, high-mileage service, manufacturers invest in superior metallurgy. That increases first-cost but lowers the risk of early failure. Buyers must weigh higher initial price against the potential savings from fewer overhauls and lower downtime.

Integration with vehicle electronics and telematics also adds cost. Modern transmissions often communicate with fleet management systems and with vehicle electronic control units. That requires secure protocols, additional hardware, and certification testing. Some systems include subscription-based services for cloud diagnostics or predictive maintenance. While subscriptions are not a factory price per se, they influence the effective purchase cost when bundled into financing or warranty packages.

Supply chain and scale are economic levers that influence final pricing. Low-volume, highly customized gearbox models will carry a higher per-unit cost. Conversely, systems that achieve broad adoption allow manufacturers to amortize development costs across many units, reducing per-unit price. Component shortages, geopolitical constraints, and logistics disruptions can also spike costs. When specialty sensors or semiconductors are constrained, manufacturers either absorb costs or pass them to buyers.

Serviceability and lifecycle costs form the other side of the pricing equation. Complex systems require specialized diagnostics, trained technicians, and specific tooling. Routine maintenance can demand electronic calibration and software updates beyond mechanical inspections. Repair shops must invest in diagnostic licenses and training. Those service costs raise the total cost of ownership even if the initial gearbox price seems competitive. Warranties and extended service agreements can mitigate this, but they add to upfront procurement costs when purchased with the gearbox.

When evaluating price, decision-makers must compare initial cost with measurable operational benefits. Advanced gearboxes commonly deliver improved fuel efficiency through optimized shift strategies. That improvement translates to fuel cost savings over thousands of miles. Smooth shifts reduce driveline shock and lower stress on other components, lengthening the life of axles and clutches. Automated systems reduce driver fatigue and variation in driving behavior. For fleets, consistent shift strategies can mean predictable fuel performance across drivers. These operational savings can offset the higher purchase price over time.

To quantify the trade-off, organizations should use a simple total cost of ownership framework. Estimate the initial premium for the advanced gearbox. Project annual fuel savings, reduced maintenance frequency, and potential uptime improvements. Factor in training and diagnostic costs. Estimate residual value at resale, since systems with well-documented software support often retain value better. Discount future savings to net present value. If the NPV of savings exceeds the initial premium, the advanced gearbox is a sound investment. The calculation depends heavily on duty cycle, operating terrain, and maintenance practices.

Resale and refurbishment markets also influence effective pricing. Robust, software-driven transmissions often command higher resale prices when maintained with proper service records. Conversely, a poorly maintained unit with outdated software can decline faster in value. Reconditioned or aftermarket gearbox options can lower acquisition cost. However, the buyer must evaluate the provenance of reconditioned units and the availability of updated software and calibration. In some cases, retrofitting older gearboxes with updated control software or actuators is possible. That can deliver many benefits of new systems at a lower cost, but this approach requires careful compatibility checks.

Customization and optional features are frequent sources of sticker shock. Buyers may find base models are priced attractively, while advanced packages with telematics, heavy-duty internals, or extended warranties add substantial cost. Carefully prioritize options based on measurable benefits for the operating profile. For example, specialized gear ratios matter more for mountainous routes than for flat-haul fleets. Hydraulic actuation and reinforced internals suit heavy loads better. Avoid paying for features unlikely to provide returns in your use case.

Procurement strategy matters. Fleet purchases often obtain bulk discounts, service bundling, and favorable warranty terms. Single-unit buyers or small shops face higher per-unit pricing. Negotiation can focus on software update terms, diagnostic access, and training credits. Consider financing options that include scheduled service and remote diagnostics. Those packaged arrangements spread additional costs but can simplify budgeting and ensure consistent maintenance.

Regulatory and testing requirements also affect price. Certifications for emissions, safety, and electromagnetic compatibility require laboratory time and documentation. Manufacturers factor certification costs into unit pricing. If a gearbox must meet region-specific requirements, the price may reflect additional testing and localization work.

Finally, the pace of technological change influences perceived value. Rapid advancements in control algorithms and sensor capability can make today’s high-end features tomorrow’s standards. Buyers should assess upgrade paths and software support commitments. A vendor that offers long-term software maintenance and transparent update policies reduces obsolescence risk. When support contracts are available at predictable costs, they make the purchase decision clearer.

For buyers evaluating XShift-style gearboxes, the key is to separate hype from measurable impact. Prioritize features with clear operational returns. Use a rigorous total cost of ownership model. Verify serviceability, diagnostic access, and software update policies. And when comparing prices, remember the cheapest initial offer may cost far more over the lifecycle. For perspectives on technical design and performance characteristics, manufacturers’ official technical documentation provides authoritative details, available here: https://www.volvotrucks.com/en-us/products/transmissions/ishift/.

For hands-on buyers exploring alternative acquisition paths, a relevant aftermarket example shows how specialized gearbox solutions are offered and supported in niche markets. See a full sequential gearbox option for performance applications: https://mitsubishiautopartsshop.com/full-sequential-gearbox-for-mitsubishi-evo-4-9-and-x/.

Demand-Driven Dynamics: How Market Forces Shape the Price of Modern Automated Transmissions

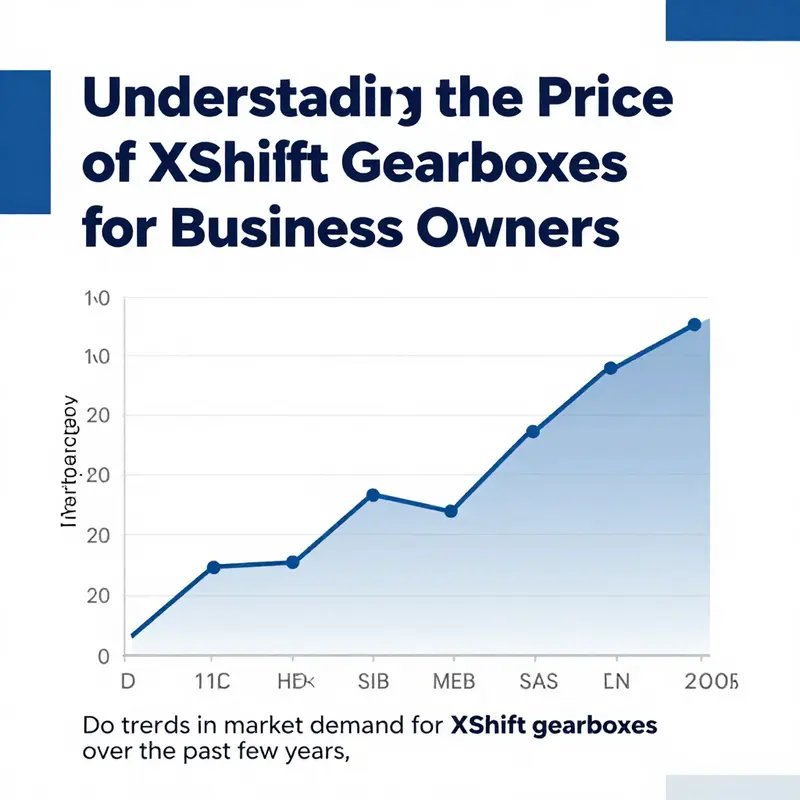

The pricing trajectory of advanced automated transmissions sits at the intersection of technology, regulation, and real-world use. As vehicle architectures shift toward electrification and efficiency, the market for transmissions that can adapt to diverse operating conditions has grown more strategic and more expensive to develop. The dynamics driving this price movement reflect broader decisions by OEMs and fleet operators about fuel economy, maintenance costs, and lifetime value. Pricing responds to a cascade of signals from how vehicles are used, how governments regulate emissions, and how suppliers compete for scarce engineering talent and critical components.

Electrification and hybridization are among the clearest forces pushing prices upward. Automating gearboxes for systems that combine internal combustion and electric assist requires balancing weight, thermal management, control software, and mechanical durability. Those trade-offs raise development costs and validation effort, which can translate into higher unit prices or premiums in contract pricing. Buyers respond differently—some accept higher upfront costs for long-term gains, while others pursue modular or retrofit solutions that lower initial expense but may require compromises in integration or performance.

Regulatory pressure further elevates price by forcing investment in control software, advanced materials, and diagnostics. Emissions standards and lifecycle assessments increase R&D and validation burdens, and these costs are reflected in unit prices and the total cost of ownership. After-sales software updates, remote diagnostics, and compliance-driven features often add recurring costs, making the gearbox part of a broader service proposition rather than a purely mechanical purchase.

Commercial and vocational applications exert a separate pricing influence. Fleets in logistics, construction, and delivery value uptime and fuel efficiency highly; they will pay premiums for transmissions that integrate with auxiliary systems (for example, PTOs), support rapid gear selection under load, or provide adaptive learning that improves shift strategies. In such cases, price becomes a reflection of operational reliability and measurable productivity gains rather than hardware complexity alone.

Technological advances blur the line between mechanical and electronic value. Modern automated transmissions depend on adaptive algorithms, predictive control, semiconductors, and cybersecurity—each adding to development and validation cost. Manufacturers therefore price both hardware and the value of a software ecosystem that enables continuous improvement. That approach can yield a more favorable total cost of ownership for buyers who benefit from updates and analytics, but it also anchors higher initial prices tied to the software backbone.

Competition moderates and shapes these premiums. While rivalry drives some commoditization and downward pressure on basic solutions, premium or analytics-enabled variants retain higher margins because they deliver measurable lifecycle benefits. Supply-chain complexity—semiconductor availability, raw material volatility, and precision machining capacity—adds episodic price pressure, while scale and interface standardization offer potential cost relief. The result is a volatile but directional pricing landscape where demand for efficiency, reliability, and integration determines which features command premiums.

From a purchaser’s perspective, total cost of ownership is central. Fleet managers increasingly evaluate transmissions on lifecycle savings, diagnostic depth, and uptime predictability rather than on upfront cost alone. Vendors respond with varying offers: all-in packages that include software support and updates, or modular pricing that separates hardware from ongoing services. The market is trending toward service-centric models where pricing reflects the value of continuous performance improvements as much as mechanical specification.

In practice, high-end, performance-oriented configurations illustrate the upper extremes of this pricing spectrum—rigorous validation, precise machining, and extensive software tuning drive costs but enable superior efficiency and control (see an example: https://mitsubishiautopartsshop.com/full-sequential-gearbox-for-mitsubishi-evo-4-9-and-x/). Broader industry analyses likewise suggest sustained growth in the gearbox market driven by electrification and efficiency imperatives, even as competition pressures price discipline around reliability-driven configurations (for market context, see https://www.marketsandmarkets.com/Market-Reports/automotive-gearbox-market-65957248.asp).

Ultimately, price is a signal of strategic choices. Where buyers value efficiency, regulatory compliance, and reduced operating costs, suppliers who can deliver reliable software, diagnostics, and integration at scale will command stronger pricing power. Conversely, where scale, standardization, and competition prevail, prices for basic automated solutions will fall. The interplay of demand signals and supply capabilities will continue to shape how premium and commoditized offerings evolve in the gearbox market.

The Price Geometry of XShift Gearboxes: How Features and Configurations Shape Value

Prices for XShift gearboxes do not appear in a single public catalog, and that silence is itself a signal. In markets that prize precision, the cost of an automated or semi-automated transmission is not a fixed line item but a geometry of choices. The baseline hardware may carry a premium for the form factor, robustness, and integration capabilities a system requires. But most of the price variance emerges from features, software, and the way those elements are packaged with a vehicle’s drivetrain and control systems. When we trace the price from chassis to road, the picture becomes a complex interplay of function, reliability, and the promise of long-term operating savings. A prospective buyer does not simply purchase a gearbox; they acquire a tailored system whose value rests on how well the gears, the electronics, and the software work together to reduce fuel use, minimize driver workload, and lower maintenance costs across the vehicle’s lifetime. In this sense, the cost is not merely a sticker price but a negotiation among competing objectives—power, efficiency, adaptability, and total cost of ownership over thousands of kilometers of service.

What drives this price geometry? First, the hardware itself—how many gears, the ratio spread, packaging depth, and the level of integration with sensors and actuators. The more compact and modular the gearbox, the easier it is to fit into a wide range of vehicles and duties. Yet that same compactness can demand tighter tolerances, more advanced materials, and more sophisticated control software to maintain performance and reliability, all of which push the upfront cost higher. Then there are the electronic and software layers. An automated or semi-automated transmission is not only a mechanical device but a cybernetic system. It constantly analyzes vehicle speed, load, road gradient, and driving behavior to decide when to shift, how aggressively to downshift, and how to coordinate with braking systems and regenerative circuits. Each layer of software—control algorithms, calibration files, over-the-air update frameworks—adds cost, but it can also shave operating expenses through more precise control, smoother shifts, and smarter energy recovery. It is not unusual for software licensing, diagnostic services, and subscription-based support to become a meaningful portion of total ownership cost. In a transportation landscape where fleets increasingly run on data, the value of that software can dwarf the raw price of the hardware over time, especially in operations that emphasize fuel efficiency and driver fatigue reduction.

Second, the configuration options. Modern gearbox families offer a spectrum of gear ratios, shift strategies, and integration levels with axle drives, traction control, and energy management systems. A given vehicle may require a particular ratio for highway efficiency, another for hill climbs, and yet another for heavy loads at altitude. The more versatile the configuration set, the more the price can vary. Some configurations enable adaptive learning that progressively tunes the transmission to a driver’s style and to route-specific conditions, while others rely on fixed maps and generic logic. The choice between adaptive, semi-automatic, or fully automated schemes is itself a driver of cost. Each option carries not only an initial price delta but a distinct pathway for maintenance and software updates. Fleet operators often weigh these factors against realized gains in miles per liter or miles per kilowatt-hour in plug-in or hybrid powertrains. The life-cycle calculus tends to favor feature-rich systems when the total cost per kilometer is considered across a vehicle’s life, but the precise break-even point shifts with usage patterns, fuel costs, and maintenance regimes.

Third, integration with vehicle electronics and diagnostics. The gearbox does not operate in isolation. It sends and receives data across the vehicle’s electronic architecture, consuming bandwidth and sometimes demanding dedicated control units or high-fidelity sensors. This level of integration improves performance and reliability, enabling predictive maintenance and remote diagnostic capabilities. But it also ties the price to the sophistication of the vehicle’s electrical architecture. In some cases, the gearbox becomes a node in a broader energy-management ecosystem, coordinating with battery management, motor control, and route- and workload-aware strategies. The cost implications are twofold: higher upfront price for the integration hardware and software licenses, and potential savings through reduced unscheduled downtime and optimized maintenance planning. The integration approach chosen by a manufacturer or operator—ranging from off-the-shelf compatibility to bespoke interfaces—can therefore swing the price by substantial margins, depending on how exclusive the software hooks and how deeply the system must communicate with other subsystems.

Within this landscape, a useful way to view price is through the lens of lifecycle economics. A growing body of research in advanced gearbox design for electrified and hybrid applications shows that design variability and packaging constraints exert outsized influence on total cost and performance. In systems where packaging is tight and the control logic is elaborate, even modest shifts in gear ratios or control algorithms can ripple into meaningful differences in fuel savings and maintenance costs. A representative study of optimized gearbox configurations for electrified axles found that the cost of ownership can be significantly shaped by these decisions, yielding a higher upfront investment but strong long-term efficiency gains. In practical terms, this means that buyers who pursue higher initial complexity—more gear options, more adaptive software features, more stringent diagnostics—often secure superior lifetime performance, even if the first price tag looks steep. The implication for procurement teams is clear: the value argument hinges on the expected utilization profile, rather than on the sticker price alone. If a fleet operates in conditions where the gearbox can adapt to varied terrains, loads, and climate, the pull toward feature-rich configurations strengthens, and the payback period shortens accordingly.

Another axis shaping price is the market channel through which the gearbox is sourced. When manufacturers or authorized distributors present a system, they often bundle hardware with software licenses, maintenance plans, and diagnostic services. The scope of software updates, the cadence of firmware refreshes, and the availability of remote support all influence the overall cost profile. The purchase decision thus becomes a negotiation over what services are included by default and what must be added as optional packages. In our broader understanding, this mirrors the way other high-end propulsion components are priced, where the initial hardware price is just one element of a longer, multi-faceted relationship between supplier and operator. For buyers, the message is straightforward: ask not only for the price of the gearbox in isolation but also for the cost of software permissions, service intervals, diagnostic coverage, and the predicted maintenance expenditure over the vehicle’s service life. In the end, the most compelling offers are those that align upfront investment with predictable, data-driven savings in fuel, wear, and downtime.

The market behind XShift gearboxes is also shaped by transparency, or the lack thereof. Publicly disclosed price data for such systems tends to be incomplete or model-specific, reflecting a broader trend in high-performance drivetrain components where manufacturers prefer to discuss capabilities, not price sheets. This opacity encourages buyers to engage directly with manufacturers or authorized partners to quantify the precise cost implications of a given configuration. It also motivates buyers to consider professional platforms and marketplaces that specialize in industrial components and fleet systems. The payoff for diligence is a more accurate estimate of lifecycle cost, tailored to a vehicle’s duty cycle and geography, rather than a generic average that fails to capture regional price differences, currency fluctuations, and after-sales commitments. In practice, the most reliable price guidance emerges from an iterative process: define the required features and integration constraints, obtain quotes for the hardware and software stack, and then model the expected fuel and maintenance savings under realistic operation scenarios. This approach converts a pricing exercise into a strategic financial analysis, one that clarifies whether a feature-rich configuration delivers near-term payback or longer-term strategic value.

To connect the abstract with the concrete, consider how a careful configuration choice can influence kilometers traveled per unit of operating cost. A modern gearbox that features adaptive shifting, terrain-aware algorithms, and robust diagnostics can deliver improved fuel efficiency and reduced wear on clutch packs, bearings, and hydraulic systems. While the initial investment may be higher, the operating cost per kilometer can drop enough to offset the higher price within a few years of service, especially in fleets that accumulate high annual mileage or operate across varied topographies. Conversely, for operators with simpler duty cycles, a leaner configuration with essential shifting logic and standard diagnostics might meet performance needs at a more modest upfront price, with a proportionally smaller payback period. The optimal choice sits at the intersection of performance requirements, expected duty cycle, and risk tolerance for maintenance complexity. In other words, price here is not just what you pay; it is what you are prepared to invest to secure reliability, efficiency, and fleet resilience across a vehicle’s life.

For readers seeking a practical anchor in this landscape, imagine the broader insight from a recent multi-parameter gearbox analysis: the most valuable configurations are those that align mechanical packing with adaptive control and energy management while preserving diagnostic transparency and serviceability. In such cases, the higher upfront cost becomes a rational bet on long-term performance, a bet that is reinforced by the addition of software-enabled optimization and remote support. The takeaway is not a single price point but a spectrum: the cost of XShift gearboxes varies with hardware choices, software licenses, integration depth, and service commitments, and the best decision rests on a rigorous appraisal of lifecycle value rather than a one-shot sticker price. As with any advanced powertrain component, the price geometry is best understood through direct dialogue with the supplier ecosystem, a process that translates complexity into clarity for operations planning and capital budgeting.

External resource: https://www.volvotrucks.com/en-us/technology/ishift

Internal link excerpt: For an adjacent perspective on gearbox configuration and packaging that helps illuminate how design choices feed into cost, see the discussion of a full-sequential gearbox for a performance-focused platform: full-sequential-gearbox-for-mitsubishi-evo-4-9-and-x.

Navigating the Price Landscape for Specialized Transmissions: How to Get Accurate Quotes Without Missing the Real Cost of Ownership

Pricing for specialized transmission systems is rarely transparent in public catalogs. A high-performance, electronically controlled gearbox often arrives with a price that reflects not only the hardware but also software licenses, integration services, diagnostics, and after-sales support. The initial sticker price can swing widely depending on configuration, region, and the scope of required services. In practice, this means buyers should think beyond the headline figure and consider how the price aligns with the total cost of ownership over the system’s life. This approach becomes essential when the goal is to compare quotes across manufacturers, distributors, and service networks, all while avoiding the traps of outdated price lists and uneven offers.

One of the core realities is that direct price information from manufacturers is the most credible starting point. Manufacturers control the curriculum of features bundled with a gearbox, including adaptive software, learning algorithms for terrain and load, and remote diagnostics. Each of these elements can be priced as part of a package or offered as optional add-ons. When an inquiry is made, the response often includes a current base price for the hardware, a catalog of optional software features, maintenance plans, and a clear note about what is included in the price. In many cases, the most reliable price comes with a tailored quote, because the exact combination of model, configuration, and service level creates a unique price point.

If reaching out directly to the manufacturer proves impractical, authorized distributors can provide legitimate pricing with the same emphasis on accuracy and service. Distributors typically have access to the same official catalogs and negotiated discounts, plus they can offer faster response times or localized terms. For buyers evaluating bids, it helps to request a formal quote that itemizes hardware, software licenses, training, diagnostic support, and any extended warranty or service contracts. It is also prudent to ask for delivery timelines and installation support, since lead times and on-site commissioning can influence the overall price substantially. The discipline of obtaining quotes in this way—one central price, plus a transparent breakdown of all components—reduces the risk of price drift caused by e-commerce listings that may not reflect current conditions or regional allowances.

Another practical route is to explore reputable industrial marketplaces and verified supplier catalogs. These platforms can be valuable for benchmarking, especially when price bands are difficult to gauge from a single source. When using a marketplace, buyers should verify supplier credentials, confirm the latest catalog revision, and review warranty terms and service options. The marketplace can also help surface available configurations that may not be immediately apparent in direct quotes, such as region-specific variants or compatibility packages designed for particular fleets or industrial setups. Nonetheless, caution is wise: not all listings reflect current pricing, and counterfeit or outdated offers can surface on broader marketplaces. The responsible approach is to treat marketplace quotes as a reference point and to corroborate them with manufacturer or authorized distributor data before making a purchase decision.

Beyond direct channels and marketplaces, industry reports can provide a broader frame of reference for pricing dynamics. These reports do not usually publish exact product prices but illuminate market trends, demand drivers, and the evolution of cost structures across a segment. For instance, a report focusing on the broader sequential and automated transmission landscape may show how software integration, connected diagnostics, and remote maintenance services have shifted the price-to-value proposition over time. This wider context helps buyers calibrate expectations and recognize when a proposed price includes or omits critical services. While such reports do not replace a formal quote, they offer a sanity check that helps buyers avoid overpaying for perceived sophistication or underestimating the value of after-sales support and software updates.

A central element in any price discussion is the concept of value over time. The upfront cost is only part of the story. In high-end gearboxes, software subscriptions, annual maintenance, and diagnostic service plans can add to the total cost in predictable ways, or in some cases, be bundled with the hardware at a preferred rate. When evaluating quotes, it is essential to ask what the price includes in terms of software features, upgrade cadences, and diagnostic access. Some configurations may require ongoing licenses to unlock advanced features, data analytics, or predictive maintenance capabilities. If a supplier offers a bundled package that includes software updates and remote diagnostics for a fixed period, this can be economically advantageous even if the initial price appears higher than alternatives. The decision framework should weigh not just the first purchase but the predictable annual costs and the potential savings from reduced downtime, optimized performance, and better fleet reliability.

To keep the process robust, buyers should prepare a disciplined set of inputs before requesting quotes. Details about the intended application—load profiles, typical duty cycles, environmental conditions, and duty cycles—help vendors tailor a price that truly fits. Geographic location matters as well; freight, taxes, import duties, and after-sales service coverage can shift the total cost materially. It is also wise to specify whether the quote should include installation, commissioning, technician travel, and on-site training for maintenance personnel. The more precise the input, the more accurate and comparable the output. When a quote arrives, scrutinize the line items: hardware base price, optional software modules, service contracts, calibration and commissioning, warranty terms, and any required spare parts packages. If a quote blends hardware with a subscription model for software, ask for a cost breakdown across the subscription horizon to assess the long-term financial impact.

Price transparency can also come from requesting a sample bill of materials and a proposed maintenance schedule. Some providers present a modular price structure that separates core transmission hardware from ancillary components like control units, sensors, couplings, and cooling solutions. While modular pricing can seem complex, it often reveals where the value actually lies. A configuration that looks inexpensive at first glance may require expensive add-ons to realize the full performance potential. Conversely, a price that includes an integrated control system with built-in diagnostics and remote support may deliver a lower total cost of ownership when downtime reduction and faster repair times are considered. The thoughtful buyer treats such nuances as essential data points rather than as ornamental details.

In practice, evaluating price quotes benefits from a small, repeatable decision framework. Start with a baseline: the most robust hardware configuration your application can tolerate, plus a standard software suite aligned with your maintenance philosophy. Then compare the baseline across providers, focusing on how each one packages installation, commissioning, and service. Add optional modules only if your application demands them, and assess whether the incremental benefits justify the incremental cost. When possible, request a performance warranty or uptime commitment, since reliability metrics can be a strong predictor of long-term cost efficiency. This approach helps ensure that price comparisons are meaningful and that the selected option optimizes uptime and operational readiness over the operating life of the gearbox.

In the realm of practical sourcing, a concrete example of how gearboxes are discussed in technical ecosystems can be found in related transmission technology discussions. For readers who want a tangible reference point about gearbox variants and integration considerations, the broader catalog of gearboxes used in demanding applications often reveals how different configurations influence price expectations. For instance, a full sequential gearbox designed for high-performance or specialized usage illustrates how advanced gear patterns, rapid shift capabilities, and comprehensive diagnostics shape the price envelope. While this example is not a direct substitute for vendor-specific price quotes, it demonstrates how specific design choices translate into value components buyers must weigh against the hardware cost. To explore one such gearbox family in depth, you may examine this reference page: full-sequential-gearbox-for-mitsubishi-evo-4-9-and-x.

With this framing in mind, buyers should also consider the impact of regional service presence on price stability. A strong local or regional service network can dampen price volatility by offering more predictable service costs, faster repairs, and easier access to genuine spare parts. Conversely, a sparse service footprint can push prices higher due to longer downtime, higher freight costs for replacement components, and the risk of counterfeit or non-certified technicians attempting ad hoc maintenance. A credible supplier will disclose service options and the geographic reach of authorized technicians as a standard element of the quote. When service coverage is clearly defined, it becomes a meaningful differentiator in a competitive landscape where the hardware price alone does not tell the whole story.

As buyers broaden their search, the temptation to rely on outdated or generic price data grows. To guard against this, emphasize the freshness of pricing data in requests. Ask for a quote valid for a defined window, and request a timestamp on any discount or incentive. This discipline creates a transparent audit trail that helps verify the consistency of offers over time. It also reduces the risk of accepting a favorable price that has already expired or a discount that is not applicable to the intended configuration. In addition, it is prudent to confirm any post-sale terms that could affect the total cost, such as calibration services, on-site support windows, and the availability of replacement parts through authorized channels. A well-structured procurement conversation will capture these elements and prevent expensive surprises after the deal is signed.

In sum, obtaining accurate price information for specialized transmissions requires a disciplined mix of direct manufacturer engagement, reliance on authorized distributors, prudent use of reputable marketplaces, and a broader understanding of market dynamics gained through industry context. It also demands a careful appraisal of total cost of ownership, including software licenses, maintenance, and service commitments. The process becomes more effective when buyers arrive with a clear specification, a well-defined service expectation, and a willingness to compare apples to apples rather than chasing the lowest headline price. The goal is not merely to minimize upfront expenditure but to secure a configuration that delivers reliable performance, manageable maintenance costs, and predictable availability across the life of the system.

External resource for broader pricing trends and market context, while not replacing vendor quotes, can provide helpful benchmarking: https://www.xshiftgearboxes.com/ (official pricing portal).

Final thoughts

Understanding the factors that influence the price of XShift gearboxes is crucial for business owners looking to invest wisely in gear technology. From comparative analyses with other automatic systems to the impact of advanced technology, every element plays a role in formulating the pricing structure. By staying informed about market demand trends and cost variability based on features, and by utilizing best practices for obtaining pricing information, business owners can navigate the complexities effectively and with confidence. Making informed decisions not only enhances operational efficiency but can also impact the bottom line significantly.